Ball head assembly with compensation structure and manufacturing tool and assembling method of ball head assembly

A technology of ball head assembly and compensation structure, which is applied in the direction of transportation and packaging, cantilever mounted on the pivot, interconnection system, etc., can solve the problem of reducing product quality and reliability, unstable product torque, and safety Hidden dangers and other problems, to achieve the effect of improving product quality reliability and use reliability, improving use safety, and consistent compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

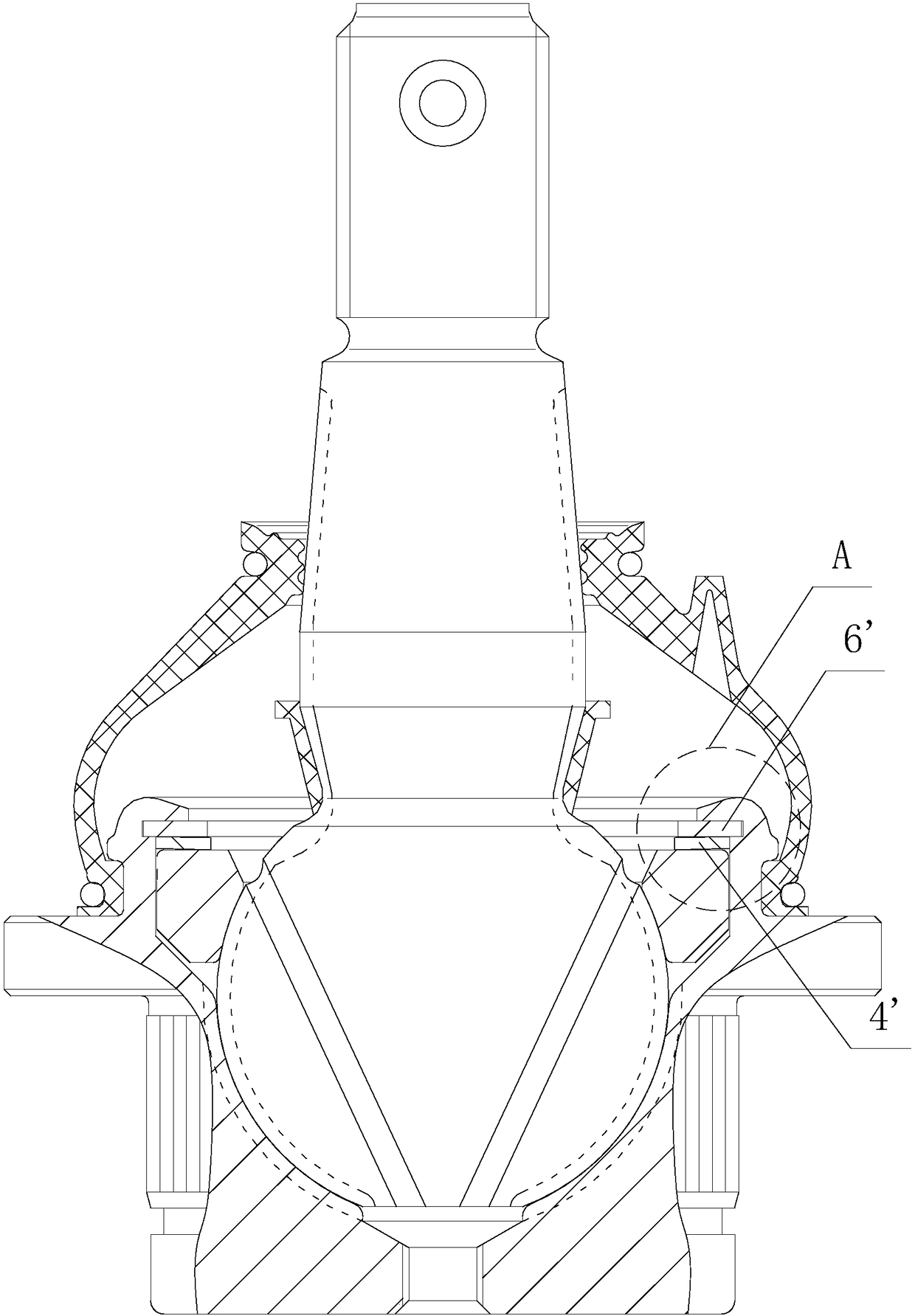

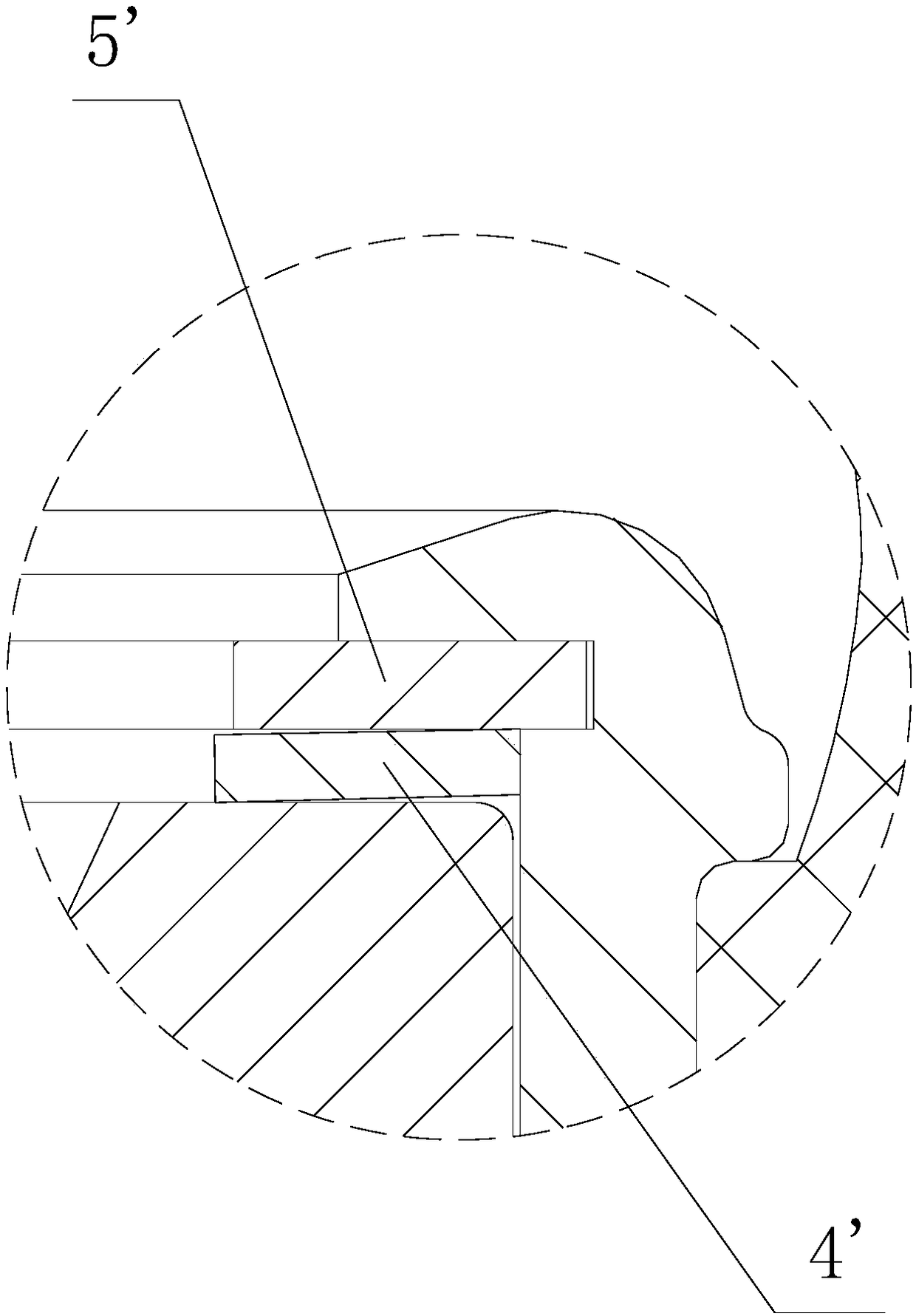

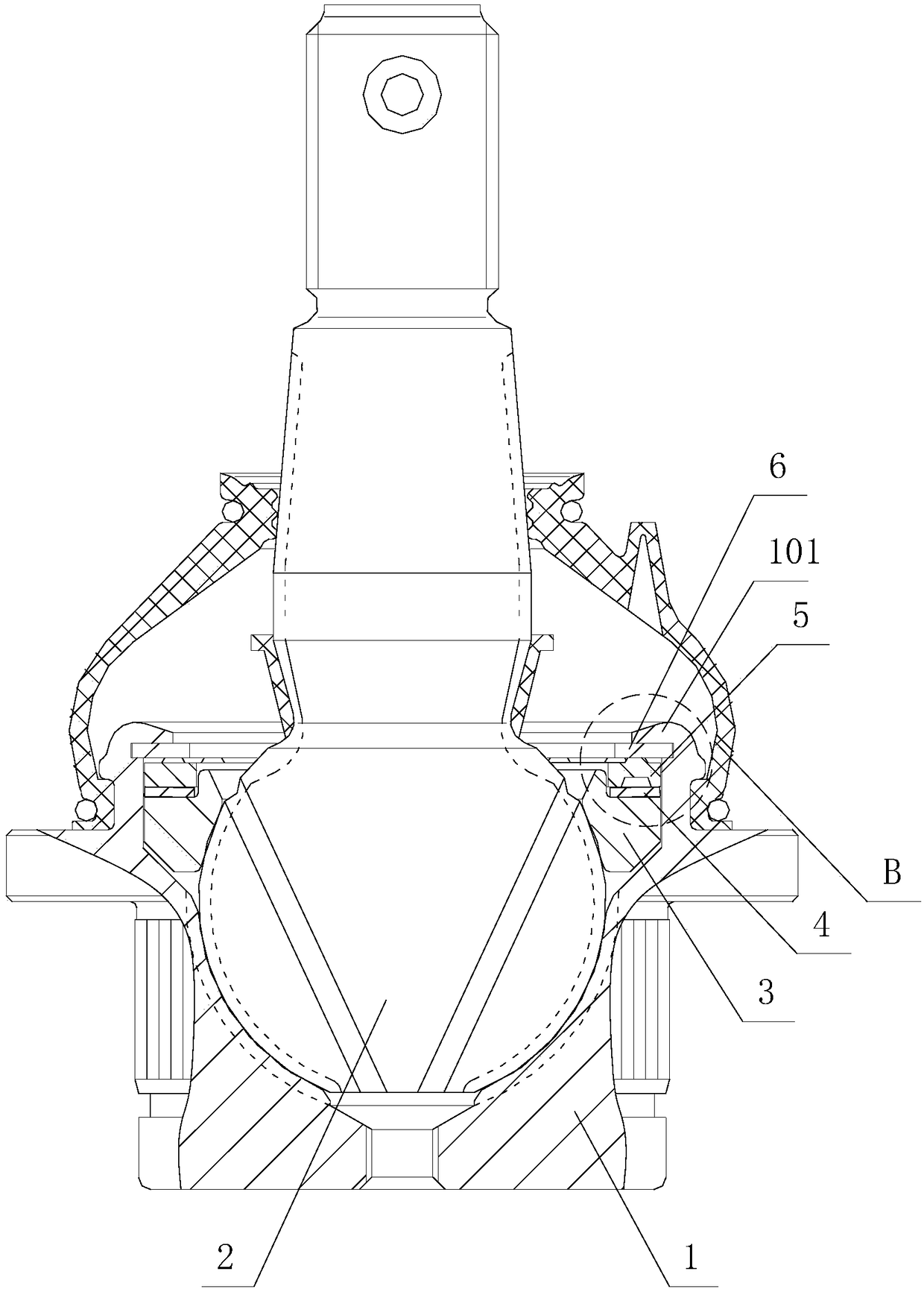

[0041] refer to image 3 with Figure 4 , the present invention provides a ball joint assembly with a compensation structure, which includes a ball shell 1, a ball seat 3 and a ball stud; a mounting cavity with an open top is formed on the ball shell; the ball seat 3 is installed at the upper end of the mounting cavity , and the ball seat is ring-shaped, forming a spherical cavity between the ball seat and the installation cavity; the ball stud includes a ball 2 rotatably installed in the spherical cavity, and is fixed on the side wall of the ball and extends to the The pin rod outside the spherical cavity; in this embodiment, the open end of the spherical shell is bent radially inward to form a flange 101, and a mounting portion is formed between the lower bottom surface of the flange and the upper end surface of the ball seat, and the mounting portion is formed by A sealing plate 6, a compensation washer 5 and an elastic member 4 are provided in sequence from top to bottom,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com