Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Consistent compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

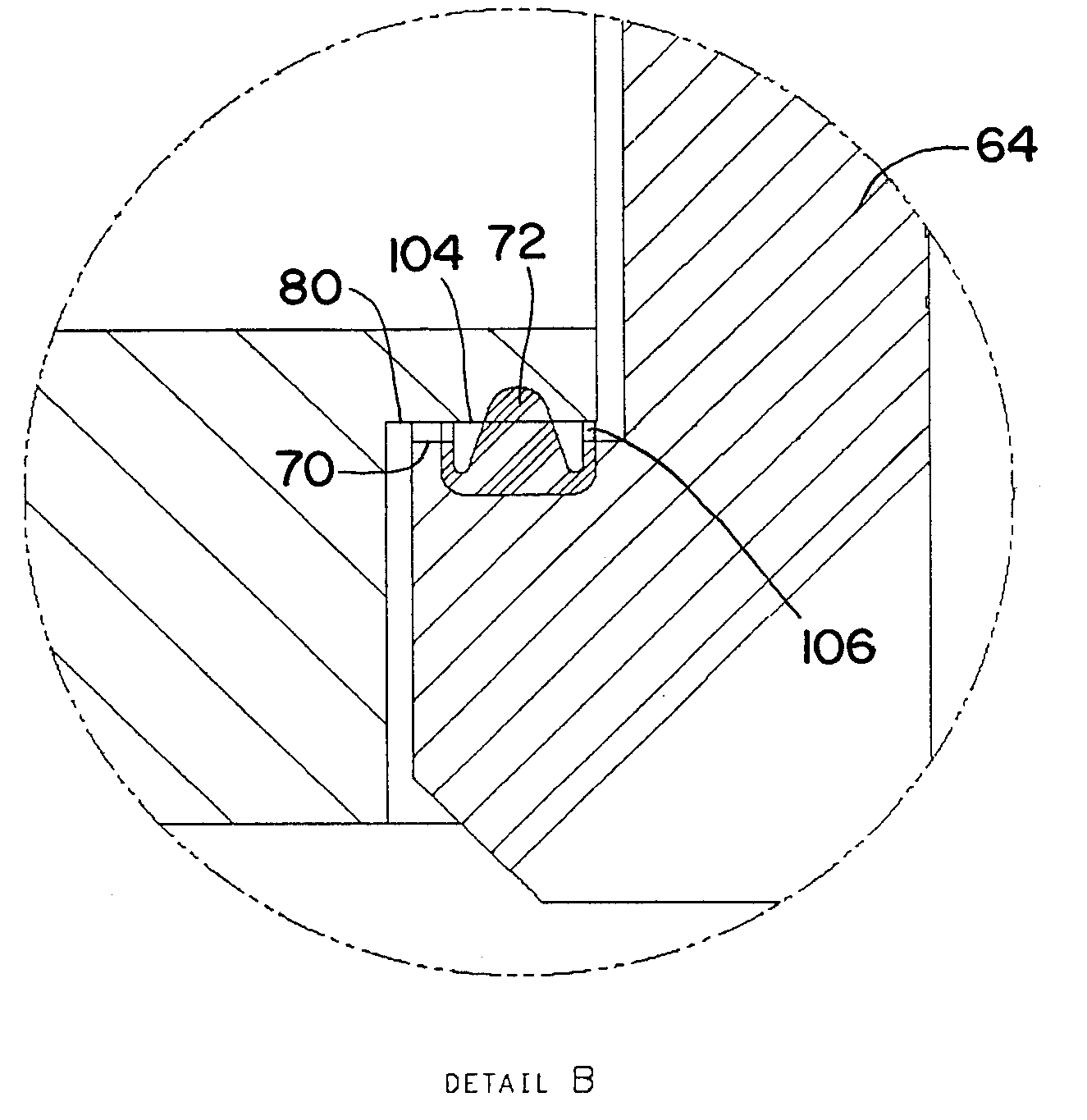

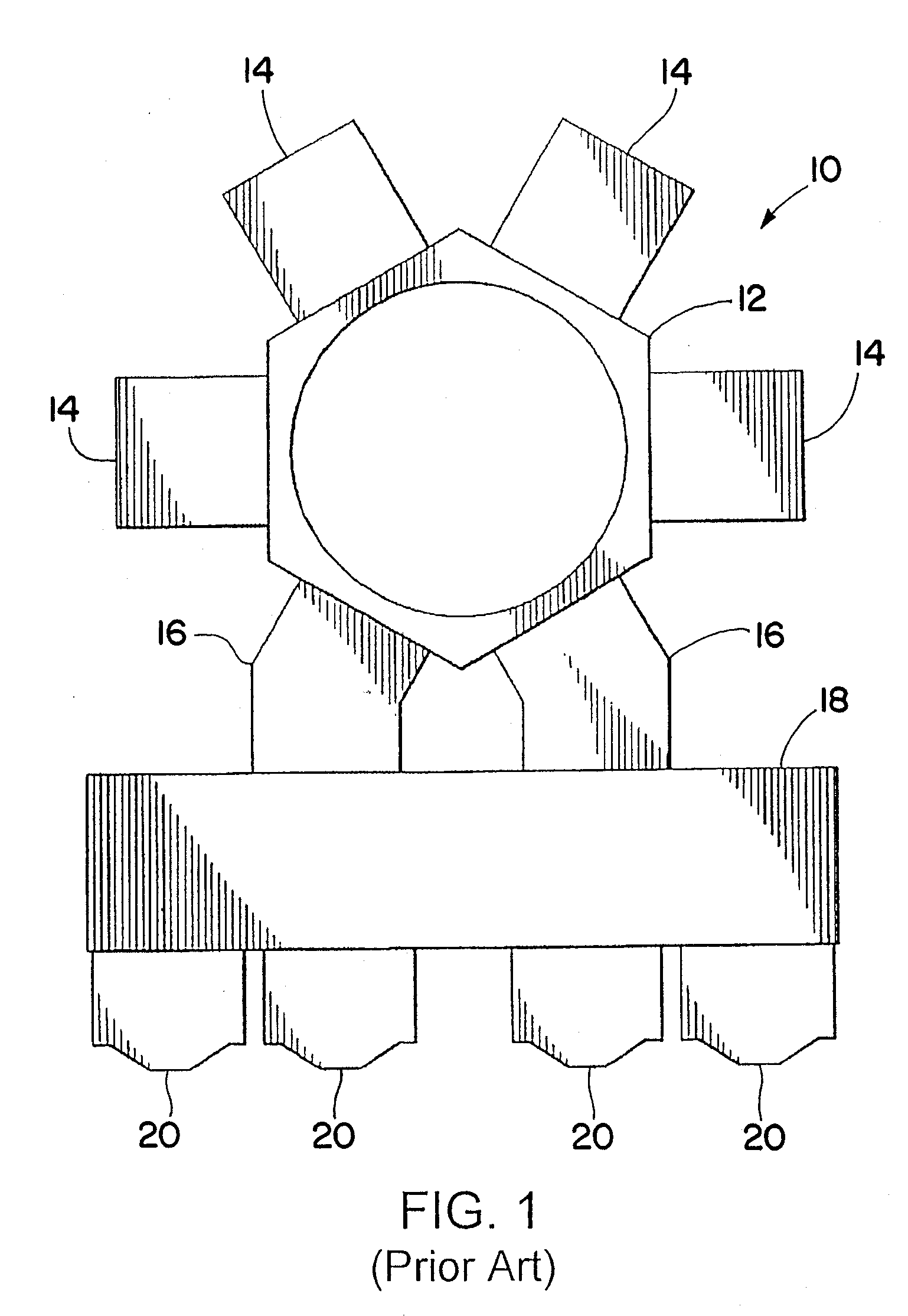

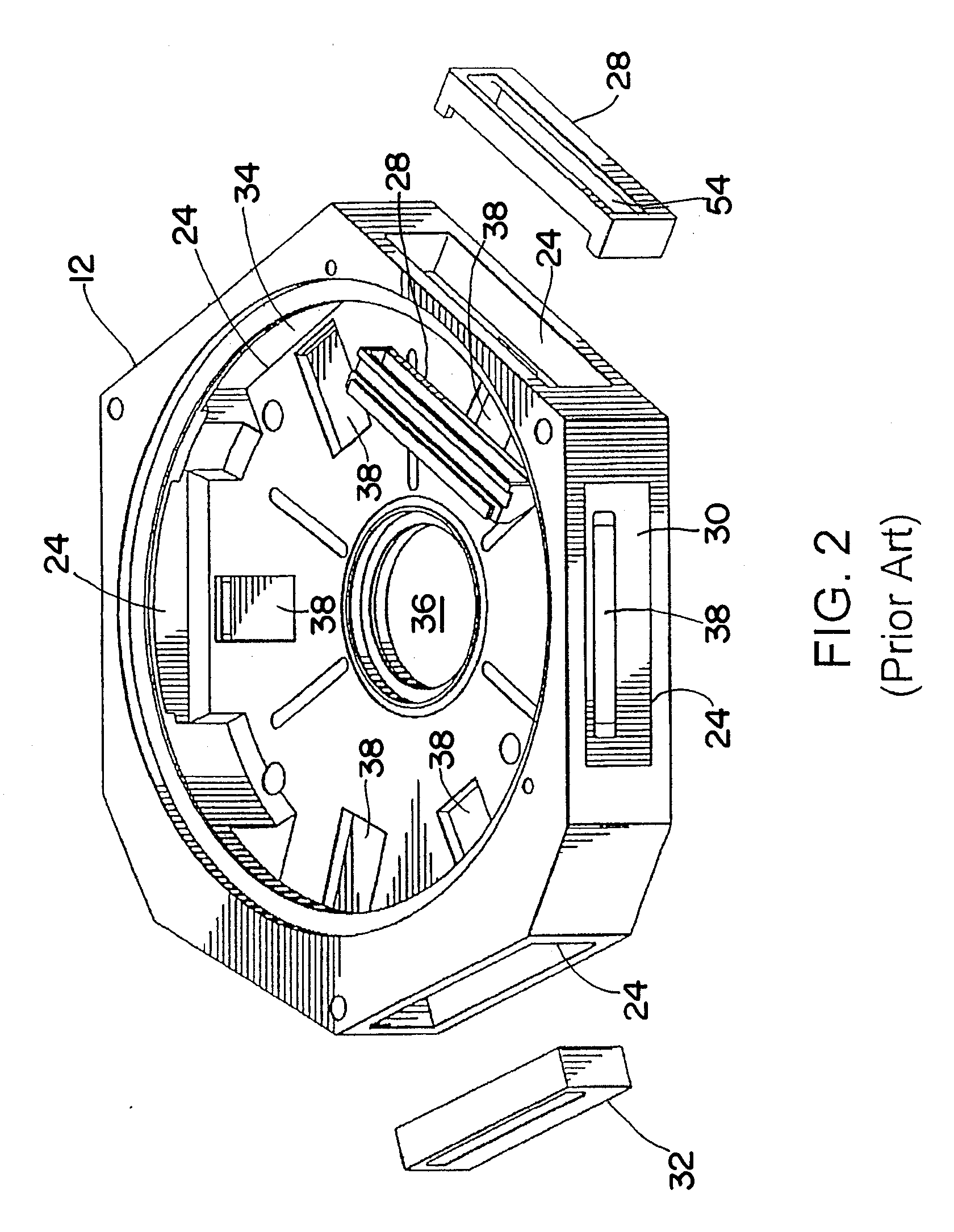

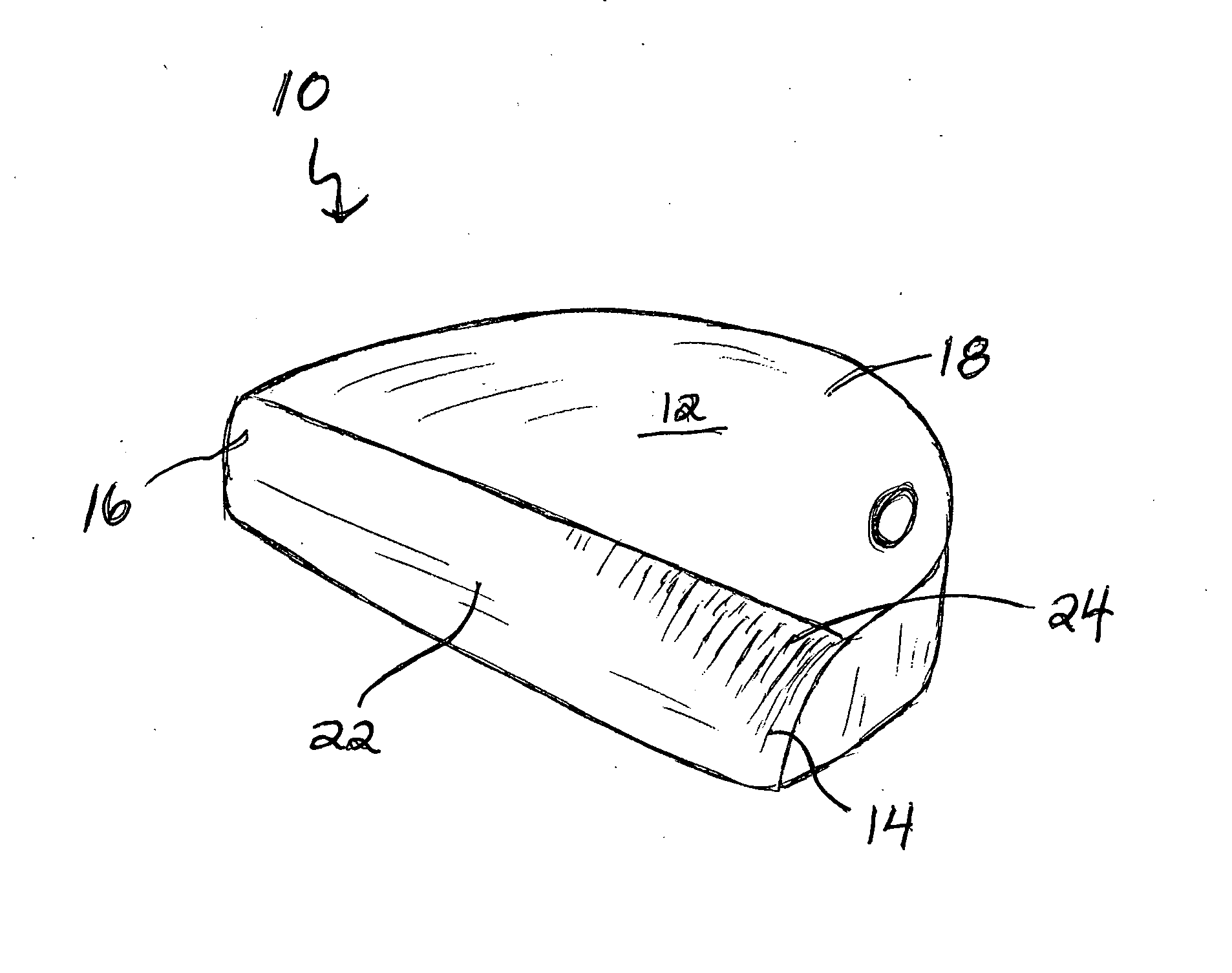

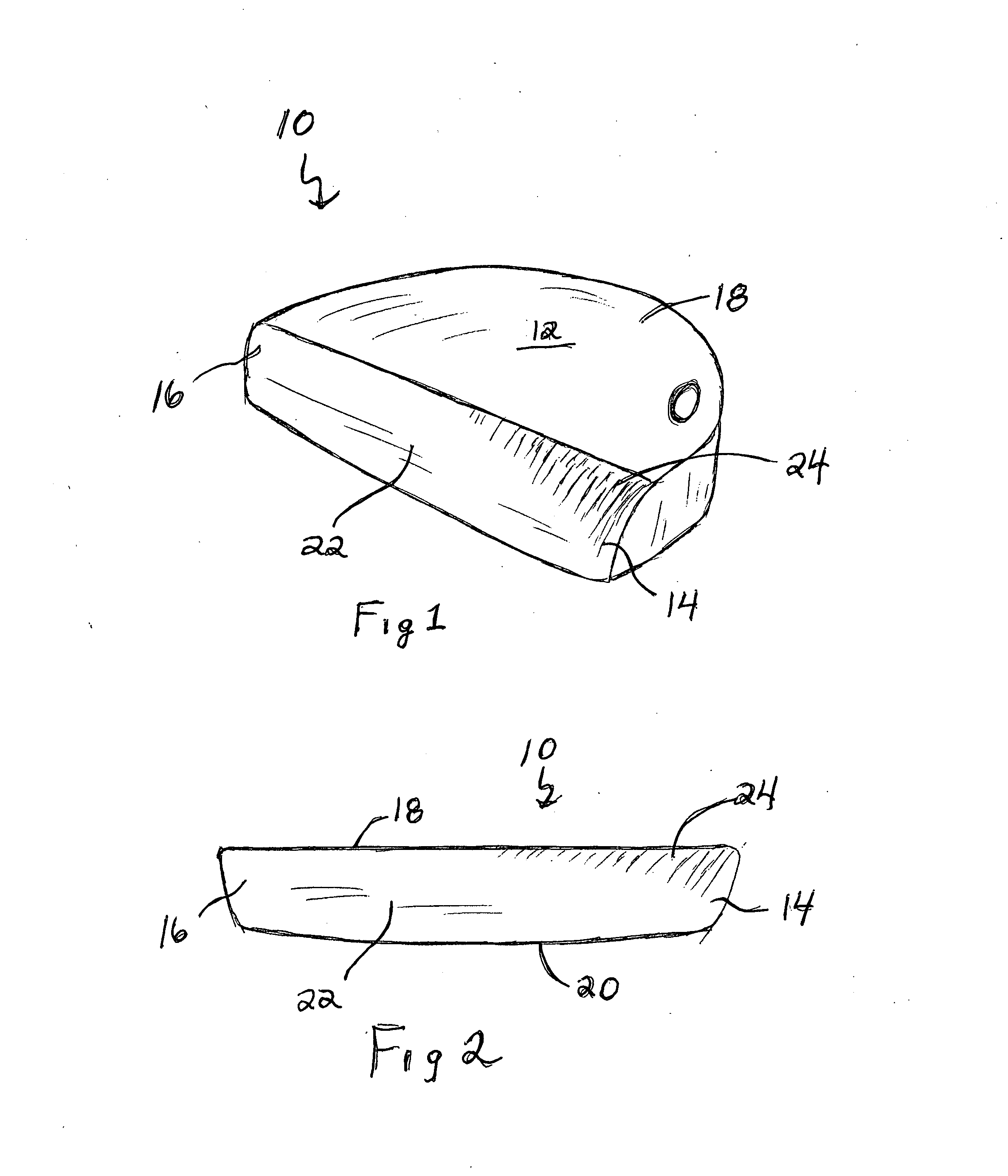

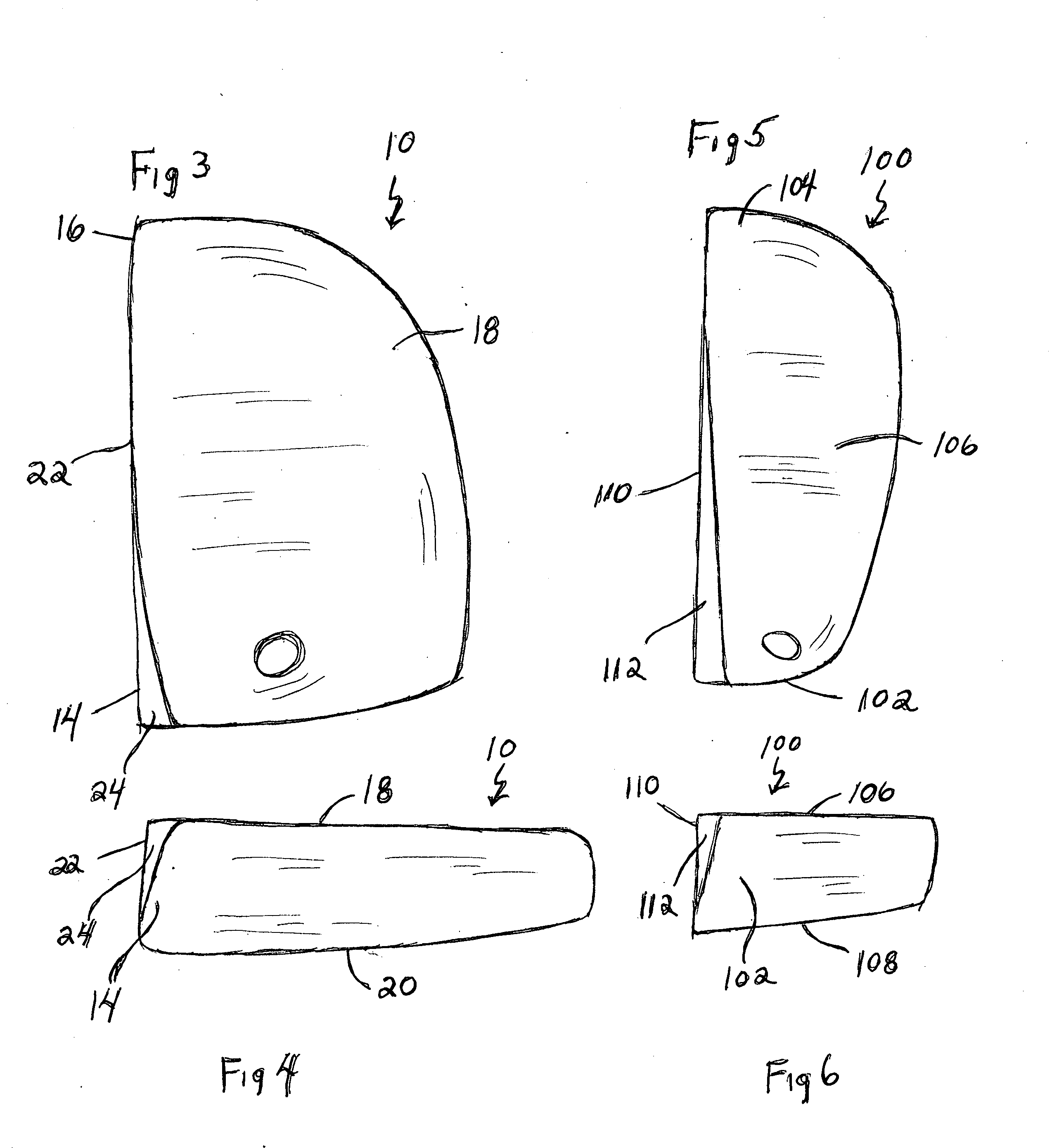

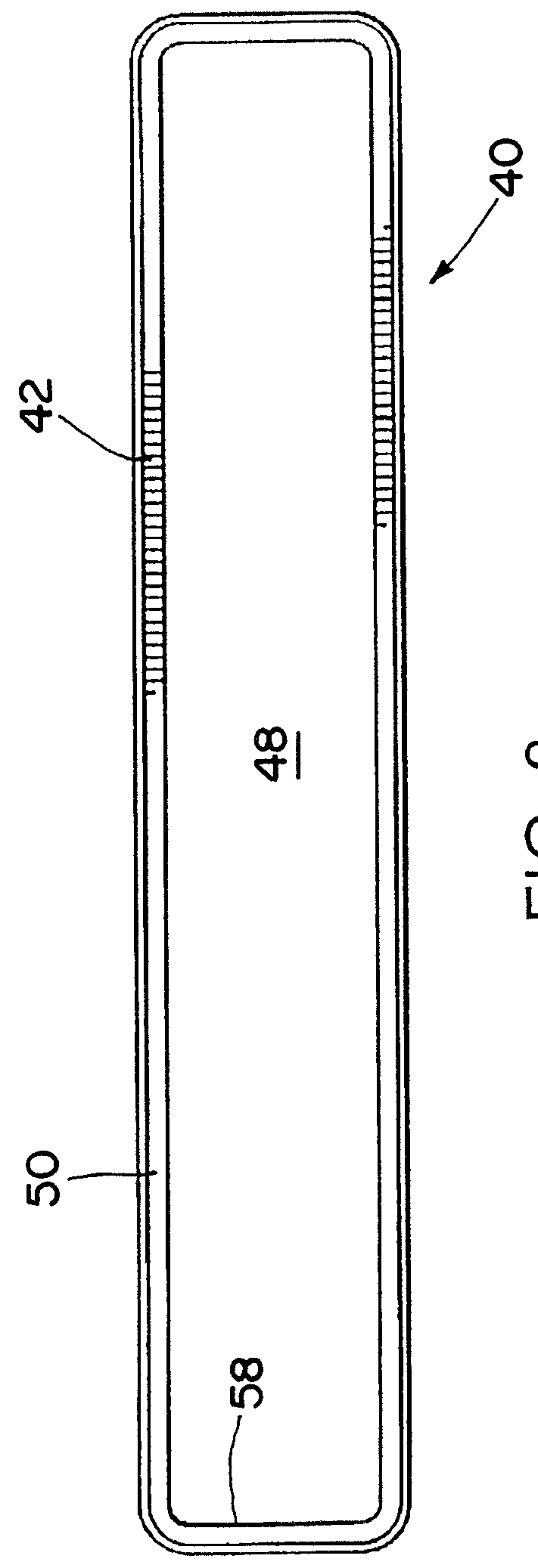

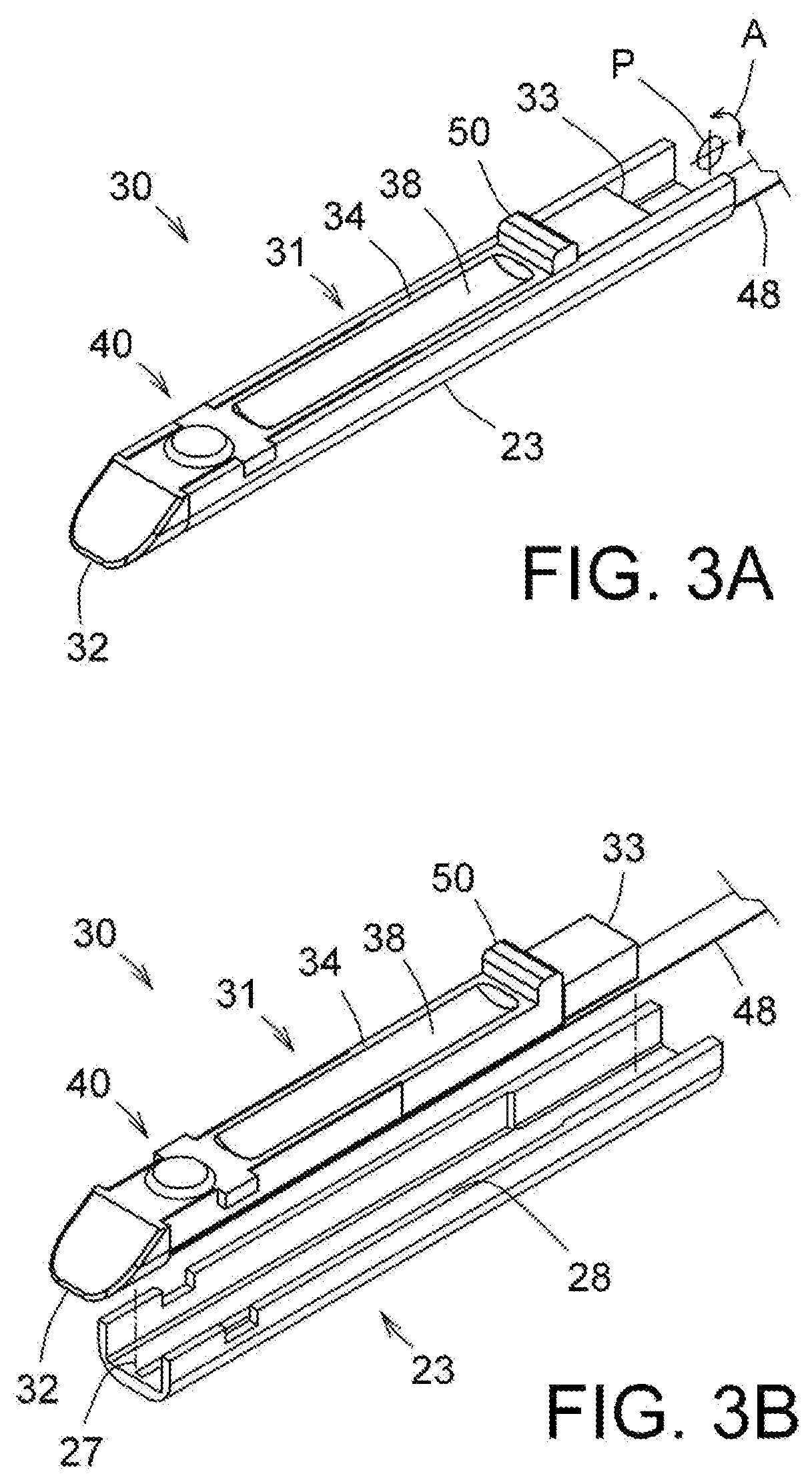

Bonded slit valve door seal with thin non-metallic film gap control bumper

The present invention provides a thin film spacer for maintaining a gap between a slit valve door and a sealing surface of a slit valve, such as a metallic insert. The film spacer can extend the life of a seal by limiting the line of sight exposure of the seal to corrosive gases within a wafer processing chamber, for example, and by controlling the compression percentage of the seal. The spacer may be located on an outer ambient side of the slit valve away from any corrosive gasses that may exist in the chamber.

