Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

127 results about "Gauge (instrument)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gauge or gage, in science and engineering, is a device used to make measurements or in order to display certain dimensional information. A wide variety of tools exist which serve such functions, ranging from simple pieces of material against which sizes can be measured to complex pieces of machinery. Depending on usage, a gauge can be described as "a device for measuring a physical quantity", for example "to determine thickness, gap in space, diameter of materials, or pressure of flow", or "a device that displays the measurement of a monitored system by the use of a needle or pointer that moves along a calibrated scale".

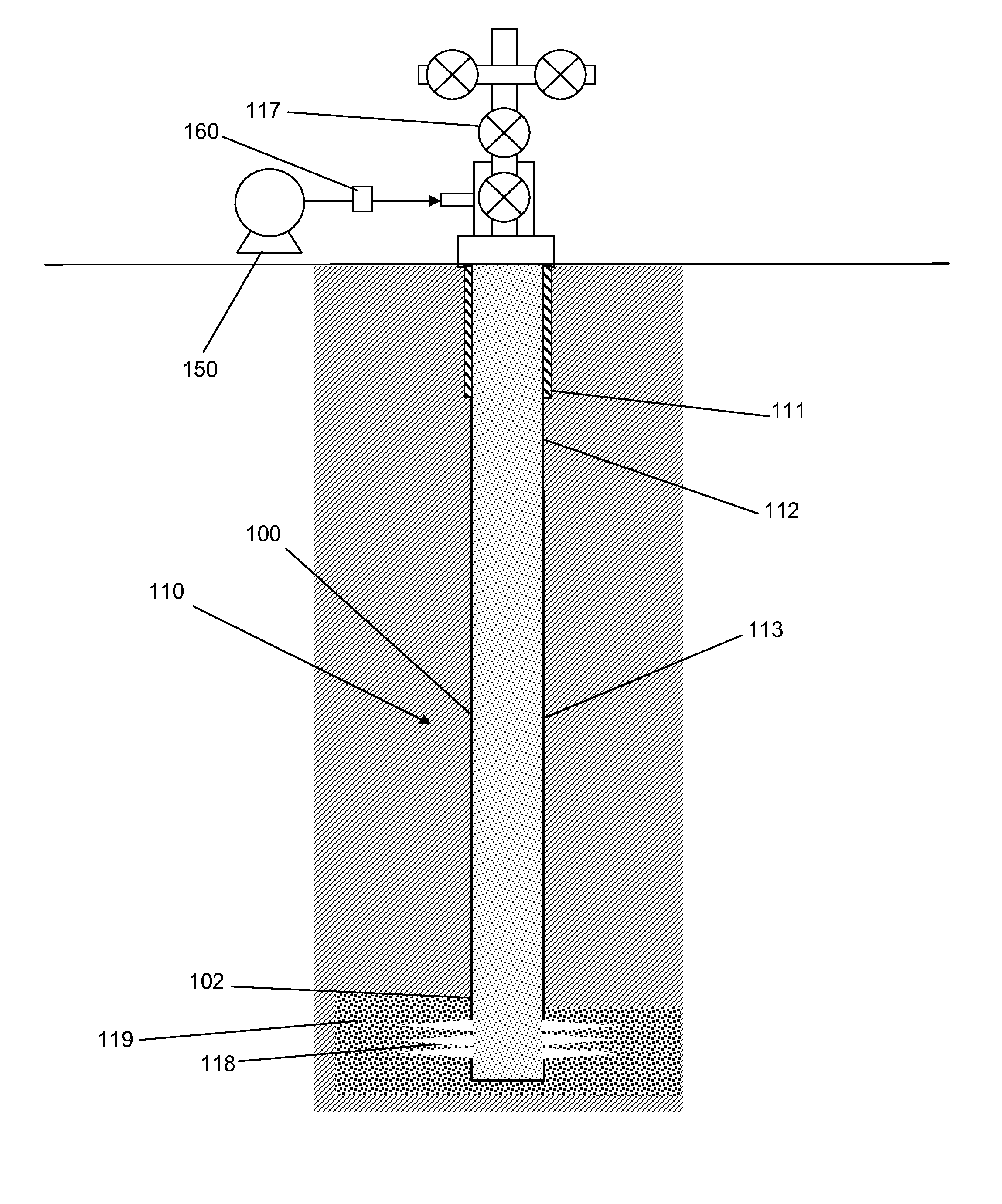

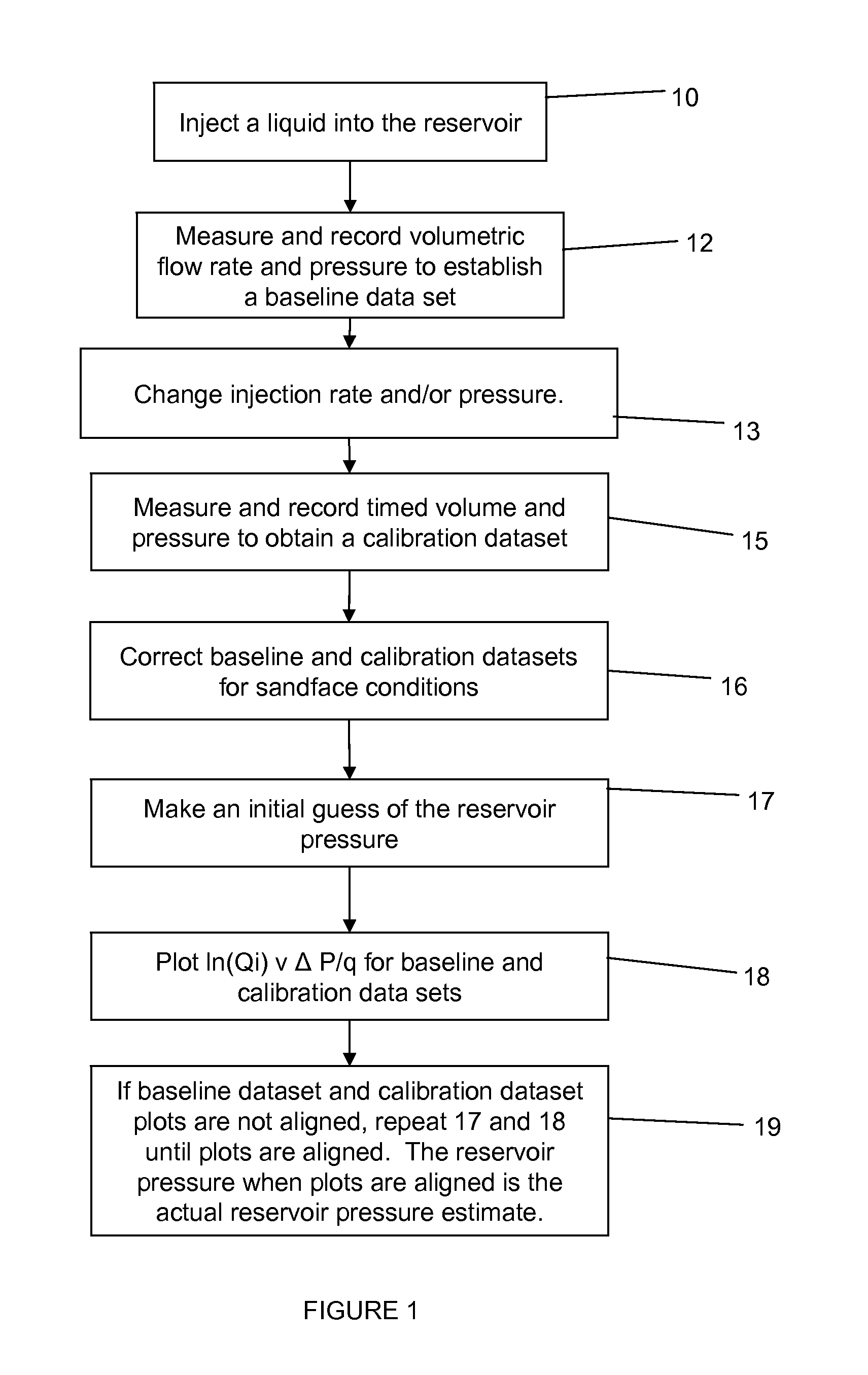

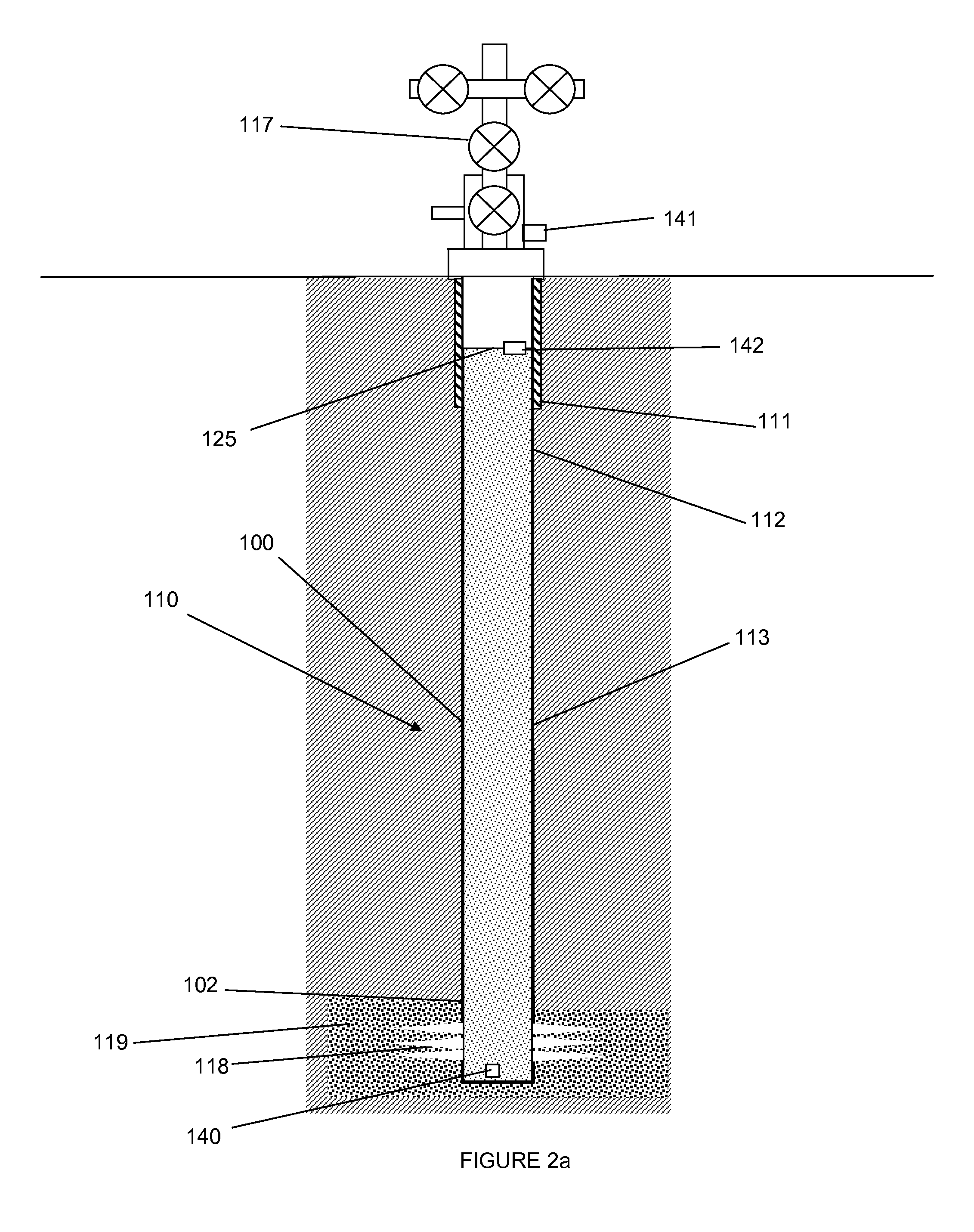

Method of determining reservoir pressure

ActiveUS20120158310A1Reduce penetrationElectric/magnetic detection for well-loggingSurveyBaseline dataInjection pressure

