Transparent two-component silane-modified polyether sealant and preparation method thereof

A silane-modified polyether, two-component technology, applied in the field of sealants, can solve the problems of limiting the application of silane-modified polyether sealants, health and environmental hazards, slow deep curing, etc. Stable construction, fast deep curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

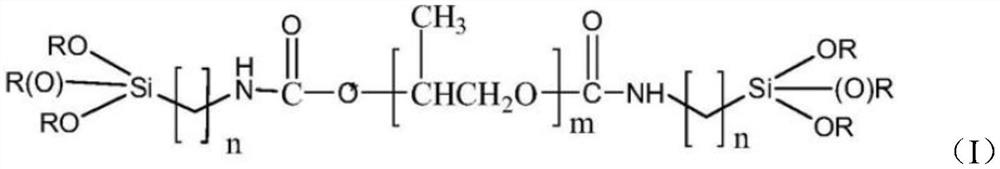

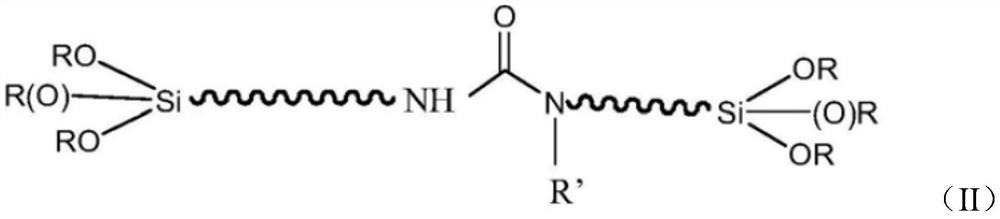

Method used

Image

Examples

preparation example Construction

[0060] In one of the embodiments, the preparation method of the silicone-modified epoxy resin comprises the following steps:

[0061] After mixing the silane monomer with the solvent, under the catalysis of the catalyst, react at 75-85°C for 3-7 hours to obtain the silicone; then mix the silicone with polyetheramine curing agent, epoxy resin Mix and react for 2-4 hours to obtain the organosilicon-modified epoxy resin. Specifically, the solvent can be 1,4-dioxane, the catalyst can be dibutyltin dilaurate; the polyetheramine curing agent can be polyetheramine curing agent D230, so The epoxy resin may be epoxy resin 828.

[0062] In one embodiment, the weight ratio of the silicone, polyetheramine curing agent and epoxy resin is 1:8-10:3-5.

[0063] More specifically, in the following Examples 1-4 and Comparative Example 2, the preparation steps of the silicone-modified epoxy resin are as follows:

[0064] (1) Silicone resin synthesis: Dimethyldiethoxysilane, γ-aminopropyltriet...

Embodiment 1

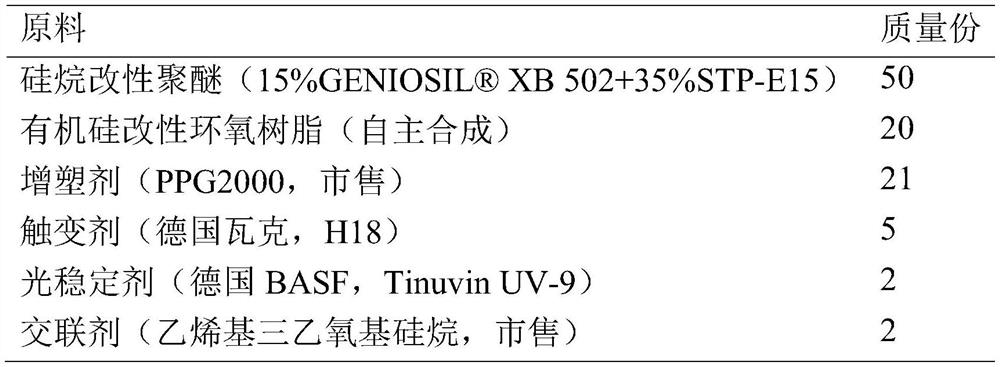

[0077] This example is a transparent two-component silane-modified polyether glue, and its raw material composition is as follows:

[0078] A component:

[0079]

[0080] B component:

[0081]

[0082] Component A is prepared by the following method: adding the silane-modified polyether, epoxy resin, plasticizer, fumed silica, light stabilizer, crosslinking agent, and coupling agent to the planetary feed tank, Vacuum stirring until the appearance is uniform to obtain component A;

[0083] The B component is prepared by the following method: add the plasticizer and amine catalyst into the planetary material tank, and stir in a vacuum at low speed until the appearance is uniform to obtain the B component.

[0084] When sizing, mix the above-mentioned components A and B according to the mass ratio of 10:1.

Embodiment 2

[0086] This example is a transparent two-component silane-modified polyether glue, and its raw material composition is as follows:

[0087] A component:

[0088]

[0089] B component:

[0090]

[0091] Component A is prepared by the following method: adding the silane-modified polyether, epoxy resin, plasticizer, fumed silica, light stabilizer, crosslinking agent, and coupling agent to the planetary feed tank, Vacuum stirring until the appearance is uniform to obtain component A;

[0092] The B component is prepared by the following method: add the plasticizer and amine catalyst into the planetary material tank, and stir in a vacuum at low speed until the appearance is uniform to obtain the B component.

[0093] When sizing, mix the above-mentioned components A and B according to the mass ratio of 10:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com