Owner:PARKER INTANGIBLES LLC

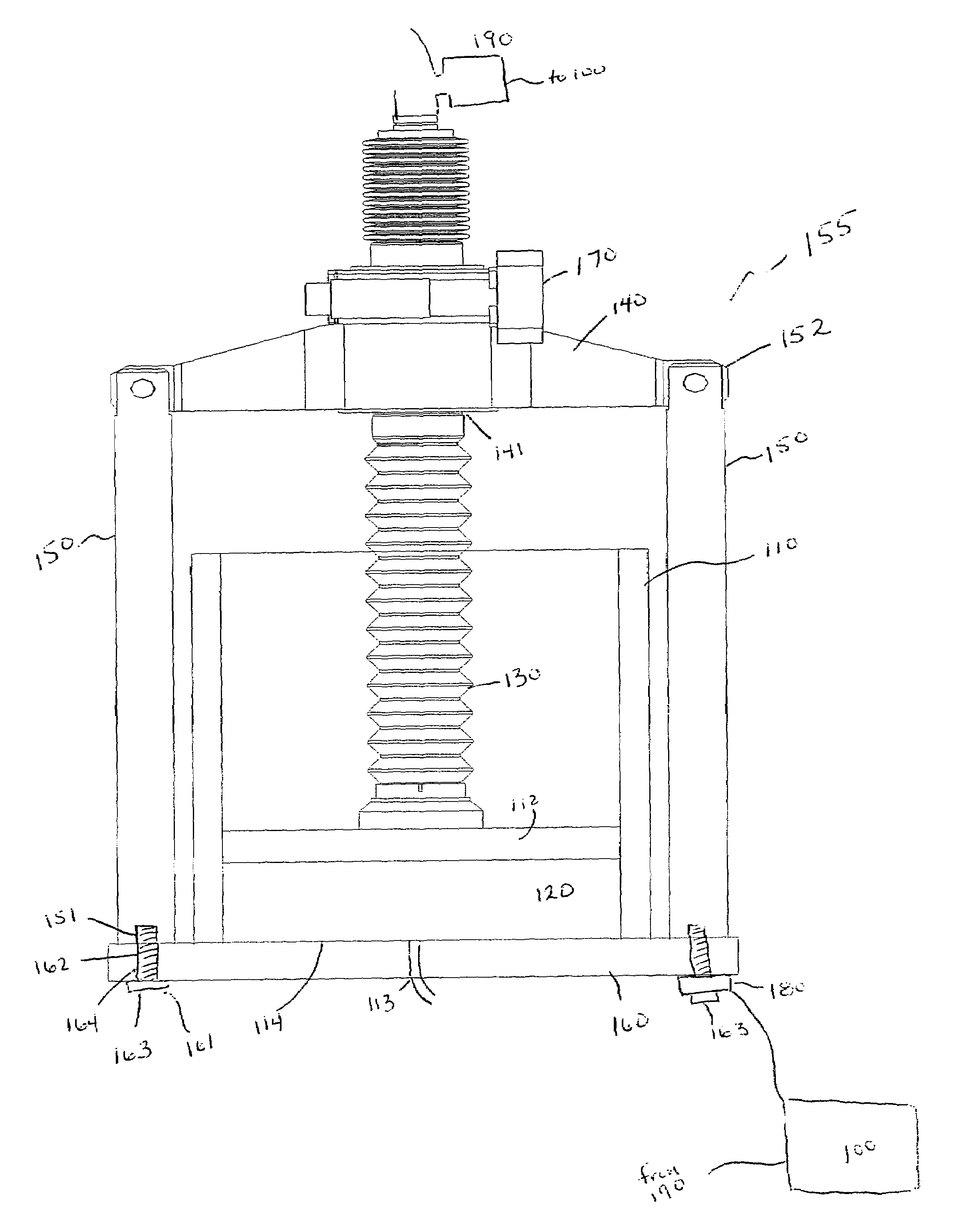

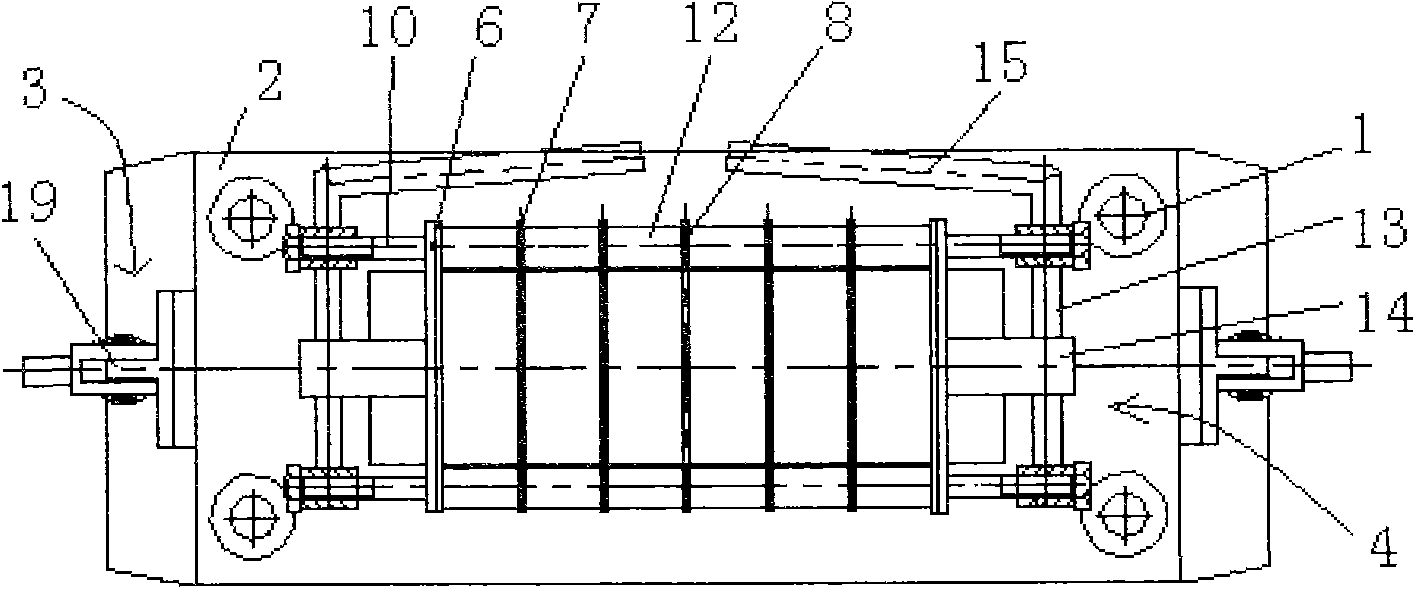

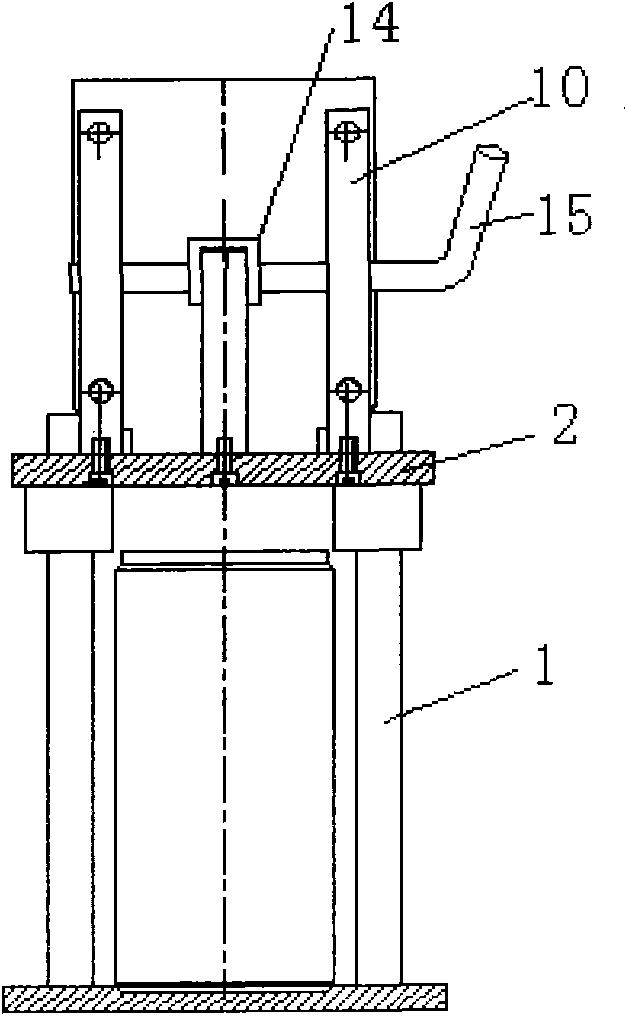

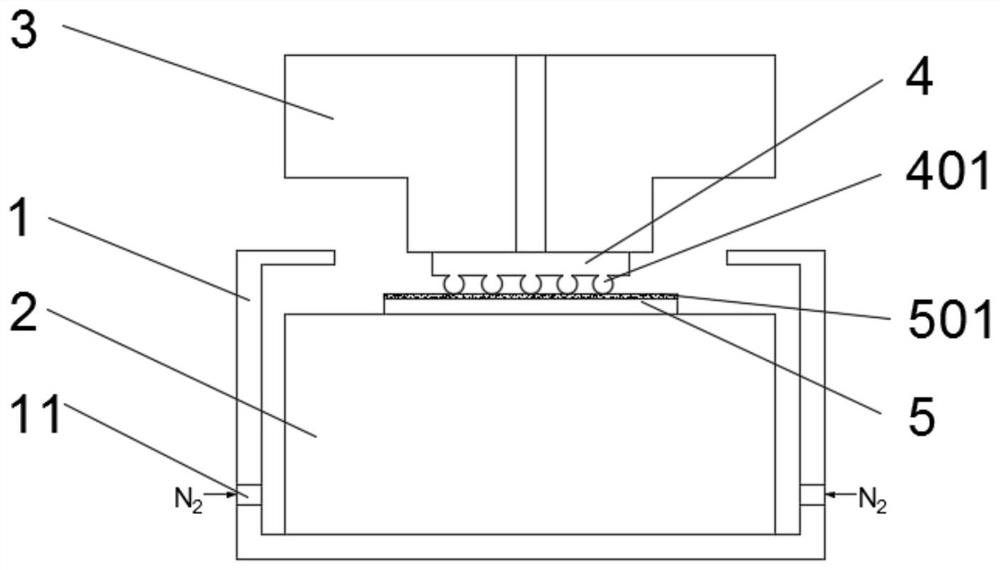

System for automated compression of chromatography columns

ActiveUS7238282B2Improve efficiencyConsistent compressionIon-exchange process apparatusComponent separationEngineeringLoad cell

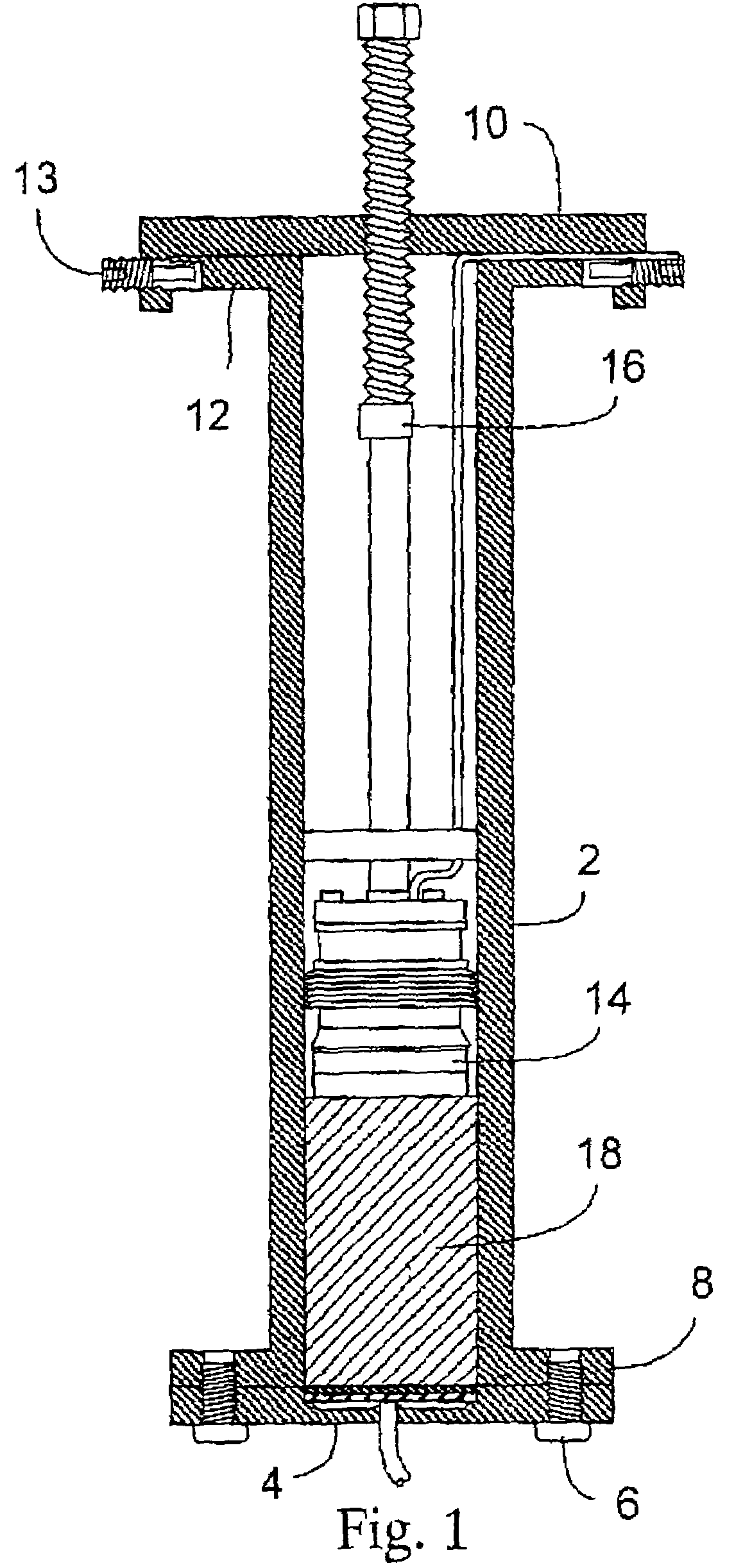

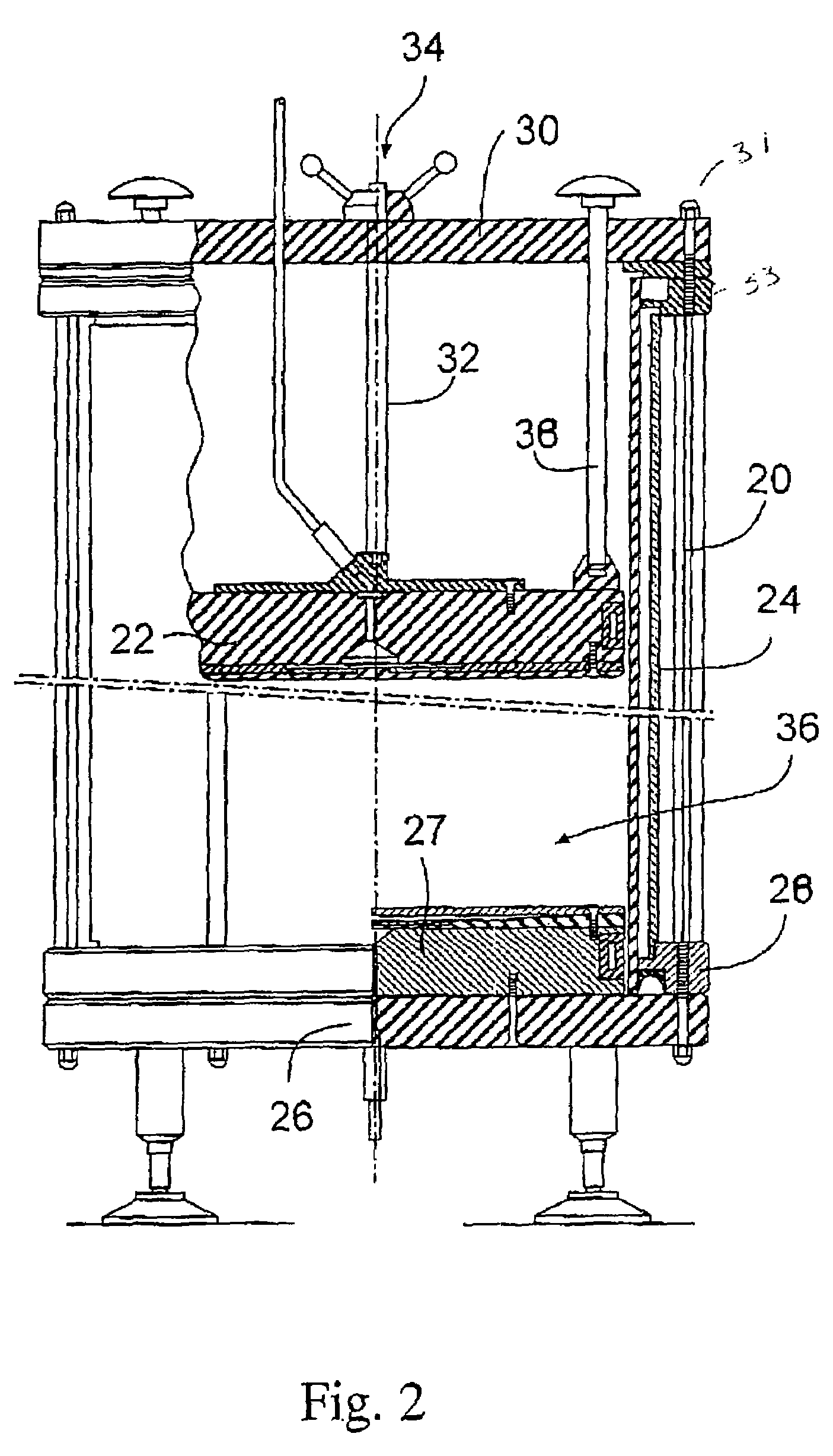

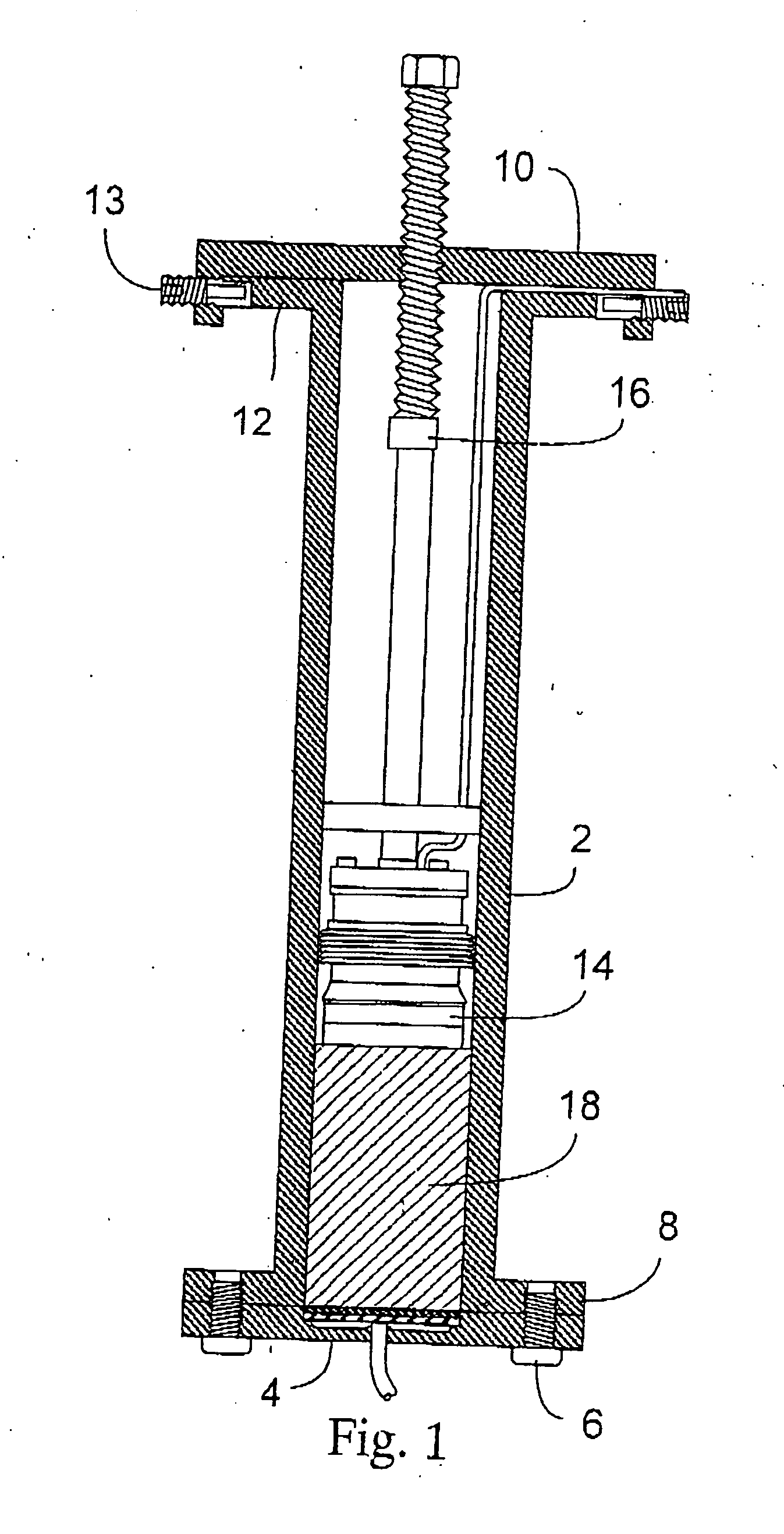

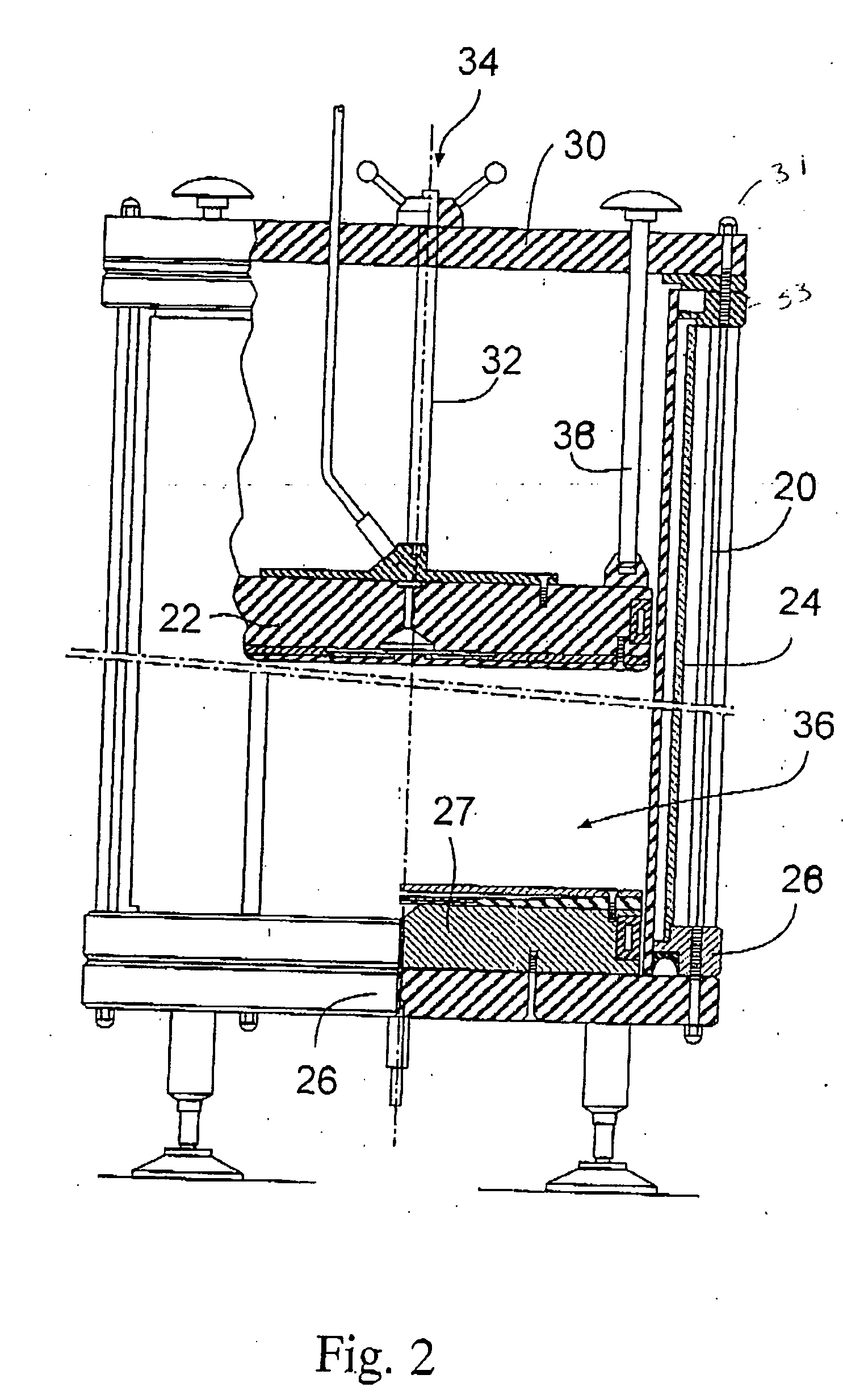

The present invention provides an automated system and method for maintaining compaction, and therefore increased efficiency, of a media bed within a chromatography column. In the preferred embodiment, an adjustment assembly is slidingly engaged inside one end of the column such that it can be moved along the column's major axis. When idle, the force exerted on this end is equal to the compression on the media. When the column is actively processing chromatographic fluid, this exerted force can be expressed as the sum of the compression on the media, and the force of the fluid being processed. This total force and the fluid pressure are monitored using a load cell and a pressure sensor respectively. The compression force operating on the media bed is then computed based on these measurements and compared to the optimal value. The position of the adjustment assembly within the column is then modified in response to changes in the measured compression force.

Owner:MILLIPORE CORP

System for automated compression of chromatography columns

ActiveUS20060196832A1Improve efficiencyConsistent compressionIon-exchange process apparatusComponent separationEngineeringLoad cell

The present invention provides an automated system and method for maintaining compaction, and therefore increased efficiency, of a media bed within a chromatography column. In the preferred embodiment, an adjustment assembly is slidingly engaged inside one end of the column such that it can be moved along the column's major axis. When idle, the force exerted on this end is equal to the compression on the media. When the column is actively processing chromatographic fluid, this exerted force can be expressed as the sum of the compression on the media, and the force of the fluid being processed. This total force and the fluid pressure are monitored using a load cell and a pressure sensor respectively. The compression force operating on the media bed is then computed based on these measurements and compared to the optimal value. The position of the adjustment assembly within the column is then modified in response to changes in the measured compression force.