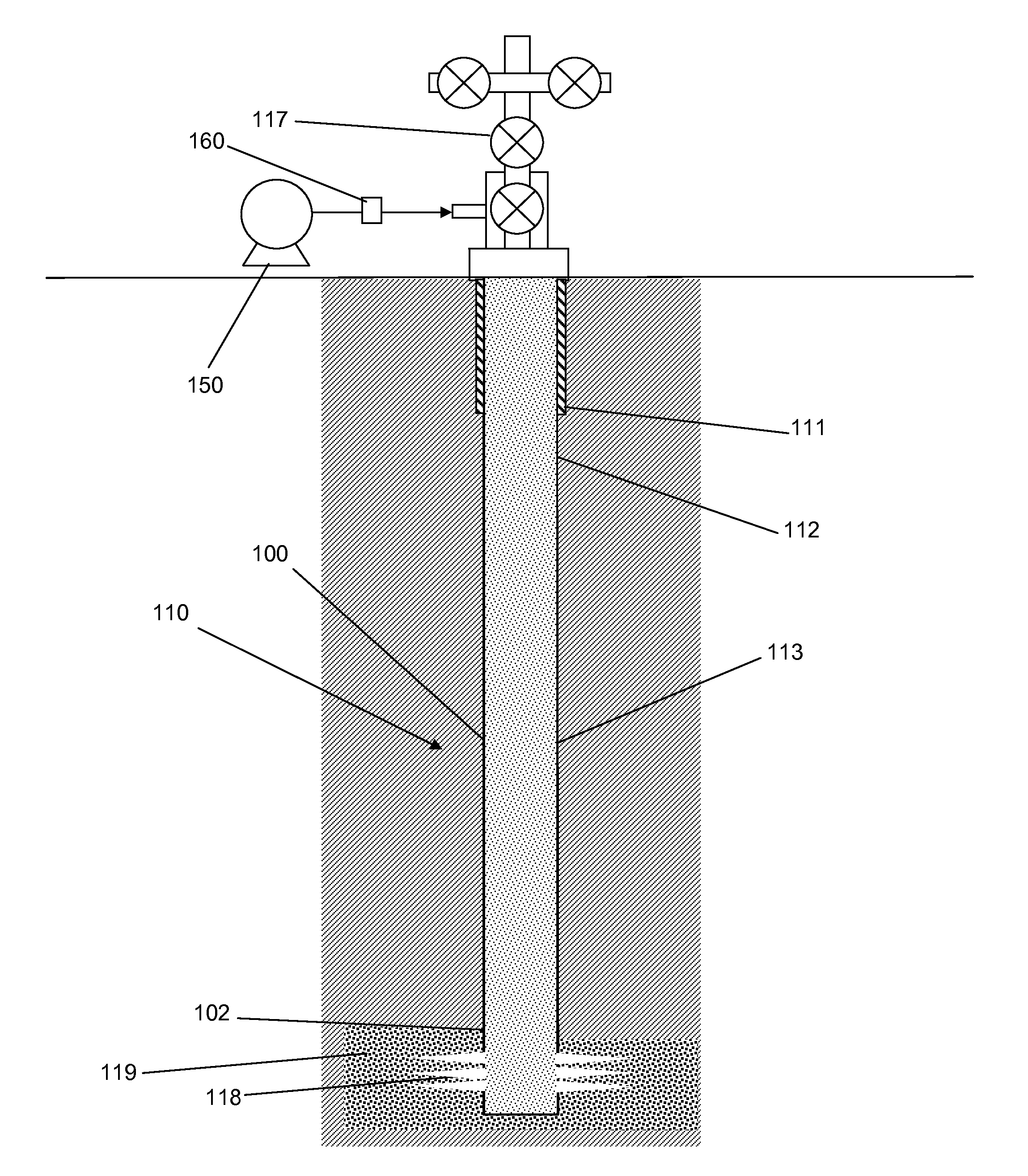

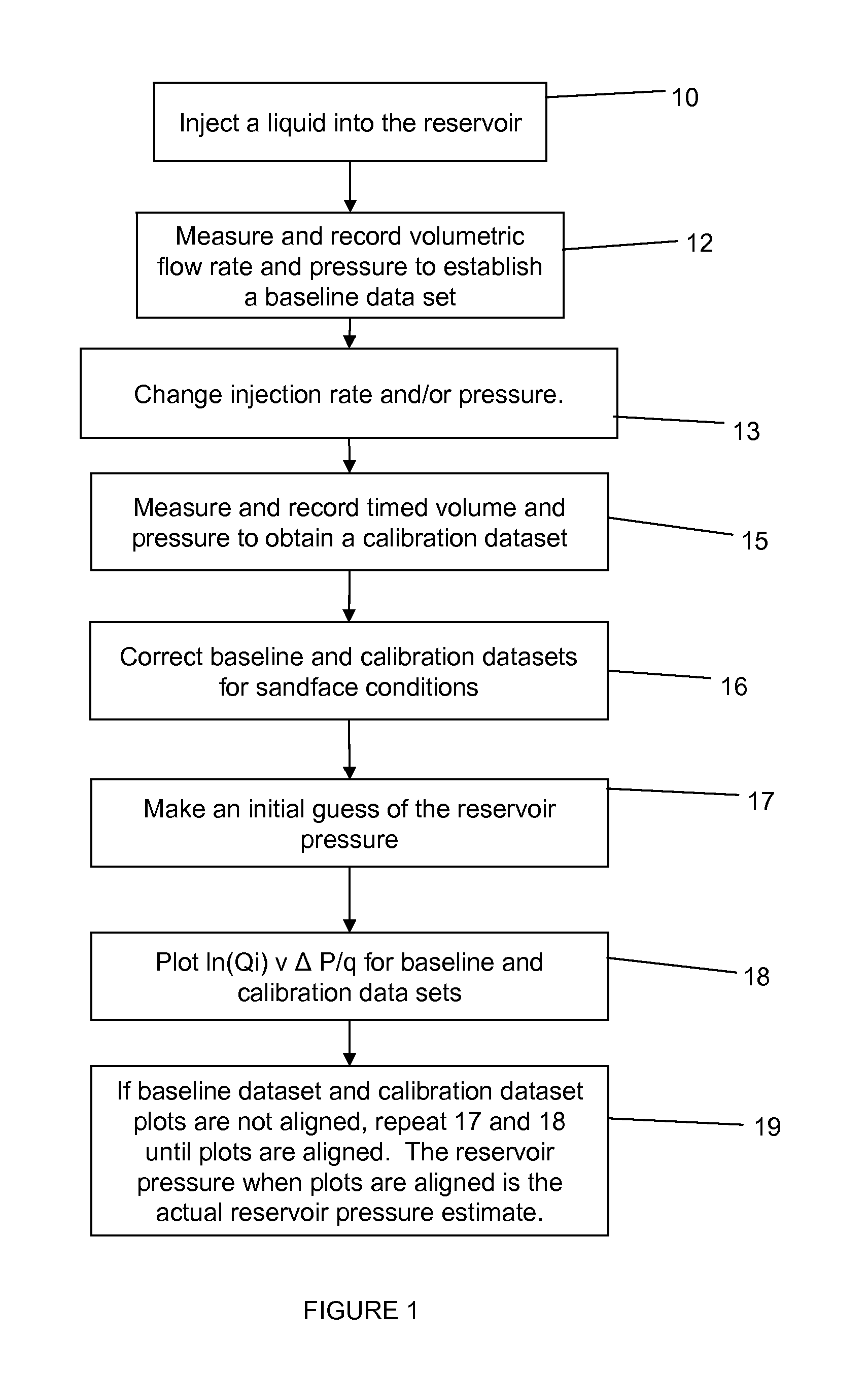

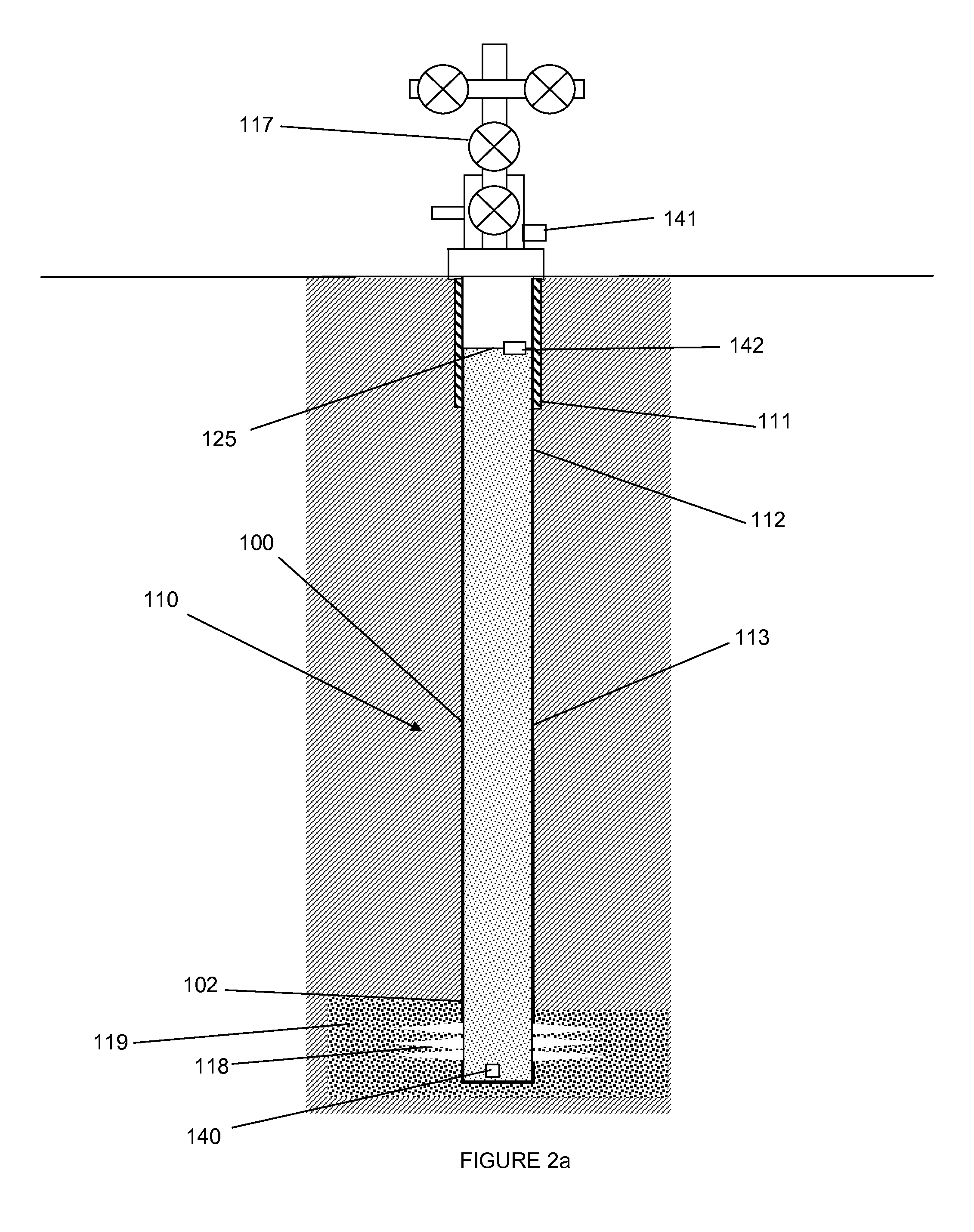

A new approach is disclosed for measuring the pressure of tight gas reservoirs, using information obtain from continuous injection prior to hydraulic fracture stimulation. The technique can be obtained utilizing either bottom-hole or surface pressure gauges and properly instrumented surface injection pumps. The analysis is completed by plotting injection and rate data in a specialized form from terms arranged in Darcy's radial flow equation to obtain a curve or trend. The key component to proper application of this technique is to obtain both baseline and one or more calibration data sets. These calibration data sets are obtained by either increasing or decreasing the injection pressure and / or rate from the baseline data. Initial reservoir pressure is assumed, but the calibration data indicates if the guess was too high or low. Accurate estimates of reservoir pressure may be obtained in a few iterations.

Owner:BP CORP NORTH AMERICA INC

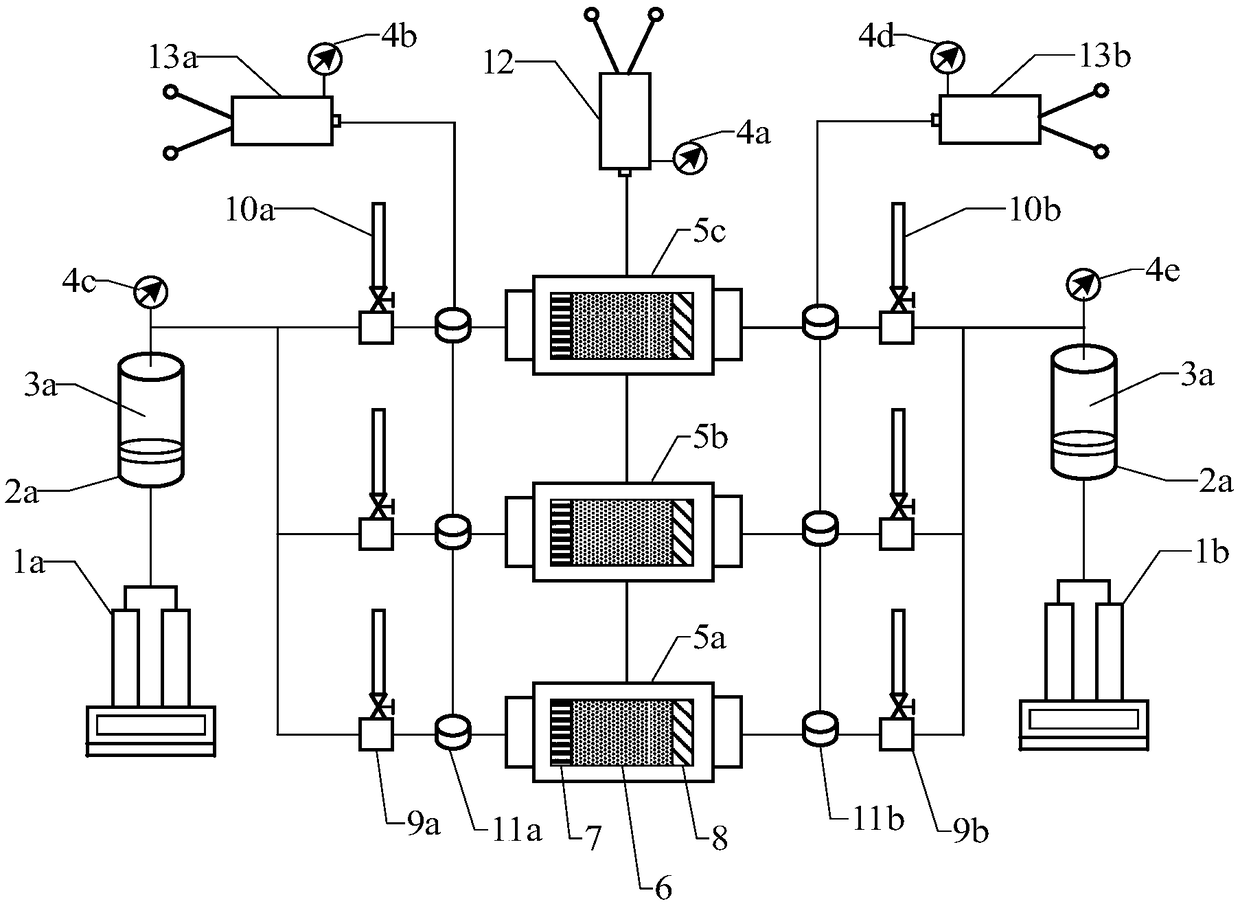

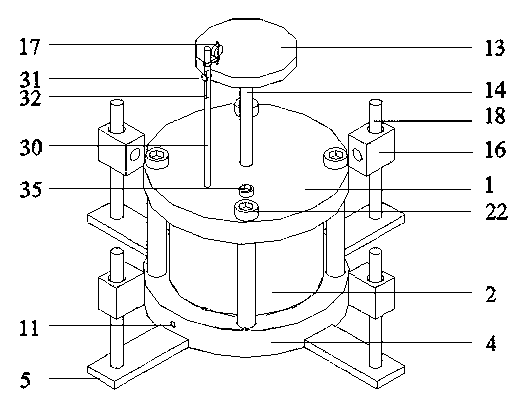

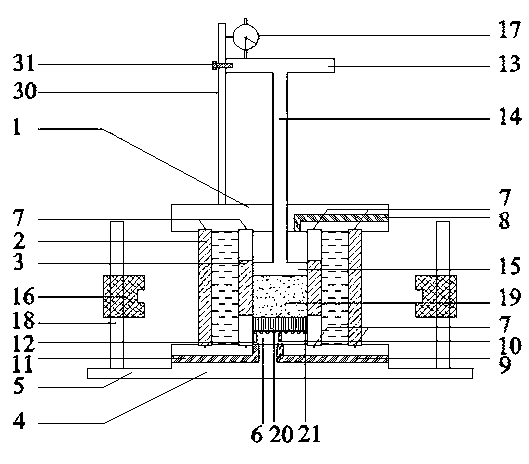

Device and method for simultaneous detection of displacement and sucking capillary force curves under oil reservoir conditions

PendingCN108181224ASolve the disadvantages of only measuring displacement capillary force curveSolve the problem of continuous accurate measurementPermeability/surface area analysisEngineeringThermostat

The invention relates to a device and a method for simultaneous detection of displacement and sucking capillary force curves under oil reservoir conditions. The device comprises a triaxial stress rockcore holder, wherein a wet phase semi-permeable separator and a non-wetting phase semi-permeable separator are respectively placed at both ends of a rock core, an annular pressure and axial pressuremechanical pump and a back pressure mechanical pump are used to pressurize and simulate formation pressure, a thermostat simulates formation temperature, a non-wetting phase fluid piston container, awet phase fluid piston container and a constant speed constant pressure micro pump control a displacement and suction process, a pressure flow rate sensor group, a pressure gauge, a metering tube anda computer collect pressure and liquid volume data and process and calculate the displacement and sucking capillary force curves; the method continuously measures the displacement and sucking capillary force curves of different wettable rocks in one time and scans the displacement and sucking capillary force curves by simulating true oil reservoir temperature pressure and fluid conditions, makes up for the shortcomings of conventional methods, solves the defect that a common instrument can only measure displacement capillary force curves, and solves the problem of continuous accurate measurement of underground real displacement and sucking capillary force curves.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

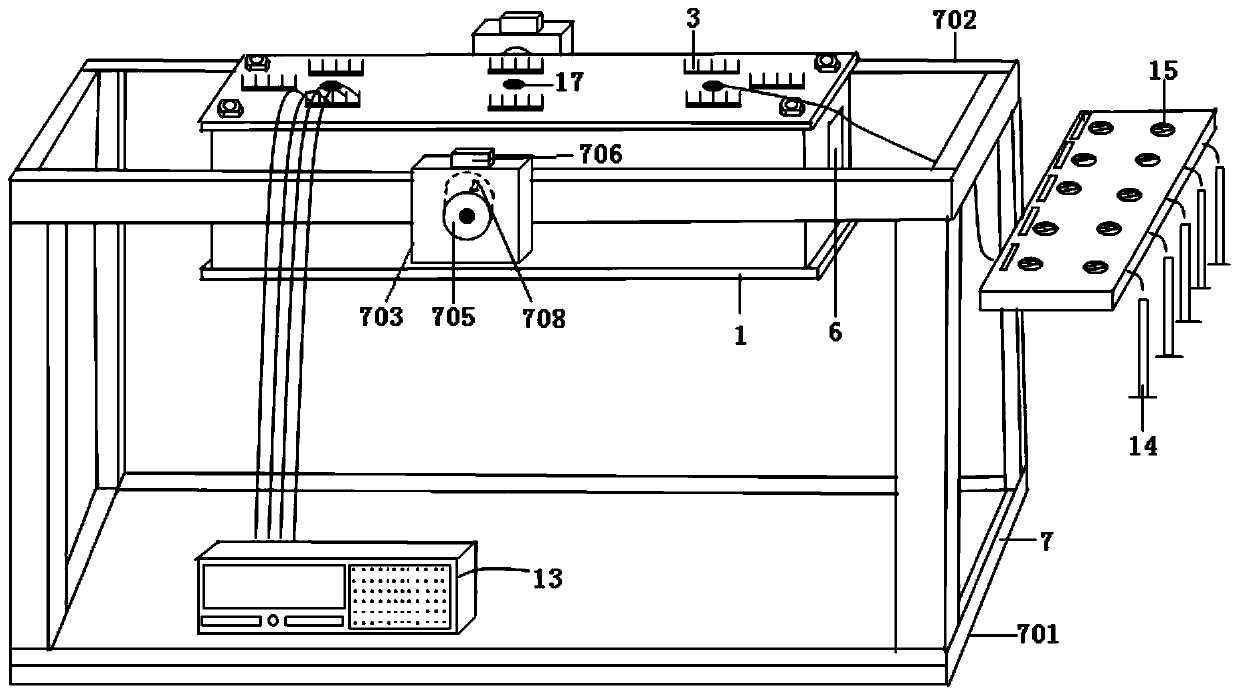

Vacuum preloading and electroosmosis combined testing device and vacuum preloading and electroosmosis combined testing method

InactiveCN104569341ASimple structureEasy to operateEarth material testingCopper wirePore water pressure

The invention discloses a vacuum preloading and electroosmosis combined testing device. The vacuum preloading and electroosmosis combined testing device comprises a tempered glass model box, wherein a measurement hole site is formed on the tempered glass model box, a minitype pore water pressure gauge is arranged in the tempered glass model box and penetrates through the measurement hole site to be connected with an external instrument by an information wire, a plastic drainage plate is vertically inserted in the middle in the tempered glass model box, a reinforcing steel bar is inserted in the tempered glass model box, the reinforcing steel bar is connected with an anode binding post, a conductive copper wire is connected with a cathode binding post, a main drainage pipe is connected with a suction filtration bottle which is connected with a vacuum pump by a pipeline, a vacuum meter is arranged on the main drainage pipe, and the suction filtration bottle is arranged on an electronic scale; lateral displacement scales are marked on the tempered glass model box horizontally, and multiple lateral displacement scales are distributed on the tempered glass model box in the height direction. The vacuum preloading and electroosmosis combined testing device also provides a vacuum preloading and electroosmosis combined testing method. The vacuum preloading and electroosmosis combined testing device can be used for conveniently and rapidly simulating a soft foundation after being subjected to vacuum-electroosmosis combined treatment in a room, can accurately measure the vacuum degrees and the pore water pressures of soil bodies at different positions, and can clearly observe the bending change of the plastic drainage plate in a solidifying process of the soil bodies.

