Corrugated skins for aircraft and methods of their manufacture

An aircraft and shell technology, applied in the field of aircraft shells, can solve problems such as inappropriateness, and achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

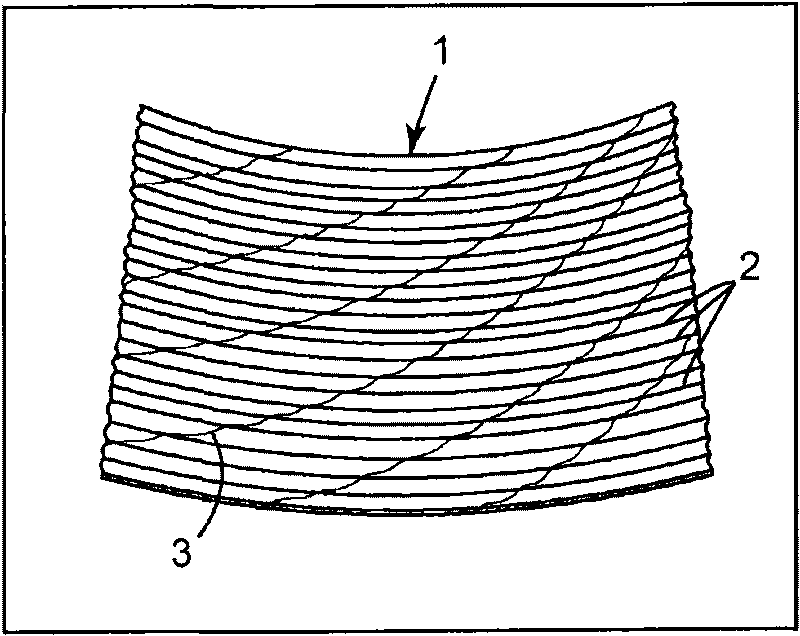

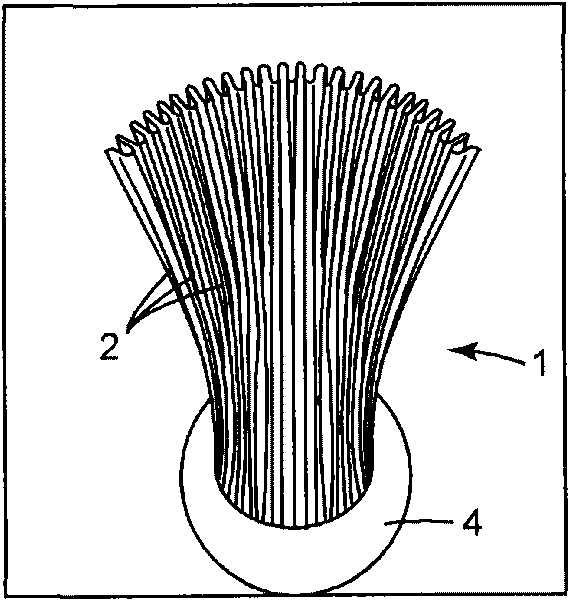

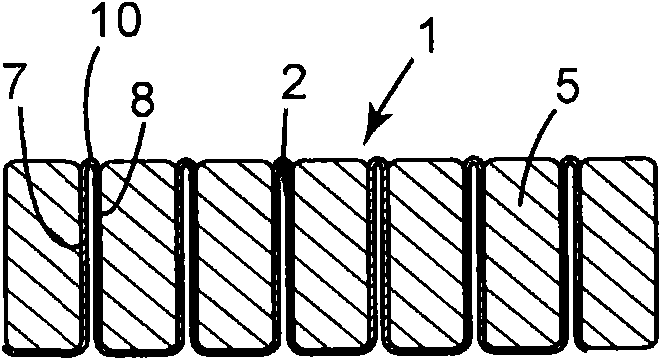

[0022] figure 1 is a schematic perspective view of a corrugated shell region 1 with a series of corrugations 2 . The casing (skin) 1 is formed using a substrate material impregnated with a curable resin, and after the molding process, the casing is cured to harden the resin. The resin-impregnated substrate material is applied to the flexible corrugated mold by forming a flexible corrugated mold (not shown) using a master tool, and is applied to the flexible corrugated mold by applying it to a bending rigid forming machine (not shown). ) to shape the mold and the substrate material on it, so that the substrate material can be formed.

[0023] Specifically, the flexible corrugated mold was made by applying silicone rubber to a standard tool comprising a corrugated rigid mold without any curvature. Once the silicone rubber has been cast, the finished flexible rubber mold is removed from the standard tool. A layer of backing material, optionally covered with fluorinated ethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com