Owner:MILLIPORE CORP

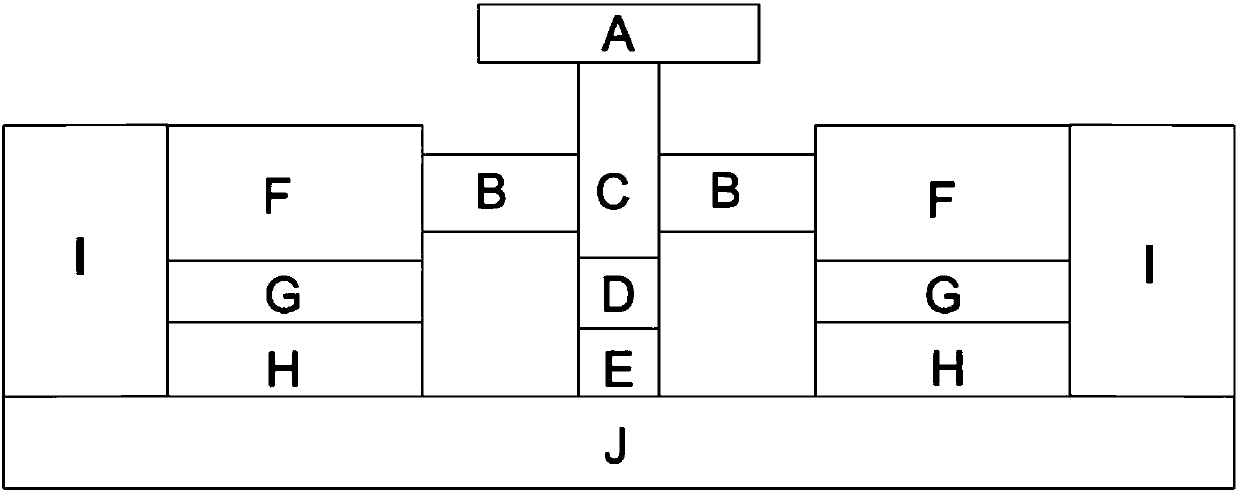

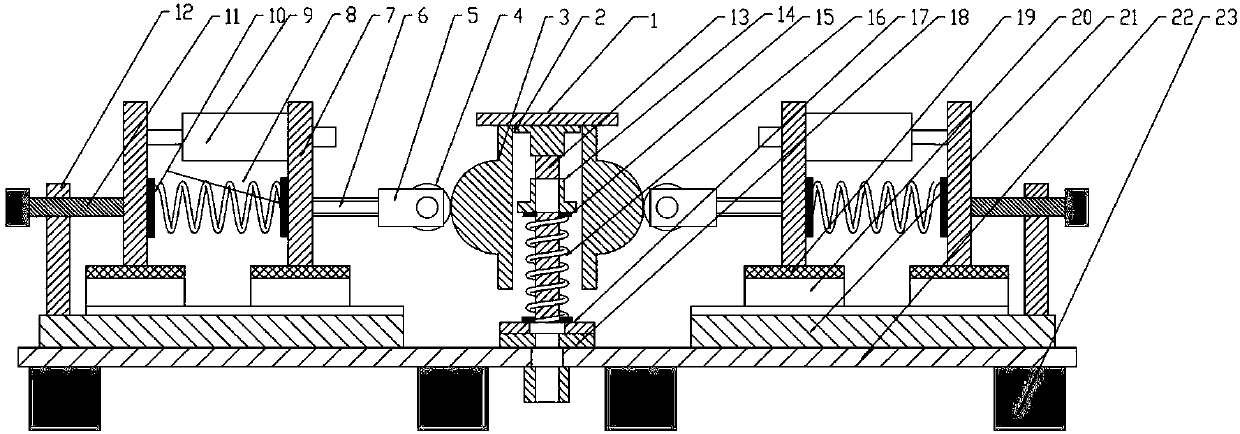

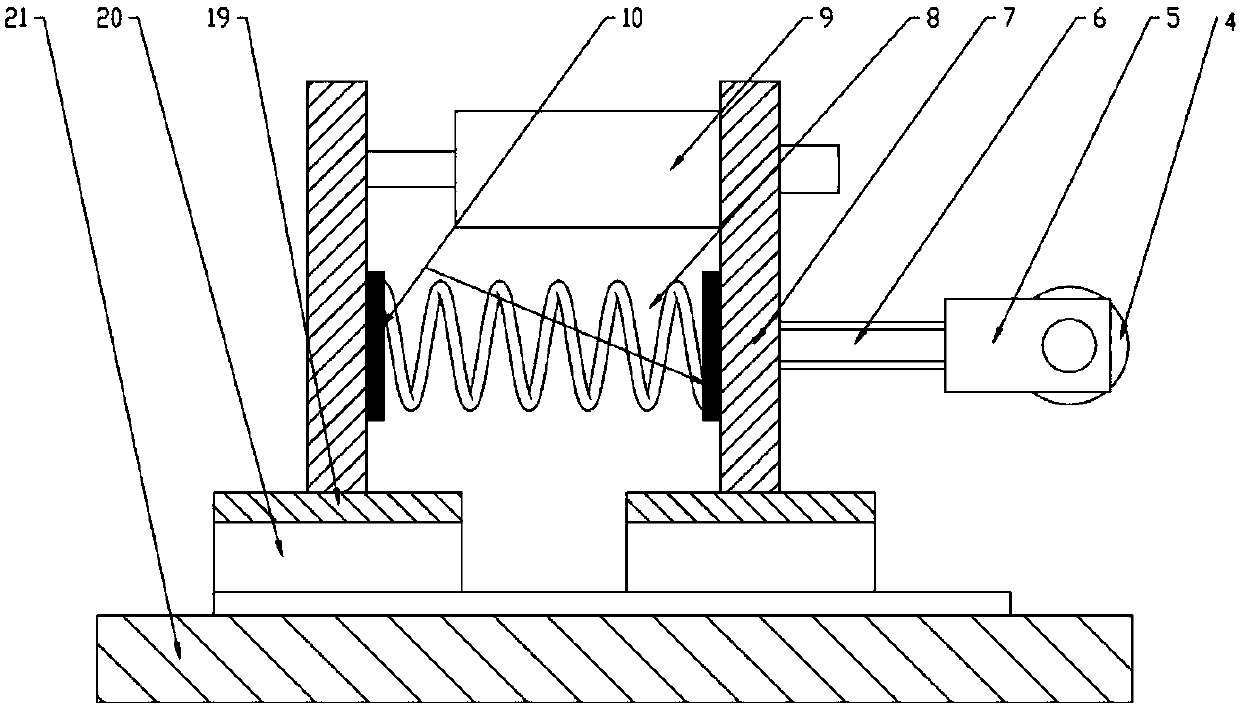

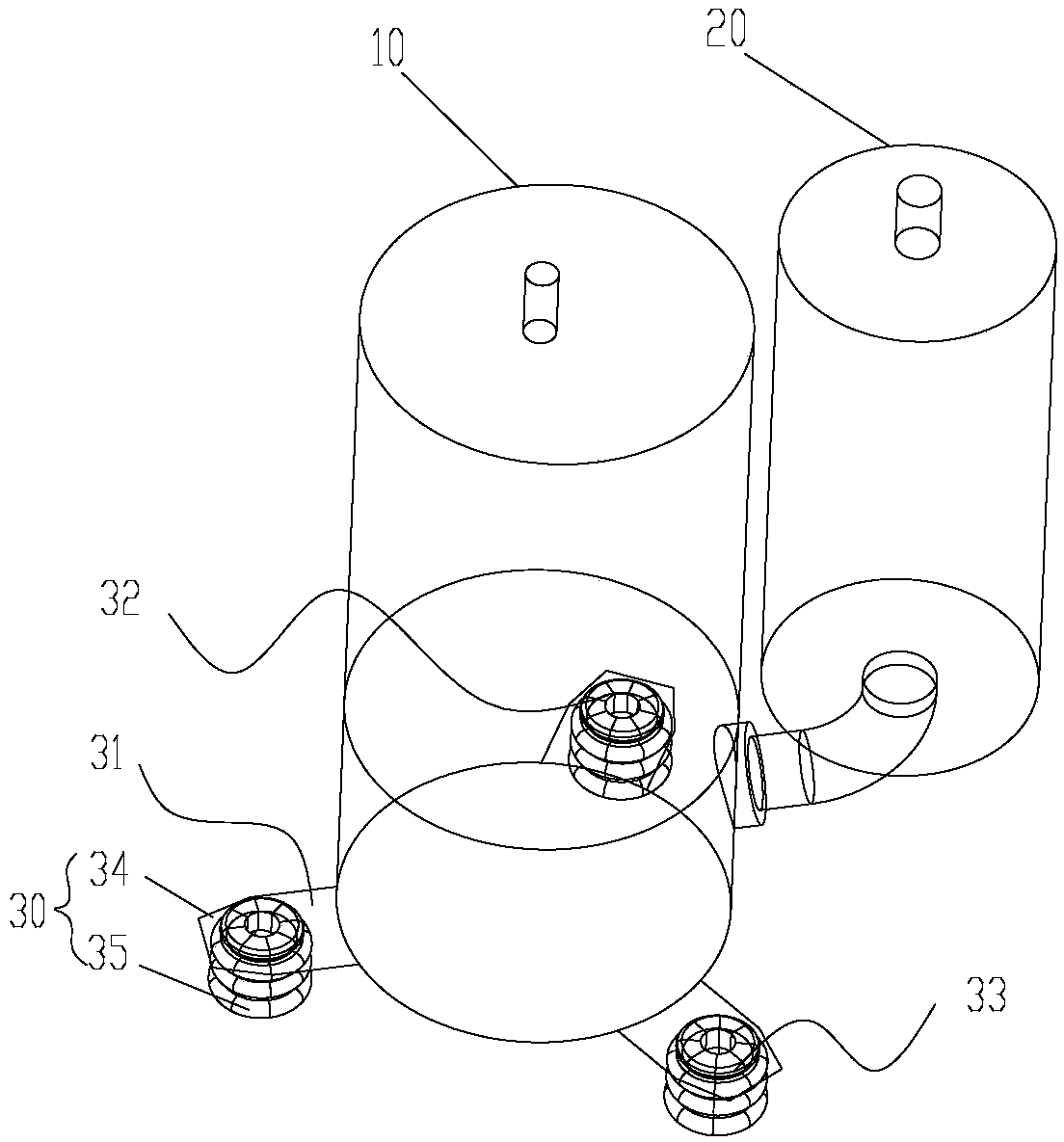

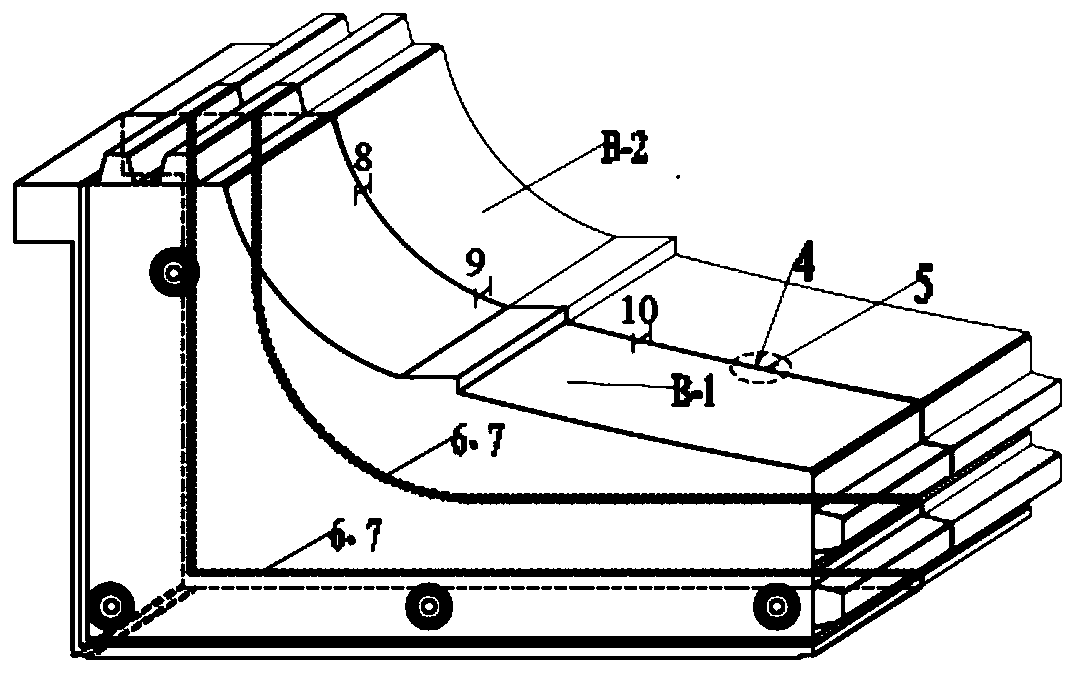

Cam roller negative stiffness structure low-frequency vibration isolator

PendingCN107740843AReduce stiffnessImprove static stiffnessNon-rotating vibration suppressionResonanceEngineering

The invention relates to a cam roller negative stiffness structure low-frequency vibration isolator. According to the low-frequency vibration isolator, a positive and negative stiffness parallel connection principle is adopted, a positive stiffness element and a negative stiffness element are connected in parallel, system resonance is restrained in combination with an added damping device, and protection is provided for drastic situations. A positive stiffness adjustment device and a negative stiffness adjustment device are used for realizing effective and accurate adjustment of the positive stiffness range and negative stiffness range to meet different bearing mass and vibration isolation requirements. The problems that an existing low-frequency vibration isolator is inconvenient to install, complex in structure, poor in work condition adaptability and the like are solved.

Owner:BEIJING MUNICIPAL INST OF LABOUR PROTECTION +1

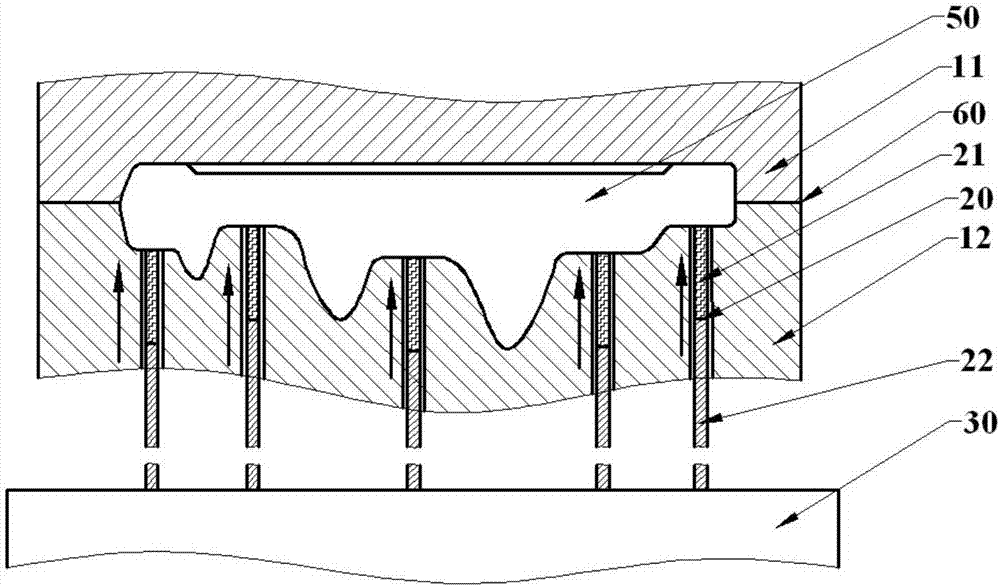

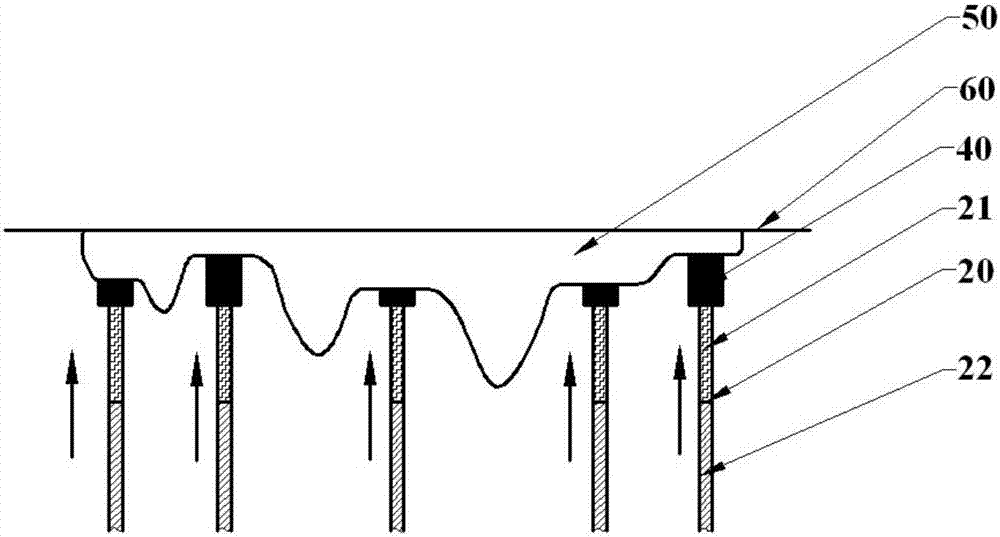

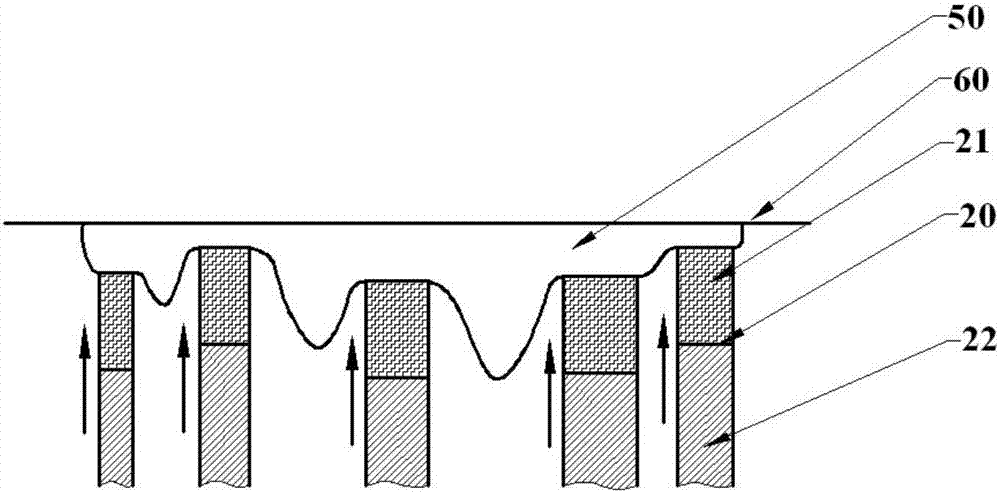

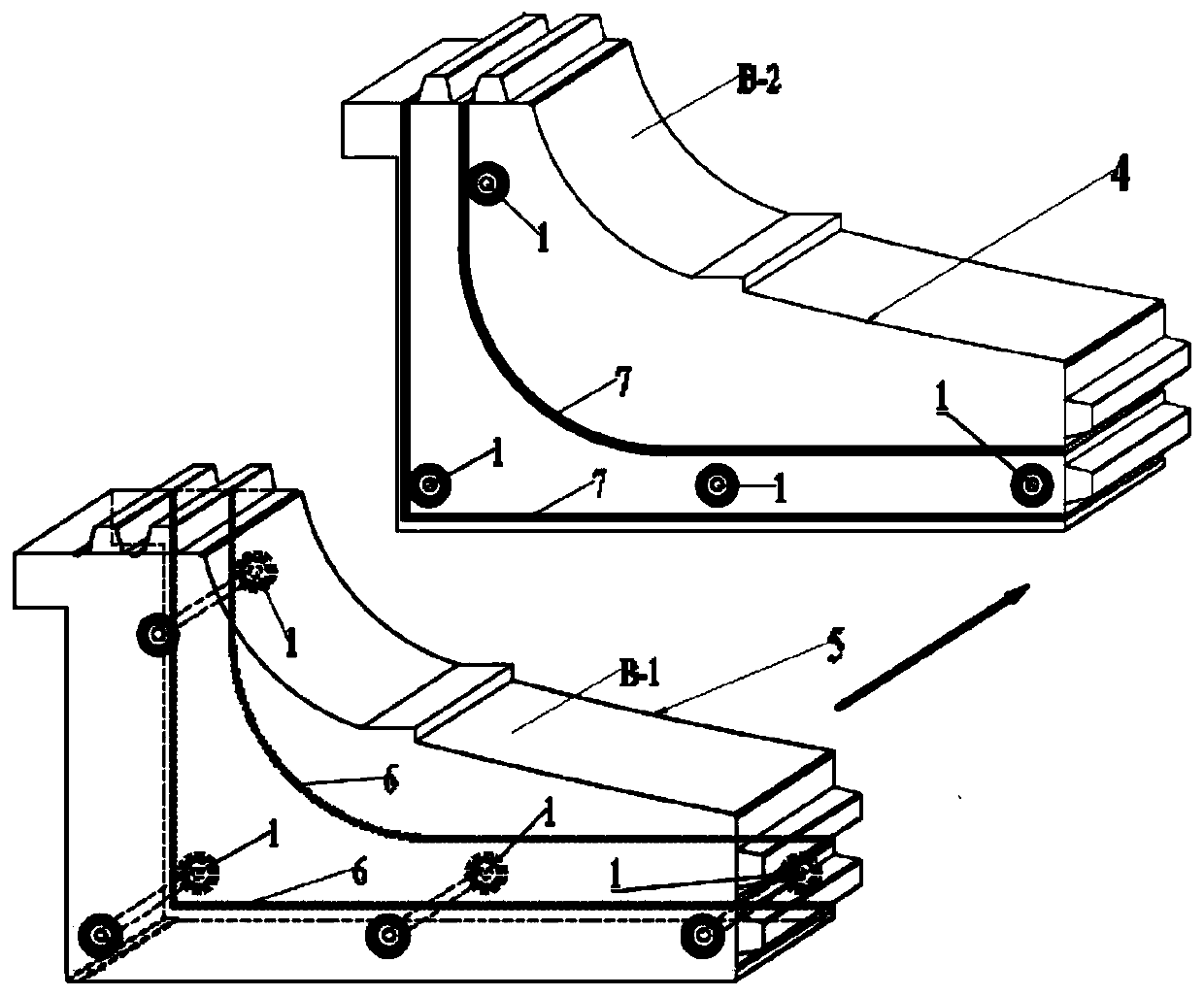

Flexible die releasing method of closed die forging large irregular profile structure forge piece

ActiveCN106975722AEject evenlyReduce contact areaForging/hammering/pressing machinesPush upsEngineering

The invention discloses a flexible die releasing method of a closed die forging large irregular profile structure forge piece. The flexible die releasing method comprises the steps that an upper forging die is taken out firstly and then force is applied to pushing rods to push up the large irregular profile structure forge piece in a lower forging die; flexible sections of each pushing rod are compressed to the elastic limit, and the compression amount is equal; when push-out force of a certain pushing rod is larger than frictional resistance of the position, located on the pushing rod, of the forging piece and a die mold cavity, the position of the forging piece loosens firstly and produces certain displacement, the pushing rod is not separated from the forging piece, the situation same with the just pushing rod occurs gradually on the other one pushing rod or the other multiple pushing rods, and the process occurs randomly and is conducted continuously; and when the total push-out force of all the pushing rods is larger than the total frictional resistance of the forging piece, the forging piece loosens overall, bears relatively-even force and is steadily pushed out of the die mold cavity. According to the flexible die releasing method, the die releasing process of the forging piece becomes steadier and is not liable to damage, and the flexible die releasing method is mainly used for die releasing after forging of forging pieces such as large aircraft structural pieces.

Owner:贵州锆石科技发展有限责任公司

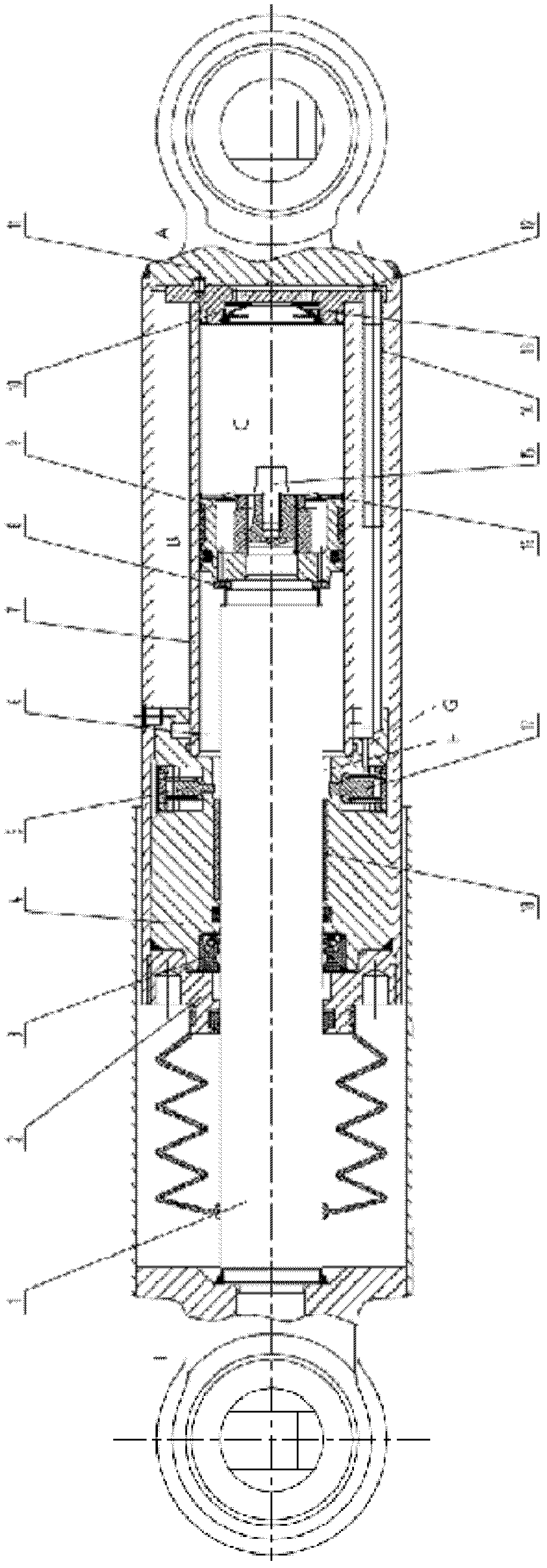

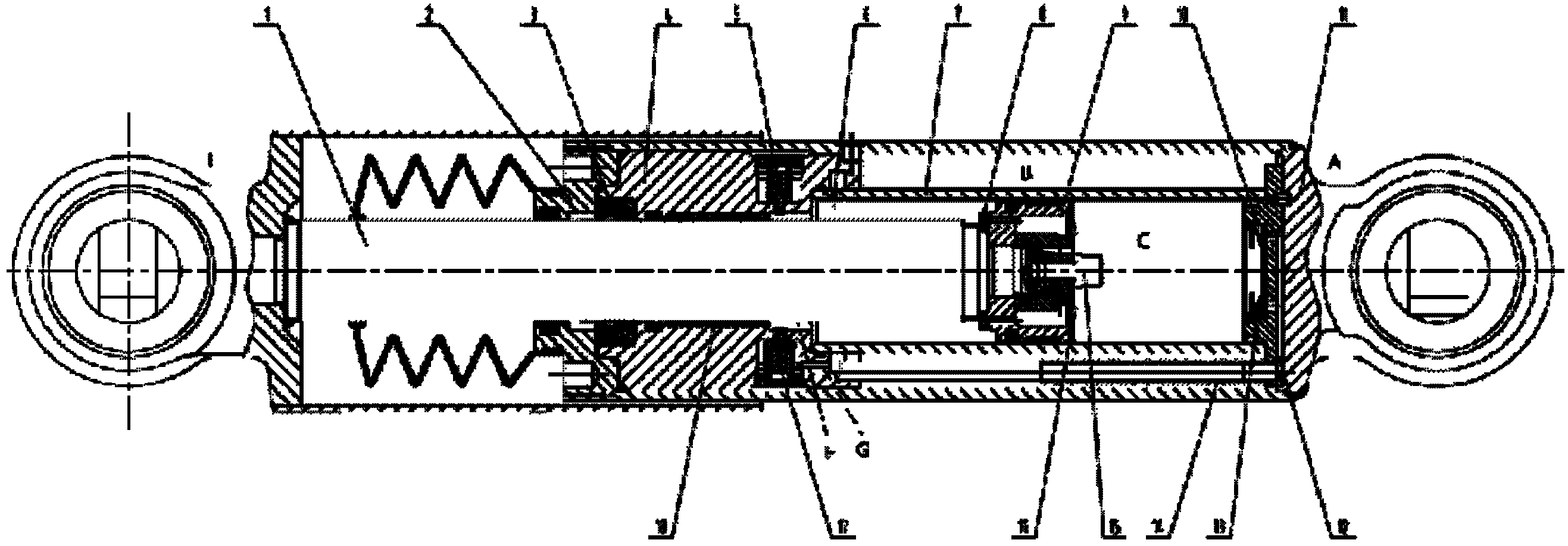

Transverse shock absorber for locomotives

The invention relates to a transverse shock absorber for locomotives, which belongs to the technical field of locomotives and comprises a pressure cylinder mounted in an oil storage cylinder. An oil return cavity is formed between the oil storage cylinder and the pressure cylinder, the pressure cylinder is peripherally matched with a piston on the head of a piston rod, and the piston rod extends out from the other end, away from a mounting end, of the oil storage cylinder and is fixedly connected with another mounting end with a dustproof tube. An end cover is fixed into the other end of the oil storage cylinder, a damping valve and a first one-way valve are mounted on the end cover and a bottom valve respectively, a second one-way valve is mounted on the piston, one end of the end cover is provided with a stepped hole, the bottom of the stepped hole is provided with a shrinkage hole which forms an annular groove with the piston rod, the shrinkage hole is communicated with the interior of the pressure cylinder, and a radial damping valve and an axial oil return pipe communicated with the oil return cavity are mounted on the end cover at the position corresponding to the shrinkage hole. The transverse shock absorber is high in processing and assembly manufacturability and more effective in damping, the compression damping force and the stretch damping force are basically uniform, and the symmetry rate can reach more than 90%.