Owner:WENZHOU UNIVERSITY

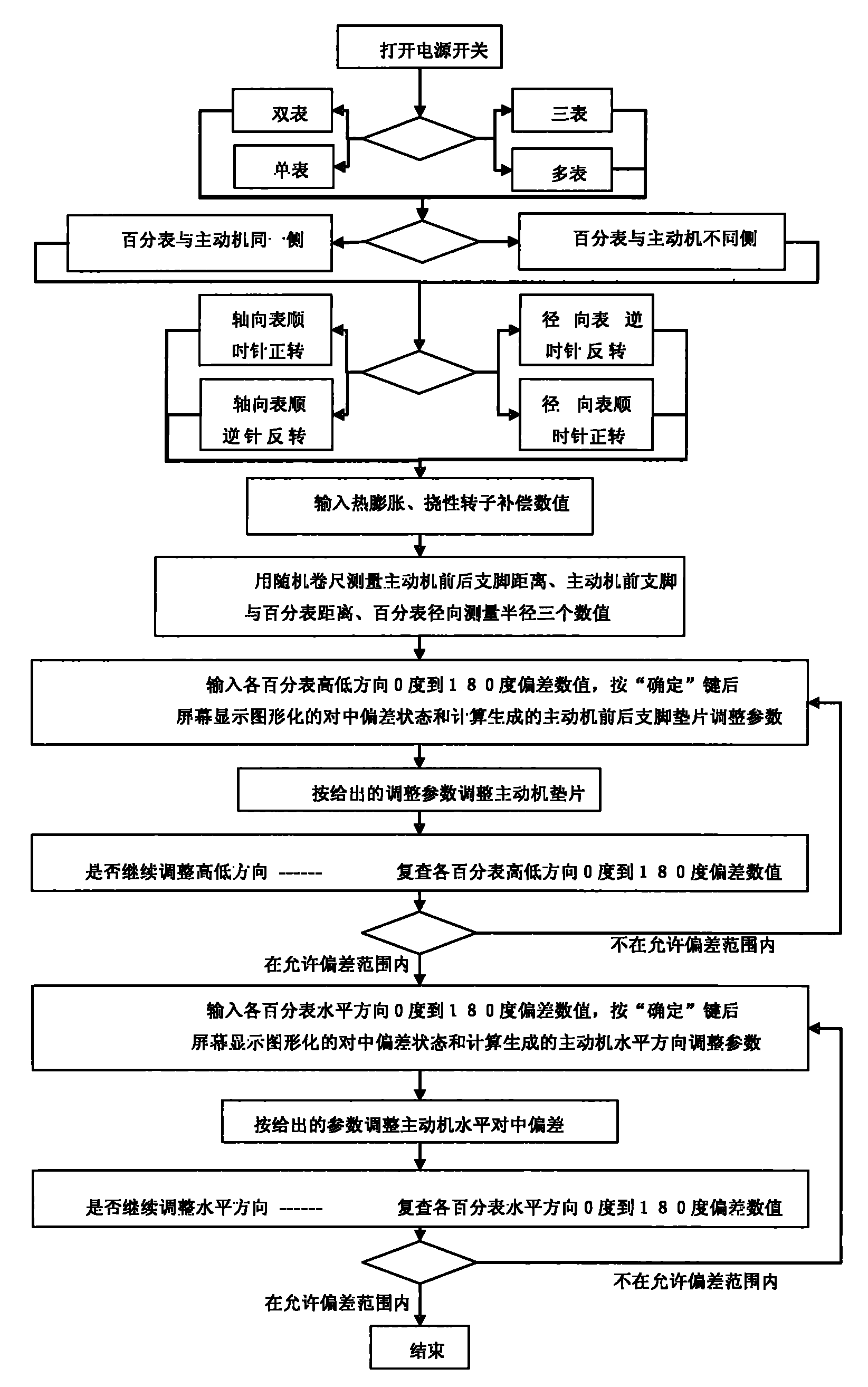

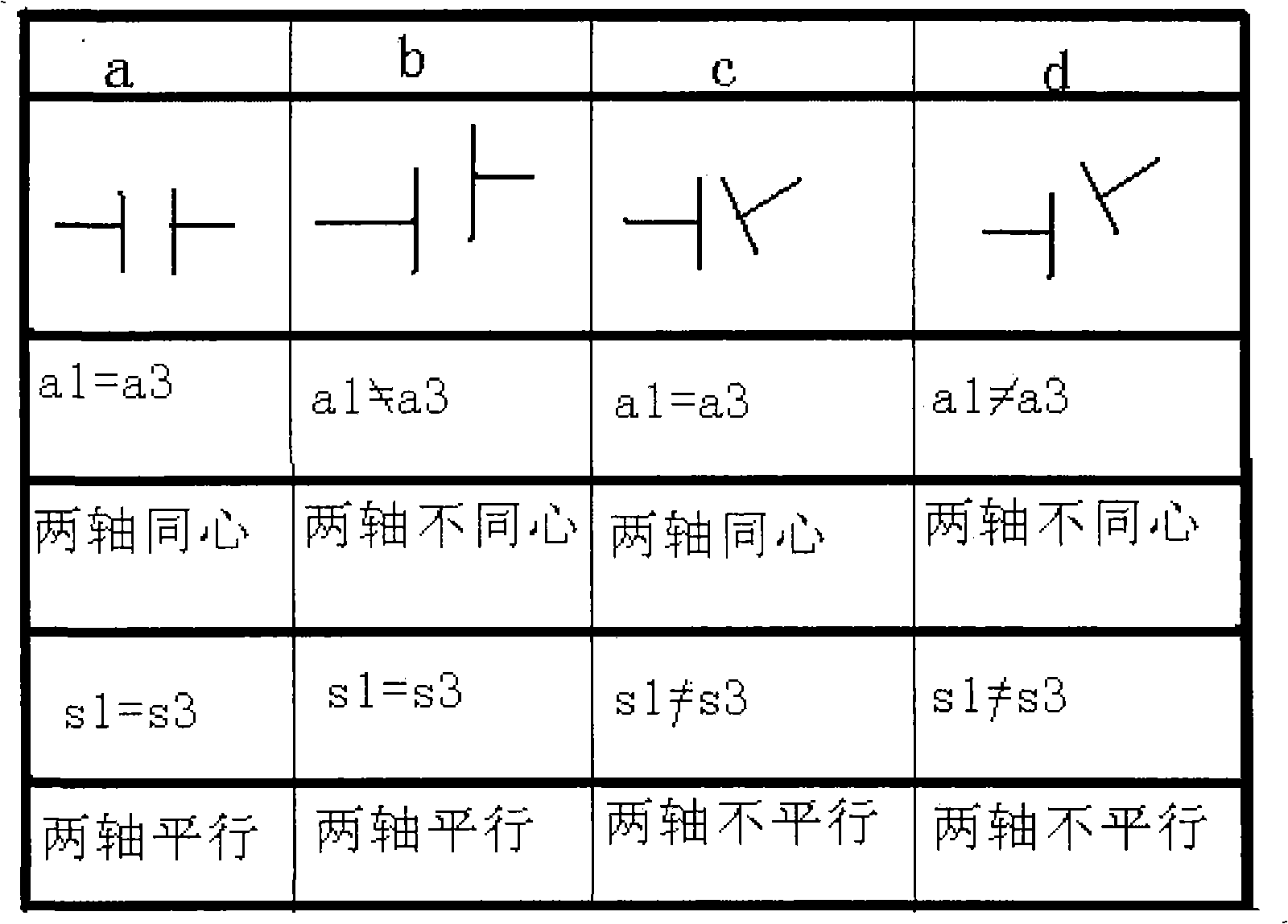

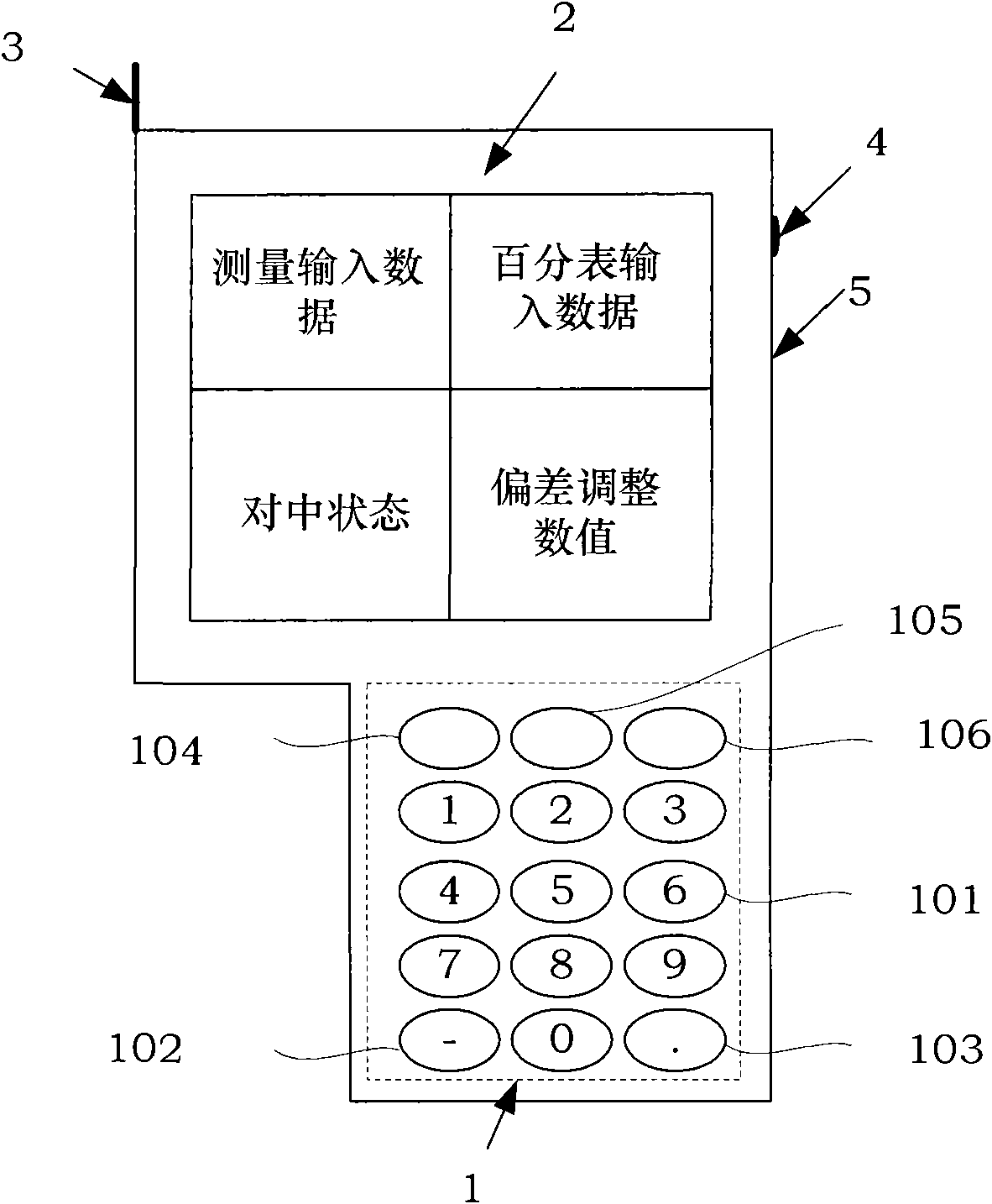

Method for aligning and centering coupler of rotating machinery and special calculator thereof

InactiveCN101813448ATime-consuming and laborious to solveSolve the problem that the calculation formula is not easy to graspDigital computer detailsMechanical measuring arrangementsCouplingEngineering

The invention discloses a method for aligning and centering a coupler of rotating machinery and a special calculator thereof, and is applied to occasions needing alignment during arranging or maintaining the rotating machinery. By combining a dial gauge and a gauge frame, or during the use of a dial gauge type aligning and centering instrument, the aligning and centering work can be rapidly and accurately finished. Several necessary dimension parameters and the indication of the dial gauge are only needed to be measured; the patterned working process is selected according to an internal procedure; and an aligning and centering adjustment value is generated by calculating according to the internal procedure in the device, and the aligning and centering adjustment is performed. Therefore, the aligning and centering work can be conveniently and rapidly finished. The method for aligning and centering the coupler of the rotating machinery and the special calculator thereof have the advantages that: the aligning and centering work of the rotating machinery is performed without tedious calculation or graphical method, and particularly the aligning and centering process evaluated and repeatedly adjusted by experiences is not needed. Therefore, the method is simple, easy to master, time-saving and labor-saving, can lighten the labor intensity and has more visualized determined value. Compared with a laser alignment instrument, the method has the characteristics of wide applicability, low cost, and portability.

Owner:北京燕化正邦设备检修有限公司

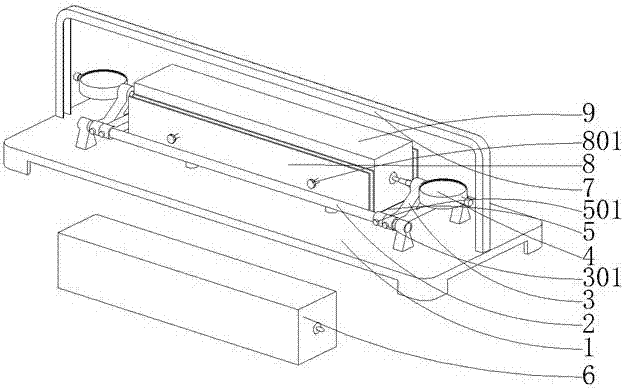

Concrete expansion and shrinkage test length measuring instrument and measuring method

PendingCN107514960AReduced position adjustment requirementsReduced adjustment requirementsMaterial testing goodsMechanical measuring arrangementsMeasuring instrumentEngineering

The invention discloses a concrete expansion and shrinkage test length measuring instrument and a measuring method. The measuring instrument includes a standard length rod and a base, two guide rails are fixed on the base, a test piece fixture is arranged between the guide rails and the bottom of the test piece fixture is installed on the base, a test piece fastening device is arranged on the test piece fixture, a locator is arranged on the top of the test piece fixture and the locator is fixed on the base, a positioning vernier and a sliding dial gauge frame which can slide on the guide rails are installed on both ends of the guide rails, the positioning vernier is located on the inner side of the sliding dial gauge frame, and a dial gauge is arranged on the sliding dial gauge frame. The concrete expansion and shrinkage test length measuring instrument can be applied to the precise length measurement of the concrete test pieces with different specifications through replacing the test piece fixture, dedicated measuring instrument is not needed, the applicability is strong, the length of concrete test pieces for different tests and different specifications can be accurately measured by a single instrument, the standardization and unification of length measurement tests of the concrete test pieces with different specifications can be ensured, and the consistency and accuracy of measurement data are ensured.

Owner:甘肃建科技术试验检测有限责任公司

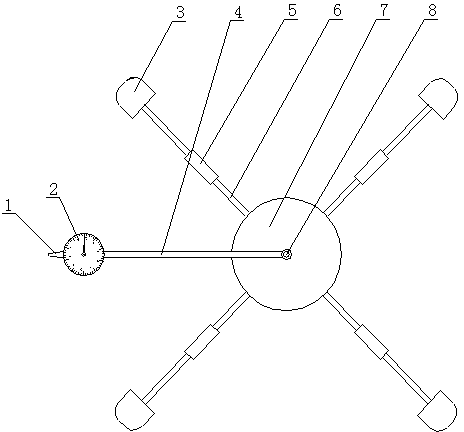

Round hole inner diameter measuring instrument

InactiveCN103185562AExtended service lifeNot easy to wearMeasurement devicesMeasuring instrumentEngineering

The invention discloses an inner diameter measuring instrument and relates to a measuring tool. The inner diameter measuring instrument is provided with a measuring rod, wherein a measuring gauge outfit is arranged on the front end portion of the measuring rod, and a measuring probe is arranged on the measuring gauge outfit. The inner diameter measuring instrument is characterized in that a positioning seat is arranged, at least four positioning rods of adjustable lengths are evenly arranged on the positioning seat, positioning blocks are arranged on front end portions of the positioning rods, and the measuring rod is hinged in the center of the positioning seat through a hinged shaft. In the process of use, the positioning seat is arranged on a round hole of a part, the lengths of the positioning rods are adjusted to enable the center of the positioning seat to coincide with the center of the round hole and be fixed, at the moment, the measuring rod is rotated, the measuring probe of the measuring gauge outfit of the front end of the measuring rod slides along the inner wall of the round hole, and according to the length of the measuring rod and measuring value displayed by the measuring gauge outfit, the radius of the round hole can be obtained. According to changes of the measuring value of the measuring gauge outfit, the inner diameter measuring instrument can detect whether roundness and concentricity of the round hole confirm to the standard or not and can confirm the position which is not up to standard. The inner diameter measuring instrument is convenient to repair and maintain, after repaired and maintained, mechanical vibration amplitude is small, mechanical performance is improved, the inner wall of the round hole is not easy to abrade, and service life is long.

Owner:AVIC WEIHAI SHIPYARD

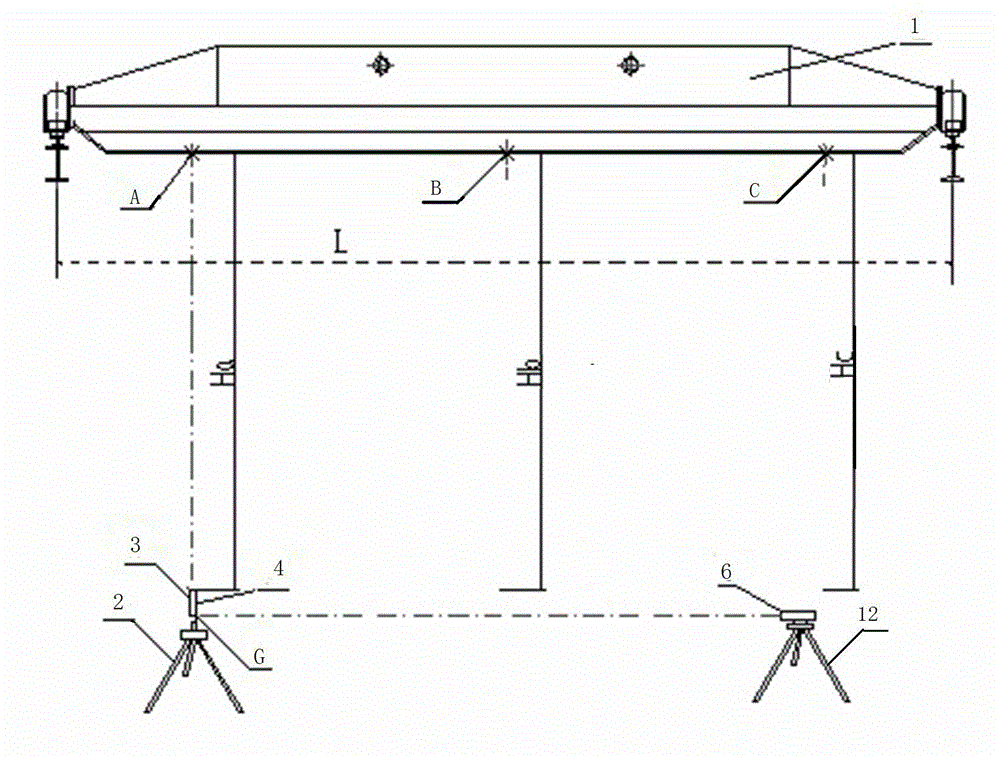

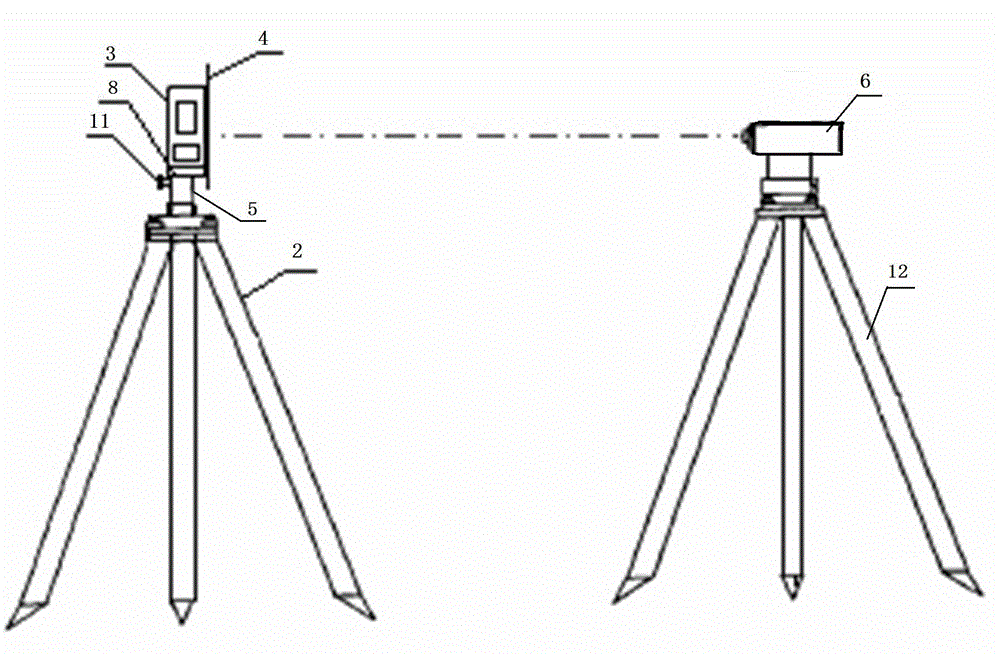

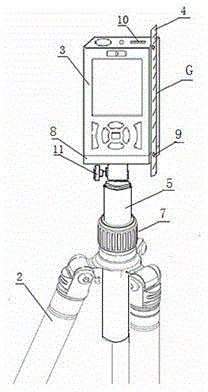

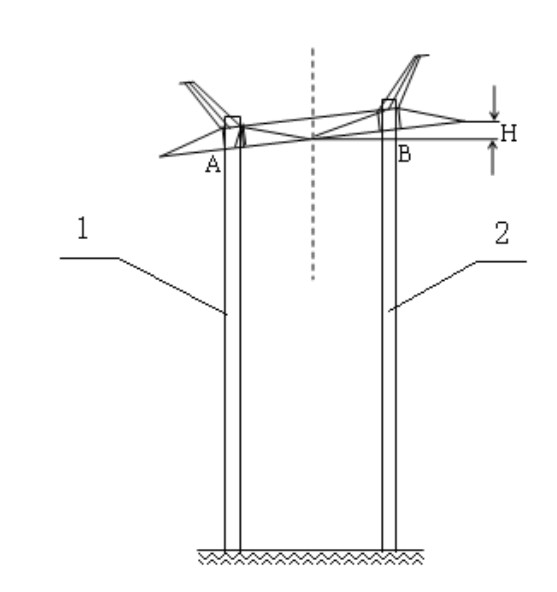

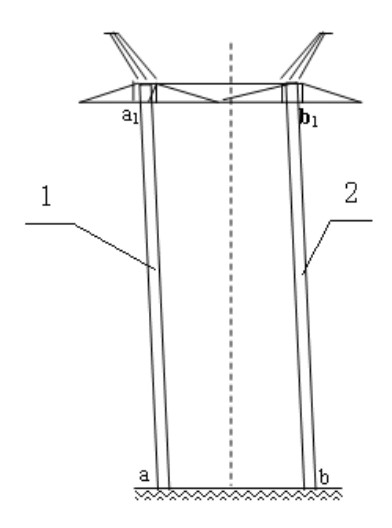

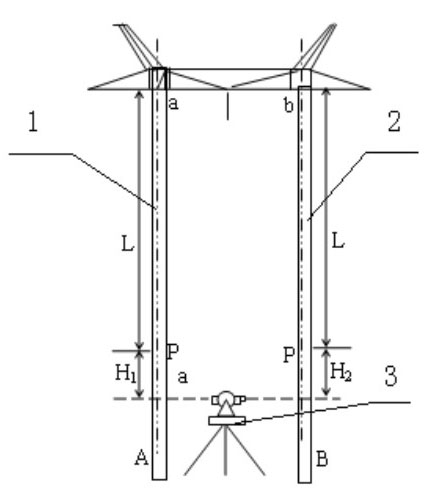

Camber measuring method of overhead and gantry crane and matched measuring device

The invention discloses a camber measuring method of an overhead and gantry crane and a matched measuring device. The method is used for measuring the camber on the overhead and gantry crane, the operation is convenient, a measuring worker does not need to assemble testing equipment on site, the measuring can be finished on the ground, the limit of erecting the instrument by the ground space and the light is small, the distance measurement scope is 1-50m, the measuring precision is plus and minus 1mm, and the measuring is accurate, convenient and suitable. The matched measuring device is mainly composed of laser distance measuring equipment, a level gauge and a calibrated scale, the laser distance measuring equipment and the level gauge are arranged on a holder of a tripod, the upper end of the calibrated scale is fixed on an outer shell on one side of the laser distance measuring equipment, the lower end of the calibrated scale is fixed on the holder of the tripod, the level gauge and the tripod are arranged within the stadia measuring scope of the laser distance measuring equipment, and the scale of the calibrated scale can be observed through an eye lens of the level gauge. The device is simple in structure, relatively cheap, convenient to carry and good in popularization application prospect.

