Silicone sealant for rail transit and preparation method thereof

A silicone sealant, base glue technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

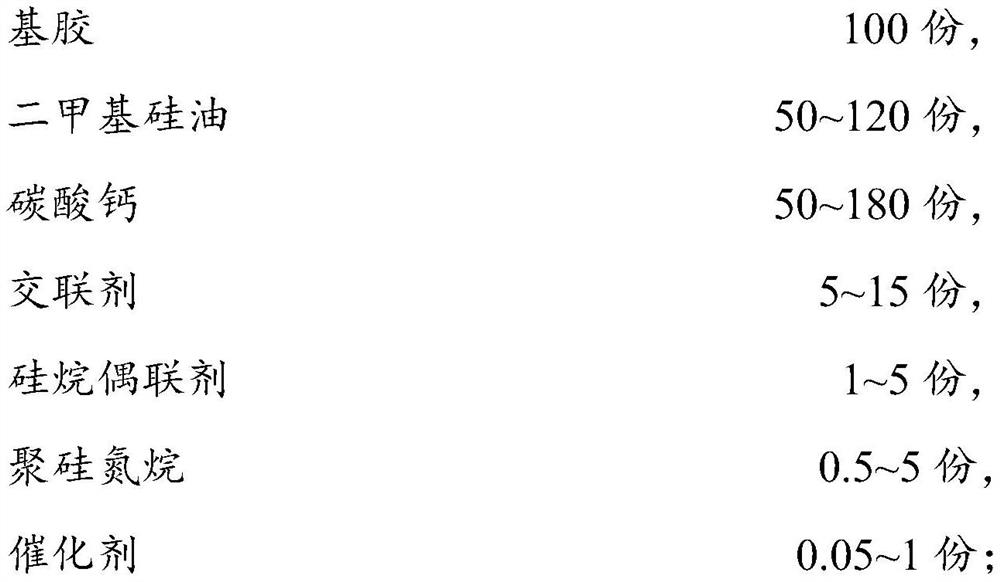

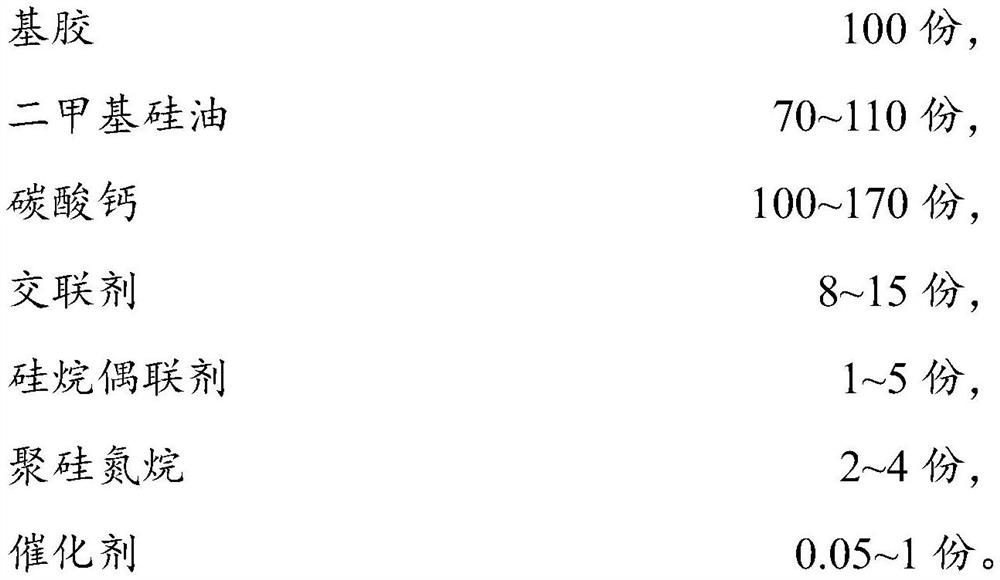

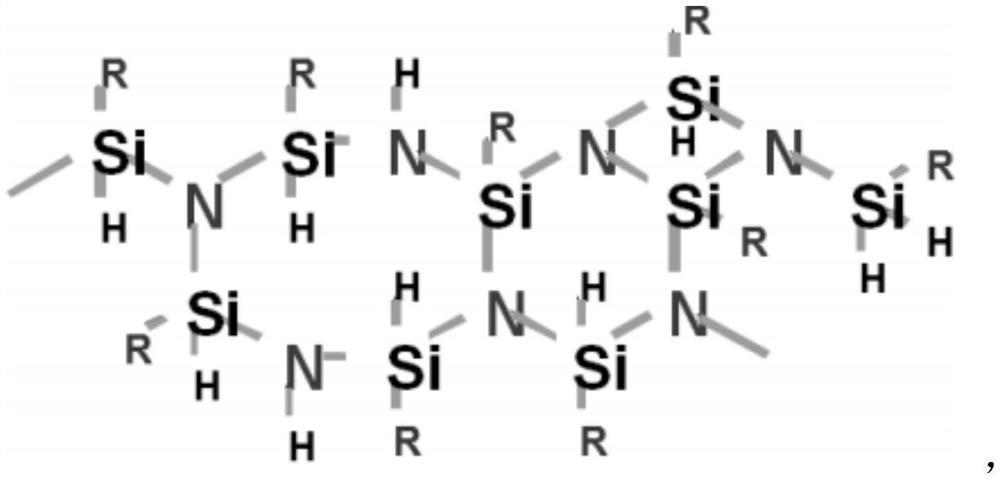

Method used

Image

Examples

Embodiment 1

[0070] A high-performance traffic silicone sealant in this example is prepared by the following method:

[0071] (1) Add 100 parts of 80000cps α,ω-dihydroxypolydimethylsiloxane, 120 parts of activated calcium carbonate and 100 parts of 350cps simethicone into the kneader, set the material temperature to 120°C, vacuum The temperature is controlled at -0.09Mpa~-0.1Mpa, kneaded for 3~5 hours to dehydrate, and cooled to room temperature for later use.

[0072] (2) Base material after dehydration and cooling in step (1), 10 parts of phenyl tributylketoxime silane, 2 parts of vinyl tributylketoxime silane, 3 parts of γ-aminopropyltriethoxysilane, Add 1 part of polysilazane 1500RC and 0.25 parts of dibutyltin dilaurate to the planetary machine and stir for reaction. During this period, keep the vacuum degree not lower than -0.09MPa, rotate at 10-800rpm, and stir for 120min.

Embodiment 2

[0074] A high-performance traffic silicone sealant in this example is prepared by the following method:

[0075] (1) Add 100 parts of 20000cps α,ω-dihydroxy polydimethylsiloxane, 150 parts of activated calcium carbonate and 80 parts of 350cps simethicone into the kneader, set the material temperature to 120°C, vacuum The temperature is controlled at -0.09Mpa~-0.1Mpa, kneaded for 3~5 hours to dehydrate, and cooled to room temperature for later use.