Owner:CHANGZHOU KYB LEADRUN VIBRATION REDUCTION TECH +1

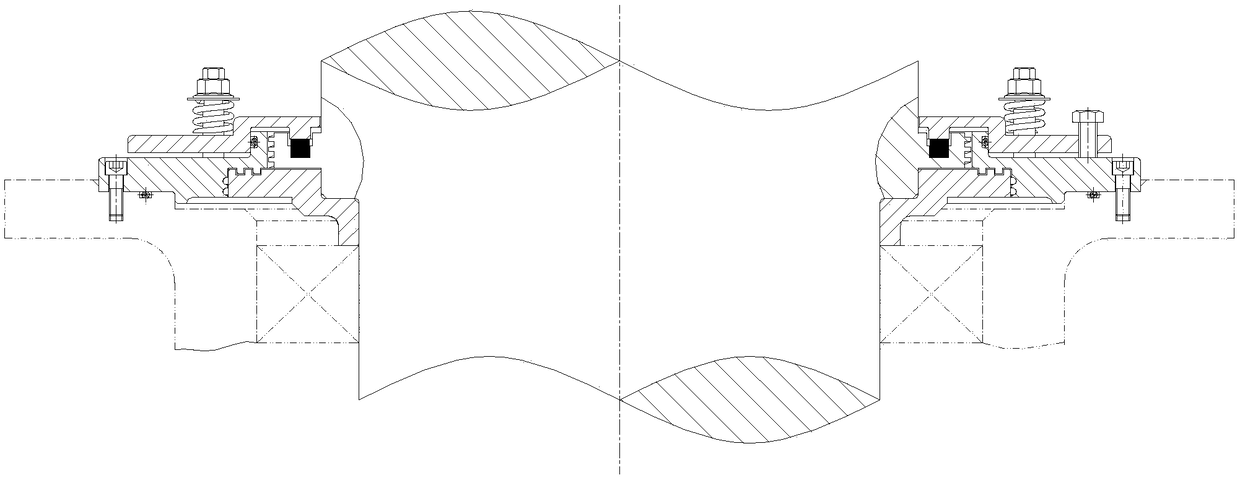

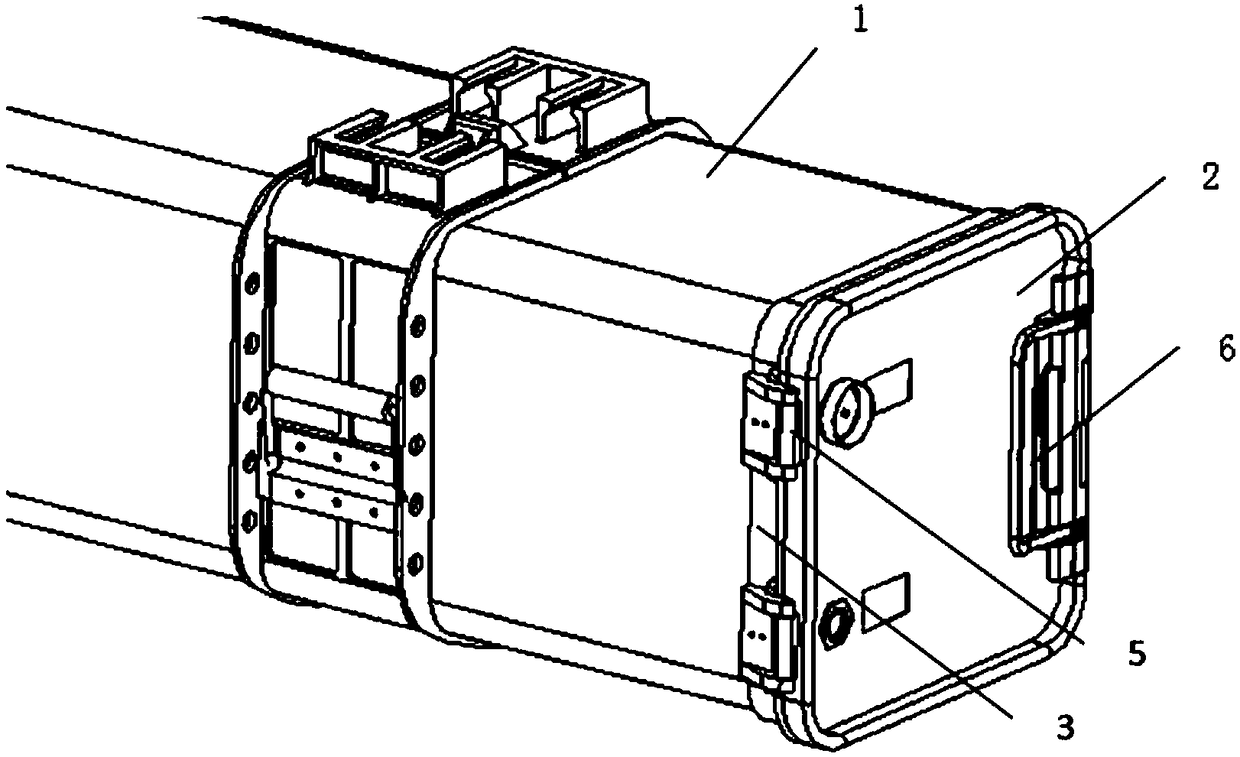

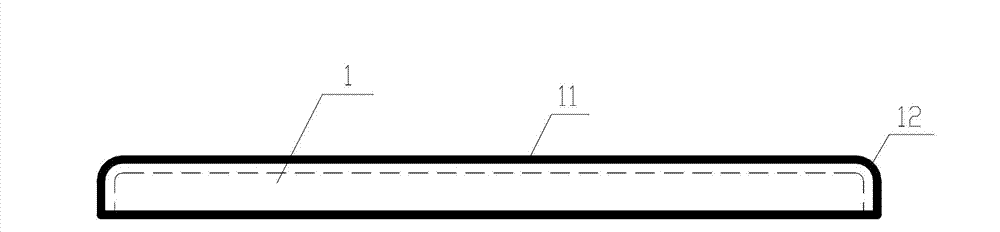

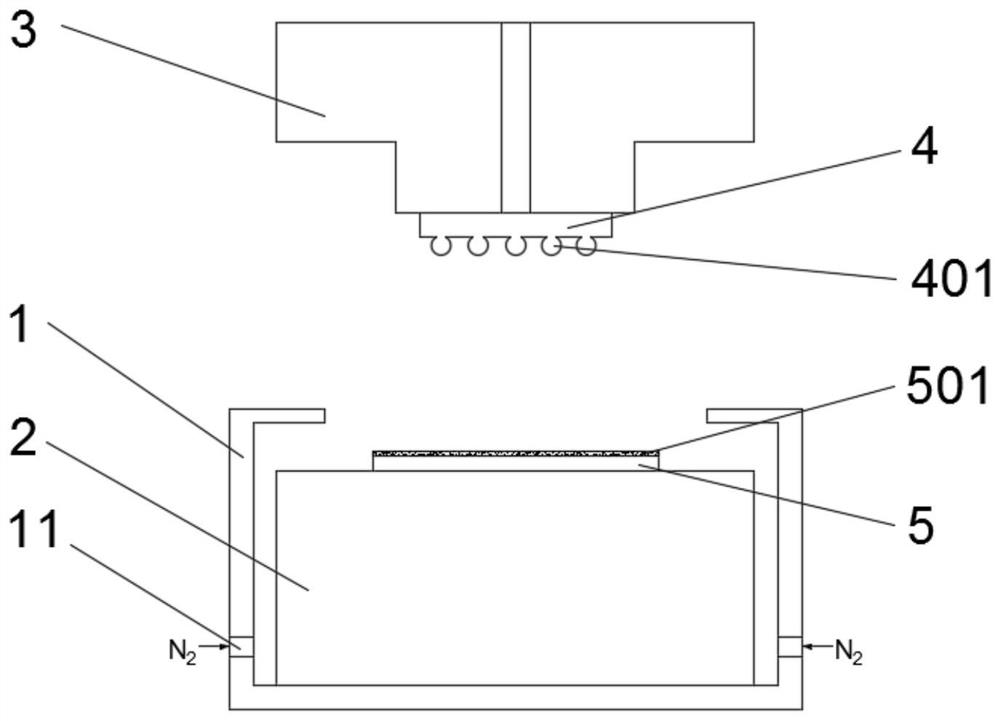

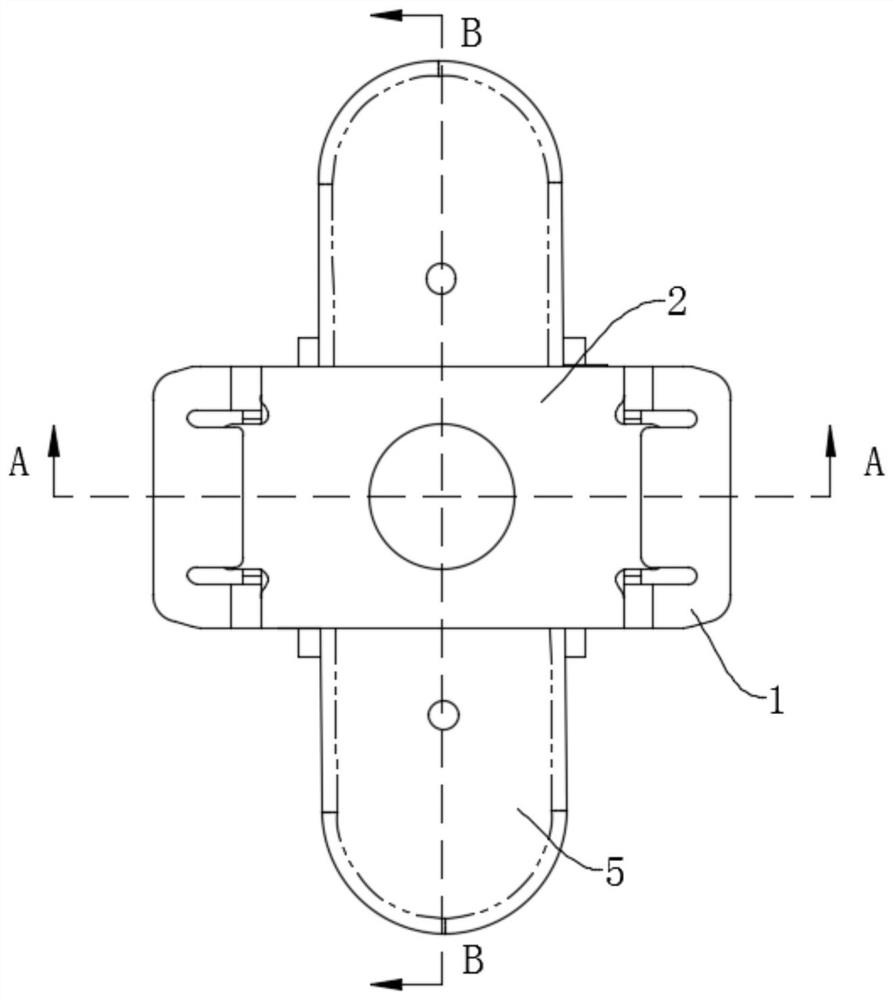

Sealing structure for sealing box

InactiveCN102182825AConsistent compressionNot easy to ageEngine sealsNutsEngineeringMechanical engineering

The invention discloses a sealing structure for a sealing box. The sealing structure comprises an annular accommodating groove (1) positioned on an upper edge of a box body, an annular elastic sealing piece (2) accommodated in the accommodating groove (1), and a pressing plate (3) which is arranged on a box cover and is used for pressing against the elastic sealing piece (2), wherein a contact surface between the pressing plate (3) and the elastic sealing piece (2) is a plane; the elastic sealing piece (2) and the pressing plate (3) are pressed against each other through a pressing device arranged on the box body and the box cover; the elastic sealing piece (2) has the hardness of 45-50 degrees and the compression of 1-1.5mm; and the pressing plate (3) has the surface flatness of not more than 0.4. The sealing structure for the sealing box is good in sealing effect and high in insulating level, and has a protection level of IP67.

Owner:NINGBO HUAYUAN FRP ELECTRICAL APPLIANCE MFR

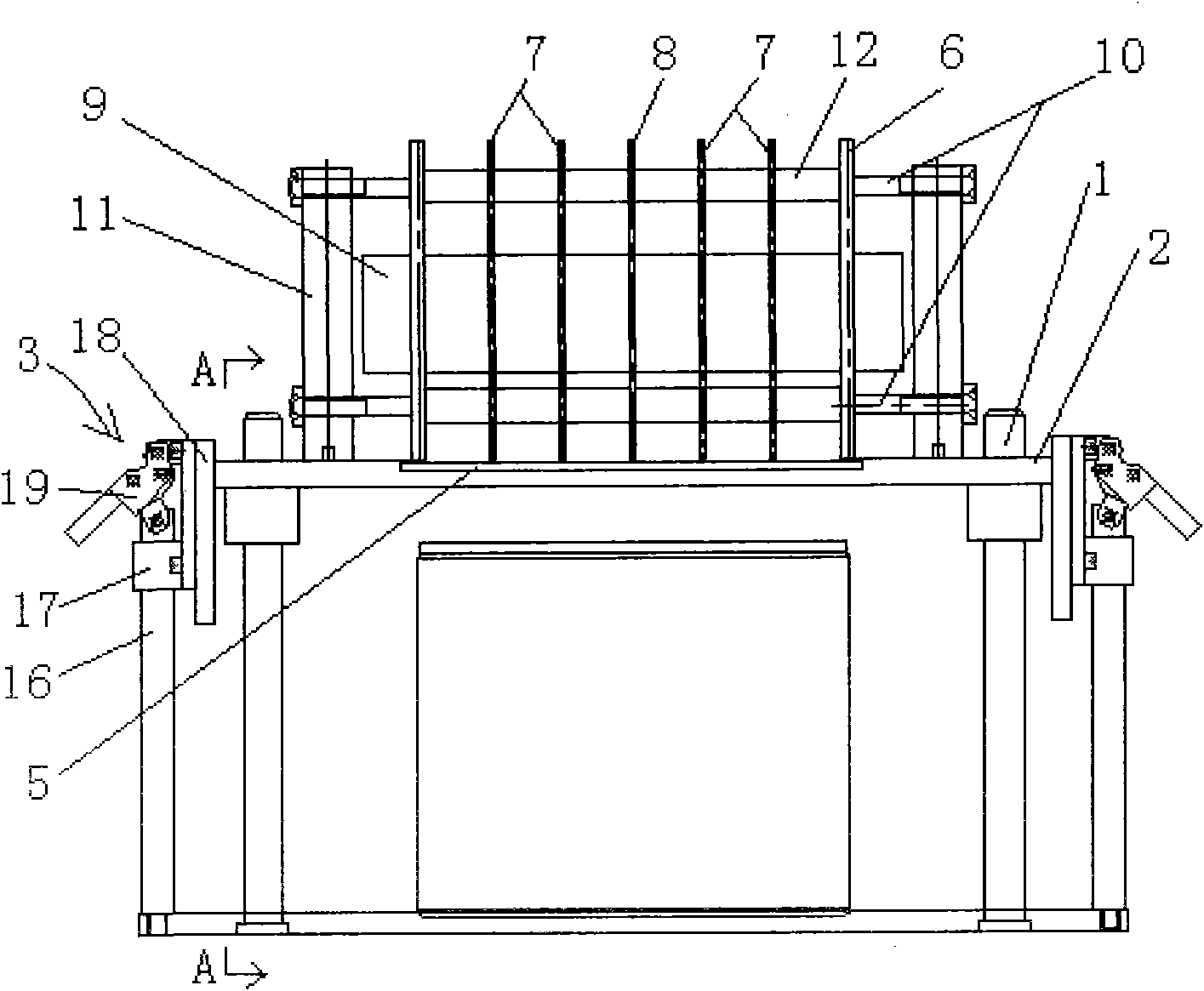

Integral manual production device for 12V20AH lead acid battery electrode group soldering and discharging

The invention discloses an integral manual production device for 12V20AH lead acid battery electrode group soldering and discharging. The device comprises a workbench, a lifting device, a soldering group box, partition plates, a pressing device and an inserting plate, wherein the workbench is movably connected to a guide column of a machine rack; the lifting device drives the workbench to move up and down; the soldering group box is arranged on the workbench; the partition plates are arranged in the soldering group box; the pressing device is used for pressing the electrode groups in the soldering group box; and the inserting plate is blocked on the discharging openings of the soldering group box and the workbench. The device is characterized in that the end plate of the soldering group box and two side parts of the first, the second, the fourth and the fifth partition plates are movably connected with a longitudinal shaft; the two side parts of the middle third partition plate are fixedly connected with the longitudinal shaft; both ends of the longitudinal shaft are fixedly connected with a support column; the longitudinal shafts between the end plate and the partition plate and between the partition plates are provided with a fixed length sleeve barrel for extruding the electrode groups; and a pressing shaft of the pressing device is movably connected with the support column and provided with a press head. The invention has the advantages of small size and light weight and ensures uniform pressing of the electrode groups.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU +3

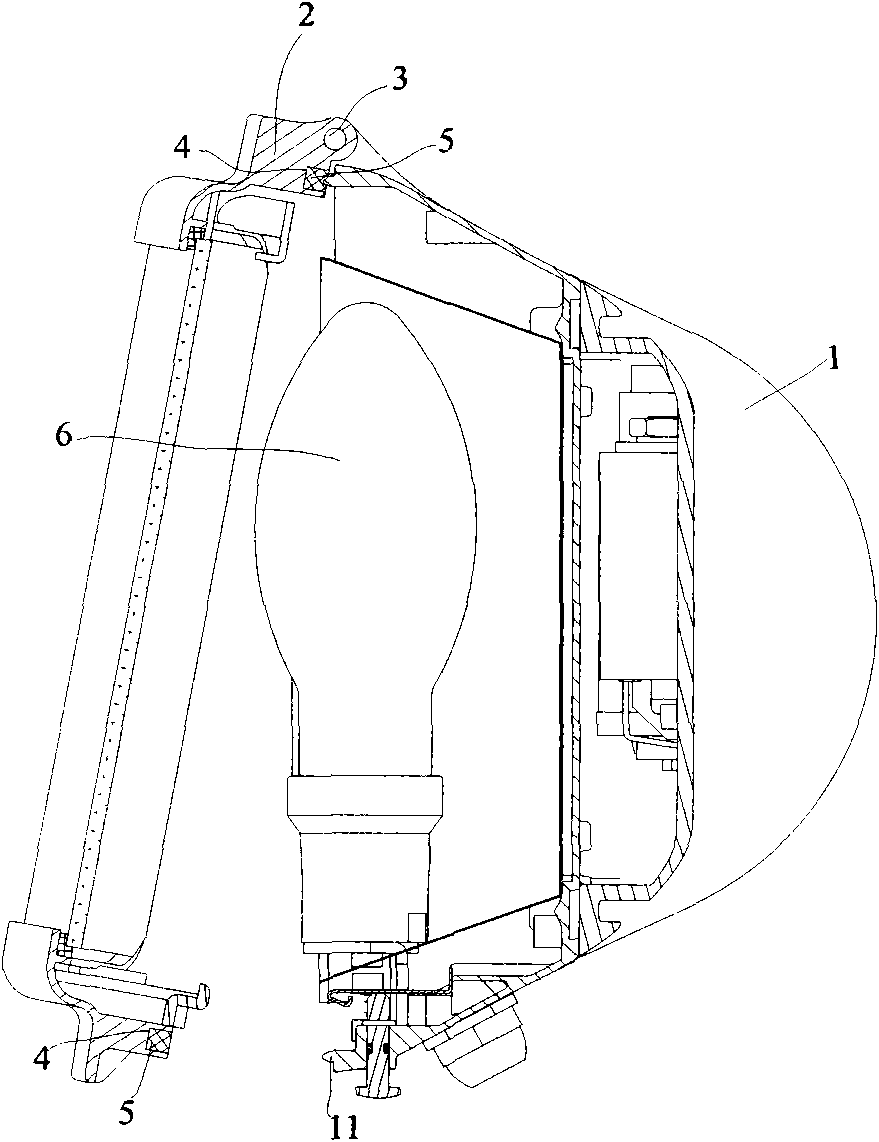

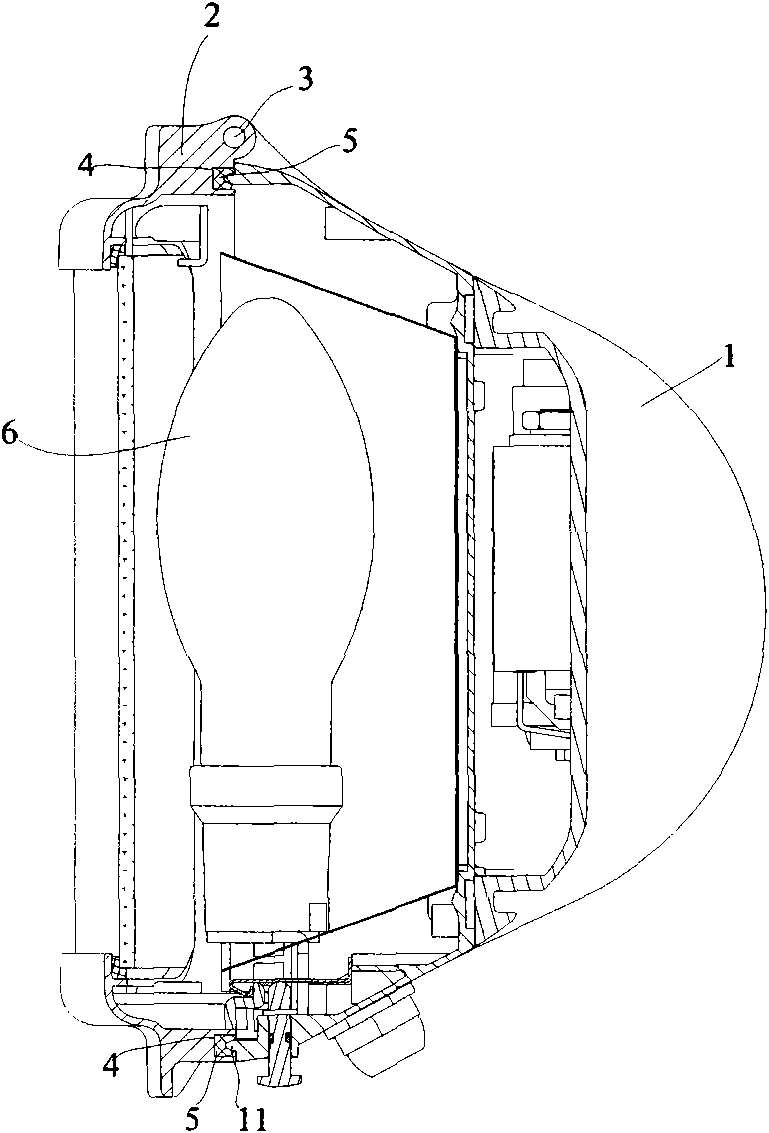

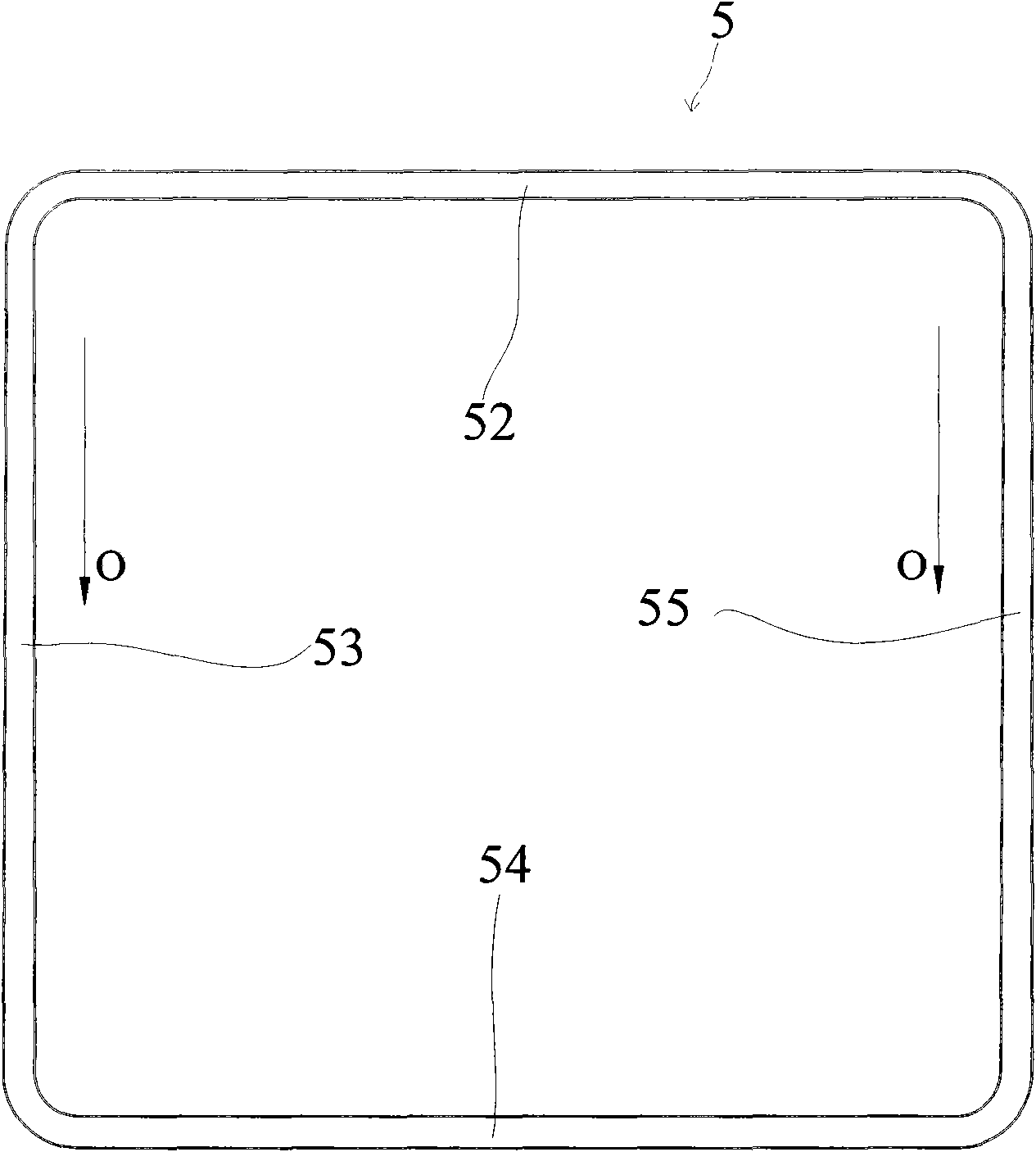

Waterproof sealing lamp

InactiveCN101956966AClosure is even and reasonableImproves waterproof seal reliabilityGas-tight/water-tight arrangementsEngineeringMechanical engineering