Owner:河南省特种设备安全检测研究院

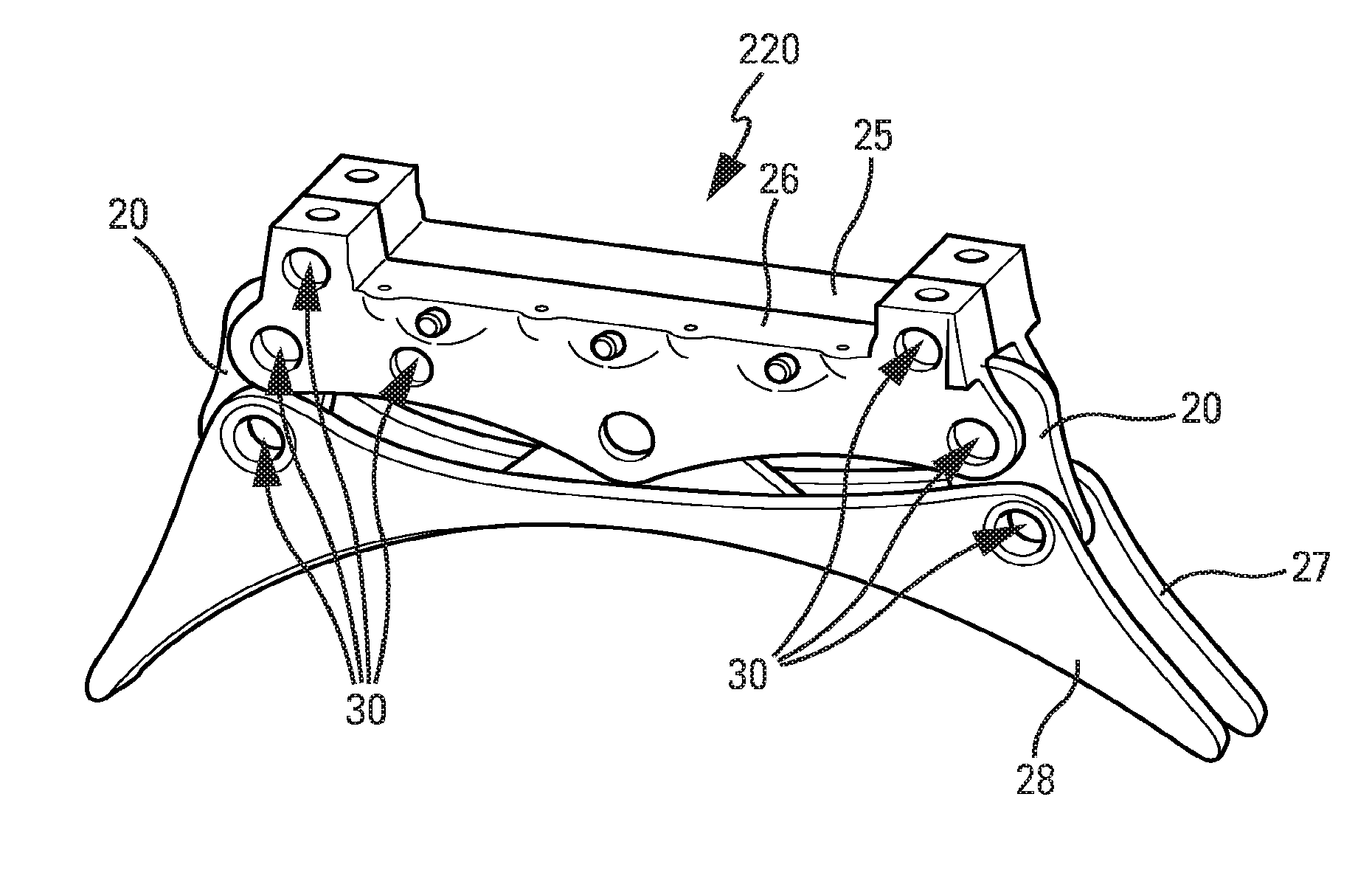

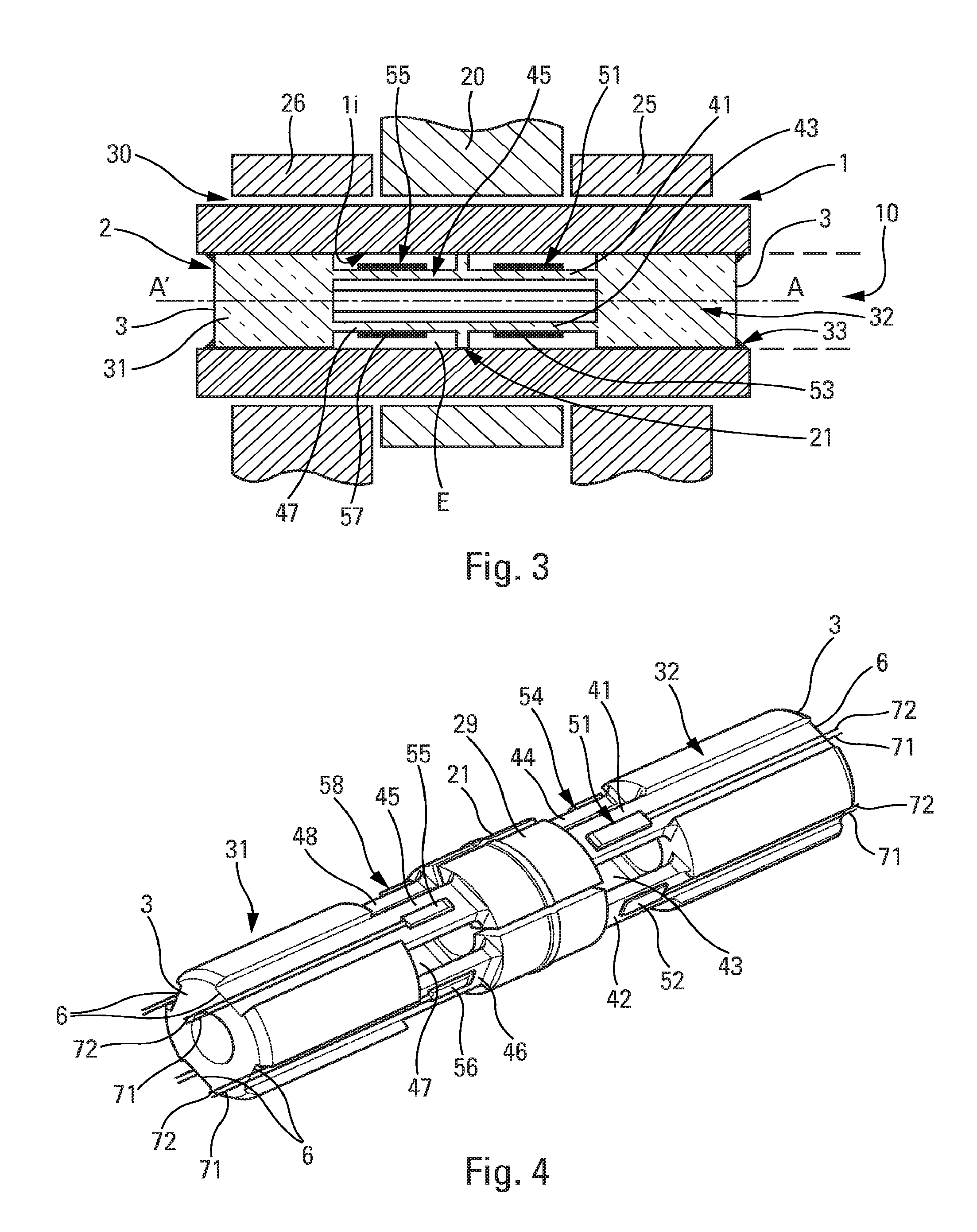

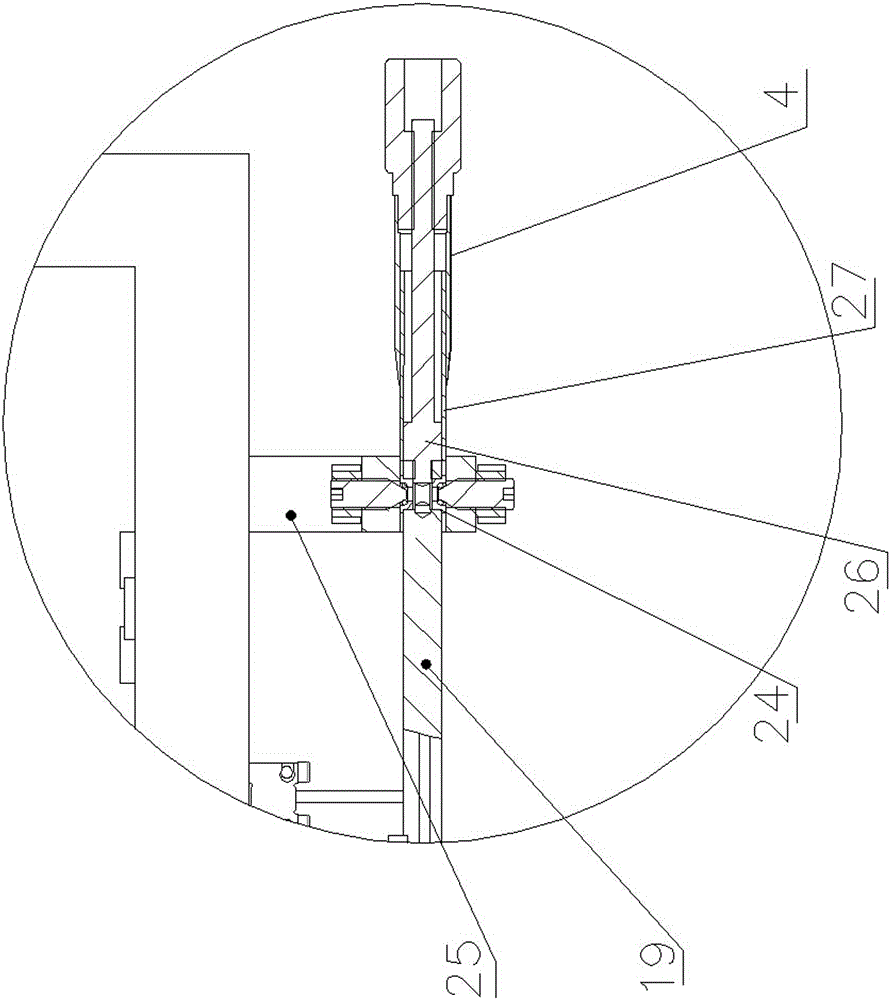

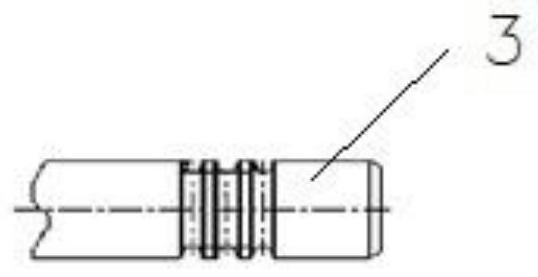

Method of measuring loadings in joins in a high-temperature environment and instrumented shaft for implementation, in particular for rear attachment of aircraft turbojet

ActiveUS20130305817A1Aircraft health monitoring devicesPower plant constructionAirplaneMechanical construction

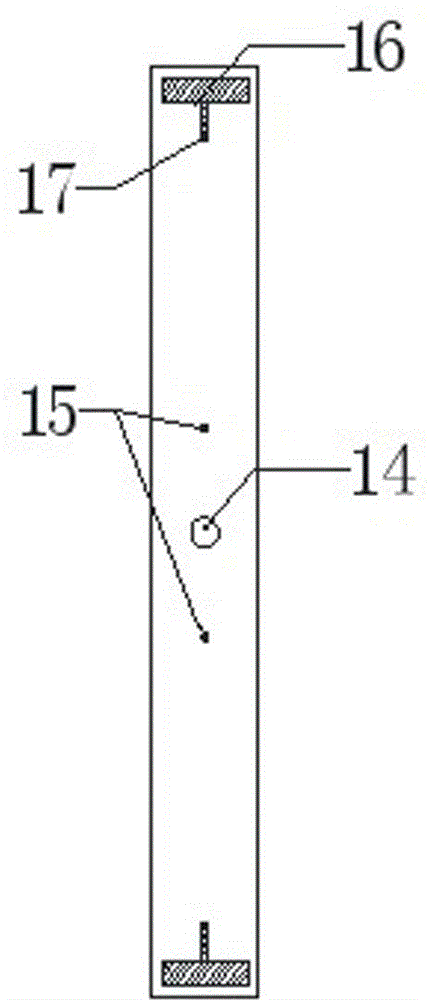

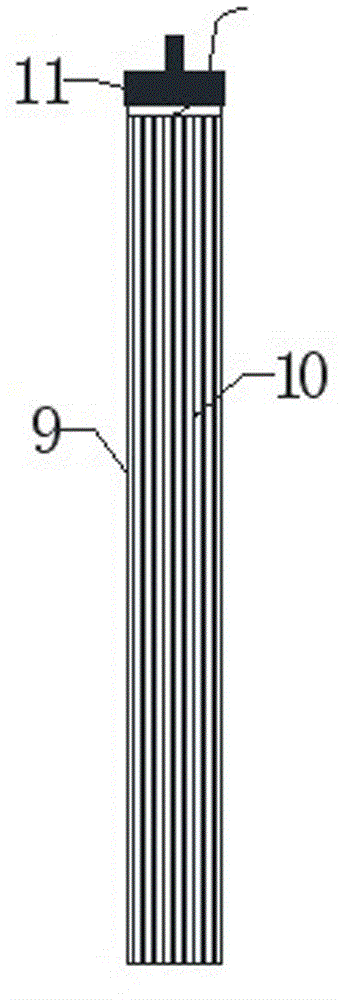

The invention aims to produce an instrumentation making it possible to measure the loadings which pass through mechanical joins between two mechanical structures, so as to best evaluate the dimensions and masses without impairing their mechanical properties of a secure transfer of load. To this end, the invention proposes introducing into the zones of transit of the loadings an instrumented component of the form that favours the measurement of shear and its installation. In one embodiment, a zone of transit of loadings consists of an instrumentalized hollow shaft which takes the form of a cylinder (1) able to be introduced into collinear openings (30) in the fittings (20, 25, 26). It comprises a longitudinal housing (10) into which is introduced an insert (2) composed of a central prop (21) in tight contact with the internal wall (1i) of the shaft (1) and connected, on each side, to a flyweight (31, 32) also in tight contact, by way of multiple tabs (41 to 44) away from contact with said internal wall (1i). High-temperature gauges (51, 53, 55, 57) are welded to the tabs (41 to 44), so as to measure a variation in electrical resistance corresponding to the bending deformation of the tabs (41 to 44).

Owner:AIRBUS OPERATIONS SAS

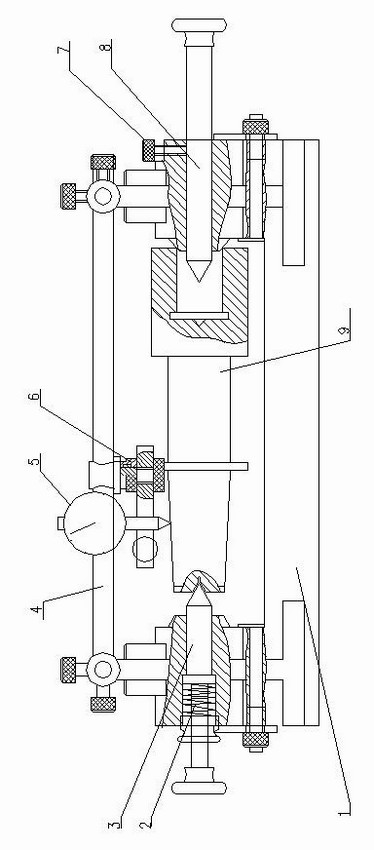

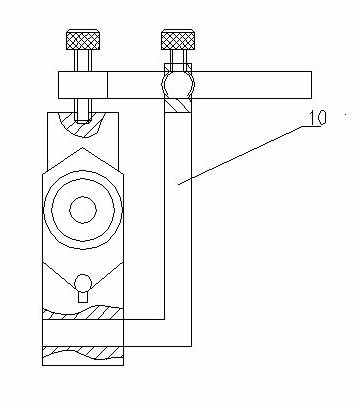

Radial jitter detector for shaft

InactiveCN102506644AAvoid wastingSimple structureMechanical measuring arrangementsReciprocating motionEngineering

The invention relates to a radial jitter detector for a shaft, belonging to the field of radial jitter detection equipment of shaft-like workpieces. The radial run-out detector for the shaft is simple in structure, has a wide measurement range, is provided with two adjustable apexes and can adjust the movable apex to measure workpieces with different sizes according to the size of the workpiece. A dial gage is arranged on a gauge bracket, the gauge bracket is fixed on a cross beam and can do reciprocating motion and up-and-down motion, so that the radial run-out value of the shaft can be measured accurately; the condition that a bench worker mistakenly judges deformation due to no detecting instrument is arranged in maintenance to cause waste phenomenon owning to scrapping can be avoided.

