Two-component silicone sealant for solar module resisting damp, heat and ageing and preparation method thereof

A solar module, silicone sealant technology, applied in chemical instruments and methods, adhesives, electrical components, etc., to achieve high room temperature strength, excellent moisture and heat aging resistance, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

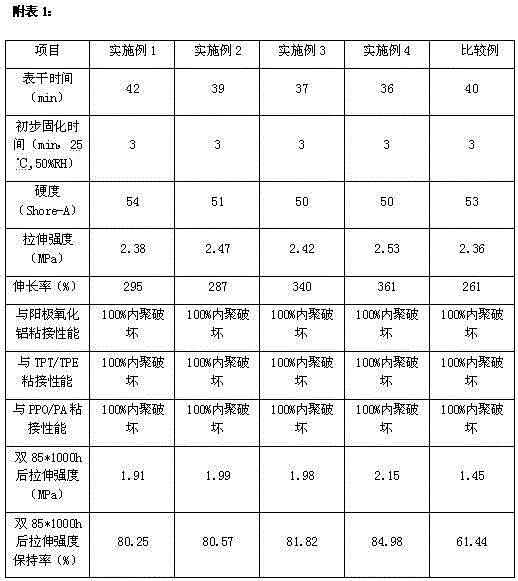

Examples

Embodiment 1

[0029] Add 100 parts by weight of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 5000cps, 3 parts of methyl silicone oil with a viscosity of 20cps, 100 parts of active nano-calcium carbonate, and 50 parts of silicon micropowder into the stirring tank , control the stirring speed to 500 rpm, temperature at 50°C, vacuum degree at 0.09~0.10MPa, stir for 3 hours, cool and pack to obtain component A;

[0030] By weight, 50 parts of MDT silicone oil, 10 parts of terminal silyl polyether, 30 parts of MQ resin, 10 parts of methyl silicone oil, 10 parts of fumed silica, 0.5 parts of organobentonite, 10 parts of tetramethoxysilane, 5 parts Tetraethoxysilane, 20 parts of methyltrimethoxysilane, 15 parts of dimethyldimethoxysilane, 5 parts of bis(3-triethoxysilylpropyl)amine, 2 parts of dilauric acid Add octyltin into the stirred tank, control the stirring speed to 500 rpm, the temperature is not higher than 50°C, the vacuum degree is 0.09-0.10MPa, stir for 2 hours, cool and pac...

Embodiment 2

[0033] 100 parts by weight of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 20000cps, 10 parts of MDT silicone oil with a viscosity of 2000cps, 80 parts of active nano-calcium carbonate, 10 parts of mica powder, and 10 parts of precipitation method white Add carbon black into the stirred tank, control the stirring speed to 1200 rpm, the temperature to 100°C, the vacuum degree to 0.09~0.10MPa, stir for 2 hours, cool and pack to obtain component A;

[0034] By weight, 70 parts of methyl silicone oil, 20 parts of MQ resin, 10 parts of vinyl silicone oil, 20 parts of active nano-calcium carbonate, 5 parts of precipitated white carbon black, 10 parts of tetramethoxysilane, 5 parts of tetrapropoxy Silane, 10 parts Trimethoxysilane, 10 parts Diethyldiethoxysilane, 5 parts γ-Aminopropylmethyldiethoxysilane, 5 parts γ-Aminopropyltriethoxysilane, 5 parts Add γ-methacryloxytrimethoxysilane, 6 parts of γ-(2,3 glycidoxy) propyltrimethoxysilane, and 1 part of dibutyltin dilaurate i...

Embodiment 3

[0037]100 parts by weight of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 50000cps, 20 parts of vinyl silicone oil with a viscosity of 500cps, 30 parts of active nano calcium carbonate, 5 parts of talcum powder, and 15 parts of fumed white Add carbon black into the stirred tank, control the stirring speed to 1000 rpm, the temperature to 50°C, the vacuum degree to 0.09-0.10MPa, stir for 1.5 hours, cool and separate to obtain component A;

[0038] By weight, 20 parts of methyl silicone oil, 60 parts of terminal silyl polyether, 20 parts of MQ resin, 20 parts of active nano-calcium carbonate, 10 parts of talcum powder, 5 parts of fumed white carbon black, 5 parts of mica powder, 0.5 parts Organobentonite, 10 parts tetramethoxysilane, 4 parts ethyltrimethoxysilane, 2 parts ethyltriethoxysilane, 2 parts vinyltrimethoxysilane, 2 parts vinyltriethoxysilane, 15 Parts of γ-methacryloxytrimethoxysilane, 5 parts of N-(β-aminoethyl)-γ-aminopropyl-methyldimethoxysilane, 10 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com