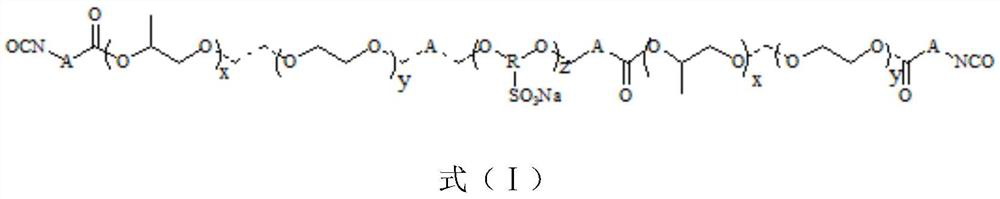

Low-temperature, low-humidity and rapid-curing polyurethane composition and preparation method thereof

A fast-curing, polyurethane technology, applied in the field of polyurethane materials, can solve the problems of complex process, inconvenient construction, high cost, etc., and achieve the effects of wide application, convenient construction, and reduced dependence on moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

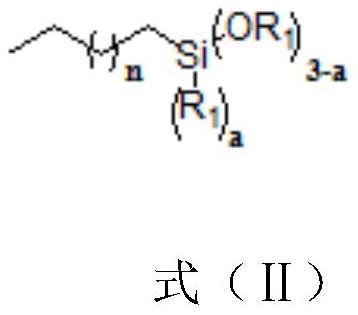

Method used

Image

Examples

preparation example Construction

[0081] The preparation method of each prepolymer is as follows:

[0082] (1) Preparation of polyurethane prepolymer P1-A

[0083] EO / PO copolyether alcohol SD-40 (hydroxyl value 37mgKOH / g) 200g, diisodecyl phthalate (DIDP) 68.36g at 120°C, 0.95Mpa to remove water in vacuum for 2h, then cool down to 90°C Afterwards, the nitrogen was released to remove the vacuum, and 30.3g of isophorone diisocyanate (IPDI) was added to the reactant and maintained at the temperature. After 2 hours of reaction, 1.34g of dimethylolpropionic acid (DMPA) (dissolved in 20g of acetone in advance) was added dropwise. Middle) continue the reaction and titrate the content of free isocyanate groups until the content reaches 2.01% (theoretical value 1.69%), decompress and evacuate for 30 minutes, and remove acetone to obtain polyurethane prepolymer P1.

[0084] (2) Preparation of polyurethane prepolymer P1-B

[0085] EO / PO copolyether alcohol LM240E (hydroxyl value 28mgKOH / g) 200g, diisodecyl phthalate (...

Embodiment 1~7

[0096] This embodiment provides a series of polyurethane compositions, the formulations of which are shown in Table 1.

[0097] The formula (part) of the polyurethane composition that table 1 embodiment 1~7 provides

[0098]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com