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

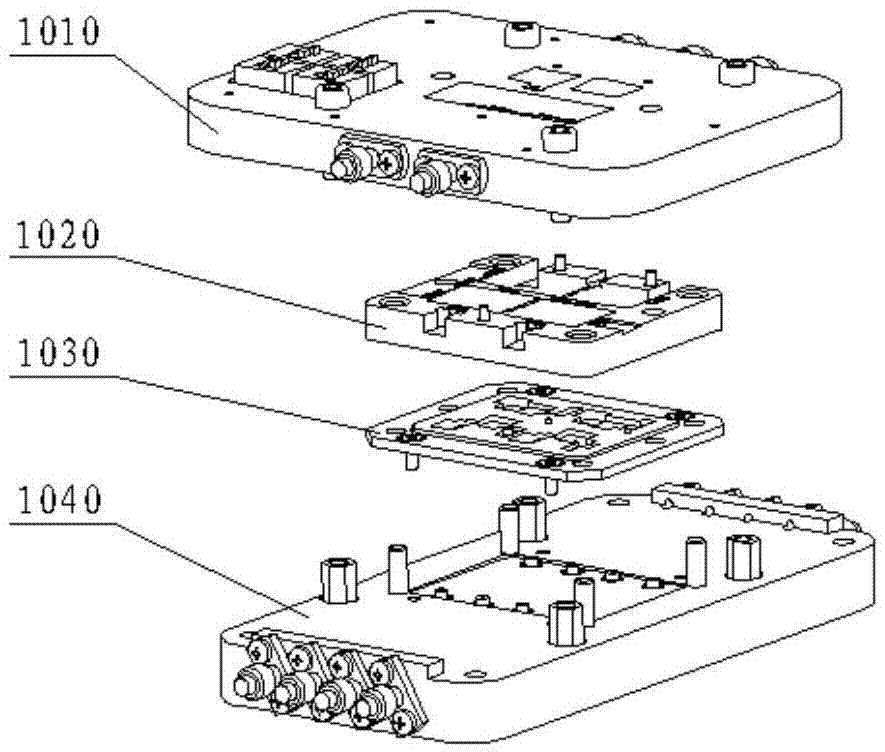

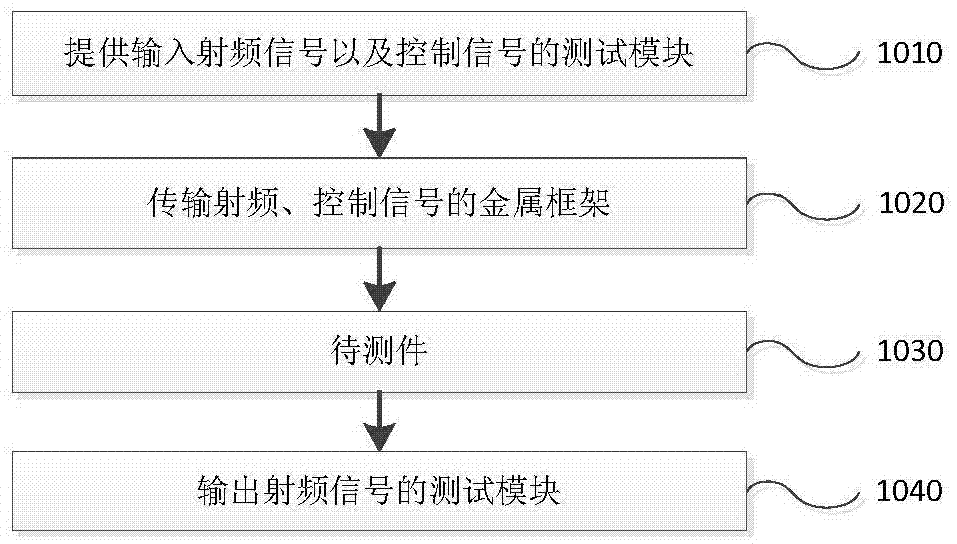

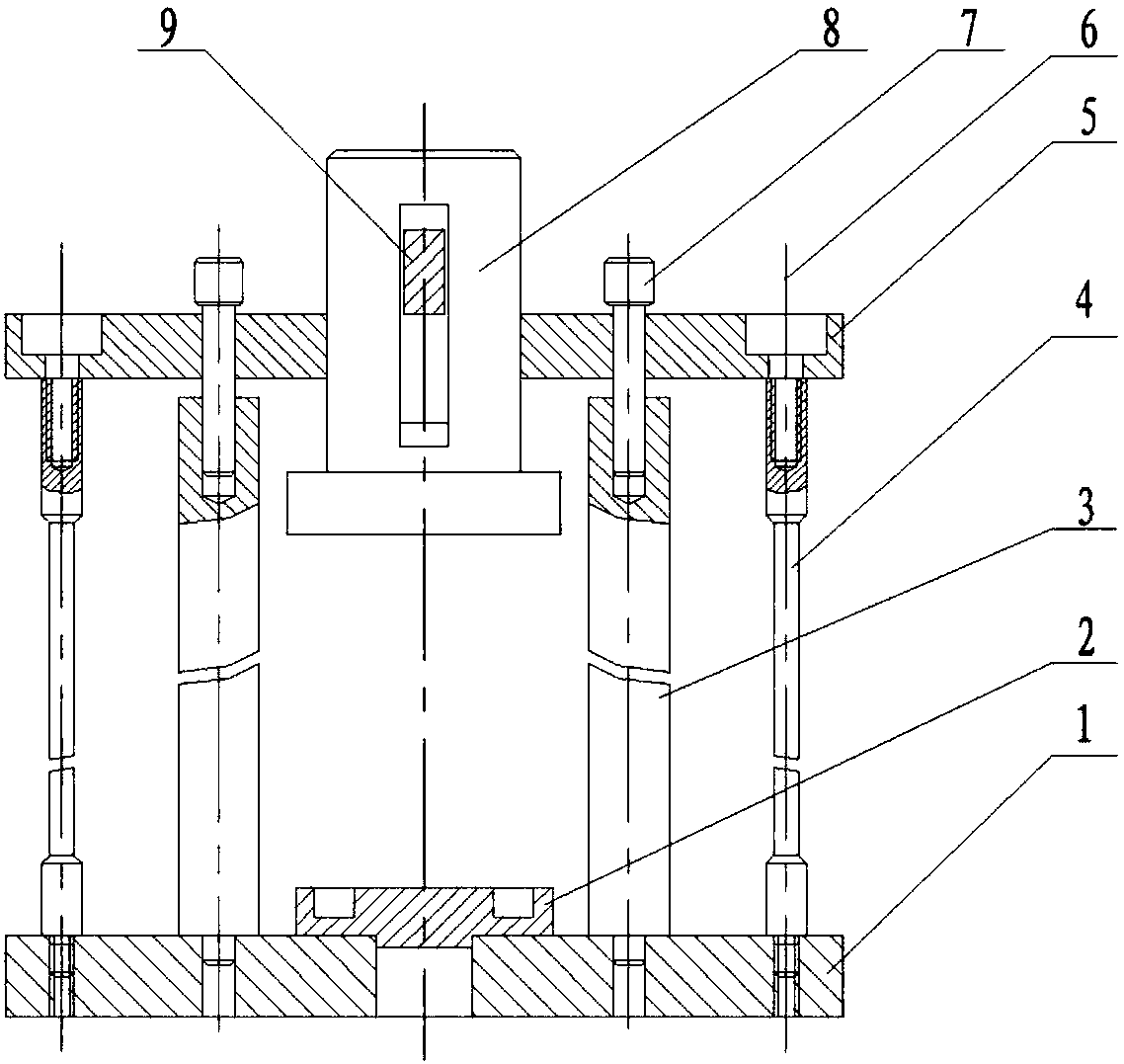

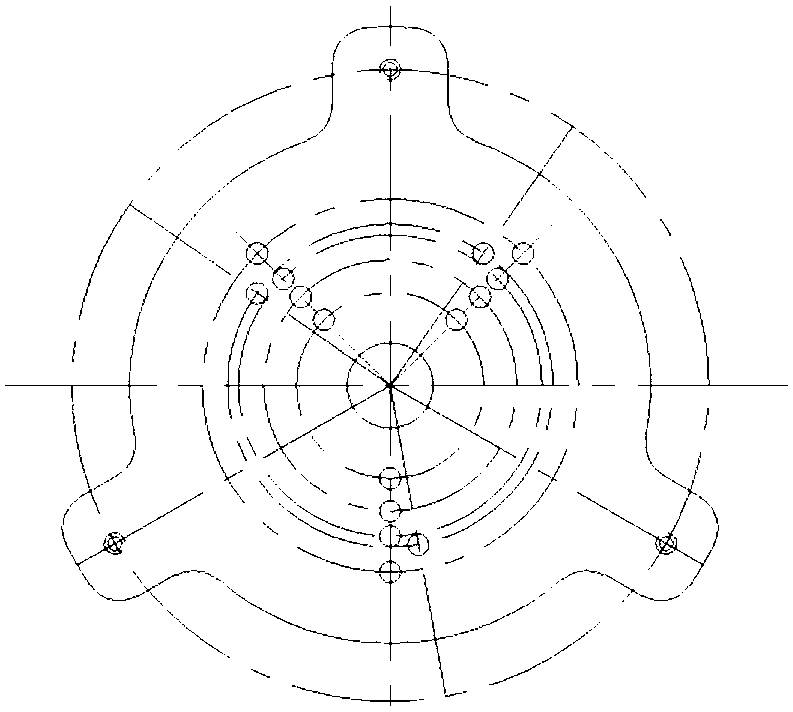

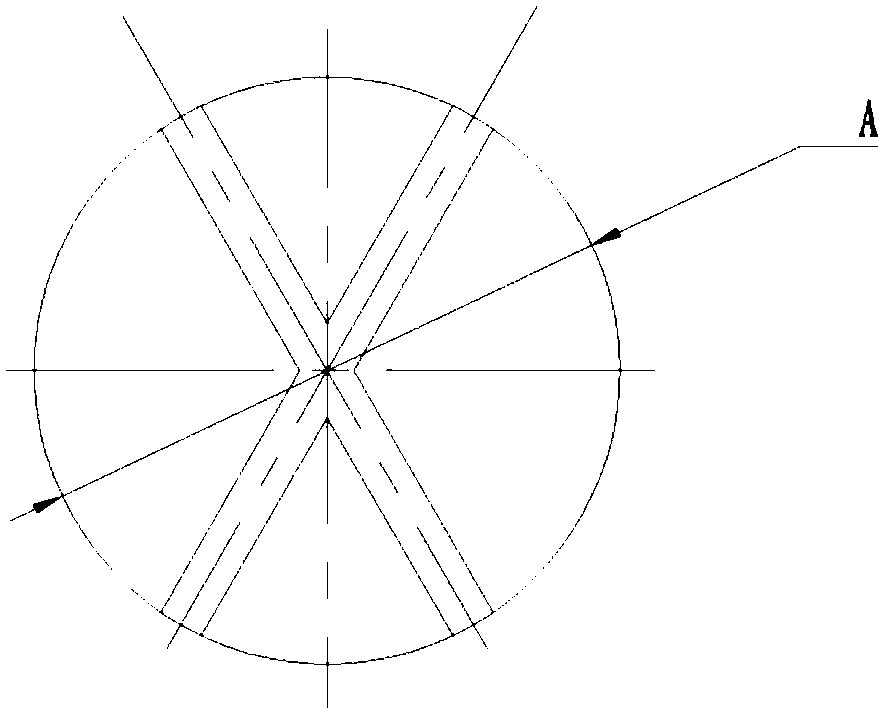

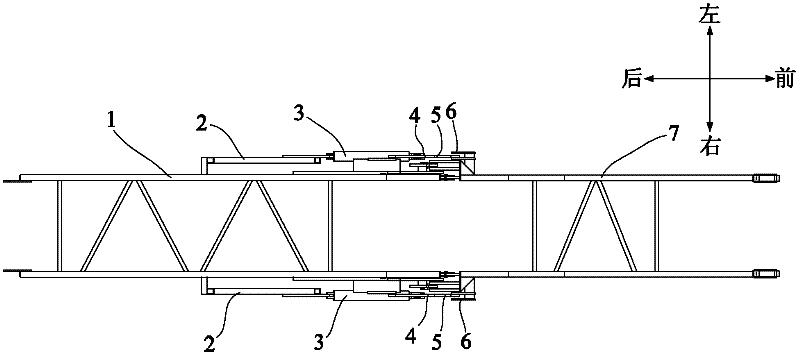

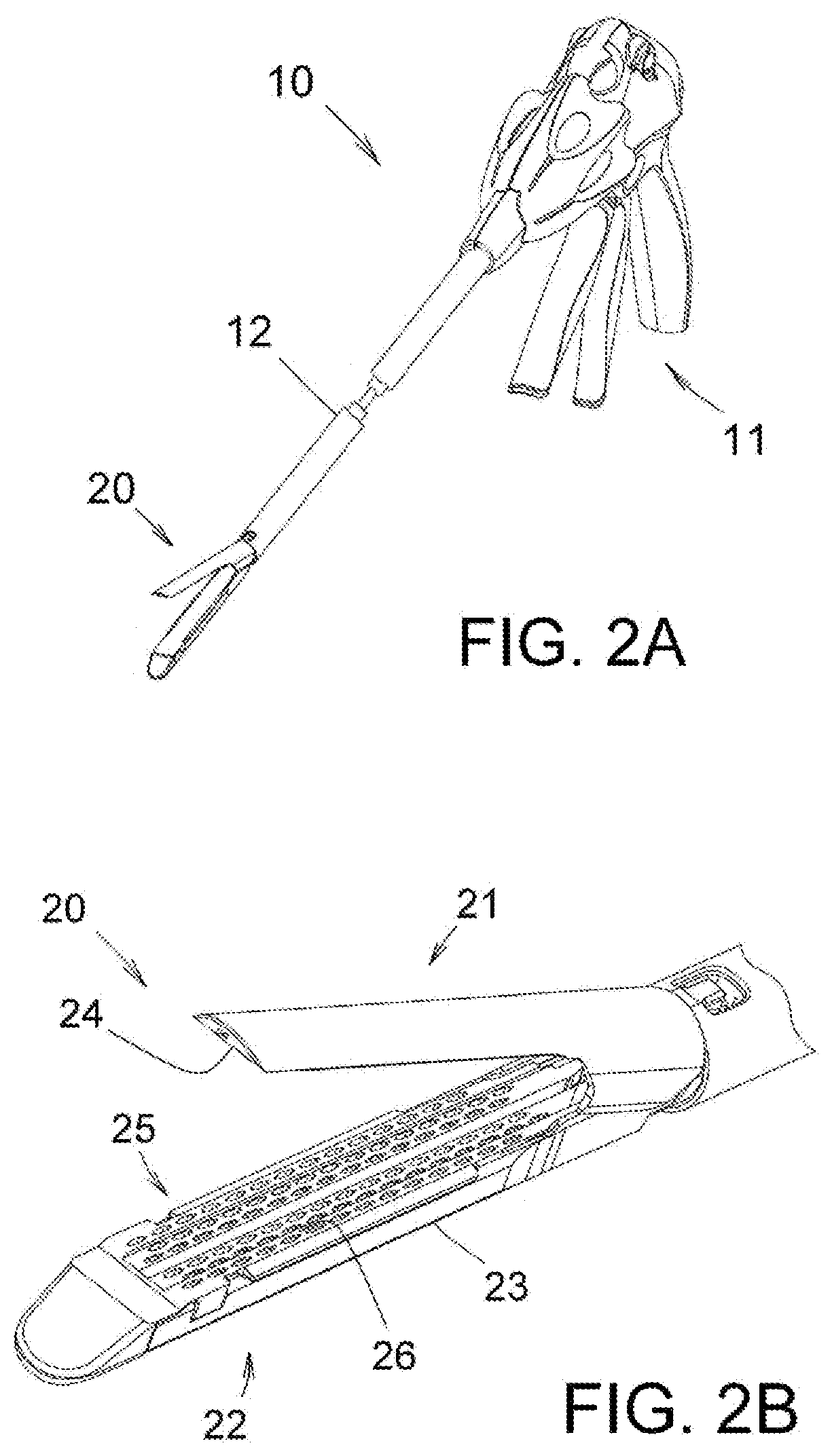

Three-dimensional stacked packaging module single-board testing tool and testing method

ActiveCN106872873ASolve the disadvantages of occupying a large area of heat transfer surfaceSolve the characteristics of small connection operation spaceElectronic circuit testingControl signalFixed frame

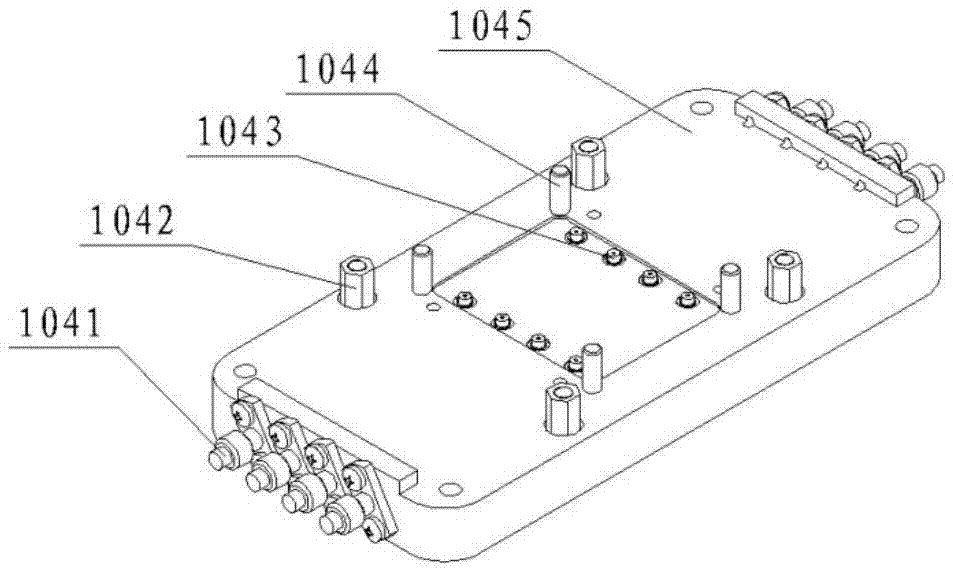

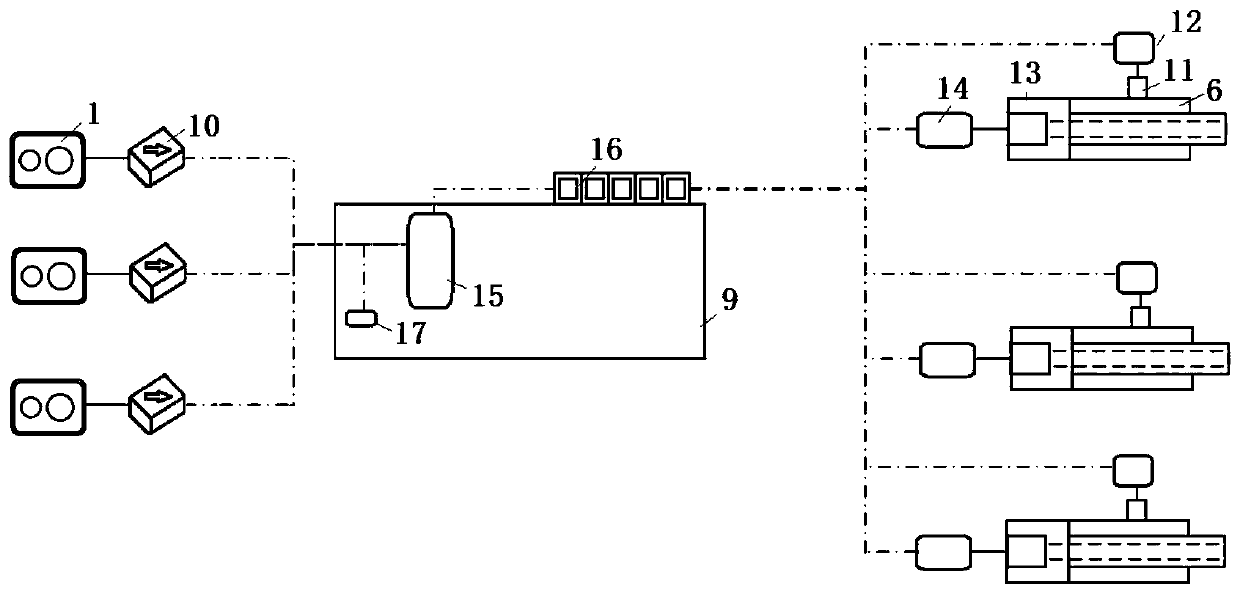

The invention relates to a three-dimensional stacked packaging module single-board testing tool. The three-dimensional stacked packaging module single-board testing tool is composed of four parts of a control signal and radiofrequency signal circuit board and an installation module thereof (1010), a vertical interconnection connector and an installation frame thereof (1020), a circuit board to be tested and a fixing frame thereof (1030) and a radiofrequency signal output module (1040). The vertical interconnection connector and the installation frame thereof (1020) are composed of an installation frame (1021), vertical transition connectors (1022) and guide sleeves (1023); the circuit board to be tested and the fixing frame thereof (1030) are composed of a metal plate to be tested (1031) and a circuit board (1032); and the signal output module (1040) is composed of radio frequency connectors (1041), hexagon copper posts (1042), fuzz button conversion coaxial connectors (1043), guide pillars (1044), a mounting base plate (1045), microstrip boards (1046) and cover plates (1047). By employing the three-dimensional stacked packaging module single-board testing tool, the contact area of a radiator is increased, space of the thermal design is expanded, natural heat dissipation can satisfy the demand, and the difficulty level and cost of the thermal design are reduced.

Owner:LEIHUA ELECTRONICS TECH RES INST AVIATION IND OF CHINA

Prefabricated assembled structure automatic splicing control device system and method

ActiveCN110894727AAssembly precisionSolve the problem of inability to cast-in-place construction workArtificial islandsLifting devicesJackscrewCentroid algorithm

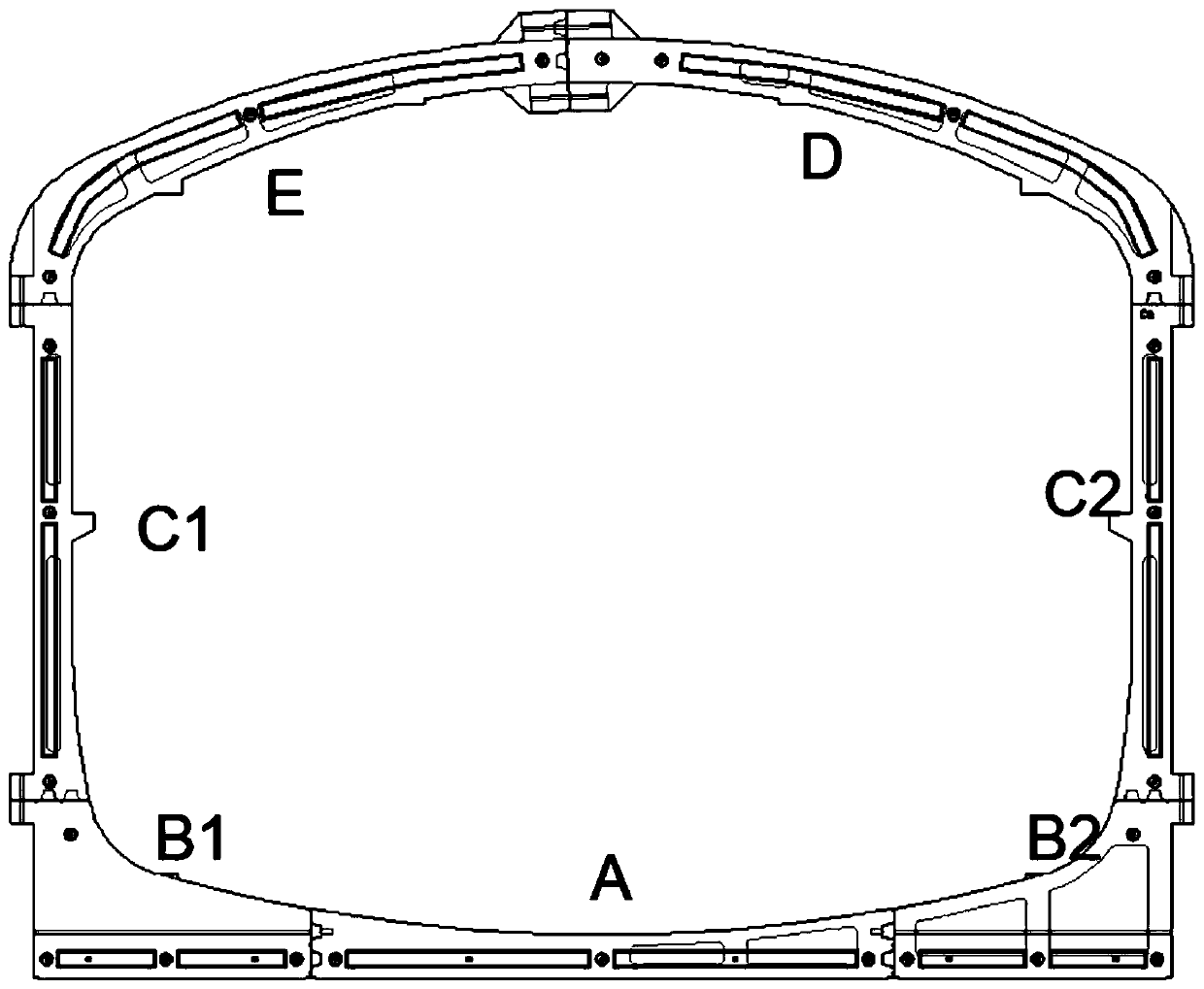

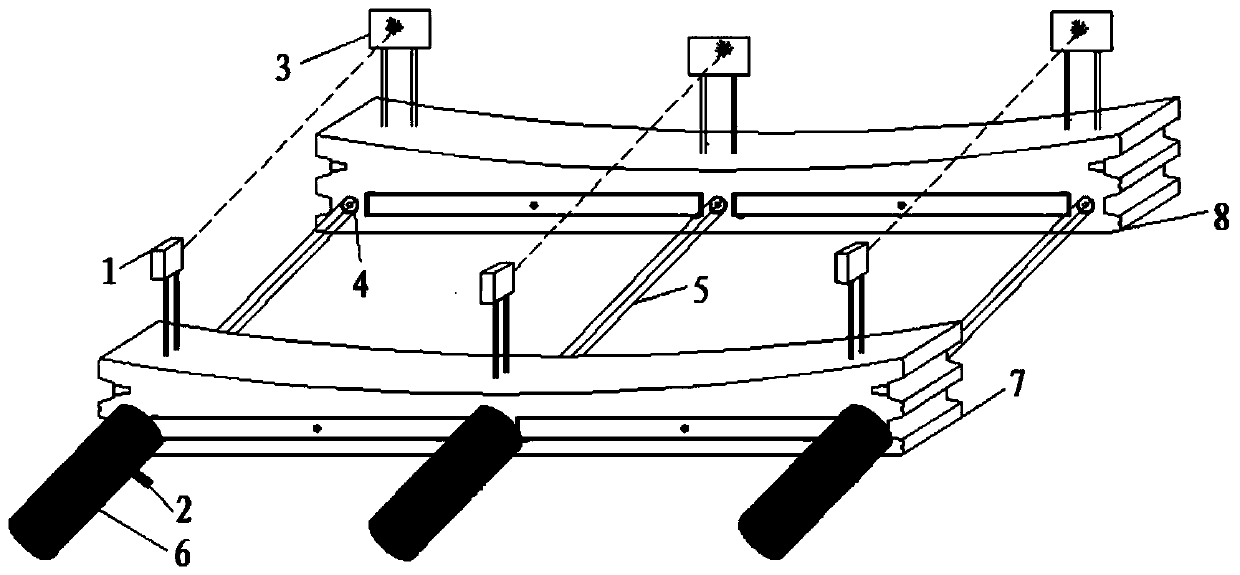

The invention discloses a prefabricated assembled structure multi-point cooperative splicing system and method. The prefabricated assembled structure multi-point cooperative splicing system comprisesprefabricated assembled underground structure splicing center control equipment, a plurality of hydraulic jacks on splicing pieces, a plurality of laser distance measuring instruments arranged on thesplicing pieces and a plurality of laser reflecting plates arranged on a target piece. By utilization of a component rubber pad counter-force centroid algorithm, a tensioning method based on centroidtracking and slit width control, an assembled component splicing frictional resistance calculating method, a multi-point cooperative communication and multi-mode protection method, a multi-point cooperative loading control method and other methods and algorithms, simultaneous different-amount accurate output control over the tensioning force and the tensioning speed when the different jacks are tensioned is achieved, accordingly, the prefabricated assembled component splicing control effect is effectively improved, smooth and safe proceeding of splicing is guaranteed, accurate output control is achieved, the assembling quality is improved, structure damage is avoided, and the prefabricated assembled component splicing control effect can be effectively improved.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO

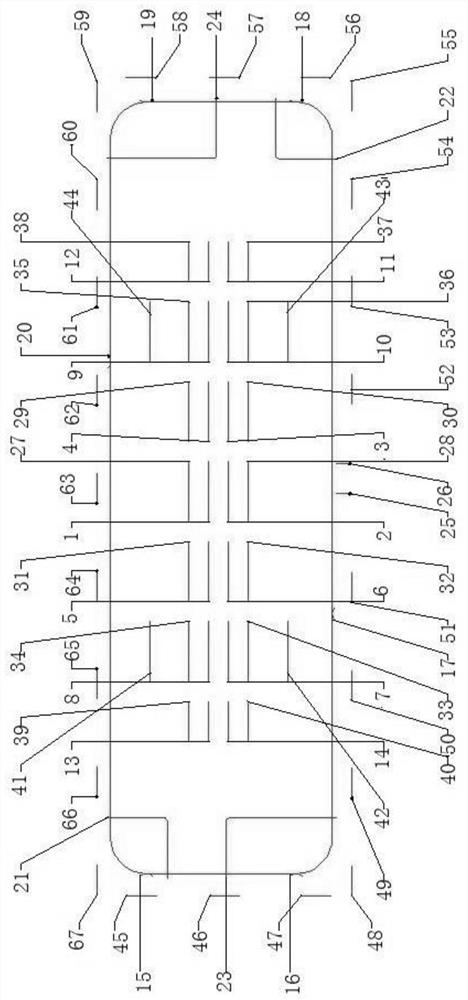

Universal stack banding mold for thermal battery

InactiveCN108598517AImprove general performanceRealize bundlingPrimary cell to battery groupingEngineeringThermal Battery

The invention provides a universal stack banding mold for a thermal battery. An upper support plate and a bottom plate are fixedly connected by a plurality of columns, a plurality of location holes are uniformly distributed along several circumferences of different diameters on the opposite surfaces, and several limited posts are fixedly connected through pins along the circumference of the same diameter. A cushion block is a stepped column having an upper end with the diameter being greater than diameter of the lower end, and the end with smaller diameter is installed in a through hole on theupper surface of the cushion block. By installing the cushion blocks with different thicknesses, stack height is regulated. An indenter is mounted in a through hole of the upper support plate, and arectangular through hole is opened in the horizontal direction. When a wedge-shaped sizing block is inserted in the rectangular through hole on the upper surface of the upper support plate, the indenter can be prevented from falling down. When the wedge-shaped sizing block is inserted into the rectangular through hole on the lower surface of the upper support plate, pressure of the indenter can belimited. The universal stack banding mold of the invention is efficient and fast to use and accurate in localization, and has strong practicality and universality.

