Organosilicon sealant and preparation method thereof

A silicone and sealant technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of loosening, poor deep curing, and debonding of the bonded materials, and improve flexibility, The effect of increasing the vulcanization rate and improving the ability of the cross-linking reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] This embodiment also provides a method for preparing a silicone sealant, comprising the following steps:

[0044] (1) Preparation of curing agent: reacting diethylene glycol with 3-isocyanatopropyl trialkoxysilane to obtain an intermediate product; reacting the obtained intermediate product with methyl ethyl ketone oxime to obtain a curing agent;

[0045] (2) mixing the α,ω-dihydroxypolydimethylsiloxane, reinforcing filler and plasticizer to obtain a base material;

[0046] (3) Mixing the base material obtained in step (2) with the crosslinking agent, curing agent, coupling agent and catalyst to obtain a silicone sealant.

[0047] In some embodiments, the 3-isocyanatopropyltrialkoxysilane is 3-isocyanatopropyltrimethoxysilane or 3-isocyanatopropyltriethoxysilane.

[0048]In some of these embodiments, in the step (1), the reaction also includes a catalyst, the catalyst is cyclohexylamine, and the addition amount of the cyclohexylamine is 0.5‰-1.5 parts by weight of the ...

Embodiment 1

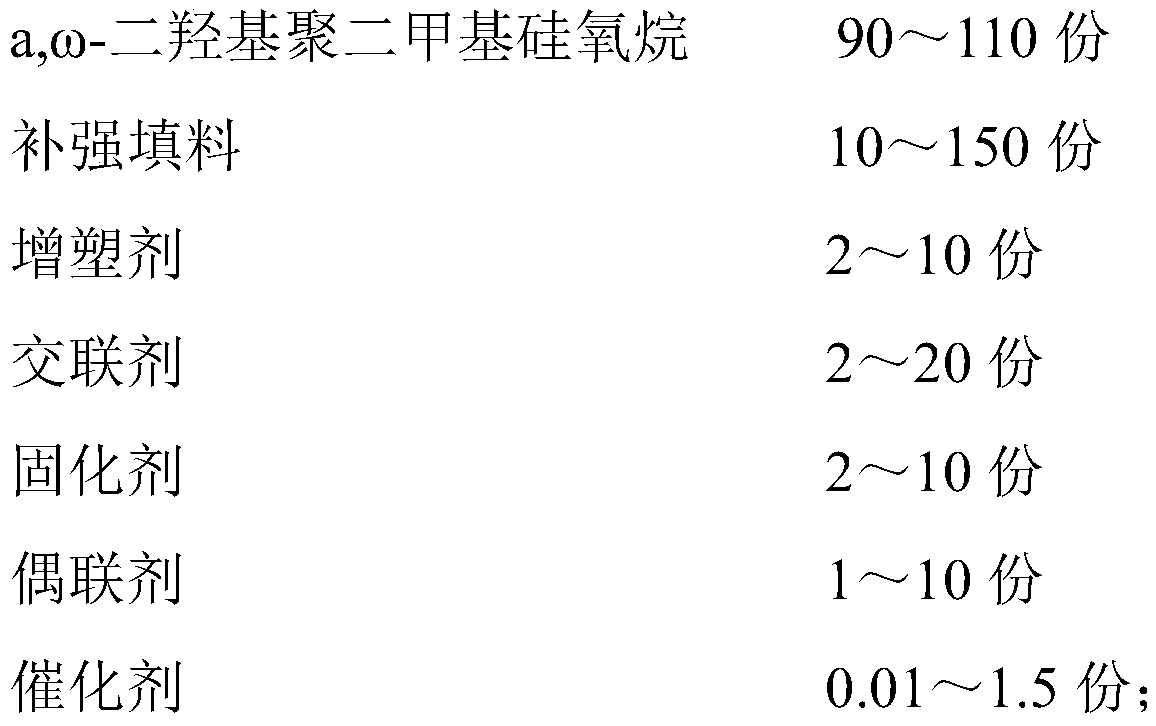

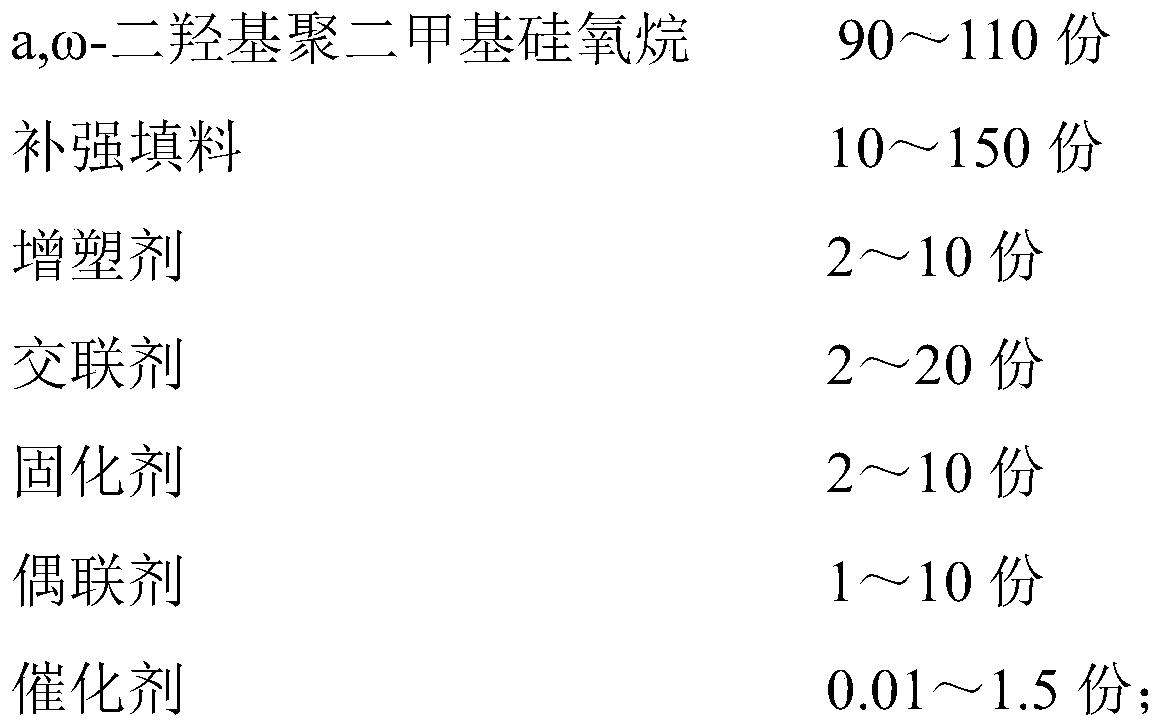

[0064] Formulation of silicone sealant:

[0065]

[0066] The preparation method of silicone sealant is as follows:

[0067] (1) Preparation of curing agent: under the condition of nitrogen protection, diethylene glycol is slowly added dropwise to 3-isocyanatopropyltrimethoxysilane of twice the molar amount at room temperature to react for 4 hours, and cool to After room temperature, add methyl ethyl ketone oxime in a molar ratio of 8 times, and then add cyclohexylamine of 1‰ of the total material as a catalyst, slowly heat to 110-130°C and react for 6 hours to remove excess methyl ethyl ketone oxime to obtain a curing agent.

[0068] (2) Add a,ω-dihydroxy polydimethylsiloxane, nanometer calcium carbonate and simethicone oil into the kneader and mix evenly according to the above weight parts, heat to 120-130°C, vacuum- 0.095MPa or more continued for 2 to 3 hours, and the obtained base material was cooled to room temperature.

[0069] (3) Add crosslinking agent, curing age...

Embodiment 2

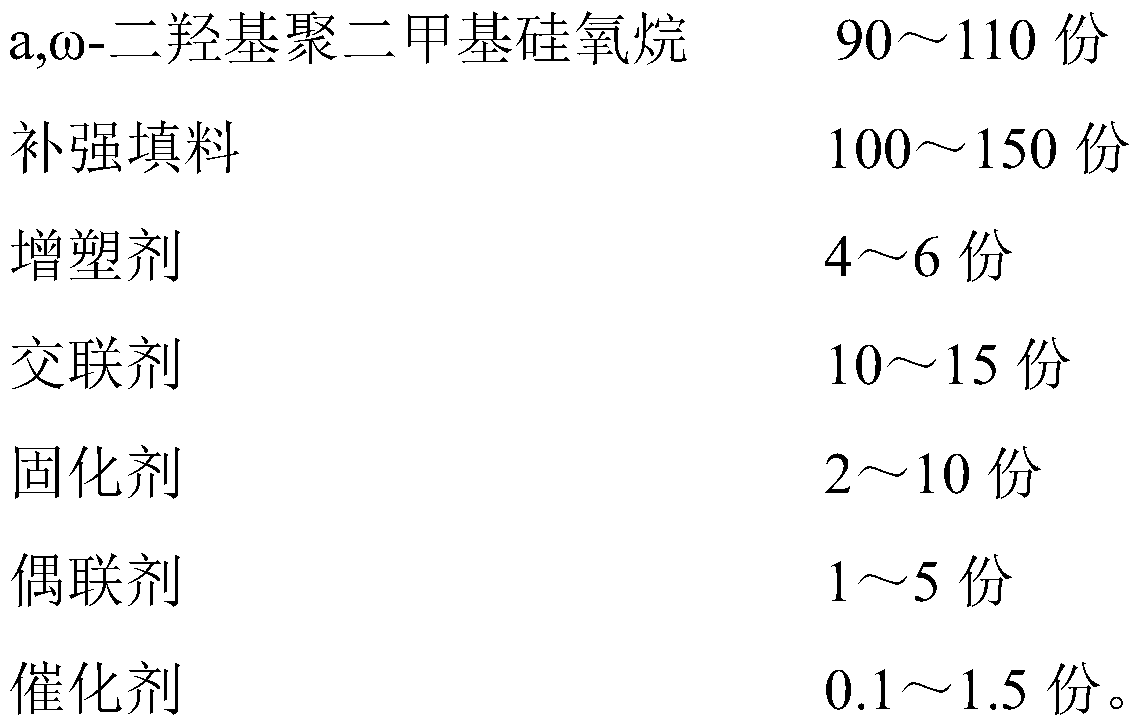

[0071] Formulation of silicone sealant:

[0072]

[0073] The preparation method of this embodiment is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com