[0076] (2) The base material after dehydration and cooling, 8 parts of methyl tributylketoxime silane, 4 parts of vinyl tributylketoxime silane, 2.5 parts of γ-aminopropyltriethoxysilane, 1.5 parts of polysilicon Azane 1500RC and 0.25 parts of dibutyltin dilaurate are sequentially added to the planetary machine and stirred for reaction, during which the vacuum degree is kept not lower than -0.09MPa, the rotation speed is 10-800rpm, and the mixture is stirred for 120min.

Embodiment 3

[0078] A high-performance traffic silicone sealant in this example is prepared by the following method:

[0079] (1) Mix 50 parts of 80000cps α, ω-dihydroxypolydimethylsiloxane, 50 parts of 20000cps α, ω-dihydroxypolydimethylsiloxane, 120 parts of activated calcium carbonate and 80 parts of 350cps dimethicone Add methyl silicone oil into the kneader, set the temperature of the material to 130°C, control the vacuum degree at -0.09Mpa to -0.1Mpa, knead for 3 hours to dehydrate, cool to room temperature and set aside.

[0080] (2) The base material after dehydration and cooling, 8 parts of phenyl tributylketoxime silane, 4 parts of vinyl tributyl ketoxime silane, 3 parts of N-β aminoethyl γ-aminopropyl trimethoxysilane , 2 parts of polysilazane 1500RC and 0.25 parts of dibutyltin diacetate were sequentially added to the planetary machine and stirred for reaction, during which the vacuum degree was kept not lower than -0.09MPa, the rotation speed was 10-800rpm, and the mixture was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com