Owner:WAFANGDIAN BEARING GRP CO LTD +1

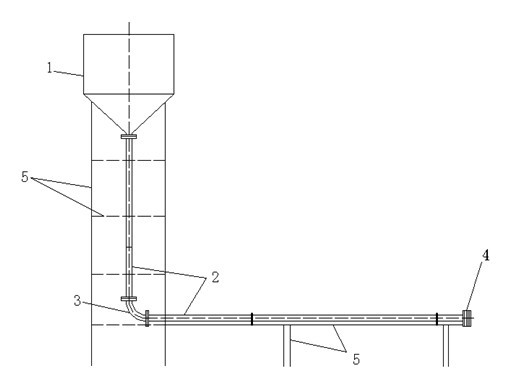

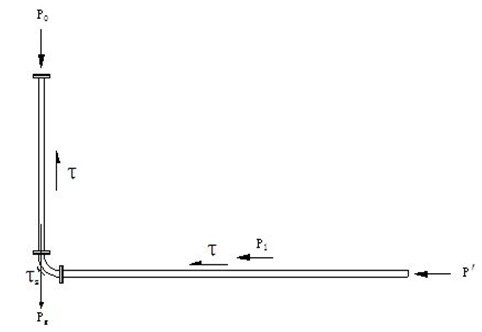

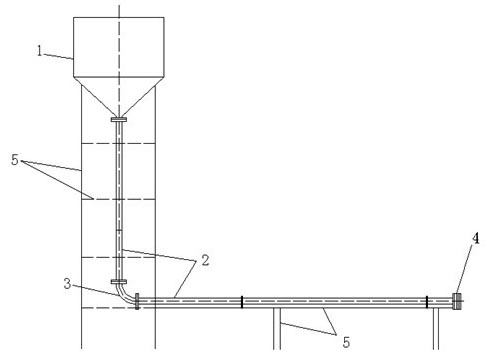

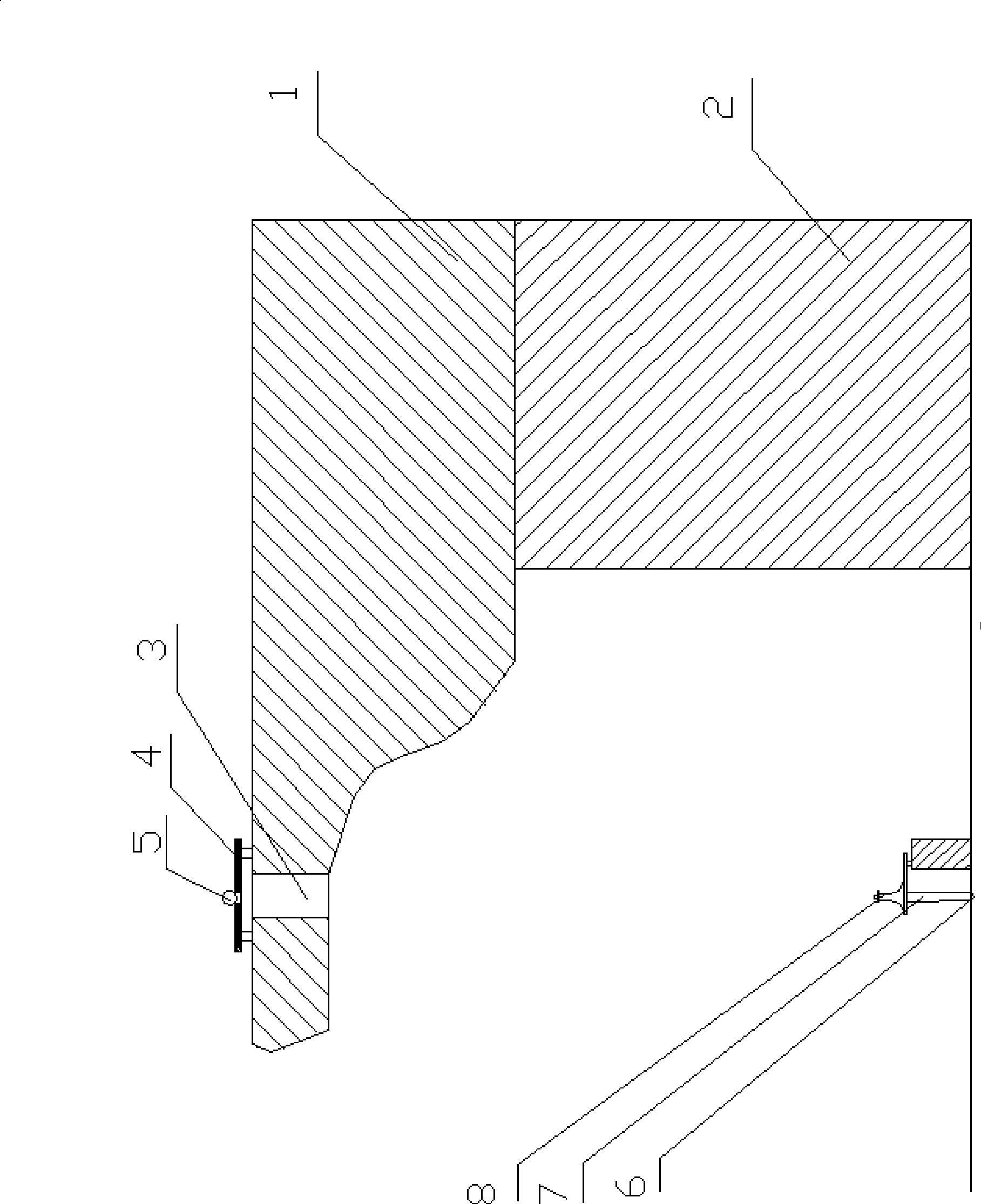

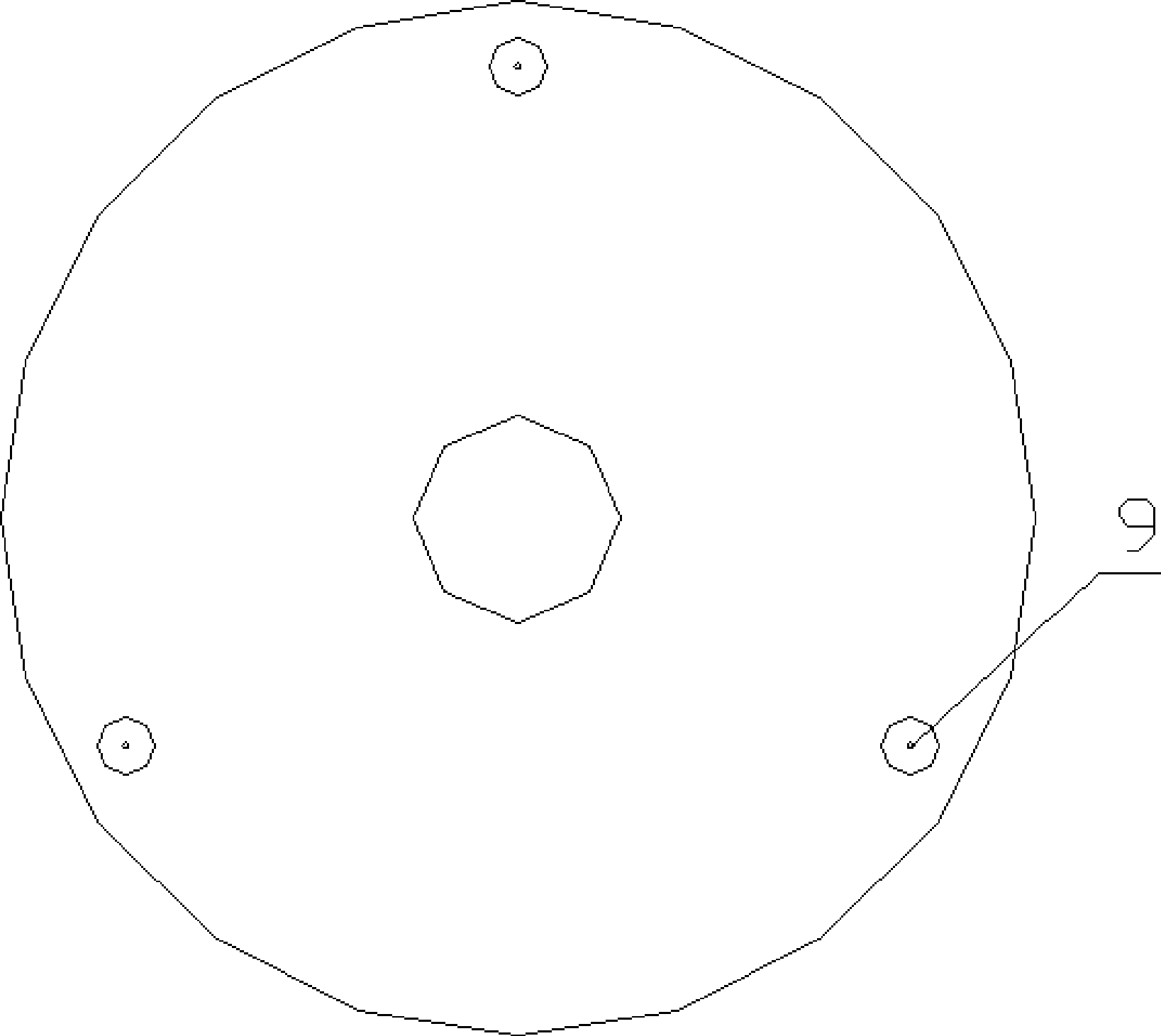

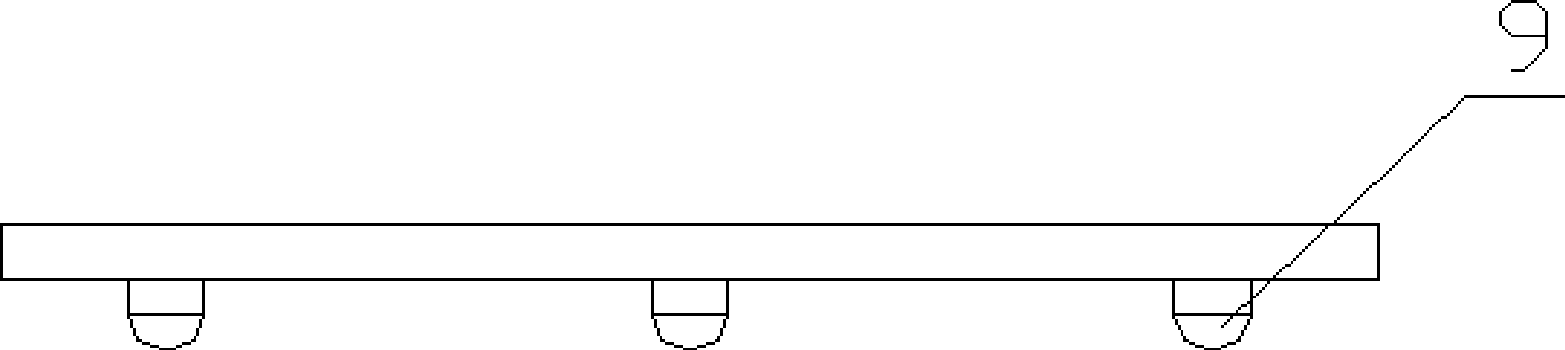

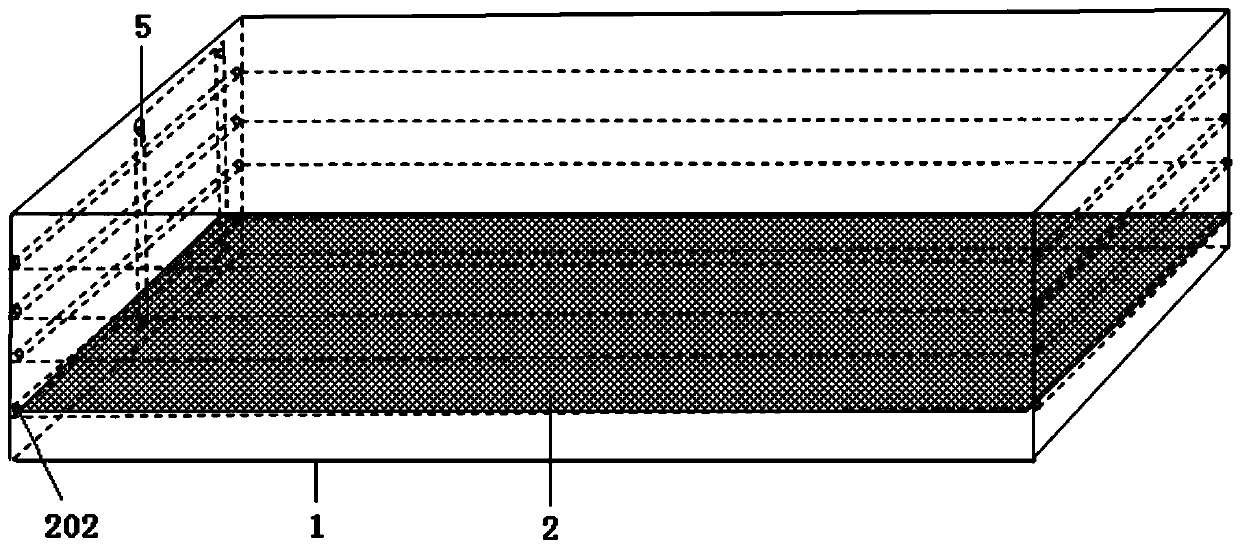

Mine-filling pipage test method and special equipment

InactiveCN102507138AEasy to operateMeet the design requirementsFlow propertiesHydrodynamic testingStopwatchMining engineering

The invention relates to a mine-filling pipage test method and special equipment, which belong to the technical field of cemented filling of full tailings of mines. The technical scheme is as follows: the special equipment comprises a hopper (1), a delivery pipe (2), a detachable pipeline stopper (4) and supports (5), wherein the delivery pipe is arranged on the supports and is provided with an L-shaped pipeline structure formed by a horizontal pipeline and a vertical pipeline; the hopper is vertically distributed and is connected with one end of the vertical pipeline of the delivery pipe; and the other end of the horizontal pipeline of the delivery pipe is provided with the detachable pipeline stopper. The test equipment disclosed by the invention is simple, is easy to operate and is dispensed with any on-line detection instrument, such as a concentration meter, a flowmeter, a pressure gauge, and the like; and only simple common measuring tools such as a stopwatch, a box ruler, and the like are needed, the flow characteristic of the tailings in the delivery process and on-way resistance losses of the pipelines can be mastered within a short time, the yield shear stress of slurry, the rheological factor of the slurry and resistance losses i of the pipelines at different flow rates are obtained, the requirements of mine-filling designs and the production are satisfied, the cost is low, and the popularization and the application are easy.

Owner:HEBEI IRON & STEEL GRP MINING +1

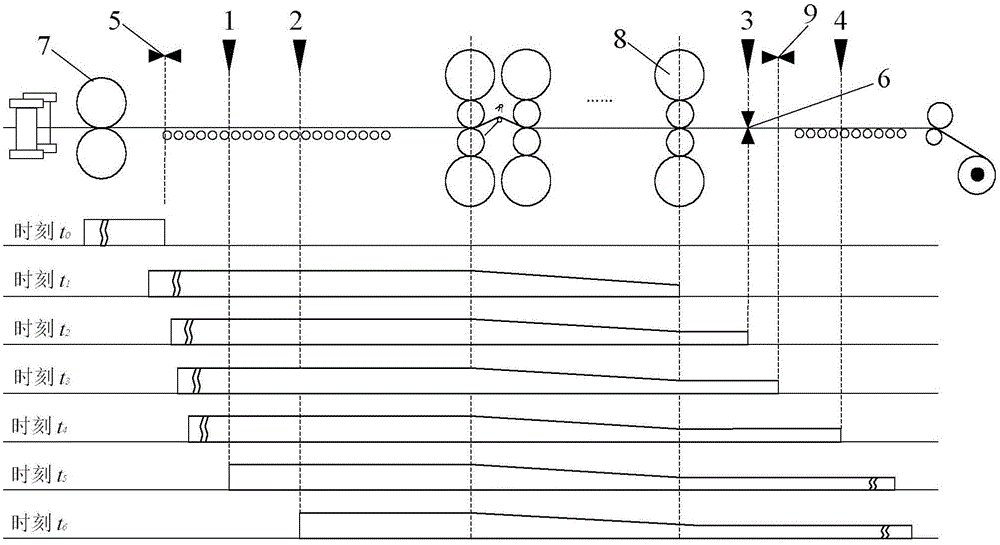

Hot continuous rolling intermediate billet thickness calculating method

ActiveCN105107849AHigh measurement accuracyGuaranteed measurement accuracyMeasuring devicesMetal rolling arrangementsContinuous rollingMaterials science

The invention provides a hot continuous rolling intermediate billet thickness calculating method. The method comprises the steps of measuring the width of a rolled piece during hot continuous rolling, measuring the thickness of the finish-rolled piece, and detecting the thermal signal of the rolled piece in real time; calculating the average velocity, average thickness and average width of the head of the finish-rolled piece; calculating the flow rate per second of the head of the finish-rolled piece according to the average velocity, average thickness and average width of the head of the finish-rolled piece; calculating the average velocity of the tail of the rolled piece and the average width of the tail of the rough-rolled piece; calculating the thickness of a rolled piece intermediate billet. According to the method, the average thickness of the rolled piece calculated according to the flow rate per second invariance principle can be taken as the actual thickness of the intermediate billet; accurate measurement of the thickness of the intermediate billet can be achieved through measured data obtained with a field instrument. By the adoption of the method, the thickness of the intermediate billet can be calculated accurately, and the problem that the thickness of the rough-rolled piece can not be measured when no thickness gauge is available is solved; productive investment cost is reduced, and thickness measurement accuracy is guaranteed.

Owner:NORTHEASTERN UNIV

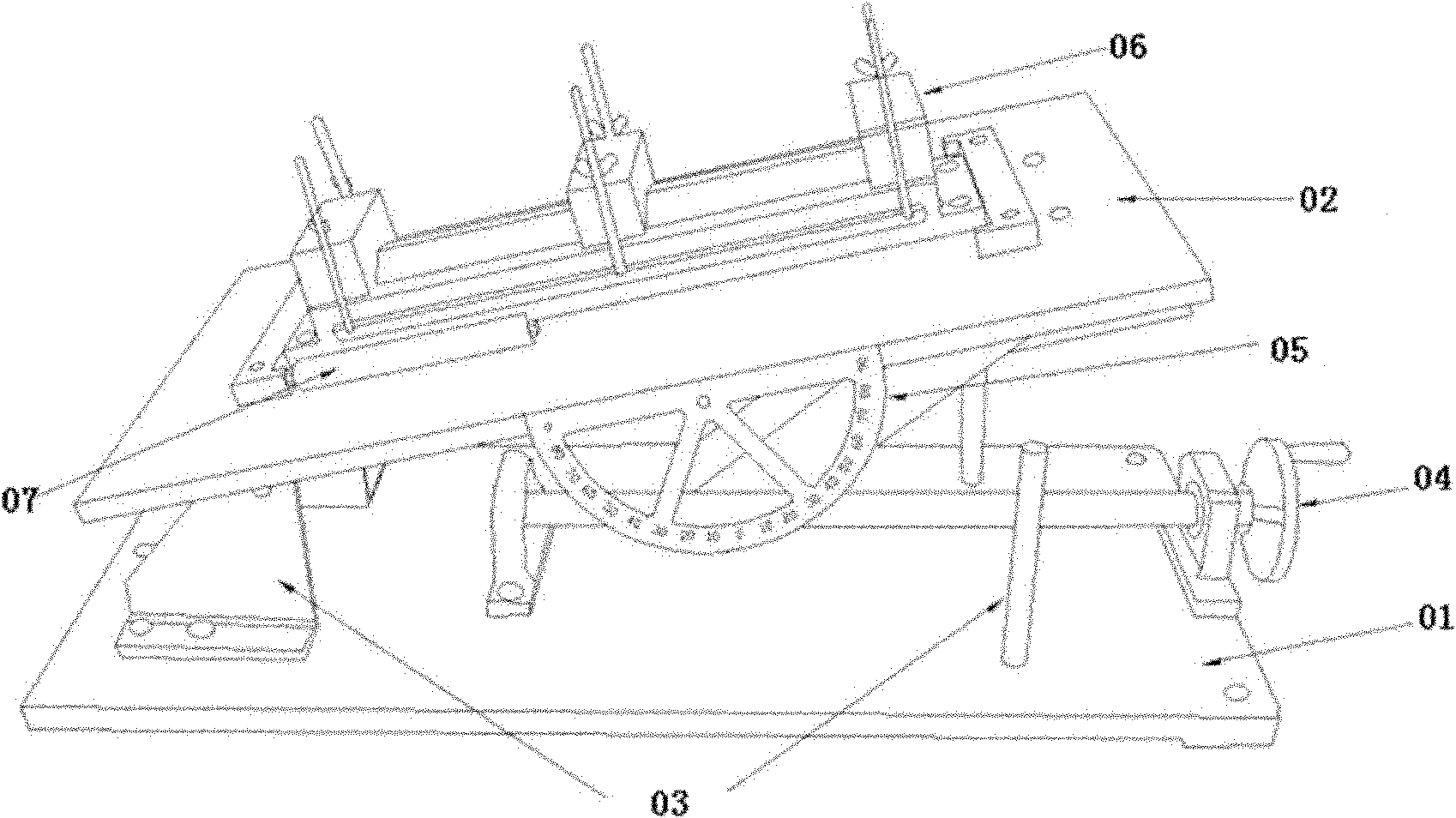

Measuring instrument of static friction coefficient of communication pipeline

InactiveCN102109459ASolve the defects of judging measurement resultsImprove accuracyUsing mechanical meansMaterial analysisStatic friction coefficientPush pull

The invention relates to a measuring instrument of static friction coefficient of a communication pipeline. A testing rack is provided with a platform; a clamping device and a measuring head push-pull device are arranged on the platform oppositely; a static friction transmission device is connected with the measuring head push-pull device; and when a spring in the static friction transmission device is displaced to a certain position, and the measuring head push-pull device starts to move, a push-pull force gauge on the measuring head push-pull device measures the static friction of a tested piece, and further calculates the static friction coefficient of the tested piece. The invention also discloses a method for carrying out static friction coefficient test and carrying out magnitude tracing on the existing measuring instrument by adopting the static friction coefficient of the communication pipeline. In the invention, the integration level is high, the measurement is accurate, and the defect that the existing measuring instrument adopts the process of observing and measuring by naked eyes to judge a measured result subjectively. By utilizing the measuring instrument disclosed by the invention, the existing measuring instrument also can be calibrated, so that the accuracy of magnitude tracing of the existing measuring instrument is improved and further the quality of communication pipeline engineering is guaranteed.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

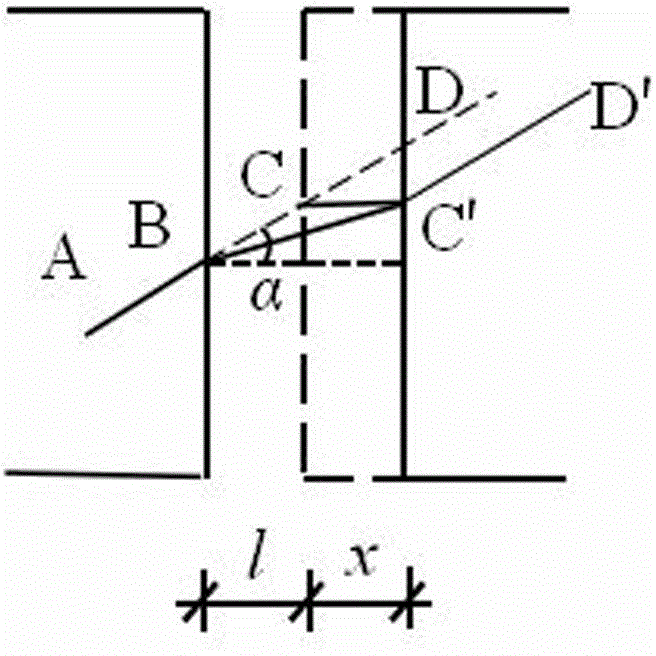

Long-gauge FBG (Fiber Bragg Grating) based settlement joint two-dimensional deformation and opposite inclination monitoring method

ActiveCN104613886AEasy to analyzeReal-time 2D deformationUsing optical meansFiber Bragg gratingEngineering

The invention relates to the settlement joint two-dimensional deformation detection technical field, particularly to a long-gauge FBG (Fiber Bragg Grating) based settlement joint two-dimensional deformation and opposite inclination monitoring method which aims at overcoming the defects that the deformation detection error is large and detection data are discontinuous in the actual use process of settlement joints in the prior art. A long-gauge FBG sensor is distributed and an average strain equation of the horizontal direction, the vertical direction and the two-dimensional deformation after the movement of a settlement joint is listed to solve the opening distance x of the settlement joint in the horizontal direction and the dislocation distance y of the settlement joint in the vertical direction. Compared with the traditional manual instrument monitoring, the long-gauge FBG based settlement joint two-dimensional deformation and opposite inclination monitoring method is high in test accuracy and continuous in data and can be popularized and utilized in engineering.

