Dynamic sealing structure of main shaft of large high speed geotechnical centrifuge

A technology of geotechnical centrifuge and dynamic sealing structure, which is applied in the direction of centrifuge, engine sealing, mechanical equipment, etc. It can solve the problems of high service life of seals, high maximum linear speed of seals, unusable sealing methods, etc., to achieve The effect of reducing the difficulty of manual operation, long service life and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

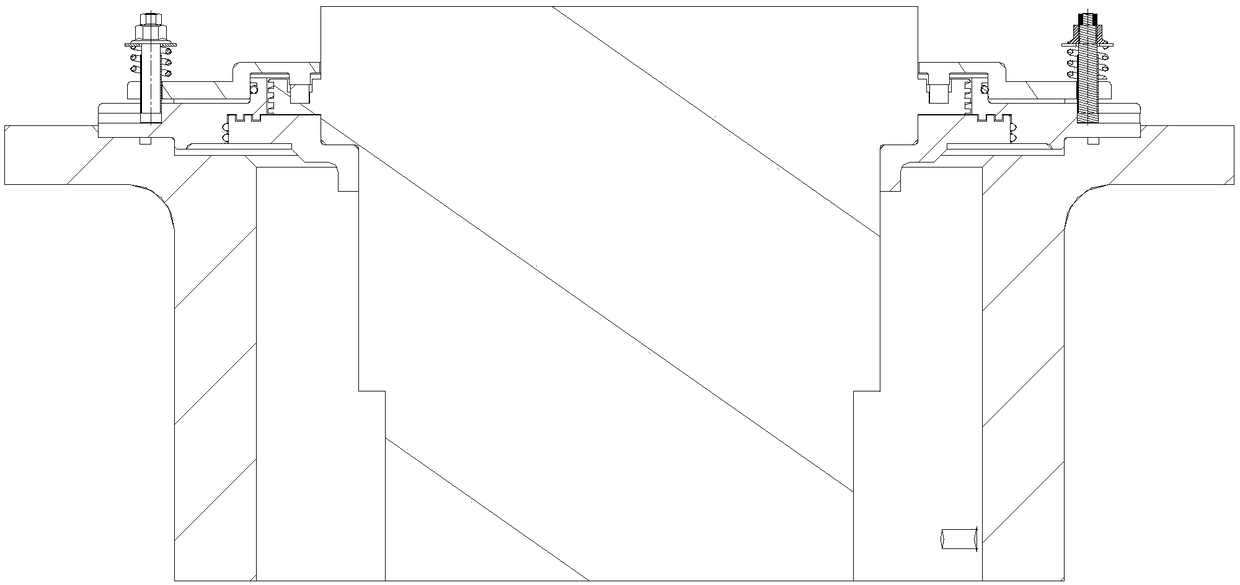

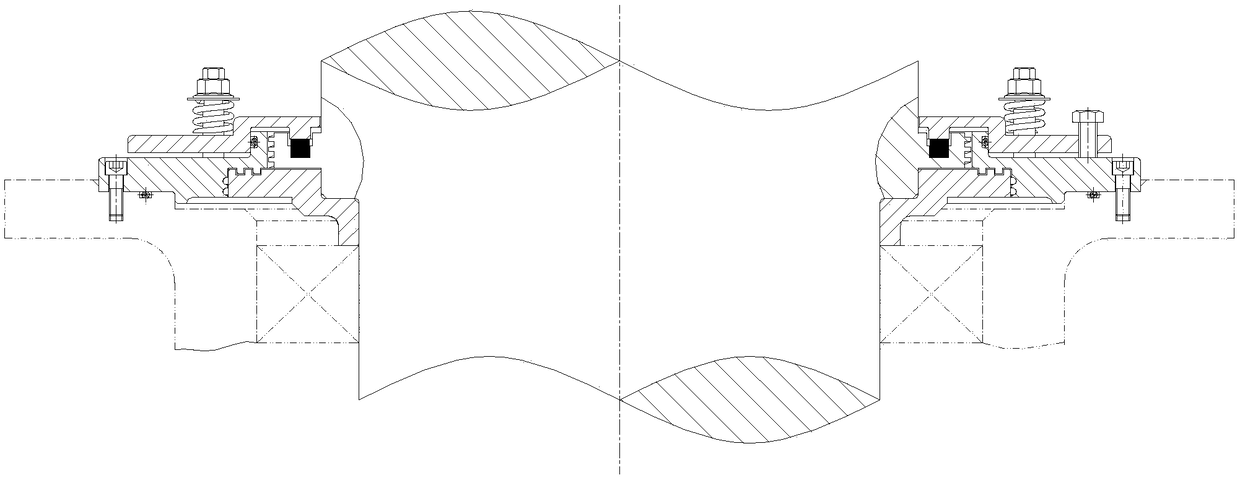

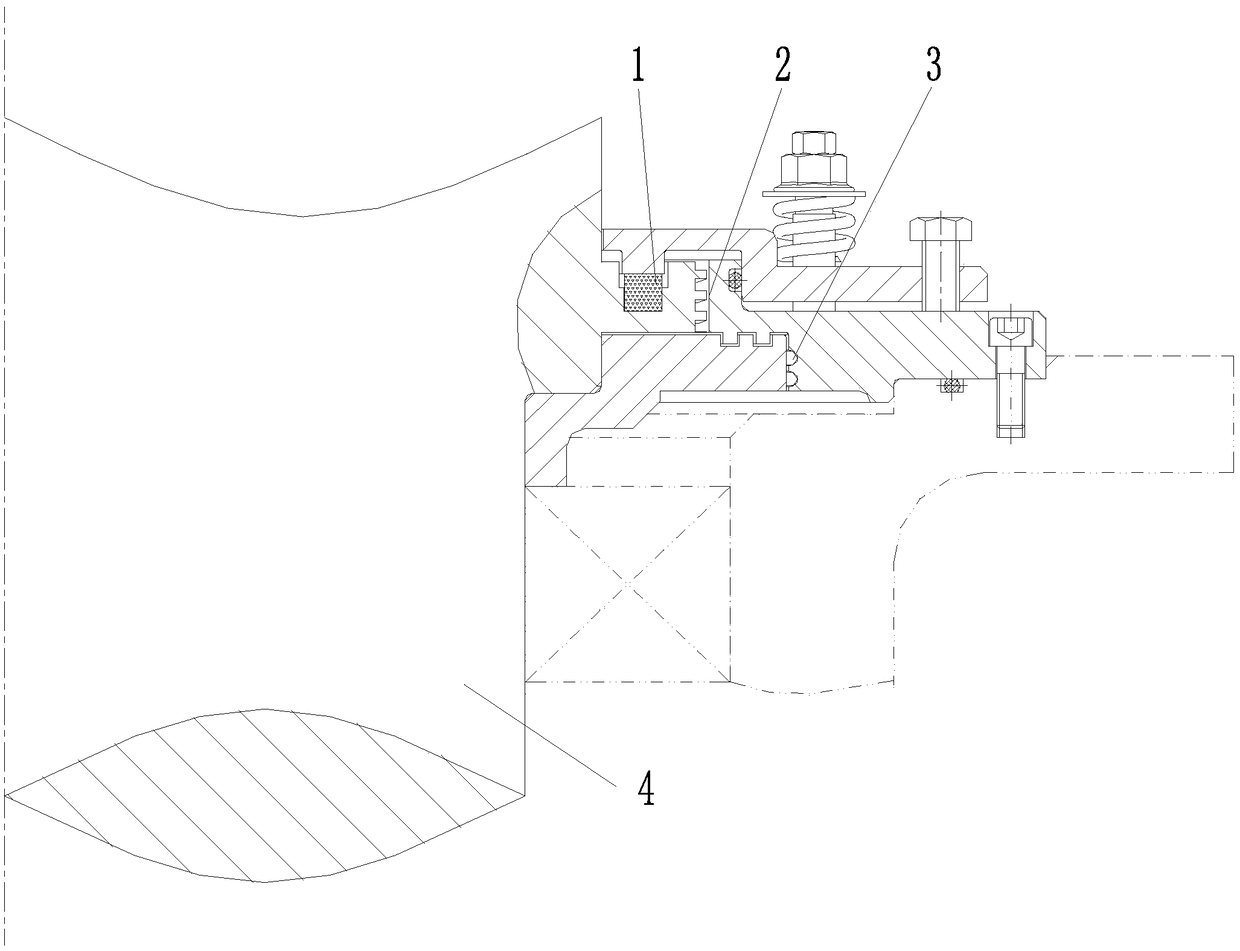

[0033] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 , Figure 7 , Figure 8 as shown,

[0034] Large high-speed geotechnical centrifuge main shaft 4 dynamic sealing structure, including:

[0035] The spiral seal structure 2; the spiral seal structure 2 is composed of the main shaft 4 and the static ring 21, there is a gap between the main shaft 4 and the static ring 21, and a multi-headed rectangular thread 312 is provided on the outer diameter side of the shaft ring of the main shaft 4. When the centrifuge is working, The multi-head rectangular thread 312 is used to drive down the sealing medium;

[0036] Packing seal structure 1; packing seal structure 1 is composed of main shaft 4, gland 12, and packing 11. In the ring groove 311; above the filler 11, an annular gland 12 for compressing the filler 11 is arranged;

[0037] Multi-channel labyrinth seal structure 3; the labyrinth seal structure 3 is composed of a moving ring 31 and a stat...

Embodiment 2

[0042] Example 2, such as Figure 4 as shown,

[0043]The difference between this embodiment and Embodiment 1 is that the inner part of the moving ring 31 is located at the lower part of the shaft ring of the main shaft 4, the outer part of the moving ring 31 is located at the lower part of the inner part of the static ring 21, and the outer part of the static ring 21 is located at the bottom of the moving ring 31. The outside of the outer part; the inner part of the gland 12 is located at the top of the main shaft 4 collar, and the outer part of the gland 12 is located at the top of the static ring 21; the outer part of the static ring 21 passes through a plurality of second rings evenly arranged along its circumferential direction. The screw 22 is installed on the frame; the gland 12 is installed on the static ring 21 through a plurality of first screws 14 uniformly arranged along its circumferential direction; The compression mechanism 13 for the compression and loosening ...

Embodiment 3

[0044] Example 3, such as Figure 4 as shown,

[0045] The difference between this embodiment and Embodiment 2 is that the first screw 14 is a jacking screw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com