Owner:北方特种能源集团有限公司西安庆华公司

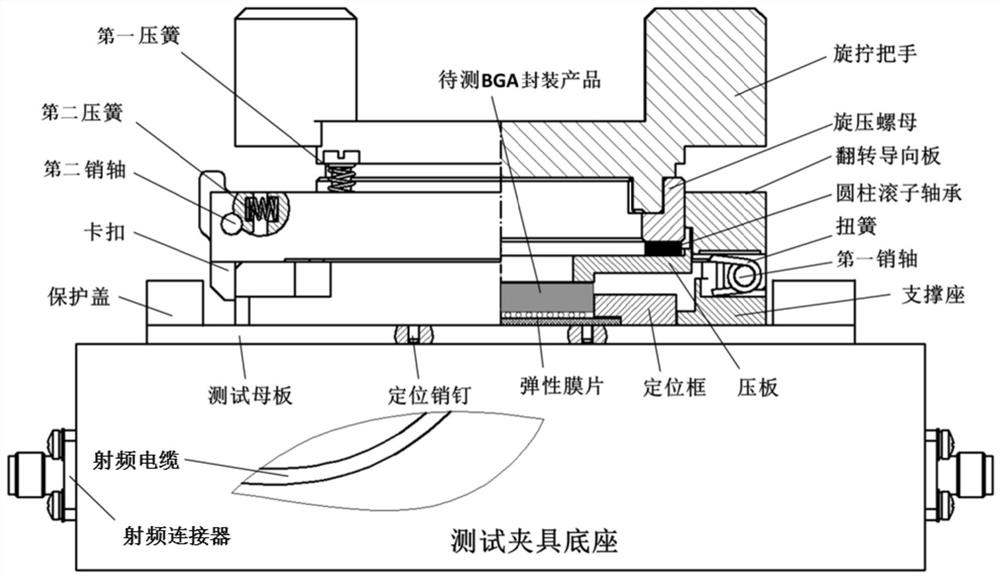

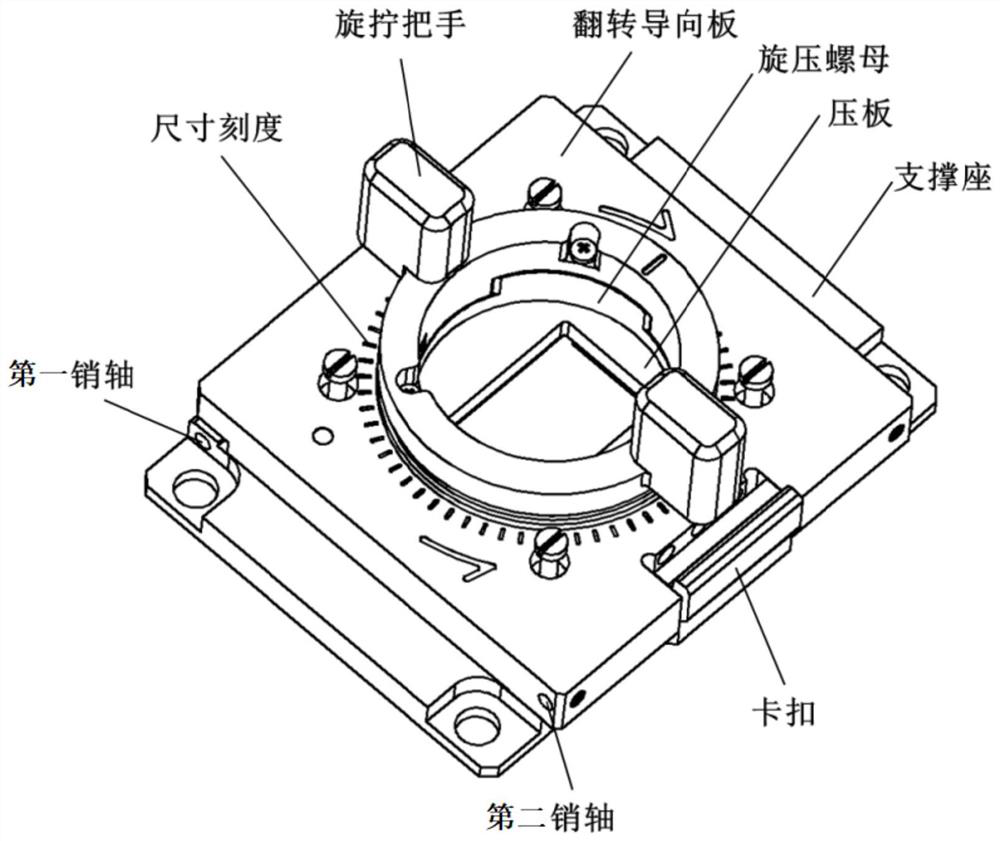

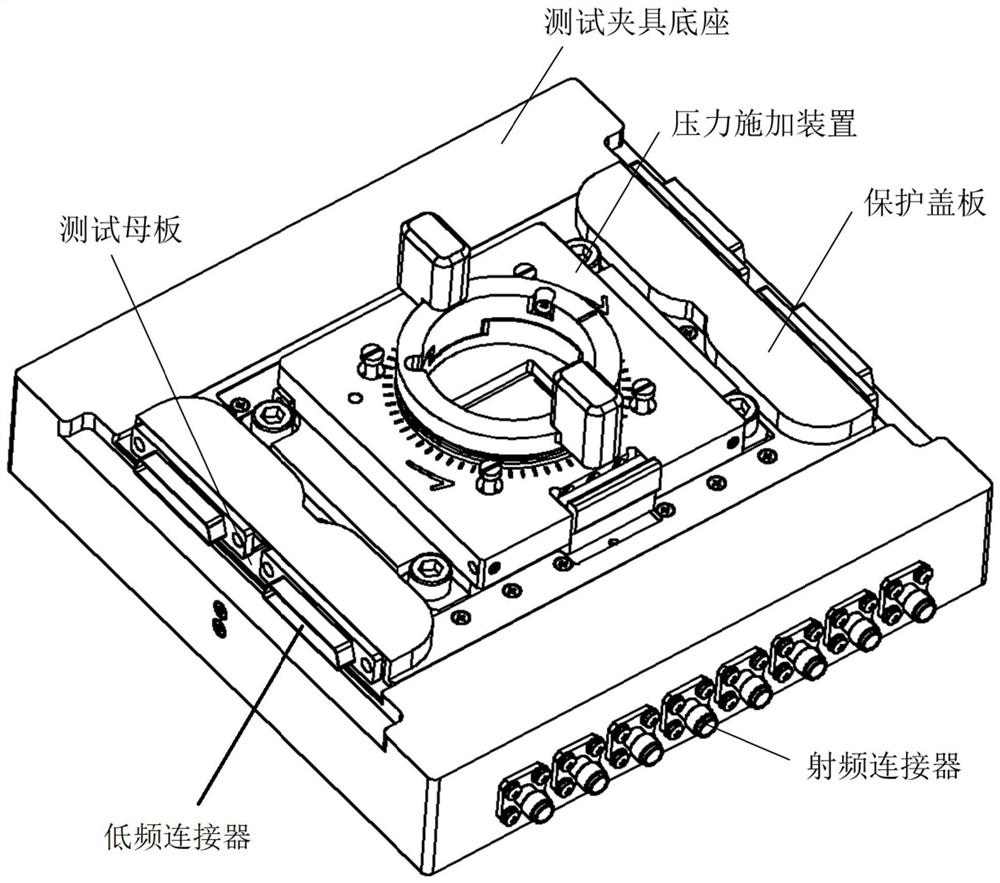

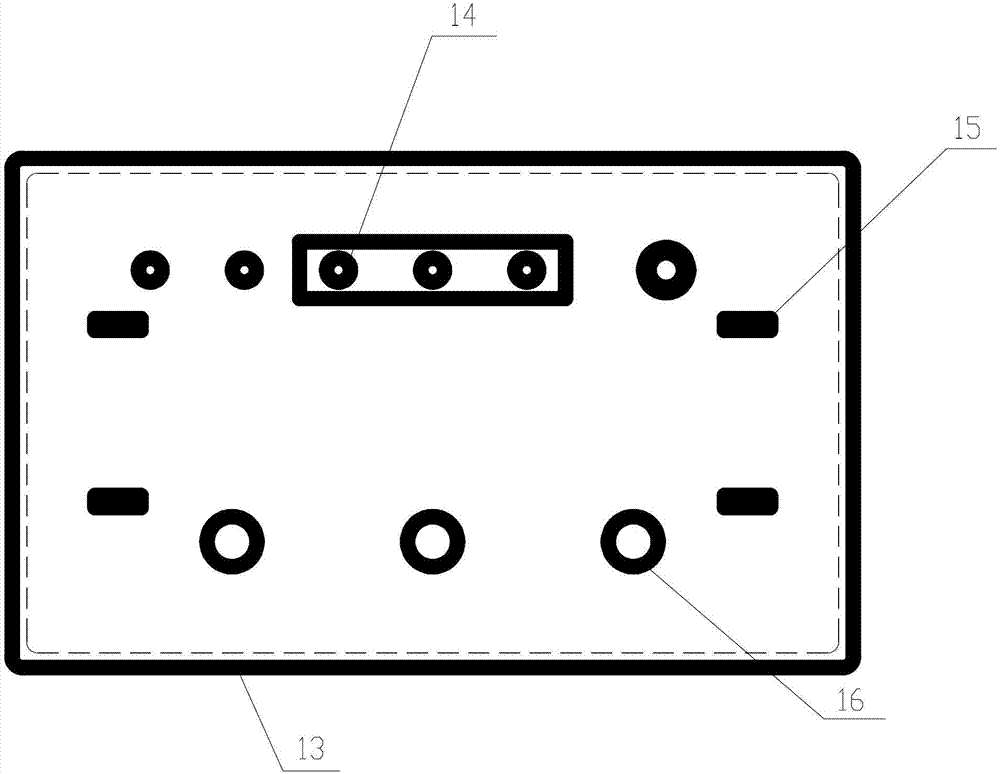

Test fixture for broadband radio frequency BGA interface system-in-package product

PendingCN112433072AStable and reliable RF signal connectionImprove test efficiencyElectronic circuit testingMeasurement instrument housingBroadbandSolder ball

The invention discloses a test fixture for a broadband radio frequency BGA interface system-in-package product. The test fixture comprises a pressure applying device, a test fixture base, a test mother board, an elastic diaphragm and a positioning mechanism; the pressure applying device comprises a guide mechanism, a pressing plate, a spinning nut and a screwing handle; a guide groove is formed inthe guide mechanism, and a threaded hole matched with the spinning nut is formed in the upper part of the guide groove; the pressing plate is installed in the guide groove, and the spinning nut is arranged in the threaded hole. And the screwing handle is used for screwing the spinning nut. According to the pressure applying device, one spinning nut is adopted to apply pressure to the pressing plate, the pressing plate applies pressure to the BGA packaging product to be tested stably and uniformly in the pressing process, the compression amount of each BGA solder ball on the BGA packaging product to be tested to the elastic diaphragm is consistent, and radio frequency signal communication is stable and reliable.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Bonded slit valve door seal with thin non-metallic film gap control bumper

ActiveUS9383036B2Prolong lifePrevent overcompressionOperating means/releasing devices for valvesSlide valveEngineeringMechanical engineering

The present invention provides a thin film spacer for maintaining a gap between a slit valve door and a sealing surface of a slit valve, such as a metallic insert. The film spacer can extend the life of a seal by limiting the line of sight exposure of the seal to corrosive gases within a wafer processing chamber, for example, and by controlling the compression percentage of the seal. The spacer may be located on an outer ambient side of the slit valve away from any corrosive gasses that may exist in the chamber.

Owner:PARKER INTANGIBLES LLC

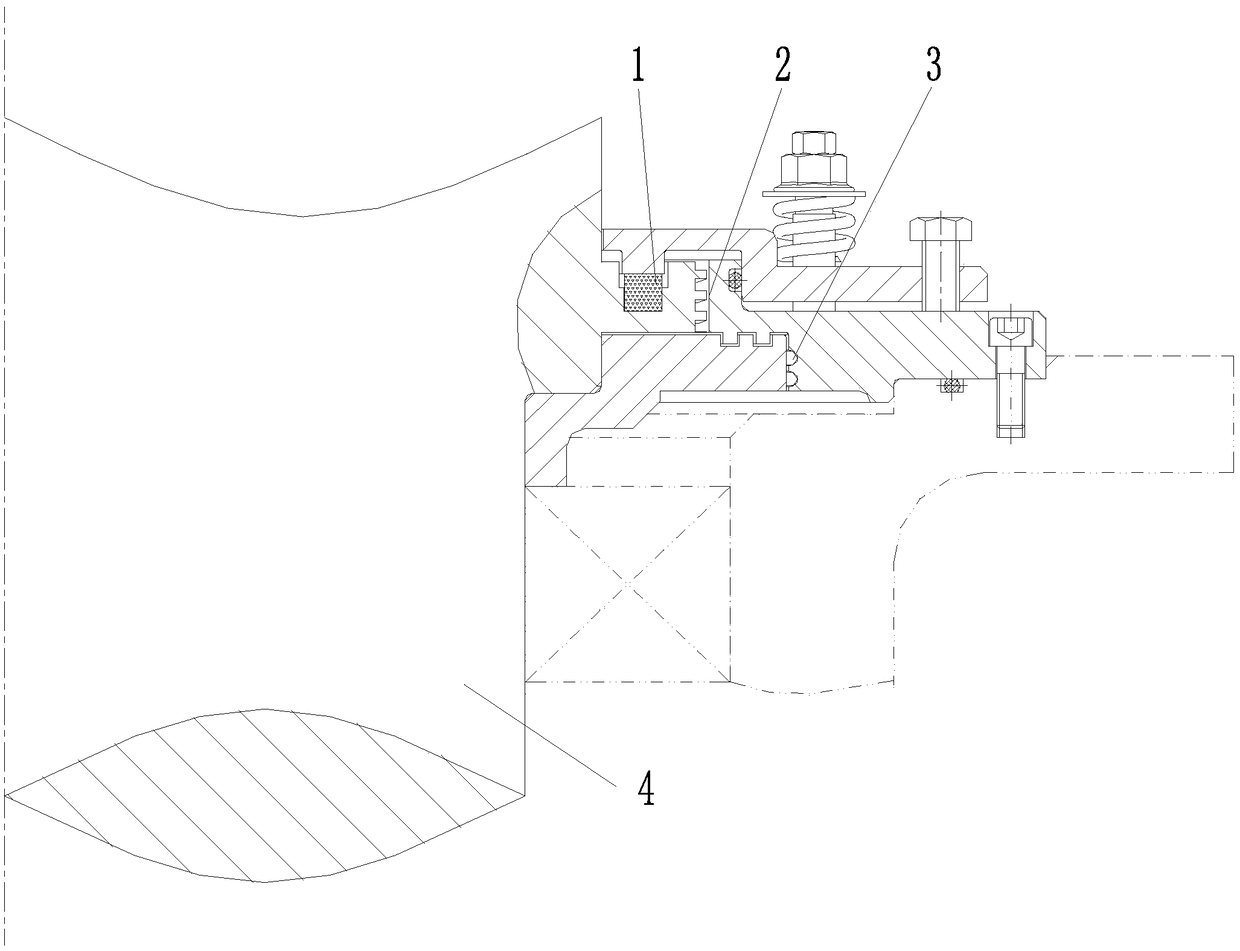

Dynamic sealing structure of main shaft of large high speed geotechnical centrifuge

PendingCN109261378AAdaptableExtended service lifeEngine sealsCentrifugesAtmospheric pressurePumping vacuum

The invention discloses a dynamic sealing structure of a main shaft of a large high speed geotechnical centrifuge, which has strong adaptability, including a combined sealing form of a multi-channel labyrinth sealing structure, a one-channel spiral sealing structure and a one-channel stuffing sealing structure. The dynamic sealing structure of the main shaft of the large high speed geotechnical centrifuge can be applied to vacuum dynamic seal and achieve oil seal under atmospheric pressure, and has long service life. The stuffing seals with wear are opened on demand through a structure of a first screw, a compaction mechanism and a gland combination, and are used only in a limited period of time when a centrifuge chamber is pumped vacuum. The vacuum dynamic seal has strong reliability, andis provided with a compression mechanism with springs in design to ensure that after the stuffing is worn out, the gland can still press the stuffing. The replacement and switching operation of the compression mechanism is simple. Arc grooves and T-shaped grooves corresponding to the compression mechanism are respectively arranged on the gland and a static ring, thereby being convenient to replace the compression mechanism. The compression is designed with a limit sleeve to guarantee the same compression amount of the springs in each compression mechanism and further reduce the difficulty ofmanual operations.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

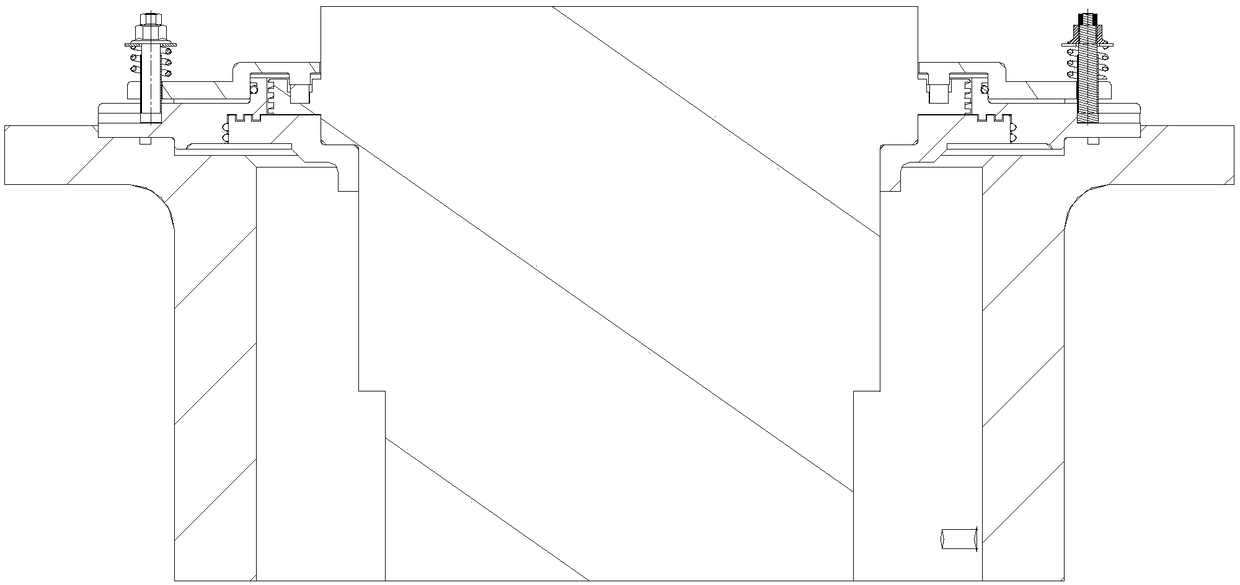

Automatic sample clamping structure and gas permeation testing system

PendingCN109799178AImprove sealingImprove stabilityPermeability/surface area analysisPermeationEmbedded system

The invention provides an automatic sample clamping structure and a gas permeation testing system. The automatic sample clamping structure which is arranged in a sealable environment bin comprises a first testing cavity, a second testing cavity, a first drive device and a second drive device and is characterized in that the first testing cavity and the second testing cavity are arranged on two sides of a sample, the first drive device is connected with the first testing cavity, the second drive device is connected with the second testing cavity, and the first drive device and the second drivedevice are used for driving the first testing cavity and the second testing cavity to move relative to each other to combine together or separate from each other so as to automatically compress the sample and allow the sample to automatically enter and exit the environment bin.

Owner:LABTHINK INSTR

Valve head, parallel error automatic compensating device and electron microscope

ActiveCN106767330AEliminate parallelism errorsReduce contact areaAngles/taper measurementsEngine sealsEngineeringScanning electron microscope

The invention provides a valve head, a parallel error automatic compensating device and an electron microscope. The valve head comprises a movable member bearer, a movable member which is accommodated in the mounting hole of the movable member bearer, and movable member supporting device which supports the movable member for floating relative to a fixed member in a direction which is opposite to the fixed member. The movable member has a second sealing plane which matches a first sealing plane of the fixed member, and a circumferential surface which is connected with the second sealing plane and is opposite to the fixed member. The circumferential surface is partially a spherical surface at least in the axial direction of the movable member. The mounting hole has a cylindrical surface which matches the spherical surface. When the movable member floats in a certain floating angle, the spherical surface is always in circumferential linear contact with the cylindrical surface of the mounting hole. According to the valve head provided by the invention, a parallelism error between two planes in each direction can be eliminated, thereby realizing sufficient fitting of the two sealing planes. The parallel error automatic compensating device with the valve head, and the electron microscope with the compensating device can ensure sealing repetition.

