Moving contact bridge retaining structure of anti-short-circuit capability improving switch device

A technology of anti-short-circuit ability and switching device, which is applied in the direction of electric switches, contacts, circuits, etc., can solve the problems of poor anti-short-circuit ability and achieve the effect of consistent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

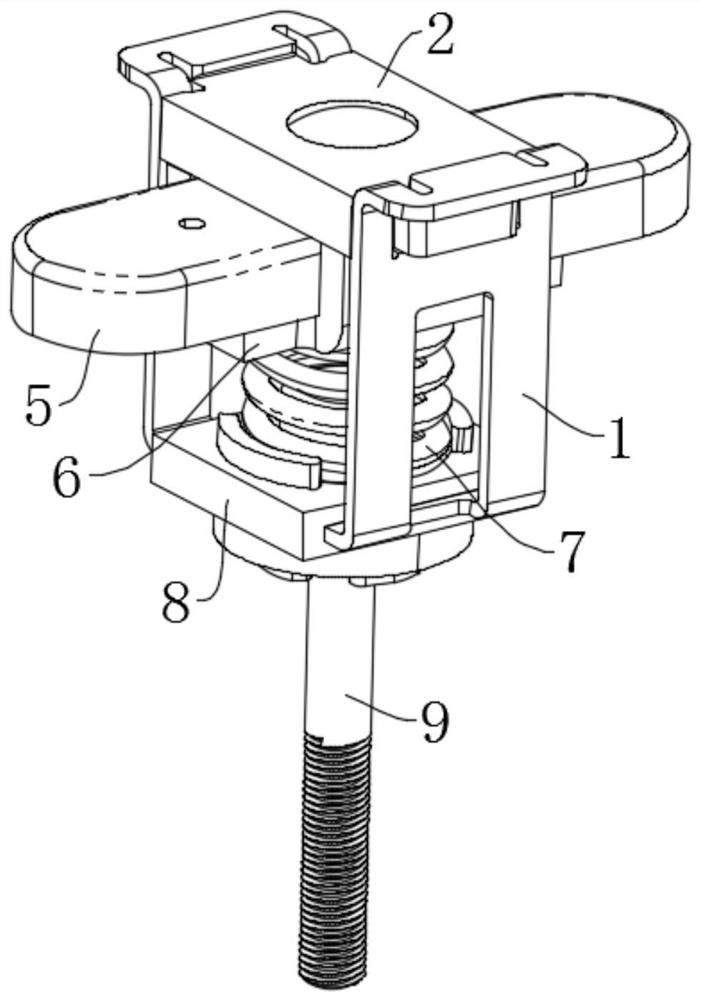

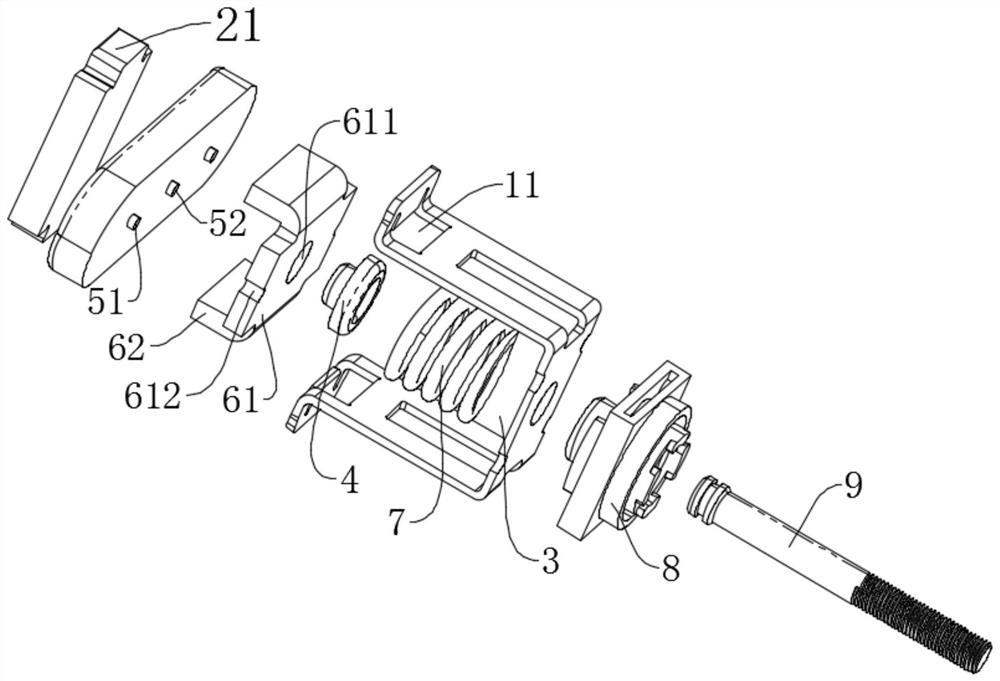

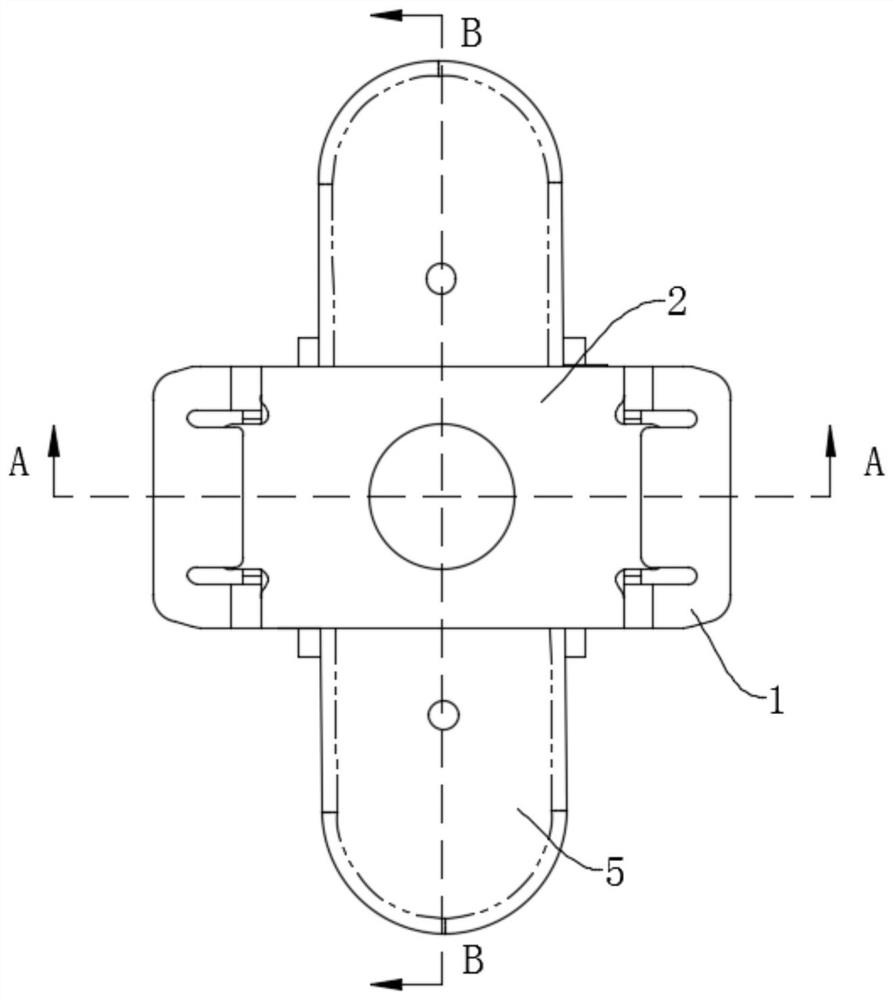

[0028] see figure 1 and figure 2 , the present embodiment provides a dynamic contact bridge holding structure for improving the short-circuit resistance of the switch device, which includes a cage 1, a top plate 2, a connecting piece 4, a moving touch bridge 5, a magnetic conductive component 6 and an elastic component 7, wherein:

[0029] Both ends of the cage 1 and the top plate 2 are fixedly connected and enclosed to form a mounting opening 3 with both ends open, and the straight line where the opening direction of the mounting opening 3 is located is the first axis a.

[0030] The movable contact bridge 5 is disposed in the installation opening 3 along the first axis a and is in contact with the top plate 2 , and the movable contact bridge 5 is arranged between two static contacts.

[0031] The magnetically conductive part 6 is arranged in the installation port 3 and connected with the movable contact bridge 5. The magnetically conductive part 6 includes a resisting part...

Embodiment 2

[0039] see Figure 8 , Embodiment 2 is basically the same as Embodiment 1, and will not be repeated here. The difference is that: the first connecting part 41 and the moving contact bridge 5' are fixed by resistance welding. Specifically, the moving contact bridge 5' After assembling correspondingly with the magnetic guide 6, put the connecting piece 4' into the installation hole 611, apply a certain pressure to the first connecting part 41 and the moving contact bridge 5' and weld them together, this process does not need to process the corresponding riveting mouth and riveting structure, reducing manufacturing process.

[0040] The following is a detailed description of the working principle of the moving contact bridge holding structure of a switch device with improved short-circuit resistance provided by the present invention: when the magnetic circuit part is energized, a magnetic field is generated to drive the driving rod 9 and the cage 1 to move toward the static conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com