Owner:SHIJIAZHUANG TIEDAO UNIV

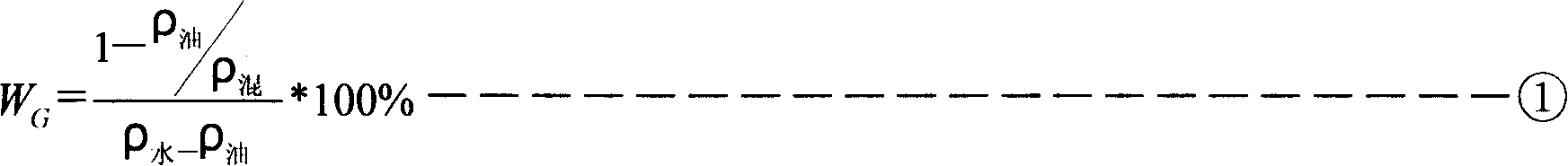

Timing method three phase metering separator

A separator capable of measuring three phase of oil, gas and water in-phase is provided. In the process of measuring, only three time parameters displayed by three level gauge are marked and the measure of oil, gas and water is finished without using other specialties instrument. Weigh (ton) and volume (square) are obtained in-phase by time measuring of constant altitude of level gauge of mix solution and corresponding column level gauge, and the parameter Rho mix=t1 / t2*Rho water which is most difficult to calculate by consistency method for measuring water content is obtained and the content of water is calculated conveniently. The gas production is measured by zero position gauge timing of emission chamber, and the timing method of oil, gas and water is obtained. Three-chamber structure, pull rod valve, pneumatic valve and electromagnetic valve are combined with measuring signal, the switch of series measure is finished by self energy, and the frock match and cost of three-phase measure are simplified. In addition, many infection factors of water content measuring of consistency method is eliminated in technics and precision of water content measuring is ensured.

Owner:常荫铎

Composite calibration/verification gauge and method of its manufacture

InactiveCN102124298AEasy to operateSimple structurePlug gaugesApertured gaugesMeasuring instrumentSoftware engineering

The present invention relates to a combination calibration / verification gauge for calibrating measuring instruments with a measurement precision. More particularly, the present invention relates to a multi-function, multi-dimension length standard and works as a working standard to compare various measuring instruments on the shop floor.

Owner:沙拉卜・库马尔・拉斯托吉

Measuring method and apparatus for accurately transmitting ground bench level to overhead viaduct

InactiveCN101464146AHigh precisionObservation conditions are relaxedHeight/levelling measurementTotal stationPrism

The invention provides a measurement method for accurately transmitting the ground bench level onto a high-level bridge. The measurement method comprises the following steps: 1) projecting the centers of the effective aperture or the space of drain holes or beam crevices to the ground, pre-burying a measuring nail thereon, and gravitationally measuring the level thereof from the bench of a known level through a level gauge; 2) mounting a diagonal eyepiece on the eyepiece of a total station instrument, and rotating the total station telescope to the vertical direction; 3) placing a flat plate on the drain holes or the beam crevices, and placing a measuring prism on the circular hole of the flat plate; 4) ranging the center of the measuring prism, and acquiring the average value of qualified observed values for a plurality of times; 5) observing the difference in height from the vertex of the measuring prism to the CPIII point at the top end of a bump wall; and 6) processing data to acquire the level HCPIII of the CPIII point at the top end of the bump wall. The invention has the advantages that the difficult problem in directly transmitting the bench level to the viaduct can be solved; the accuracy is high; the requirement for observation conditions is low; and the operation is easy.

Owner:成都十九号极速文化传播股份有限公司

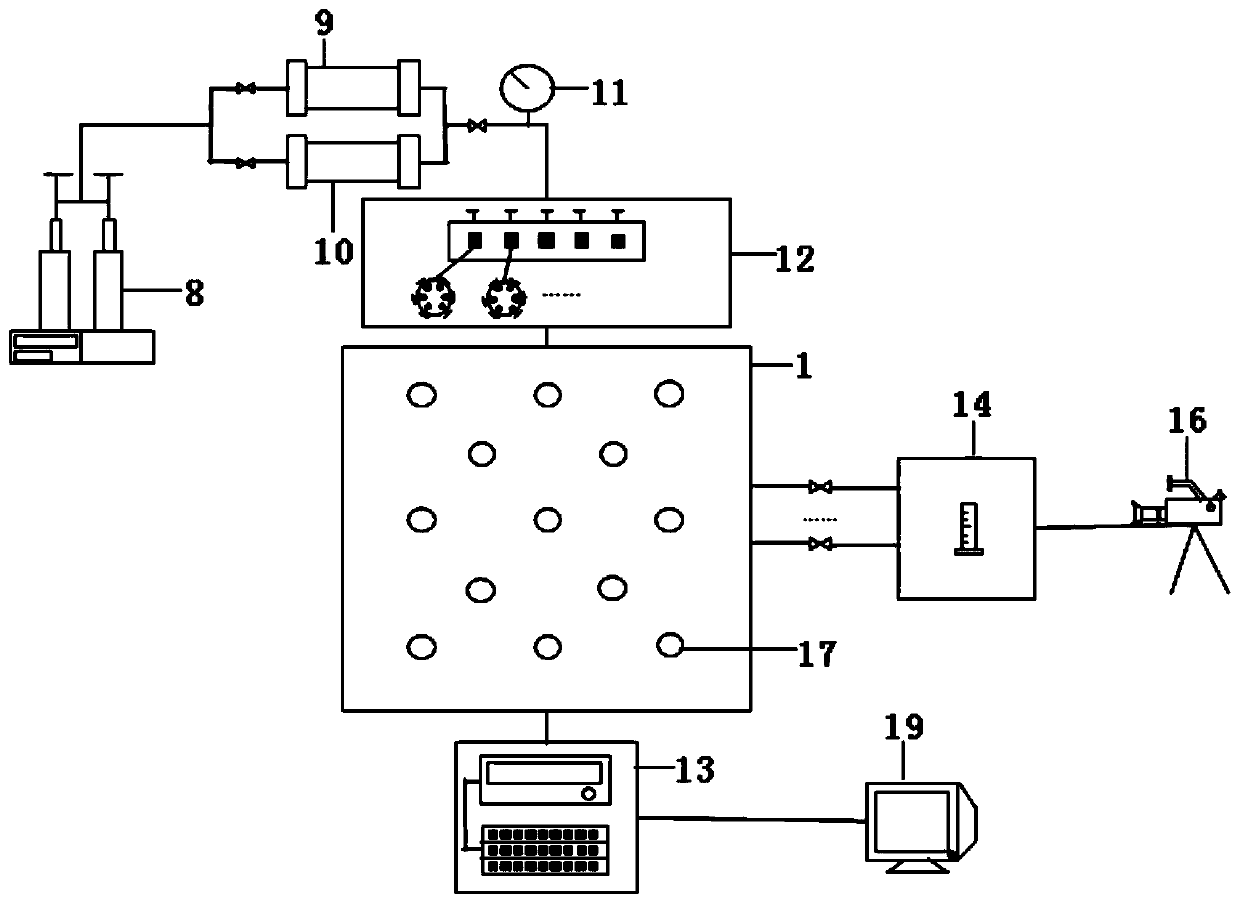

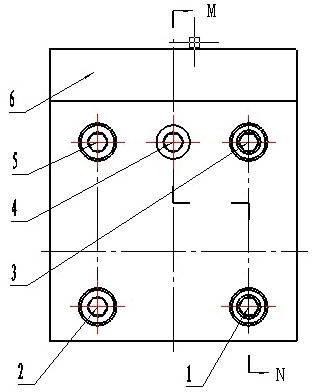

Three-dimensional heterogeneous oil-reservoir multi-well-pattern mode water flooding physical simulation experiment device

ActiveCN111022010AReduce the difficulty of filling and fillingStable in natureFluid removalWater storage tankWater production

The invention discloses a three-dimensional heterogeneous oil-reservoir multi-well-pattern mode water flooding physical simulation experiment device. The three-dimensional heterogeneous oil-reservoirmulti-well-pattern mode water flooding physical simulation experiment device comprises a reservoir simulation system, an injection system and an experimental measurement system, wherein the injectionsystem and the experimental measurement system are separately connected with the reservoir simulation system. The reservoir simulation system comprises an experiment box, an insulating filter screen and a measurement electrode. The insulating filter screen is detachably arranged to divide the experiment box into multiple layers; the injection system comprises an injection pump, an oil-and-water storage tank, a pressure gauge and a multiported valve, wherein the injection pump, the oil-and-water storage tank, the pressure gauge and the multiported valve are connected in sequence; the oil-waterstorage tank is connected with each layer of the experiment box through the multiported valve and an injection pipeline; and the experimental measurement system comprises a multi-channel resistance measurement instrument and a flow measurement system, wherein the multi-channel resistance measurement instrument is connected with the measuring electrode, and the flow measurement system is connectedwith each layer of the experiment box through discharging pipelines. According to the three-dimensional heterogeneous oil-reservoir multi-well-pattern mode water flooding physical simulation experiment device, multi-layer filling and leveling degree is ensured, the development of an interlayer can be more accurately simulated, the oil-and-water production can be measured in layers under the simulated multi-well-pattern mode, and the resistance is measured in real time to obtain the saturation distribution.

Owner:SOUTHWEST PETROLEUM UNIV

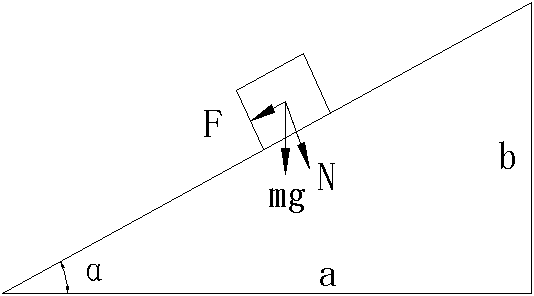

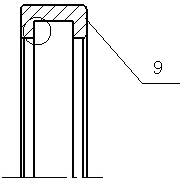

Method and device for measuring angle of flange

ActiveCN102322785AImprove accuracyImprove stabilityAngles/taper measurementsMeasurement deviceAngular degrees

The invention relates to the technical field of bearing measurement and discloses a method and device for measuring the angle of a flange; the method comprises the following steps of: converting the angle measurement into the straightness measurement, using a sine instrument for direct measurement when a is larger than or equal to 45 degrees or is less than or equal to 90 degrees, enabling the end surface of a workpiece 9 to be close to the locating 'D' surface of the vertical stand column; adopting the 'B' surface of a transverse plate of a straightness measurement device when a is larger than or equal to 0 degrees or is less than or equal to 45 degrees, placing a block gauge 13 under a locating stand column 11, converting the locating 'D' surface of the stand column into a locating surface which is parallel to the guide rail 12, enabling the end surface of the workpiece to be close to the 'B' surface of the transverse plate of the straightness measurement device, and using a gauge needle on a measuring gauge 14 on a guide rail 12 for contacting a measured surface, wherein the height deviation indicated by the measuring gauge is an included angle error between an inclined surface and the reference end surface; and the invention can enable the accuracy of measurement on the included angel between the flange and a reference end surface in the cylinder roller bearing production process to be higher and the stability to be better. The invention is not affected by the size of chamfering of the flange, the parallel error of the flange and the experience of survey crews.

Owner:中浙高铁轴承有限公司

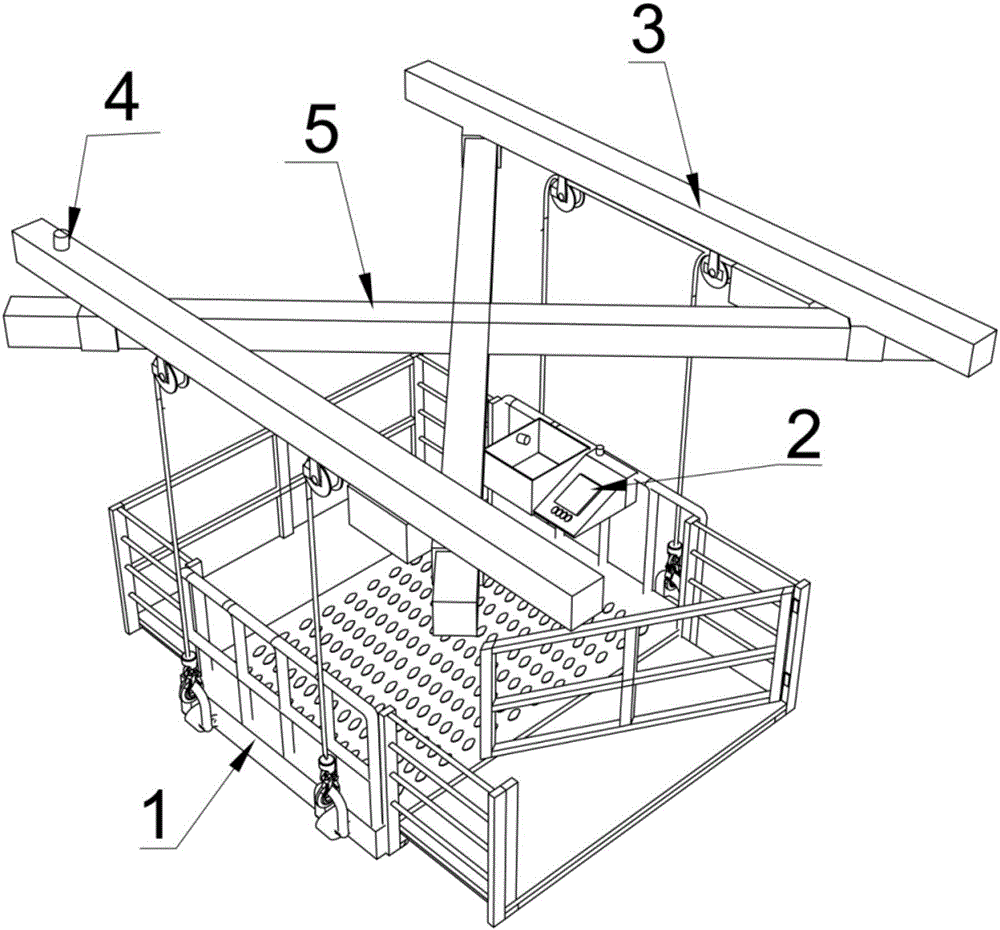

Multi-azimuth regulating type operation platform based on construction field and construction method of multi-azimuth regulating type operation platform

PendingCN106812300AIncrease the use of spaceReasonable structural designBuilding support scaffoldsMeasuring instrumentControl engineering

The invention provides a multi-azimuth regulating type operation platform based on a construction field and a construction method of the multi-azimuth regulating type operation platform. The platform includes an operation platform body, an operation control platform, a lifting device and a wind speed measuring instrument. A balance inductance gauge is arranged on the operation platform body and used for detecting the horizontal balance condition of the operation platform body in real time and feeding back a detected signal to the operation control platform; the lifting device is provided with a hook device and fixedly connected with the operating platform body through the hook device, and the operating platform body is spatially perpendicular to the lifting device; the wind speed measuring instrument is arranged on the upper surface of the lifting device and used for detecting the wind speed condition of a work environment in real time and feeding back a detected signal to the operation control platform; the operation control platform is arranged on the side wall of the operation platform body and used for receiving the detected signals of the balance inductance gauge and the wind speed measuring instrument and controlling the operation platform body to move up and down through the lifting device. The operation platform is convenient to adjust, high in turnover efficiency, simple in operation, high in safety performance and wide in application range.

Owner:SUNYOUNG CONSTR GROUP

Shaft length and inner bore size detection device in shaft detection equipment

ActiveCN107121105AGuaranteed accuracyAccurate detectionUsing fluid meansMeasuring instrumentAir pump

The invention provides a shaft length and inner bore size detection device in shaft detection equipment, belongs to the technical field of measurement, and solves the technical problem that there is no corresponding automatic device for shaft detection at present. The shaft detection equipment comprises a work bench and a measurement bench. The detection device comprises a detection air pump, an airtightness measuring instrument and three detection bases arranged on the measurement bench. Central spindles of the three detection bases can rotate synchronously through a rotation structure; the work bench is provided with a station transfer device; the work bench is fixedly provided with an upper distance sensor and a lower distance sensor; each detection base can be moved to a place between the upper distance sensor and the lower distance sensor; the work bench is also fixedly provided with two pneumatic gauge heads and a lift frame; the detection bases can be moved to the space right above the two pneumatic gauge heads; the detection air pump is connected with the airtightness measuring instrument through an air pipe; and the airtightness measuring instrument is connected with the pneumatic gauge heads through air pipes. The detection device has the advantage of realizing accurate measurement of the shaft length and the inner bore size.

