Water-soaking-resistant flame-retardant single-component silane modified polyether sealant and preparation method thereof

A silane-modified polyether and sealant technology, which is applied in the field of sealants, can solve the problems of slow curing speed at low temperature, low strength, and environmental pollution, and achieve improved water resistance and bonding performance, high-efficiency flame-retardant effects, and avoid The effect of too much additive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation methods used in the following examples are conventional methods unless otherwise specified.

[0041] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0042] Among them, the silyl-terminated polyether is a silyl-terminated polyether S303H purchased from Japan Kaneka, which is dimethoxysilyl-terminated and has a viscosity of 13 Pa·S;

[0043] The plasticizer is an alkyl sulfonate purchased from Germany Lanxess Mesamoll;

[0044] The pigment and filler are nano-calcium carbonate purchased from Guangxi Warner New Material Technology Co., Ltd.;

[0045] Thixotropic agent is the polyamide wax purchased from Huanqi Chemical Industry;

[0046] The ultraviolet absorber is UV-327 purchased from Dongguan Zhisheng Chemical Co., Ltd.;

[0047] The UV stabilizer is Tinuvin770 purchased from Dongguan Zhisheng Chemical Co., Ltd.;

[0048] The crosslinking agent is methyltrimethoxysilane p...

Embodiment 1

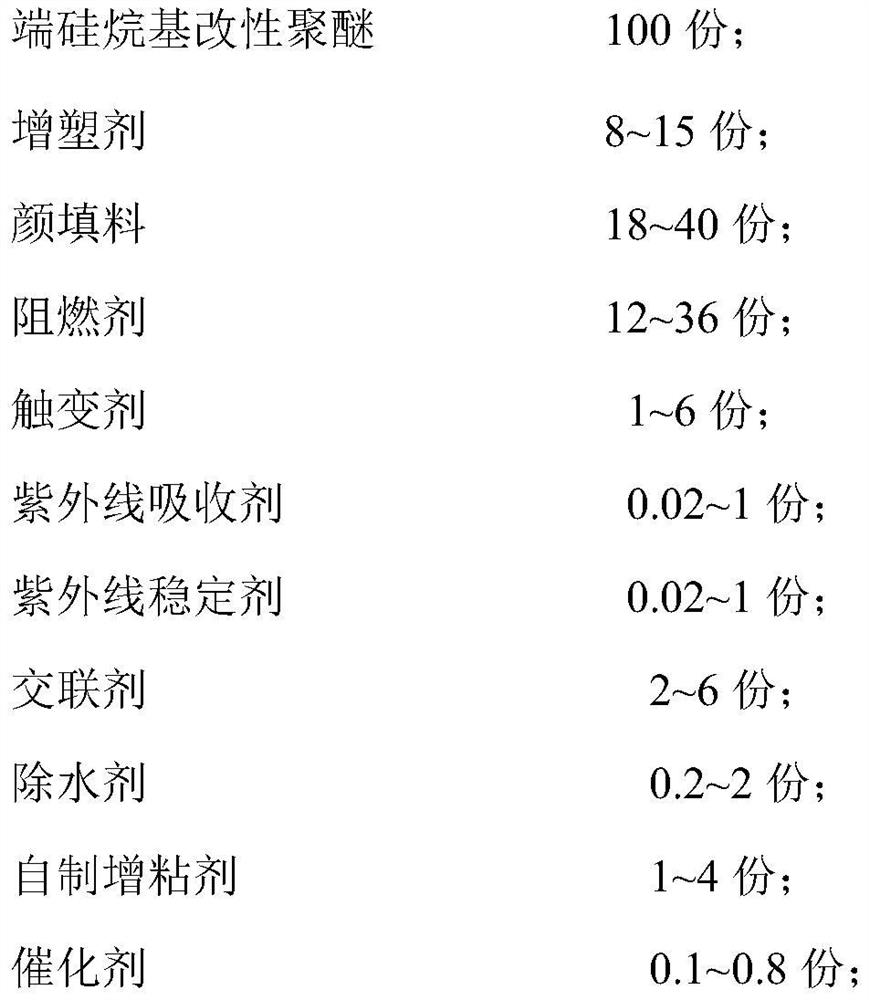

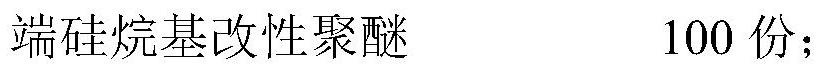

[0053] This embodiment provides a water immersion-resistant flame-retardant one-component silane-modified polyether sealant, which consists of the following components calculated in parts by weight:

[0054]

[0055] Wherein, the organosilicon-modified epoxy resin synthesized by the reaction of the self-made organosilicon oligomer of monomethyltriethoxysilane and epoxy resin E51, the modification catalyst is tetrabutyl orthotitanate, and the The solvent is xylene; 35:65:80:0.02.