Owner:KYKY TECH

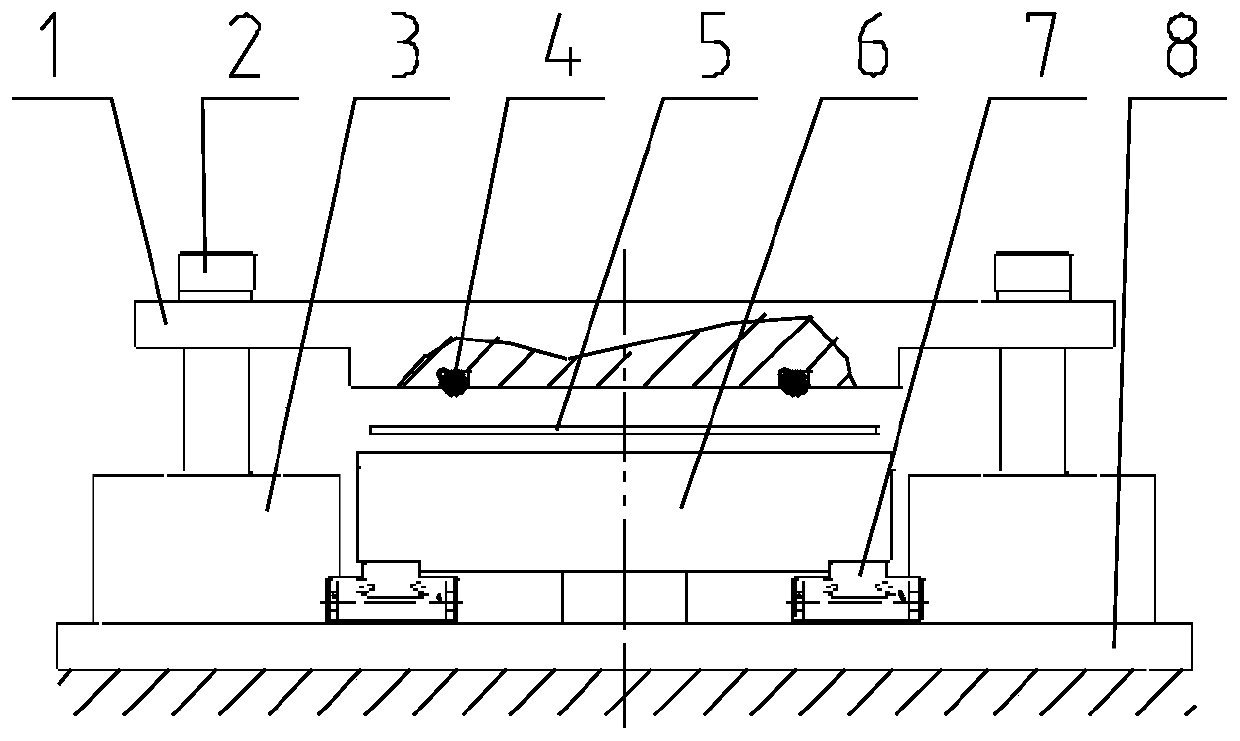

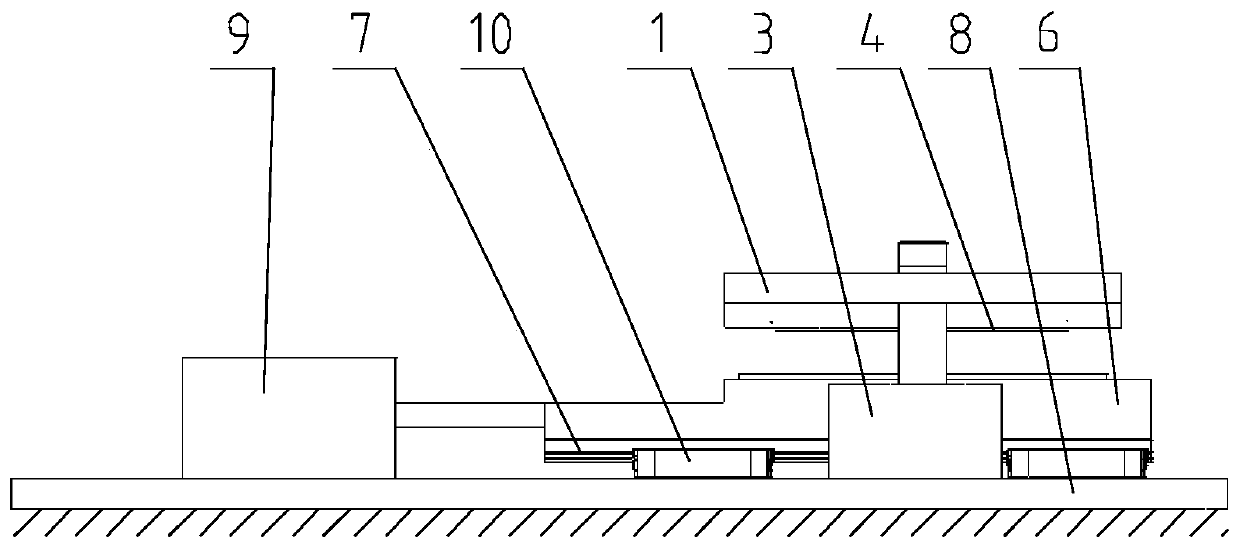

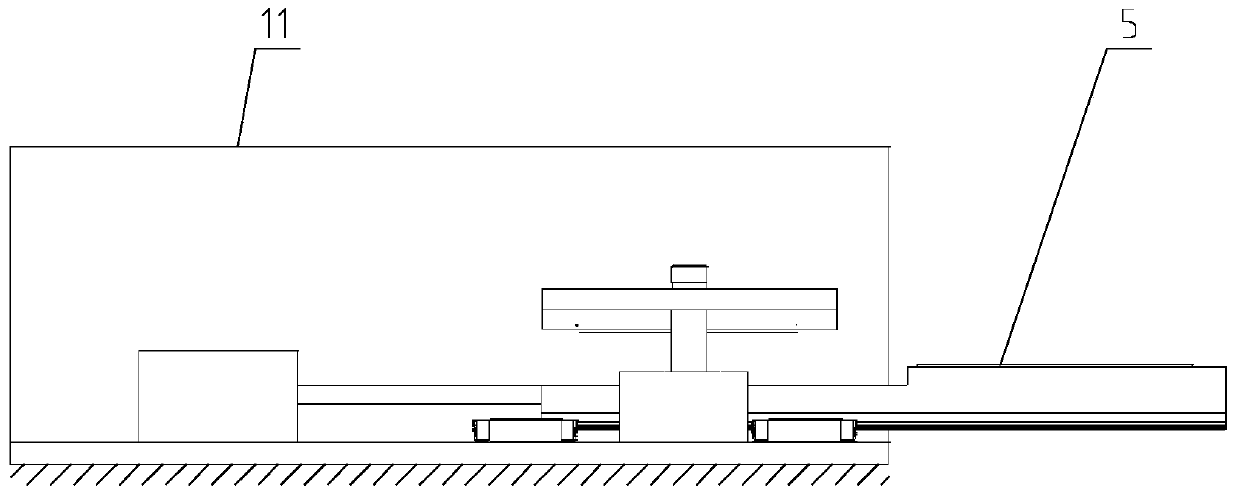

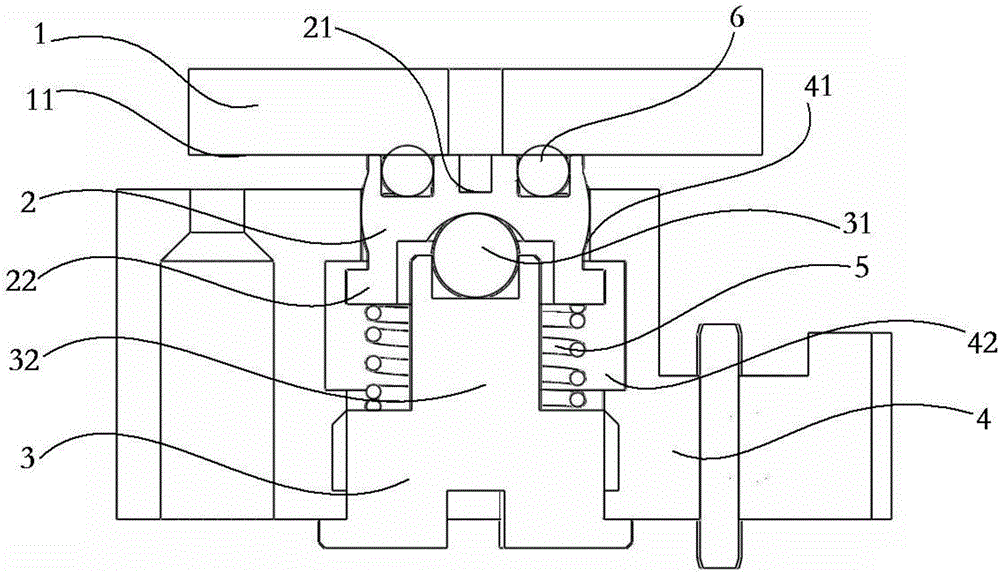

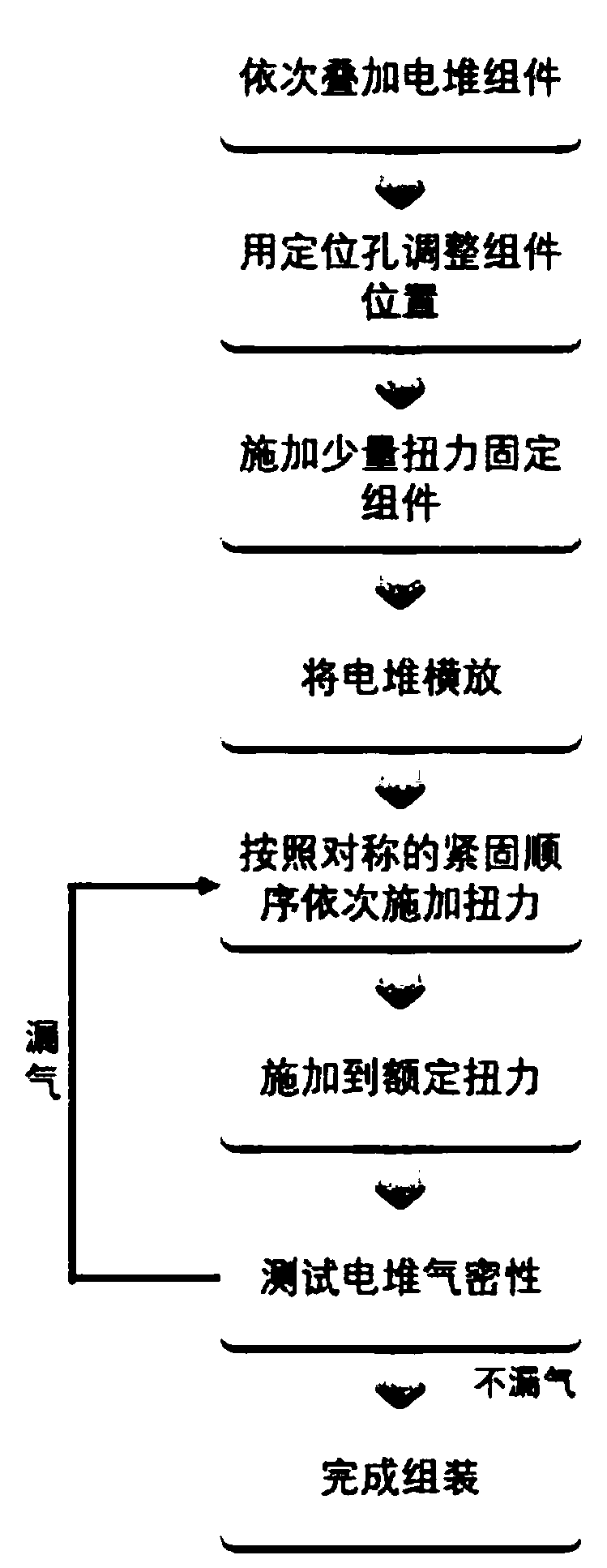

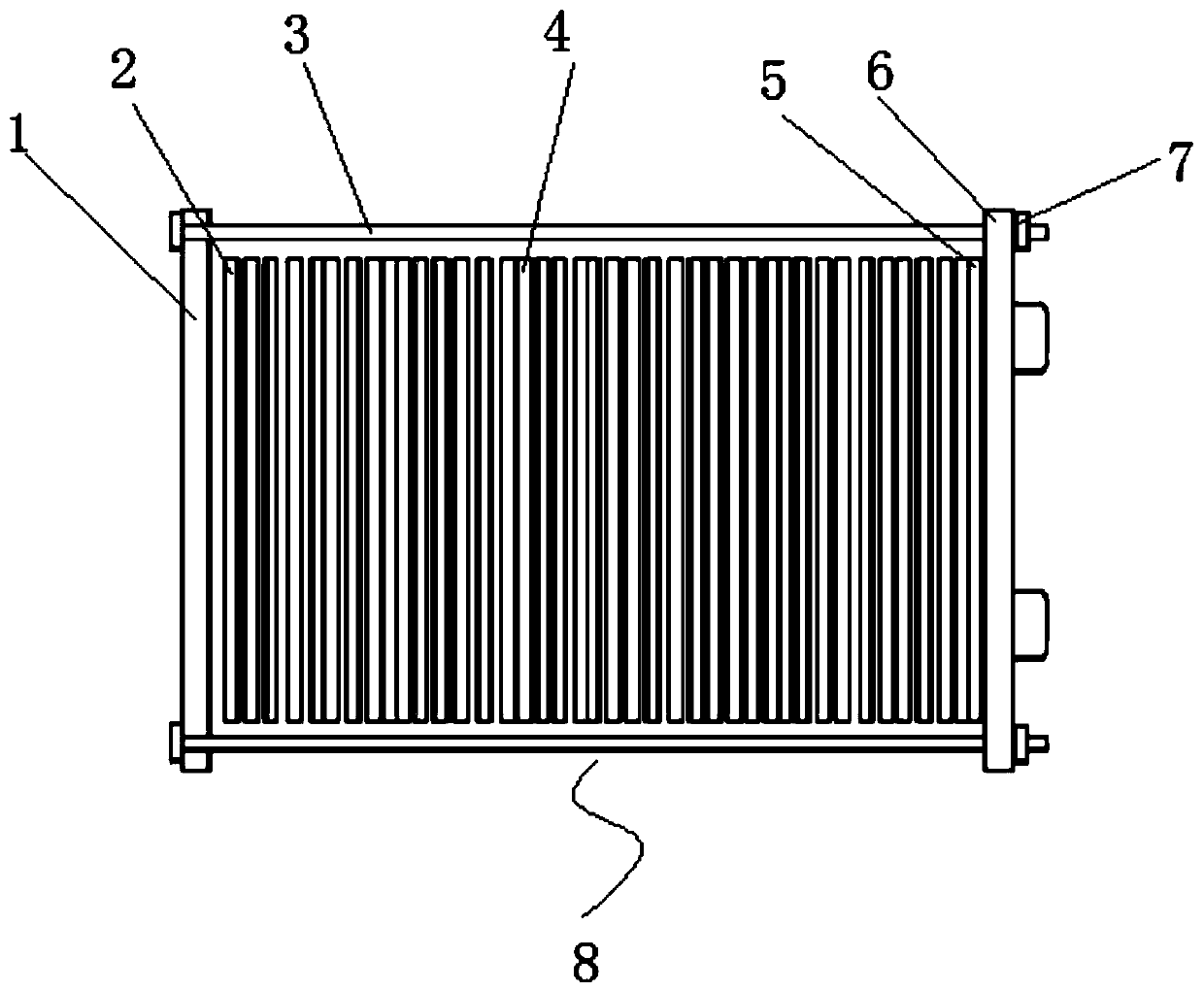

Fuel cell stack assembly method

ActiveCN110137555AEven by forceConsistent compressionFinal product manufactureFuel cellsFuel cellsMechanical engineering

The invention discloses a fuel cell stack assembly method which comprises the steps of (S1) stacking stack components in order, (S2) adjusting the positions of the components by positioning holes, (S3) applying a small amount of torque and fixing the components including the steps of threadingly connecting and fixing fastening nuts to positioning columns, applying a small amount of torsion force to fix the stack components including a stack lower end plate, a lower collecting plate, a stack single cell, an upper collecting plate and a stack upper end plate through the positioning columns, and(S4) horizontally placing the stack components. In the invention, according to the fuel cell stack assembly method, the small amount of torque is applied in step (S3), after the components are fixed,the stack components are horizontally placed through the step (S4), then the lateral assembly is used to uniformly apply pressure in each direction, therefore, the uniform stress of each position of astack is ensured, the compression of a membrane electrode is consistent, the flow resistance distribution is more uniform, and the simulation and analysis of the stack are facilitated.

Owner:WUHAN GROVE HYDROGEN AUTOMOBILE CO LTD

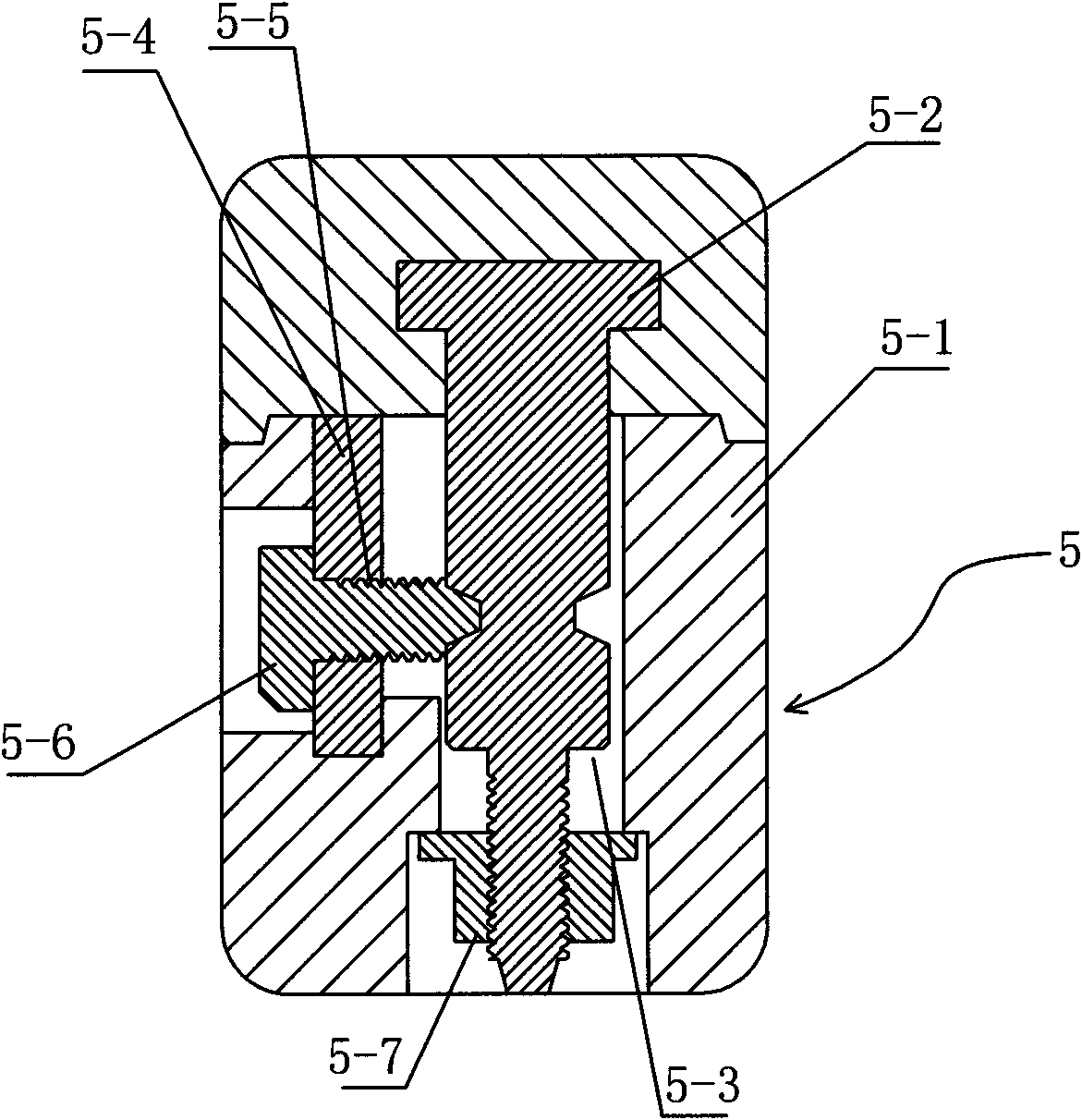

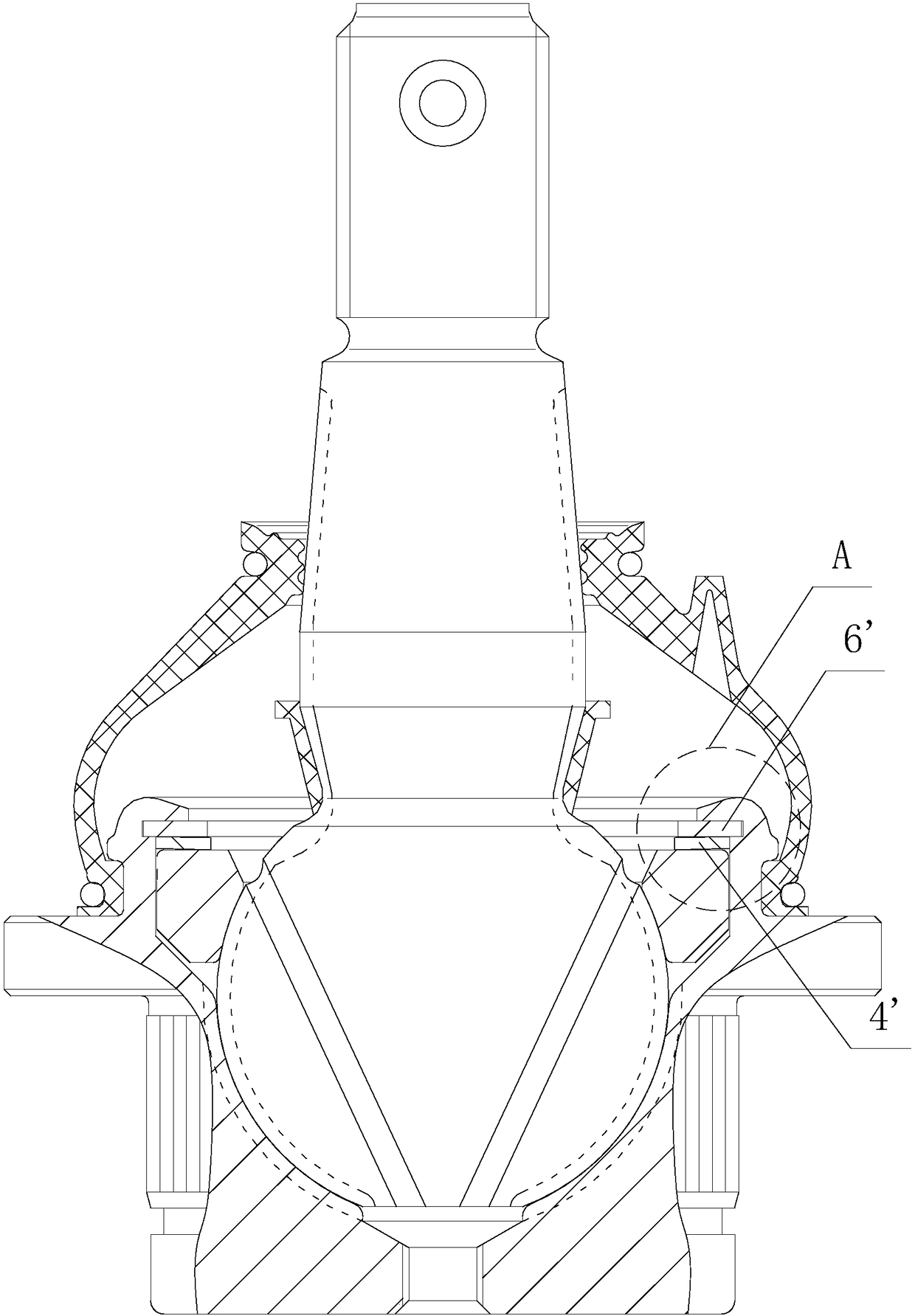

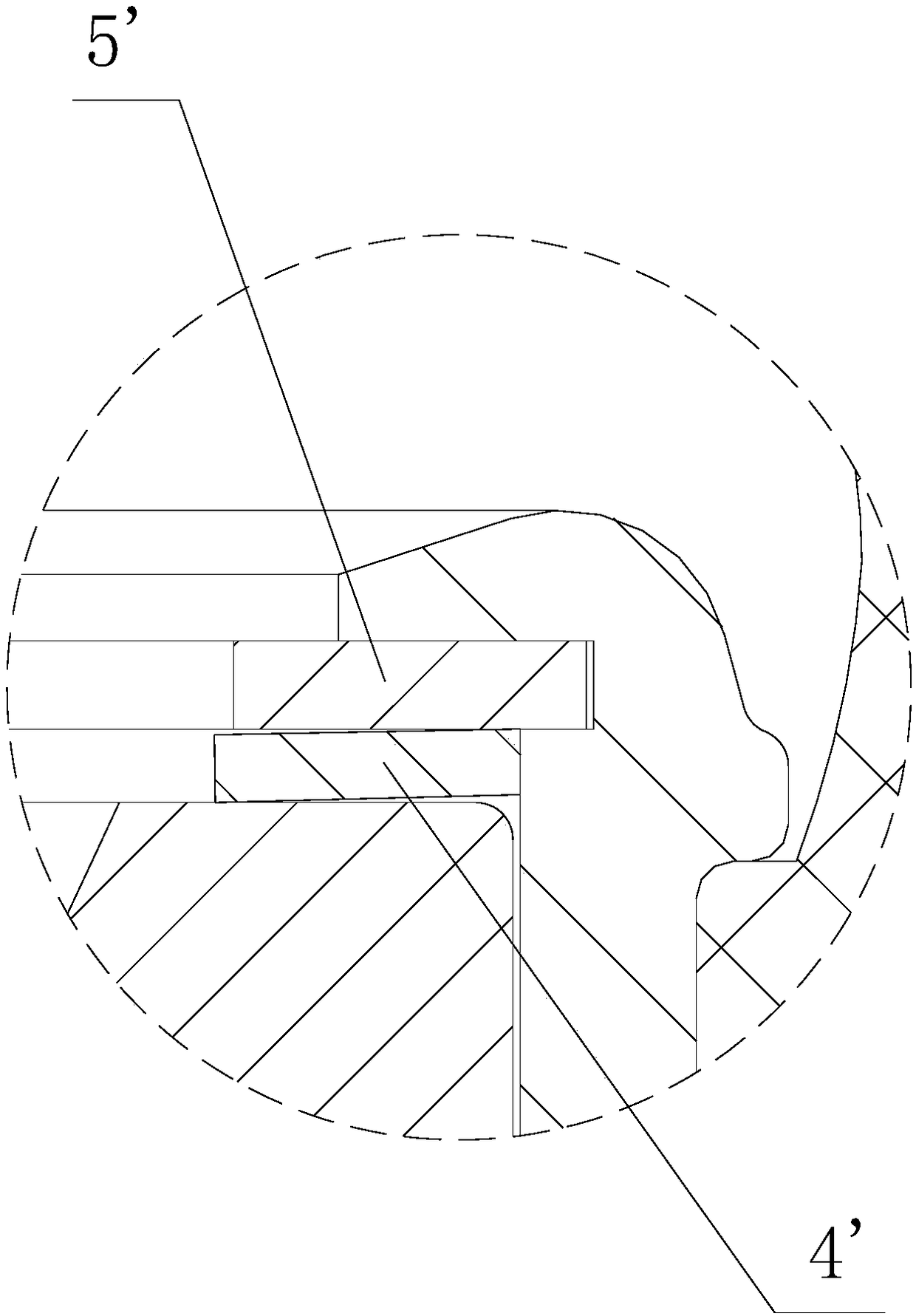

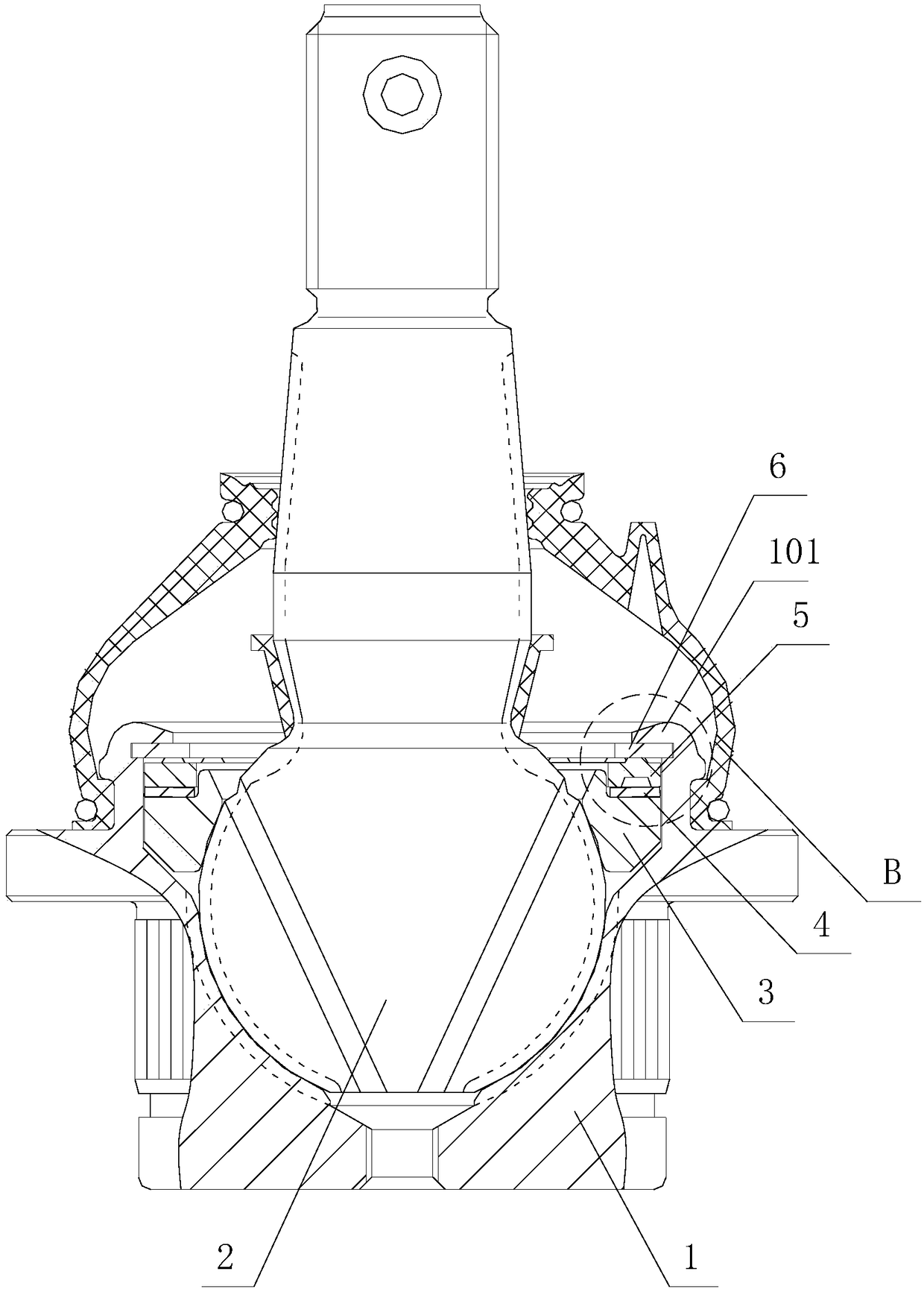

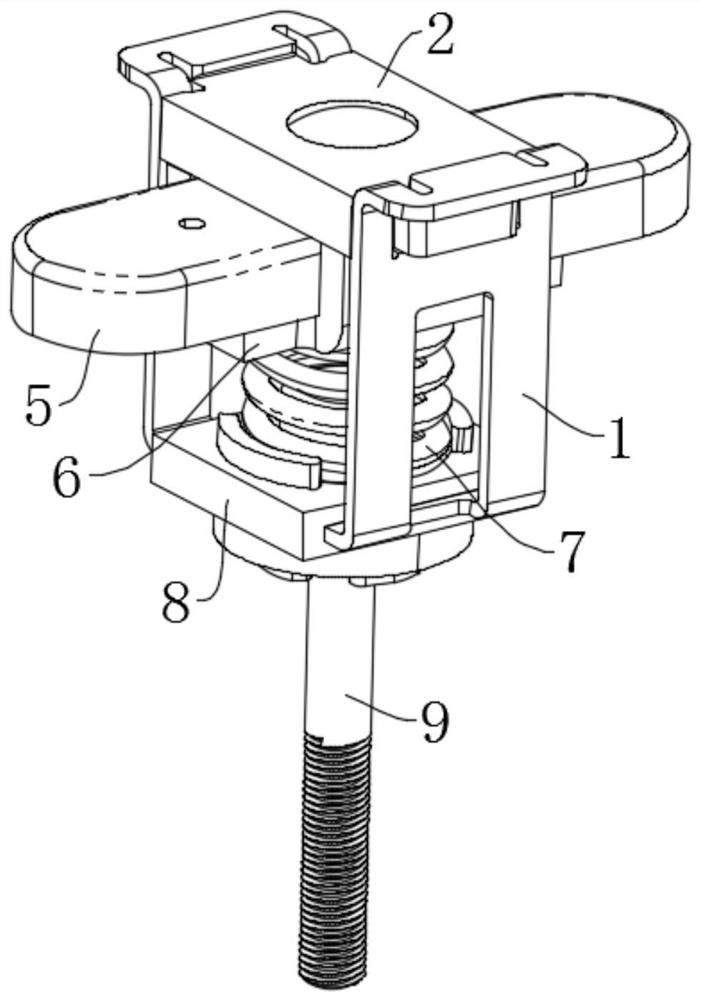

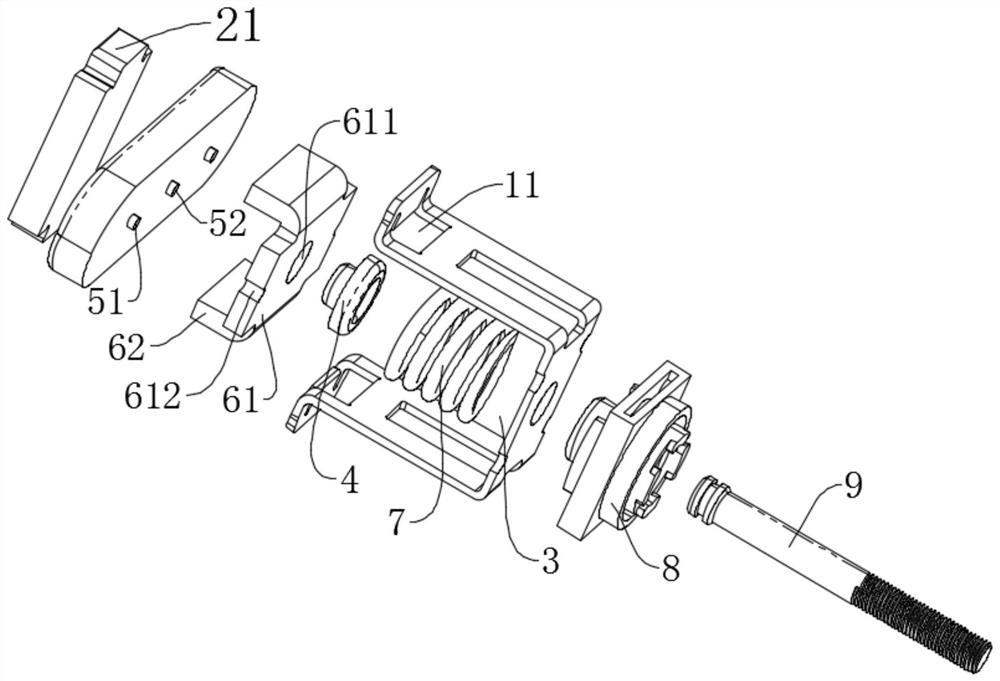

Ball head assembly with compensation structure and manufacturing tool and assembling method of ball head assembly