Owner:嘉兴晟友机械科技有限公司

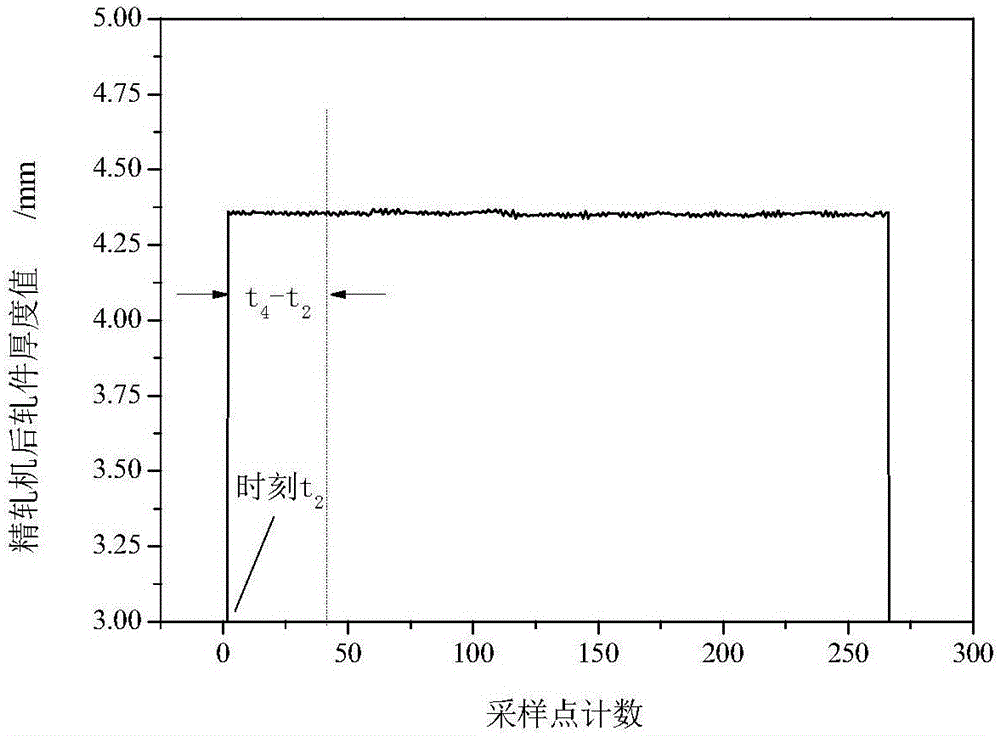

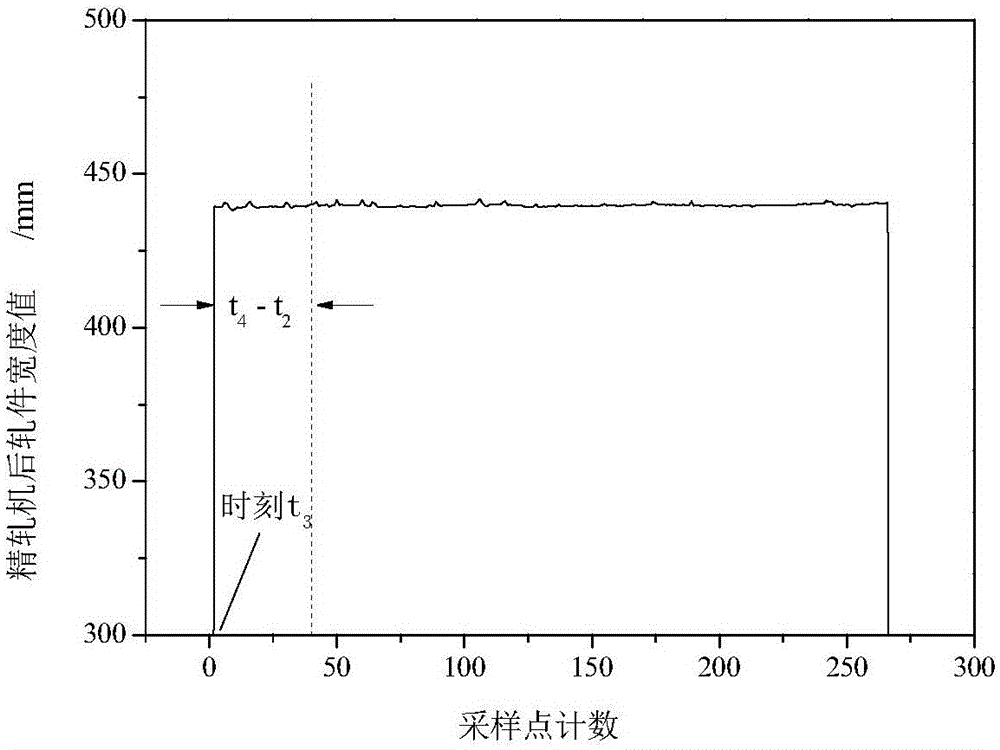

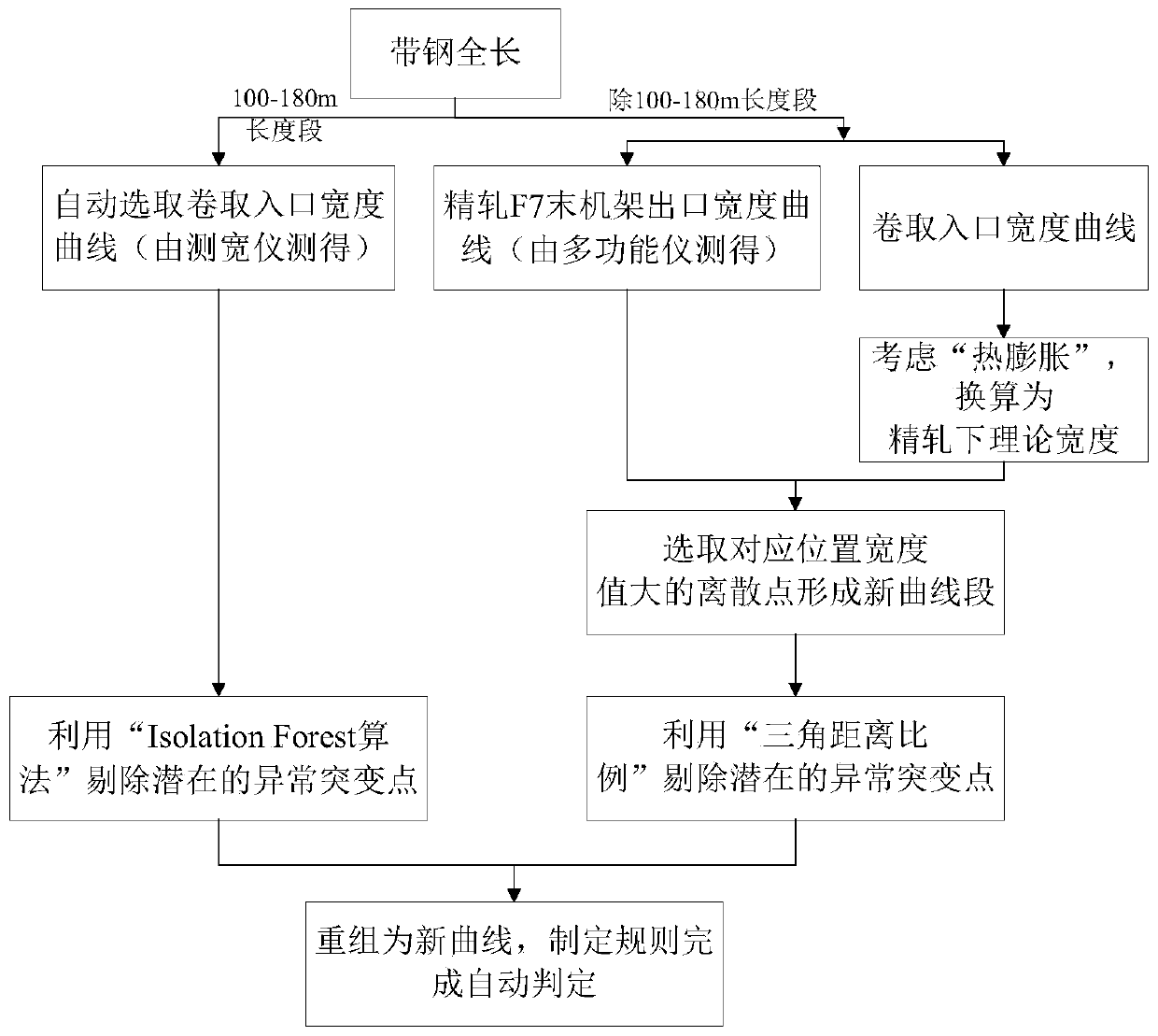

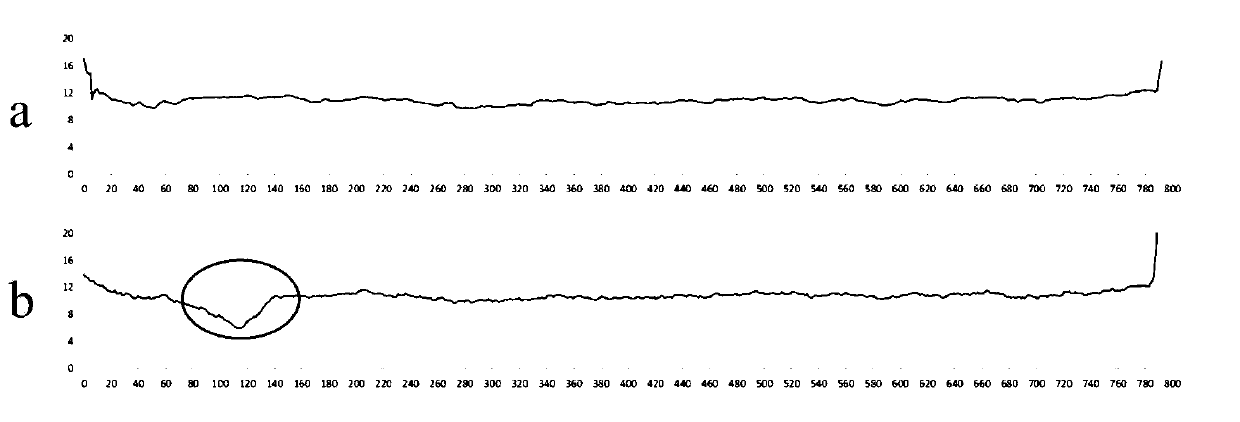

Automatic evaluation method and system for width quality of hot-rolled strip steel

ActiveCN111080054ARealize automatic judgmentRealize early warningMetal rolling stand detailsRoll mill control devicesThermal dilatationStrip steel

The invention provides an automatic evaluation method and system for the width quality of hot-rolled strip steel. The method comprises the steps of collecting a first width curve measured by a multifunctional instrument and a second width curve measured by a width measuring instrument, wherein the multifunctional instrument is arranged at an outlet of a finish rolling tail rack, and the width gauge is arranged at a coiling inlet; converting a width value in the second width curve into a theoretical width in a finish rolling state based on thermal expansion coefficients of a finish rolling areaand a coiling area of the strip steel to obtain a third width curve; recombining the first width curve and the third width curve to obtain a strip steel width curve; and analyzing the strip steel width curve by utilizing a preset strip steel width quality judgment system to obtain a strip steel width quality judgment result. According to the method, the width quality problem caused by process defects can be discovered, the influence of instrument distortion on width curve identification is eliminated, manpower can be liberated, the efficiency is improved, and the omission ratio is reduced.

Owner:UNIV OF SCI & TECH BEIJING

Method of determining reservoir pressure

A new approach is disclosed for measuring the pressure of tight gas reservoirs, using information obtain from continuous injection prior to hydraulic fracture stimulation. The technique can be obtained utilizing either bottom-hole or surface pressure gauges and properly instrumented surface injection pumps. The analysis is completed by plotting injection and rate data in a specialized form from terms arranged in Darcy's radial flow equation to obtain a curve or trend. The key component to proper application of this technique is to obtain both baseline and one or more calibration data sets. These calibration data sets are obtained by either increasing or decreasing the injection pressure and / or rate from the baseline data. Initial reservoir pressure is assumed, but the calibration data indicates if the guess was too high or low. Accurate estimates of reservoir pressure may be obtained in a few iterations.