[0056] The self-made tackifier is prepared by the following method:

[0057] S1 After mixing the organosilicon oligomer and the solvent according to the proportion, the temperature of the mixture is raised to 50°C while stirring, and then keep it warm, then add hydrochloric acid with a mass fraction of 38% to it according to the proportion to react, and wait for 2.5 hours to react After that, carry out normal pressure distillation and vacuum distillation successively, steam the ethanol and part o...

Embodiment 2

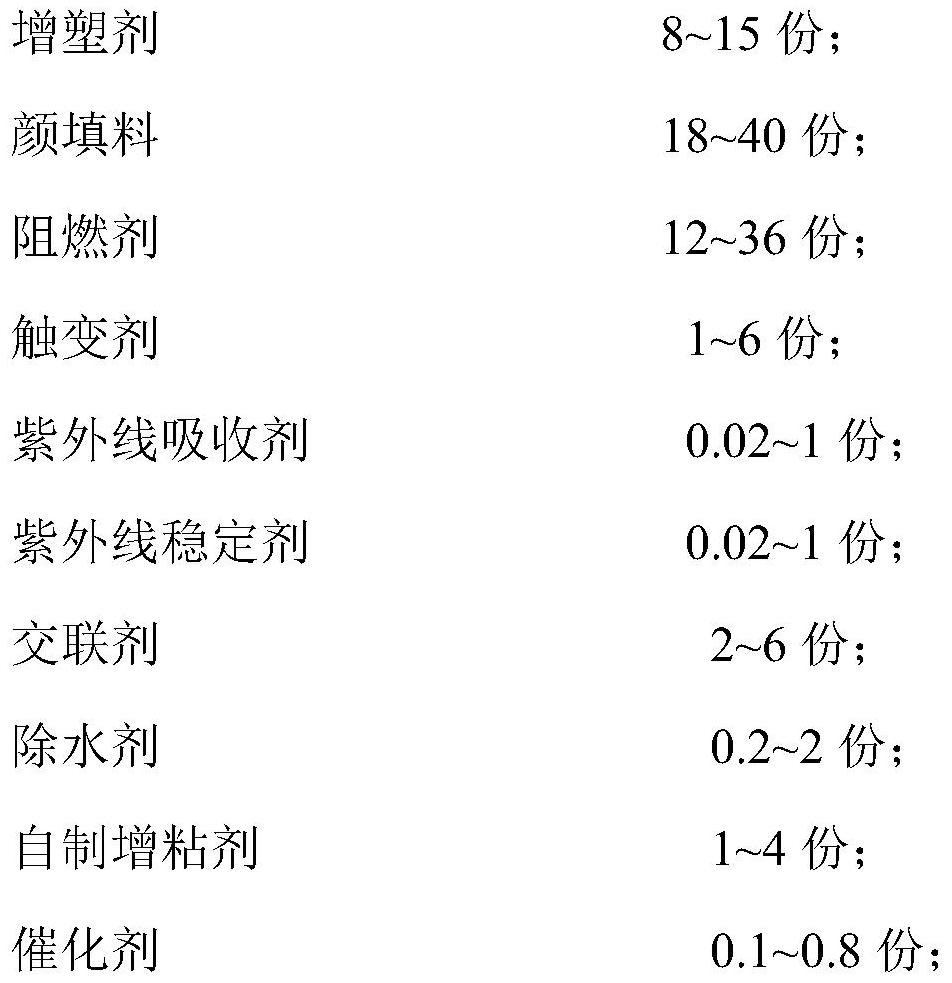

[0067] This example provides a water immersion-resistant flame-retardant one-component silane-modified polyether sealant. Basically the same as Example 1, the difference between this example and Example 1 is that it consists of the following components calculated in parts by weight:

[0068]

[0069]

[0070] Wherein, the self-made tackifier is a silicone-modified epoxy resin synthesized by the reaction of a silicone oligomer of monomethyltriethoxysilane and epoxy resin E51. The catalyst is tetrabutyl orthotitanate, and the solvent is xylene; the weight ratio of the organosilicon oligomer, epoxy resin, solvent and modification catalyst is 35:65:80:0.02.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com