Method for preparing porous nano solid by using hot pressing technique through controllable vaporized solvent

A hot-pressing technology and nano-powder technology, which is applied to the intersection of functional materials and structural materials, can solve problems such as lack of activity, and achieve the effects of improving strength and toughness, inhibiting growth, and improving mechanical strength and pore size uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

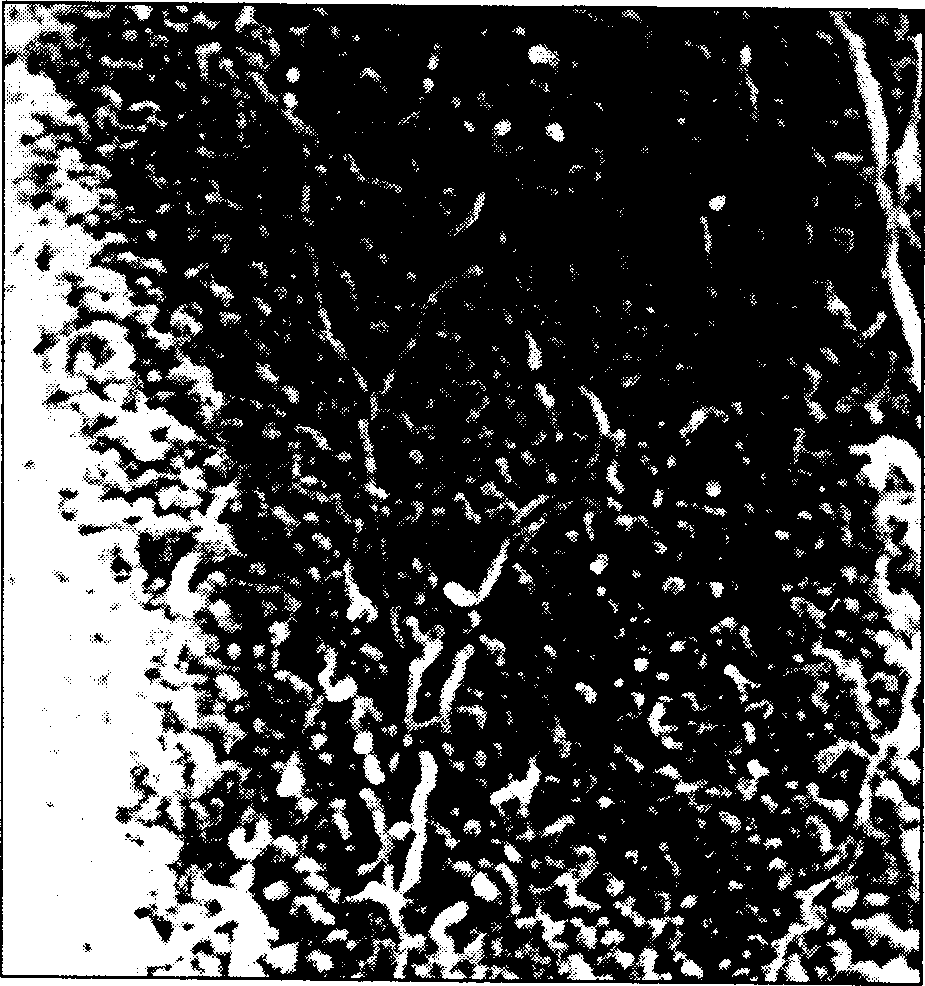

Image

Examples

Embodiment 2

[0034] Weigh TiO 2 Nano-powder (average particle size is 30nm) 2 grams, put into mortar and add 0.5 milliliter concentration and be the ammoniacal liquor of 12 mol / liter, grind and mix 25 minutes and join in the solvent heat press mould. Then, a pressure of 50 MPa was applied to the sample, and at the same time, the temperature was raised to 200° C. at a rate of 1.0-1.5° C. / minute by a temperature program controller and kept at a constant temperature for 12 hours. TiO can be obtained after the sample is cooled to room temperature 2 Porous nano-solid, the average pore size of the solid obtained in this way is 20 nanometers. Embodiment 3: with NH 4 NO 3 Preparation of ZrO by Aqueous Solution as Pore Forming Agent 2 porous nanosolid

Embodiment 3

[0035] First weigh ZrO 2 Nanopowder (average particle size is 50nm) 3 grams, put into mortar, and add the NH that 2.0 milliliters concentration is 4 mol / liter 4 NO 3 aqueous solution. After grinding for 30 minutes, the mixed powder was added to a solvent heat press mold. A pressure of 120 MPa was applied to the sample, and at the same time, the temperature was controlled by a program temperature controller to increase to 350° C. at a rate of 2.0-2.8° C. / min and kept at a constant temperature for 8 hours. After the sample is cooled to room temperature, the mold is opened to obtain ZrO 2 porous nanosolids. Embodiment 4: with (NH 4 ) 2 Aqueous S solution as pore-forming agent while controlling Bi 2 o 3 Pore arrangement of porous nanosolids

Embodiment 4

[0036] First put 3 grams of Bi 2 o 3 Nanopowder (average particle size is 12nm) is put into mortar, then adds 1.5 milliliter concentration and is 3 mol / liter (NH 4 ) 2 S aqueous solution. After grinding for 25-30 minutes, add the mixed powder into the solvent hot pressing mold. In addition, a thin layer of CaO powder (total weight 1.0 g, with a semipermeable membrane placed between the sample and CaO) was placed at both ends of the sample to absorb water and (NH 4 ) 2 S and induce directional arrangement of pores. While applying a pressure of 250 MPa on the sample, the temperature was raised to 300° C. at a rate of 2.0-2.8° C. / minute and kept constant for 6 hours. After the sample is cooled to room temperature, the mold is opened to obtain Bi with an average pore size of 100-120 nm. 2 o 3 Porous nanosolids, and most of the channels are arranged along the thickness direction of the sample. Embodiment 5: with NH 4 Cl as pore-forming agent to prepare Fe 2 o 3 porous n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com