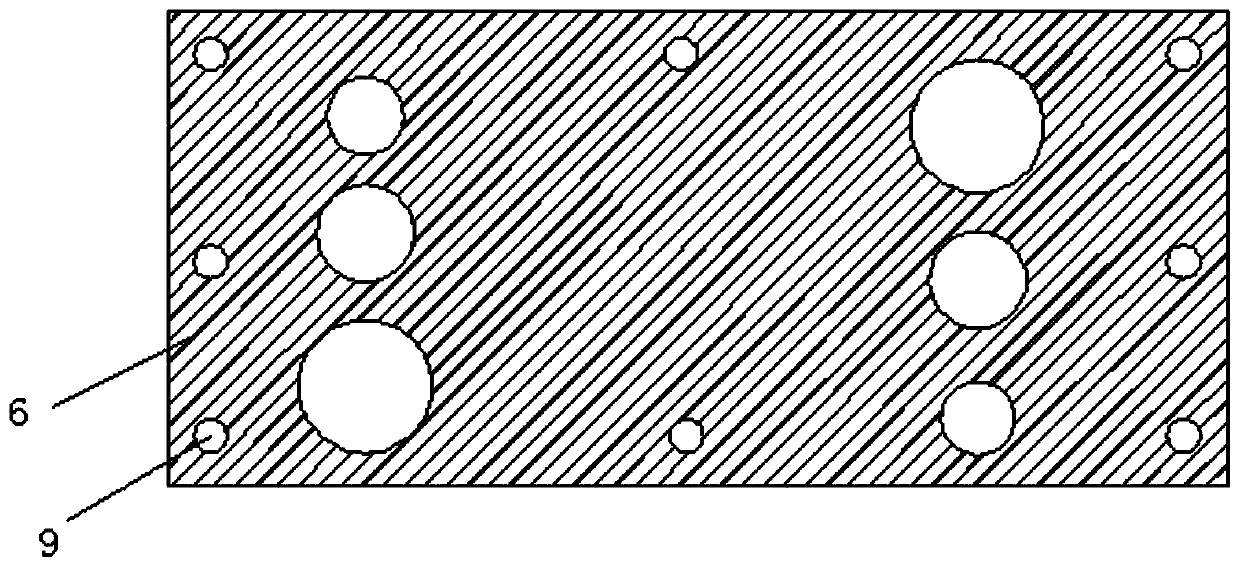

InactiveCN108058557AConsistent compressionAchieve stabilityInterconnection systemsPivoted suspension armsEngineeringSpherical form

The invention provides a ball head assembly with a compensatory structure. The ball head assembly includes a ball shell, and an installation cavity with the open top is formed on the ball shell; a ball base is installed at the upper end of the installation cavity, the ball base is spherical, and a spherical cavity is formed between the ball base and the installation cavity; a ball pin includes a ball body and a pin rod; the open end of the ball shell is bent inward in the radial direction to form a pressed edge, an installation part is formed between the lower bottom surface of the pressed edge and the upper end face of the ball base, and the installation part is internally and sequentially provided with a sealing plate, a compensating gasket and an elastic part from up to bottom. According to the ball head assembly with the compensatory structure, the compensating gasket is additionally arranged, through the deformation of the compensating gasket, accumulative errors produced by otheraccessories are compensated, the consistency of the compression amount of a belleville spring is ensured, the stability of the torque of a product is achieved, the quality reliability and use reliability of the product are greatly improved, and the use safety is improved.

Owner:ZHEJIANG RUITAI SUSPENSION SYST TECH

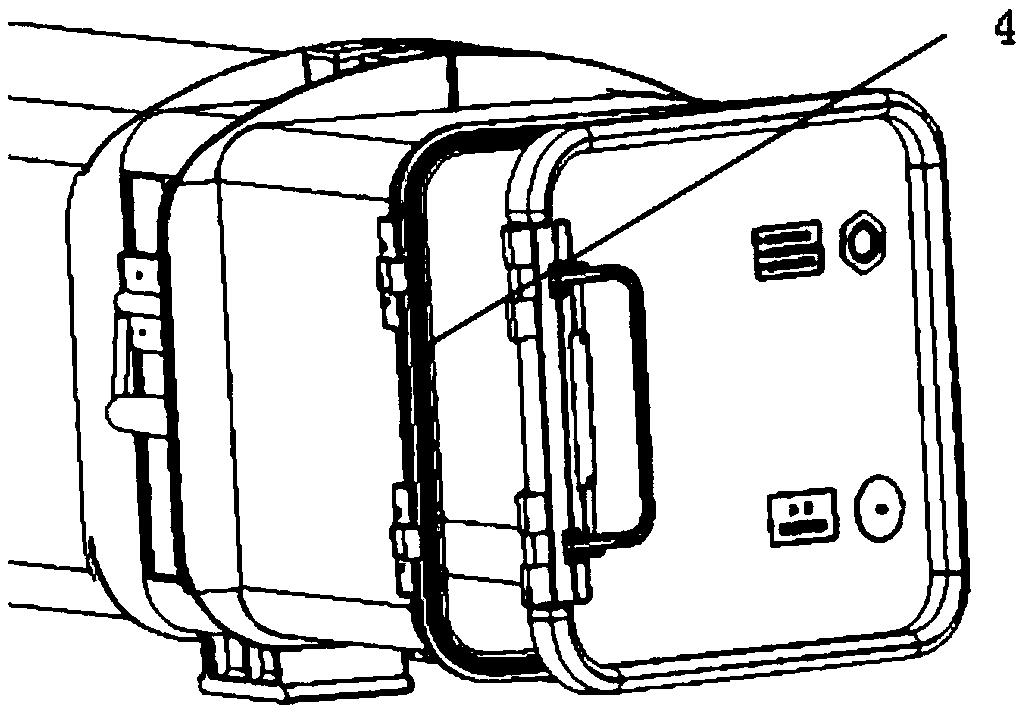

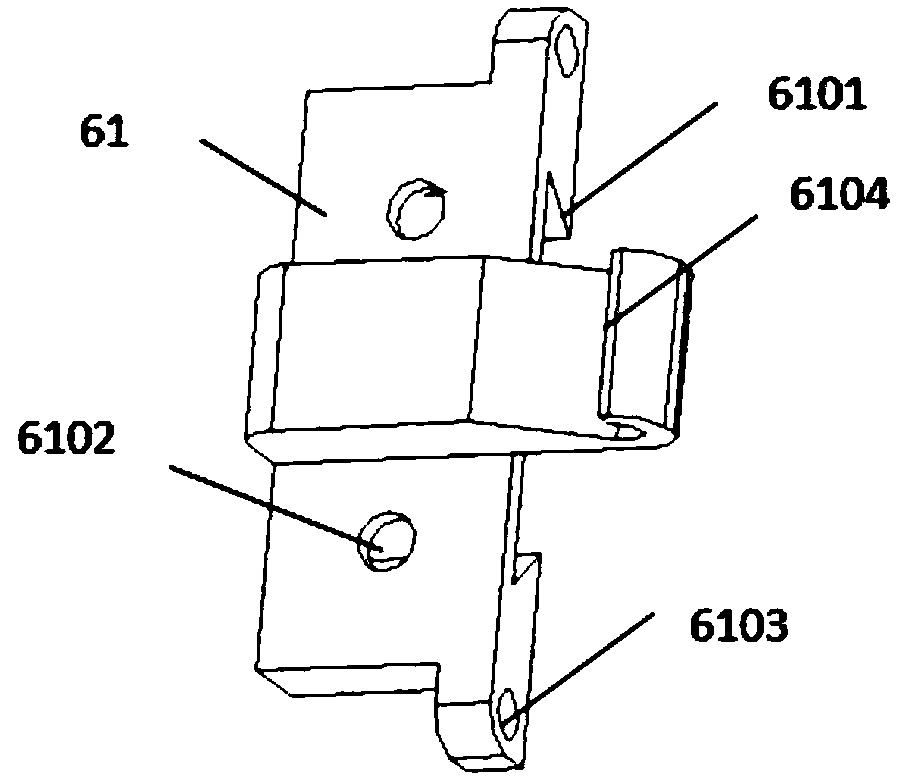

Rotary type unilateral opening adjustable sealing structure

InactiveCN109502174AConsistent compressionReduce the difficulty of operationSealingLocking devicesEngineeringMechanical engineering

The invention discloses a rotary type unilateral opening adjustable sealing structure. The sealing structure comprises a box body, a box cover, a connecting pipe, a seal ring, a rotating device and alocking device, wherein the rotating device comprises a rotating seat and a rotating shaft, the connecting pipe is rotationally connected with the box cover through the rotating shaft, the locking device is arranged on the side opposite to the rotating device, the locking device comprises a clamping hook assembly and a lock catch assembly, the clamping hook assembly comprises a dovetail groove, fixing bolt holes, adjusting fixing bolt holes and a clamping hook, the fixing bolt holes are formed in the surface of the clamping hook assembly, the adjusting fixing bolt holes are arranged on the twosides of the clamping hook assembly, the clamping hook is arranged at the protruding part of the clamping hook assembly, moreover, an arc-shaped groove is formed in the tail end of the clamping hook,the lock catch assembly comprises a lock catch base and a lock catch, the lock catch base is fixed on the surface of the box cover, the buckling part of the lock catch is connected with the clampinghook in a buckling mode, the two sides, inside the rotating device, of the rotating seat are also provided with adjusting fixing bolt holes, and the surface of a pressing plate of the connecting pipeis also provided with adjusting bolt holes matched with the adjusting fixing bolt holes.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Distribution transformer cover plate

InactiveCN103035367AReduce distortionBeautiful appearanceTransformers/inductances casingsInductances/transformers/magnets manufactureSteel platesEngineering

The invention discloses a distribution transformer cover plate which relates to the technical field of transformer devices. The distribution transformer cover plate comprises a square cover plate body and is characterized in that the upper cover surface of the cover plate body is a flat end surface, four sides of the cover plate body respectively extend by 60mm to be used as flanges, four corners of the flanges are respectively provided with a gap, and front 30-mm parts of the four flanges are inwards bent to form included angles of 90 DEG, so that edges are formed. The distribution transformer cover plate is flat, and is little in deformation of boat shape and waves, attractive in appearance and little in labor intensity; a temporary reinforcing rib is not needed to be welded or the thickness of a steel plate is not needed to be increased. The contact surface of the distribution transformer cover plate and a box edge sealing member is flat, the compression amounts of sealing members are consistent, and the leakage probability is reduced.

Owner:ANHUI SHENHONG TRANSFORMER

Folding system for secondary transfer machine of milling machine and milling machine

ActiveCN102518031AReduce in quantityReduce failureConveyorsRoads maintainenceControl systemAgricultural engineering

The invention provides a folding system for a secondary transfer machine of a milling machine. The folding system comprises a folding execution system and a folding hydraulic control system, wherein the folding execution system comprises a fixed arm and a foldable arm hinged with the fixed arm, and further comprises a connection plate, a pull rod and two driving oil cylinders, wherein the connection plate is eudipleural to the middle line of the fixed arm; the lower end of the connection plate is hinged to the lower part of the fixed arm; the upper end of the connection plate is hinged to the upper end of the pull rod; the lower end of the pull rod is hinged to the upper end of the foldable arm; the rear end of each driving oil cylinder is hinged to the upper part of the fixed arm; the front end of the driving oil cylinder is hinged to the connection plate; and the driving oil cylinders drive the foldable arm to be folded through the connection plate and the pull rod. According to the invention, the quantity of oil cylinders and the cost are reduced, and the genealogical reliability is improved. The folding hydraulic control system drives the oil cylinders to lock each other through a hydraulic lock and a flow distributing and collecting valve; and the speeds of the oil cylinders are synchronous through the flow distributing and collecting valve, so as to prevent the transfer machine from inclining laterally. The invention further provides the milling machine comprising the folding system for the secondary transfer machine.

Owner:SANY HEAVY IND CO LTD (CN)

Valve head, parallel error automatic compensation device and electron microscope

ActiveCN106595439ALow rotational resistanceHigh adjustment sensitivityAngles/taper measurementsEngine sealsScanning electron microscopeElectron microscope

The invention provides a valve head, a parallel error automatic compensation device and an electron microscope. The valve head comprises a movable member and a movable member supporting means. The movable member is provided with a second sealing plane matched with a first sealing plane of a fixed member. One side of the movable member, back on to the fixed member, is provided with a first accommodating groove. The movable member supporting means is provided with a spherical surface adapted to be embedded in the first accommodating groove. The spherical surface is in point contact with the groove bottom holding point of the first accommodating groove. The spherical surface is in line contact with the groove wall of the first accommodating groove. The spherical surface is used for supporting the movable member to float relative to the fixed member in a direction back on to the fixed member. According to the technical scheme of the invention, the valve head is low in machining difficulty and high in adjustment sensitivity, wherein the parallelism error of two planes in each direction can be eliminated. Therefore, the two sealing planes can be adequately fitted with each other. The invention also provides a parallel error automatic compensation device provided with the above valve head, and an electron microscope provided with the compensation device and used for ensuring the sealing repeatability.

Owner:KYKY TECH

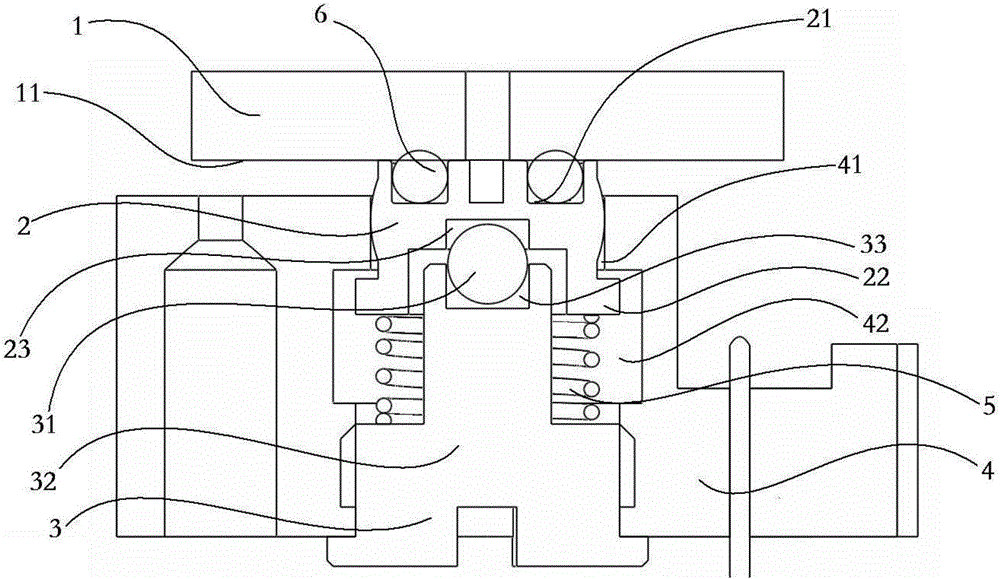

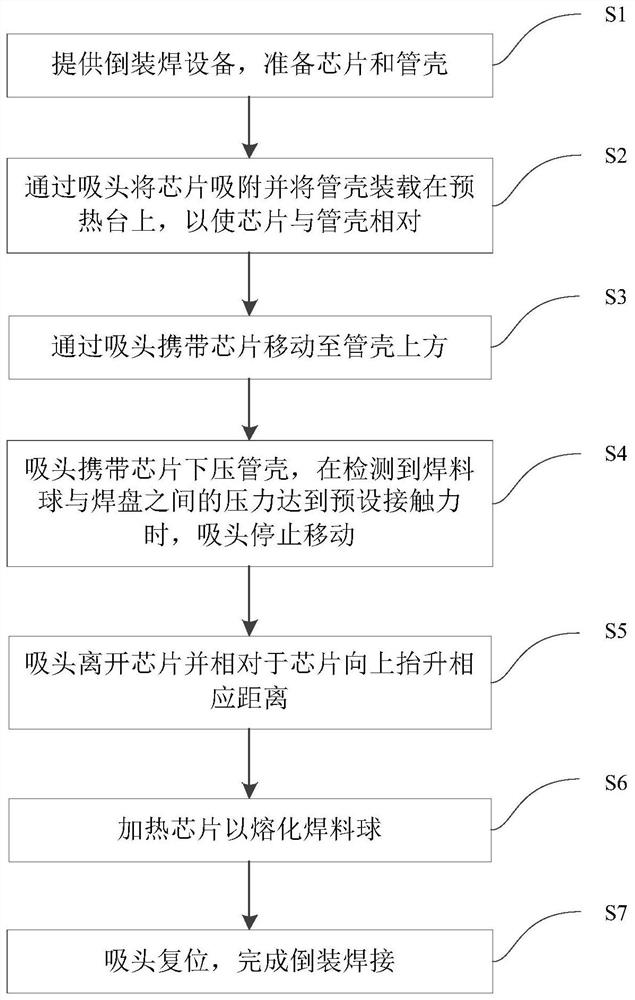

Non-contact heating flip-chip bonding process method

ActiveCN111653494AAvoid pollutionSimple processSemiconductor/solid-state device detailsSolid-state devicesSolder ballBonding process

The invention discloses a non-contact heating flip-chip bonding process method, which comprises the following steps: providing flip-chip bonding equipment, and preparing a chip with solder ball bumpsand a tube shell with a bonding pad; enabling the face, provided with the solder ball bumps, of the chip to be opposite to the tube shell; moving a suction head carrying the chip to a corresponding welding position above the tube shell; pressing the tube shell downwards by the suction head carrying the chip, and stopping movement of the suction head when the pressure between the solder ball bumpand the bonding pad reaches the preset contact force; leaving the chip by the suction head and lifting the chip upwards; starting suction head heating, heating the surface of the suction head to a preset temperature, maintaining the temperature for corresponding time, and heating the chip to melt the solder ball; and stopping heating of the suction head and lifting the suction head to reset, and completing welding of the chip and the tube shell. According to the process method, the whole process flow is simplified, the production efficiency is greatly improved, the chip and the tube shell havea self-alignment effect in the welding process, and a problem that the solder ball bumps are compressed unevenly due to mechanical stress between the solder ball bumps and the bonding pads can be effectively solved.

Owner:NO 24 RES INST OF CETC

Compressor and air conditioner with same

ActiveCN108661882AConsistent compressionReduced modal coupling vibrationPositive displacement pump componentsPump installationsEngineeringModal coupling

The invention provides a compressor and an air conditioner with the same. The compressor comprises a compressor shell, a liquid storage barrel and supporting parts; the liquid storage barrel is connected with the compressor shell, the supporting parts are arranged at the bottom of the compressor shell, the plurality of supporting parts are provided, one of the plurality of supporting parts is located on the extension line of a first connecting line between the axis of the compressor shell and the axis of the liquid storage barrel, and the other supporting parts are located on the two sides ofthe first connecting line and are symmetrically arranged with respect to the first connecting line. One of the plurality of supporting parts is located on the extension line of the first connecting line between the axis of the compressor shell and the axis of the liquid storage barrel, and the other supporting parts are located on the two sides of the first connecting line and are symmetrically arranged with respect to the first connecting line, so that the compression amount of the supporting parts is consistent, the multi-direction modal coupled vibration caused by the vibration excitation of the compressor is reduced, and the noise of the compressor is reduced.

Owner:格力电器(南京)有限公司 +1

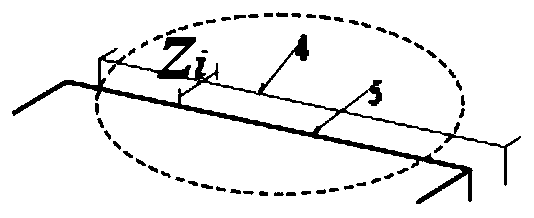

Nonlinear elastic counterforce centroid algorithm for sealing gasket of prefabricated component

ActiveCN111008415AConsistent compressionConsistent Seam WidthGeometric CADDesign optimisation/simulationAlgorithmStructural engineering

The invention discloses a nonlinear elastic counterforce centroid algorithm for a sealing gasket of a prefabricated component. The algorithm comprises the following steps: step 1, obtaining an image of the prefabricated component; step 2, correcting the obtained image; step 3, extracting key information of the image; step 4, correcting the key information of the component in the image; step 5, establishing a coordinate set of key image points of the component; step 6, calculating the centroid of the rubber sealing gasket; and step 7, calculating the counterforce centroid of the rubber sealinggasket. The overall elastic counterforce resultant centroid of the rubber sealing gasket made of a nonlinear characteristic material is calculated under the condition that the waterproof rubber sealing gasket arranged between the components is compressed to different states by a tension load so that the tensioning load of the tensioning jack at the next moment is determined to gradually approach the target position of tensioning of the assembly type component, the preset joint width is achieved and the joint width is ensured to be uniform.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO

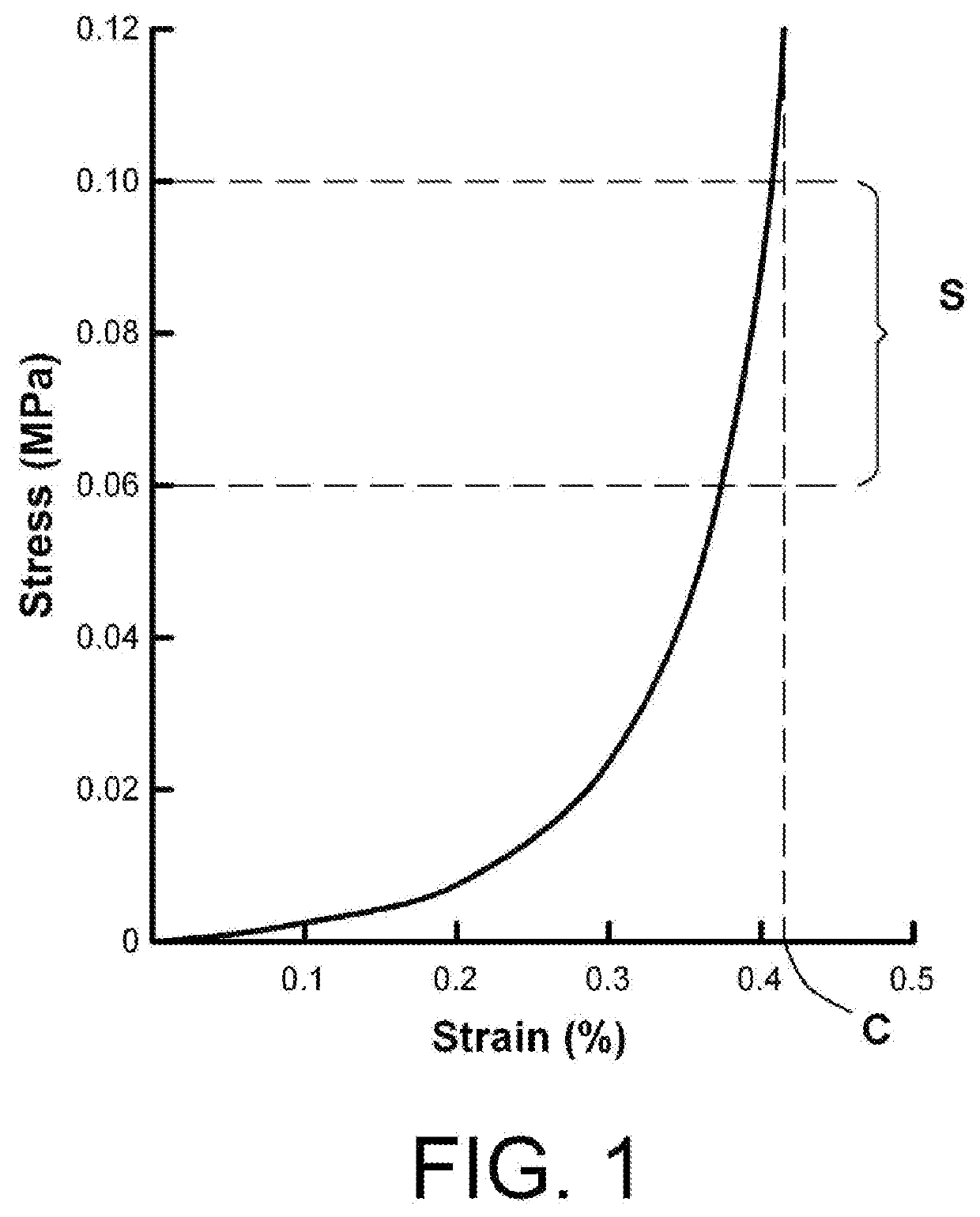

Device and Method for Assisting Selection of Surgical Staple Height

ActiveUS20210038222A1Consistent compressionConducive to selectionStrain gaugeDiagnosticsBiomedical engineeringReoperative surgery

A surgical compression gauge instrument comprising a compression gauge jaw member and an anvil jaw member for measuring a reactionary force from tissue captured and compressed to a predetermined gap distance between the two jaw members is disclosed herein. The compression gauge jaw member comprises a force gauge assembly for measuring the tissue reactionary force, and a gap sensor for generating an electrical signal indicative of the gap distance between the two jaw members.

Owner:PARK CHUL HI

A fuel cell metal bipolar plate and its welding method

ActiveCN111451638BPrevent shrinkageReduce deformationLaser beam welding apparatusCollectors/separatorsFuel cellsThermal deformation

The invention discloses a fuel cell metal bipolar plate and a welding method thereof. The welding method comprises the following steps: positioning two unipolar plates in the metal bipolar plate, wherein the anode plate is on the upper layer, and the cathode plate is on the lower layer. And make the anode plate and the cathode plate flow channel fit closely; the laser beam follows the welding track in the middle of the metal bipolar plate flow channel, the outer ring of the metal bipolar plate, the second middle of the metal bipolar plate flow channel, and the outermost periphery of the metal bipolar plate Displacement is carried out, and the front and back of the metal bipolar plate are welded sequentially. Using the thermal deformation characteristics of the metal bipolar plate laser welding, the irregular deformation caused by the original welding method is corrected, and finally a higher warpage requirement is achieved. The warpage of the metal bipolar plate of the fuel cell is 1-2mm.

Owner:北京新研创能科技有限公司

Moving contact bridge retaining structure of anti-short-circuit capability improving switch device

PendingCN112542331AAvoid separationEasy to limitContact engagementsStructural engineeringMechanical engineering

The invention discloses a moving contact bridge retaining structure of an anti-short-circuit capability improving switch device, which comprises a retainer, a top plate, a connecting piece, a movablecontact bridge, a magnetic conductive piece and an elastic piece, and is characterized in that the retainer and the two ends of the top plate are fixedly connected and encircled to form a mounting port with two open ends, a first connecting part is arranged in a mounting hole and is fixedly connected with the movable contact bridge, the second connecting part is arranged around the outer side of the mounting hole and abuts against the side, which is away from the movable contact bridge, of the abutting part so as to apply force to the movable contact bridge to the abutting part. According to the invention, because the movable contact bridge and the magnetic conductive piece are connected and fixed by the connecting piece, the magnetic conductive piece can be well limited, so that the top plate and the magnetic conductive piece are attracted stably when a large current, such as a short-circuit current, occurs in a system loop. In addition, the magnetic conductive piece and the movable contact bridge can also be matched in the thickness direction without a clearance. When the movable contact bridges in the plurality of movable contact bridge structures are conducted with the static contact, the compression amount of each elastic piece is kept consistent so as to provide consistent mechanical properties.

Owner:武汉同力同为科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com