Owner:BP CORP NORTH AMERICA INC

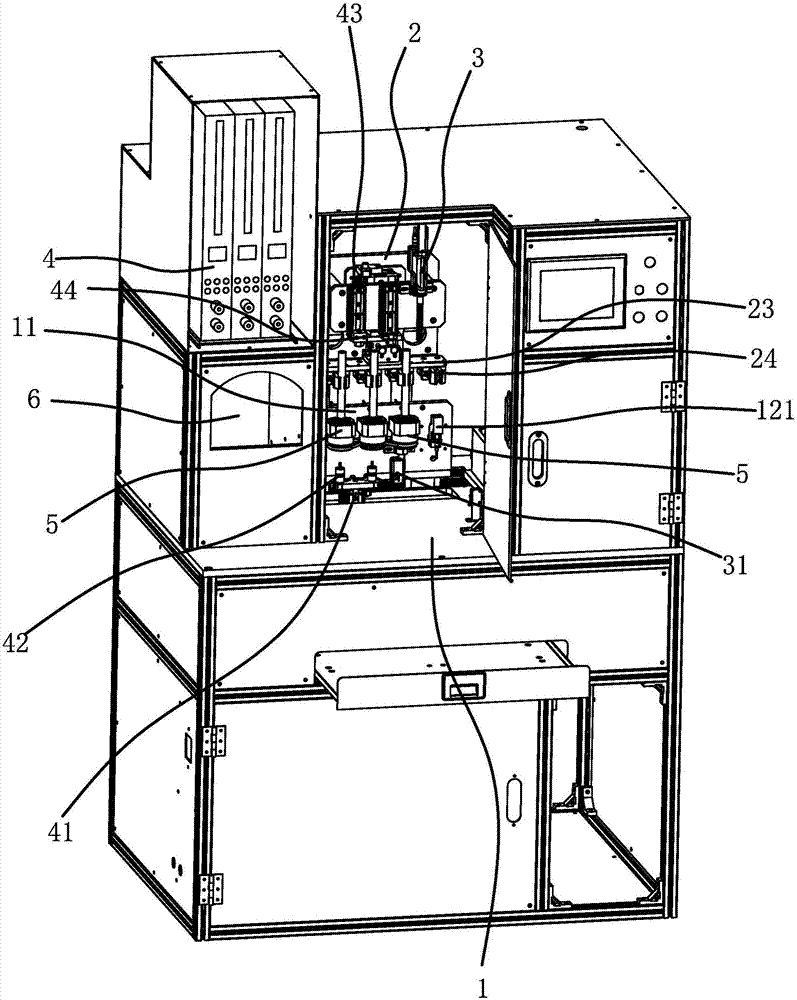

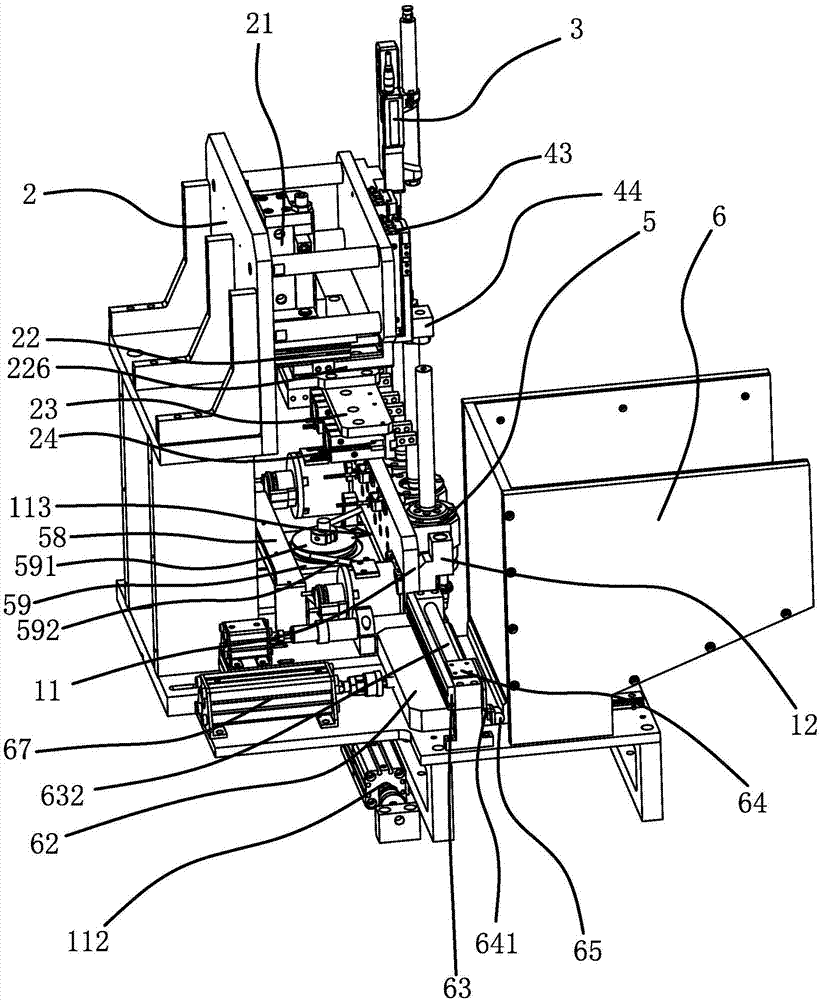

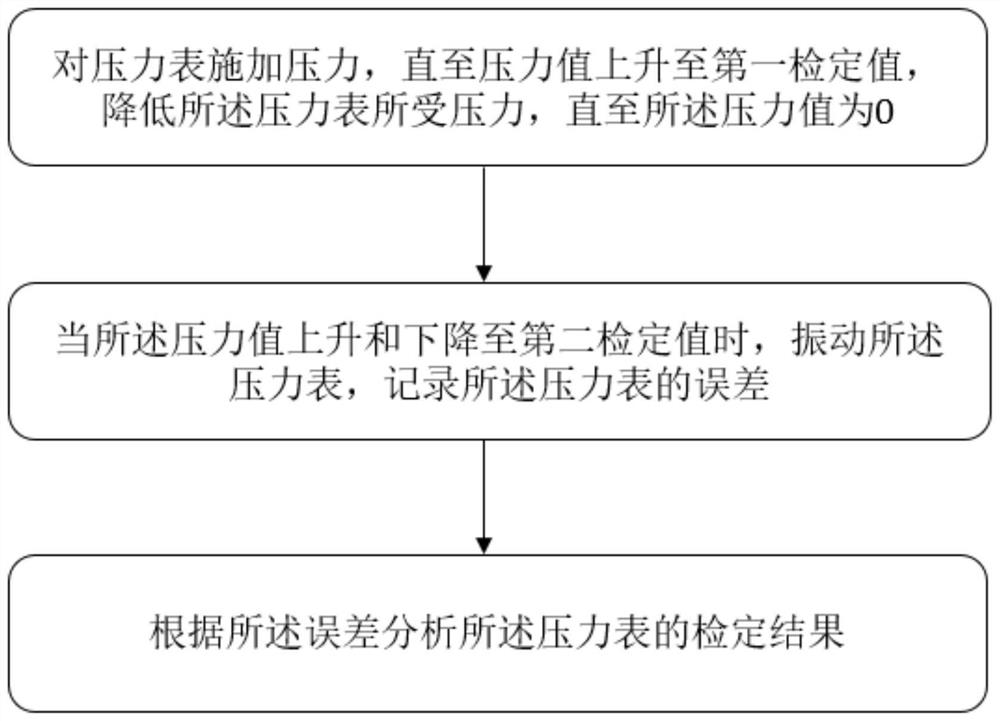

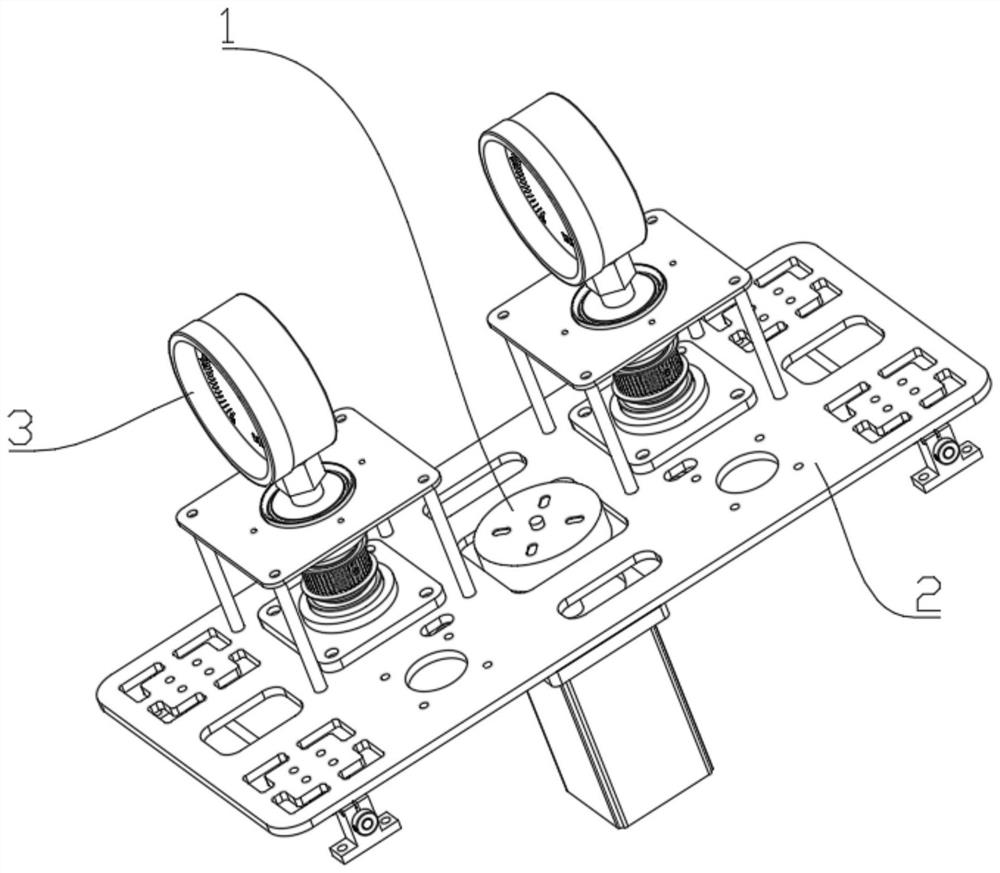

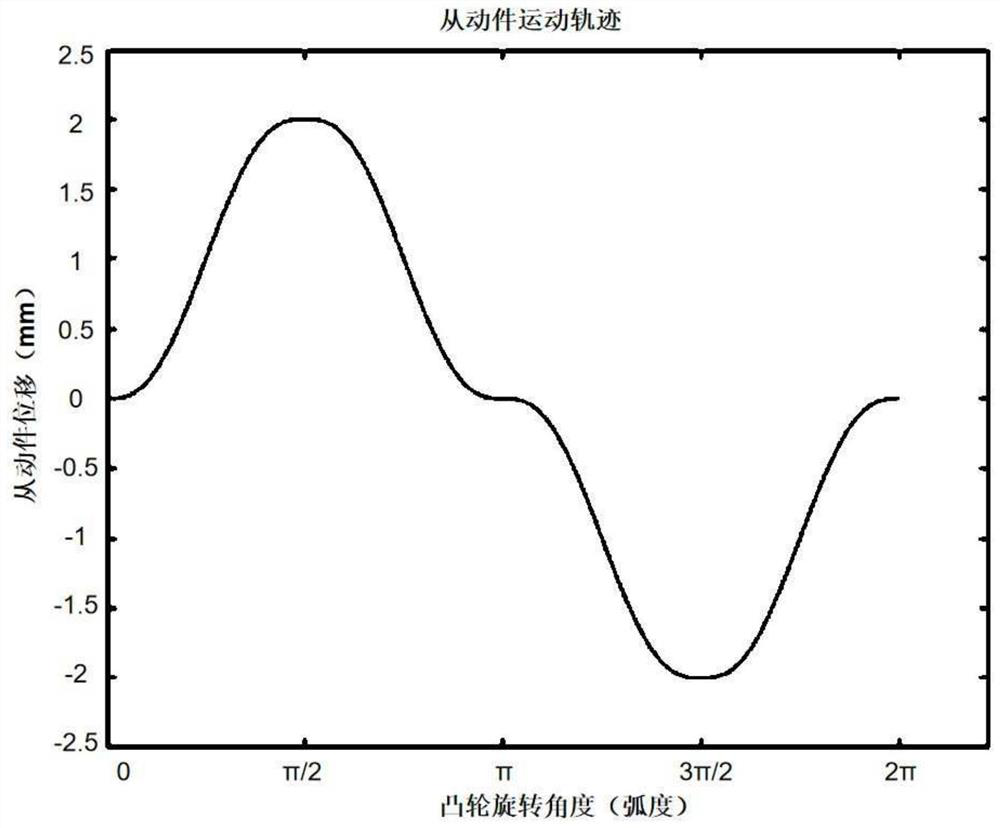

Verification method and verification system of pressure gauges

ActiveCN113063543AHigh degree of automationQuality improvementFluid pressure measurementForce/torque/work measurement apparatus calibration/testingGauge (instrument)Verification system

The invention belongs to the field of instrument verification and relates to a verification method and a verification system of pressure gauges. According to the verification method of the pressure gauges provided by one embodiment of the invention, the loading and unloading of the pressure gauges can be automatic by controlling the pressure gauges to be transmitted in specific postures, the improvement of the automation degree of the pressure gauges can be facilitated; when errors of the pressure gauges are obtained, vibration is used for replacing manual tapping operation, the multiple pressure gauges can be calibrated at the same time, and the calibration efficiency is improved. The calibration system of the pressure gauges is provided to achieve the calibration method and improve the automation degree of the calibration of the pressure gauges.

Owner:金仪计量科技(苏州)有限公司

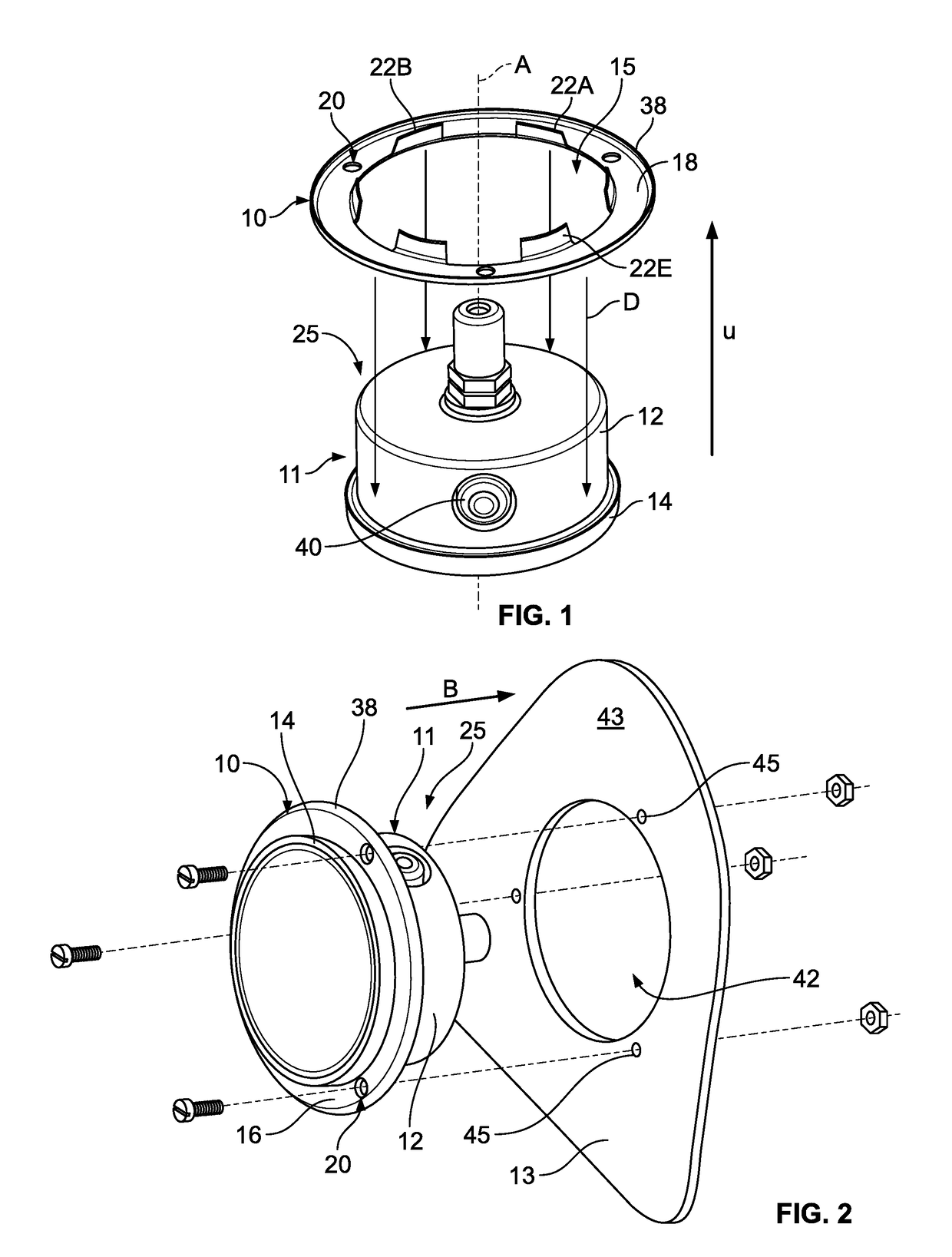

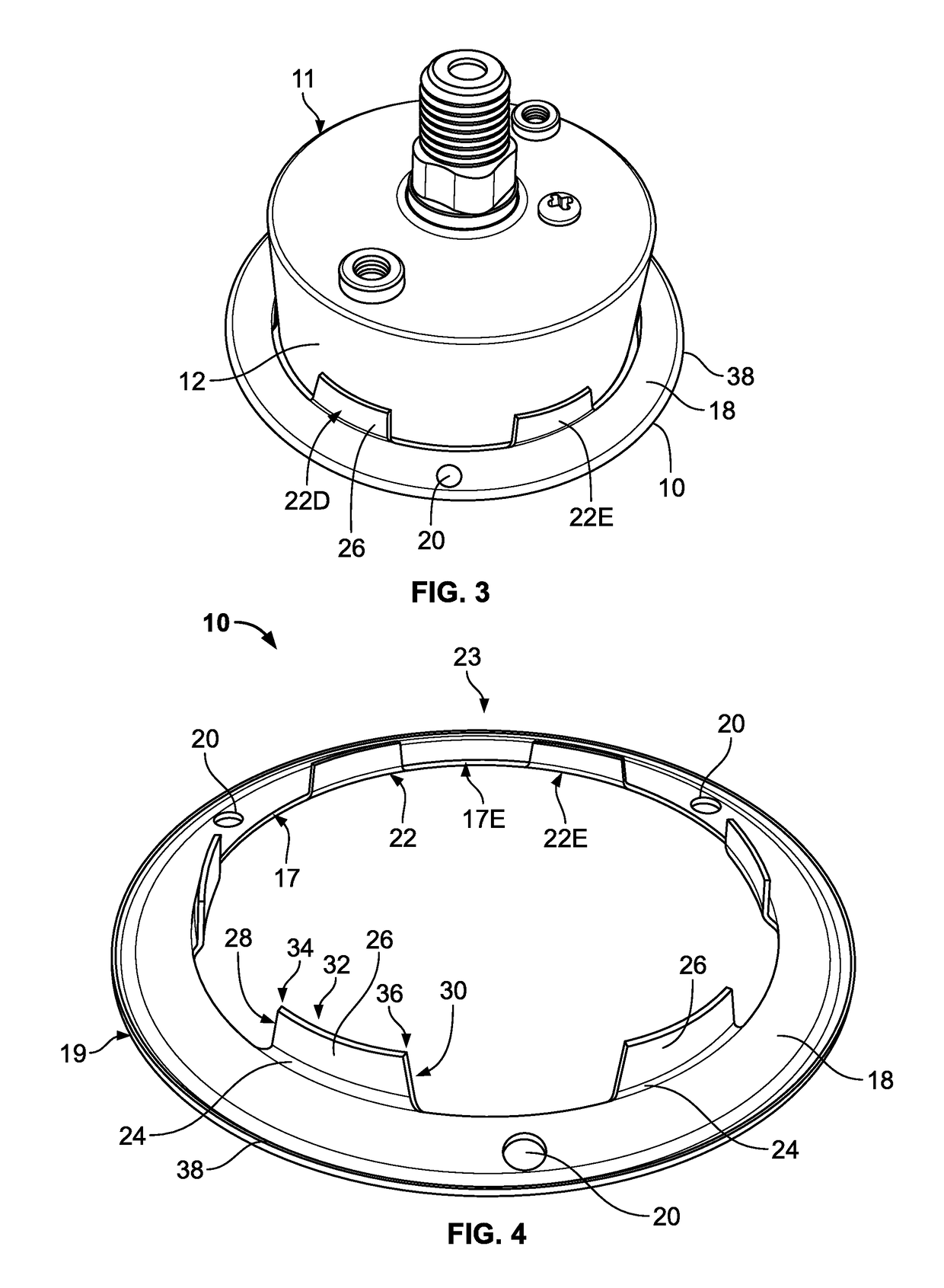

Mounting flange for measuring devices

InactiveUS20180172519A1Securely holdThermometer detailsFluid pressure measurementEngineeringInstrumentation

Advantageous mounting flanges for measuring devices and related methods of use are provided. The present disclosure provides advantageous mounting flanges configured to be mounted to measuring devices / instruments (e.g., pressure or temperature measuring devices / instruments), and related methods of use. More particularly, the present disclosure provides advantageous systems / methods for the design and use of user-friendly press-on mounting flanges configured to be mounted to pressure and temperature instruments (e.g., to the case of pressure or temperature gauges) to allow the instruments to be secured to a supporting structure (e.g., to a panel) via the mounting flanges. Disclosed herein is an advantageous mounting flange configured to be mounted to a case of a measuring device / gauge, thereby allowing the measuring device / gauge to be mounted to and held in a panel via the mounting flange. As such, the gauge case mounting flange is configured to hold the measuring gauge in place in the panel.

Owner:ASHCROFT

Method for checking height difference between joints of cross arms for cross arms of dual-column pole tower

InactiveCN102023001ASolve problems with measurement inspectionsFast placementHeight/levelling measurementMechanical measuring arrangementsElevation angleTheodolite

Owner:ELECTRIC POWER OF HENAN LUOYANG POWER SUPPLY +1

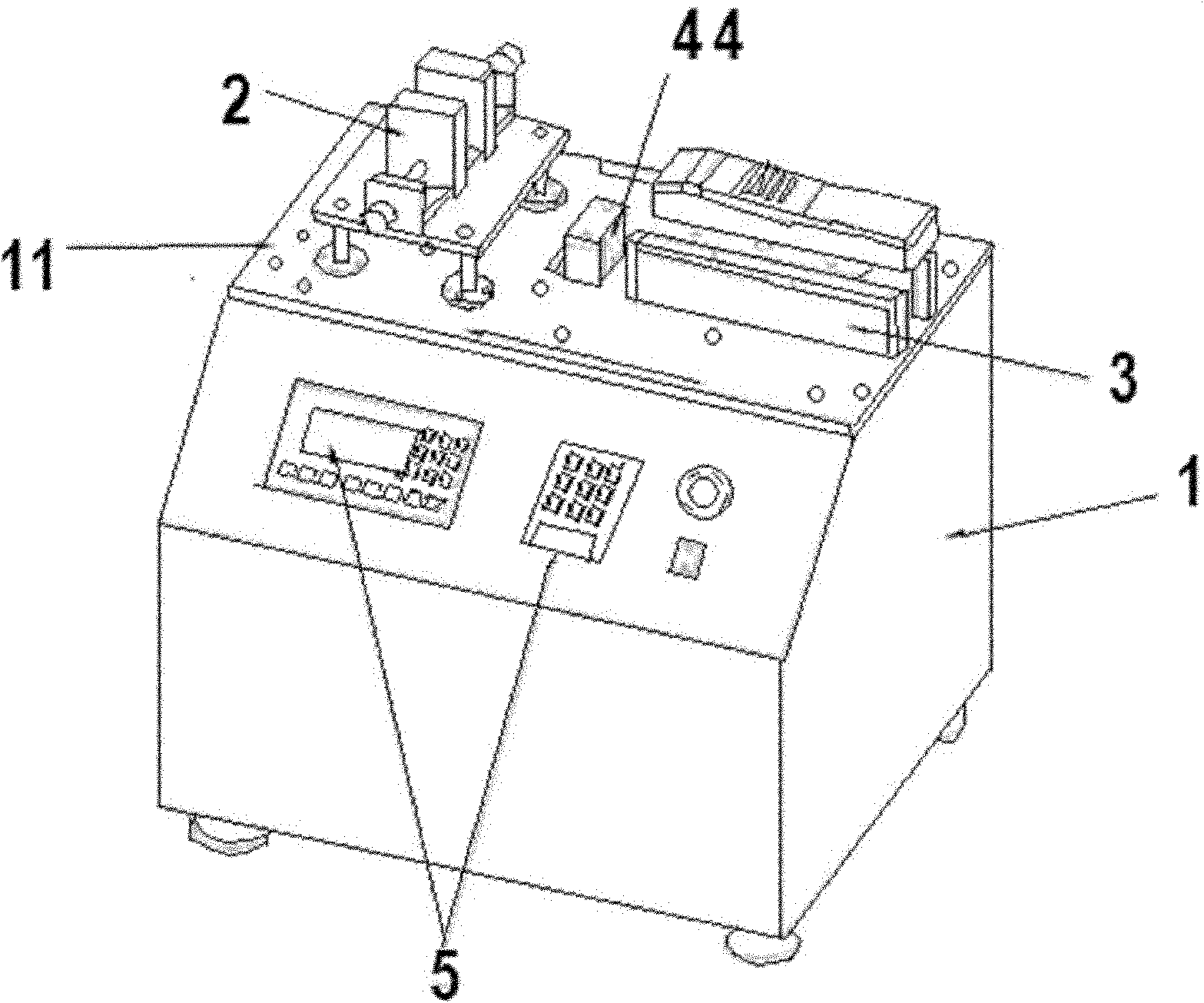

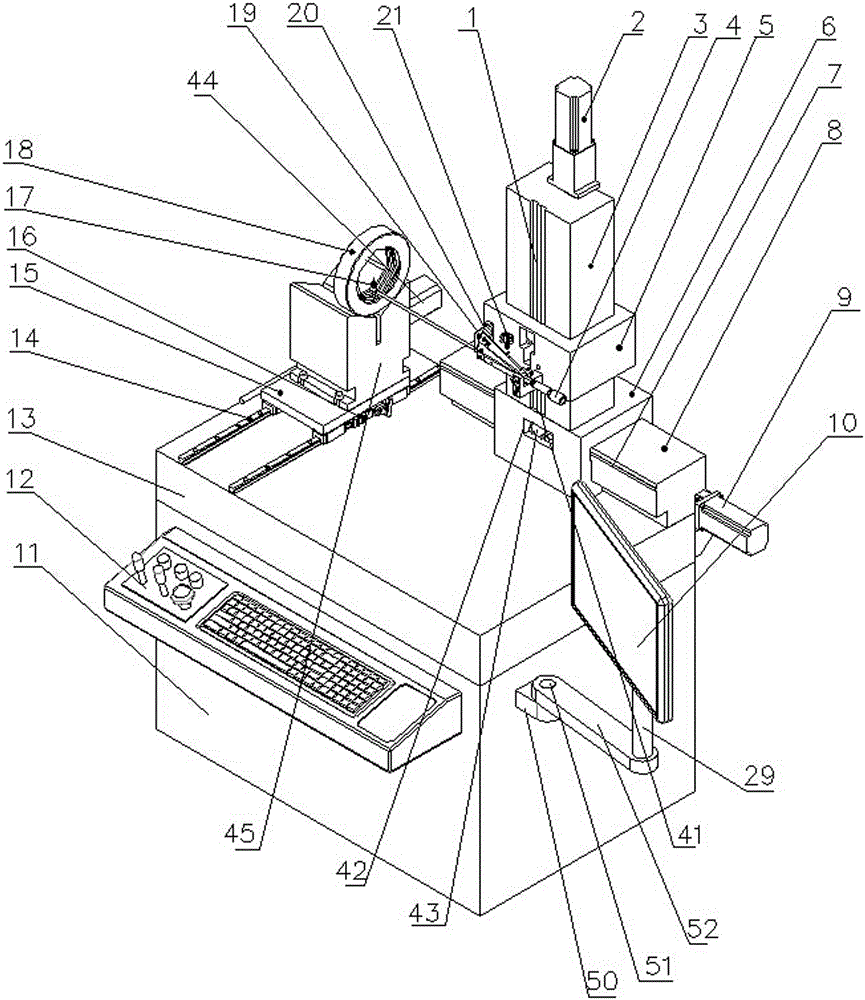

Novel semi-automatic screw gauge integrated measuring instrument

ActiveCN105091690AReduce procurement costsShorten the manufacturing cyclePlug gaugesApertured gaugesGratingMeasuring instrument

The invention discloses a novel semi-automatic screw gauge integrated measuring instrument, and relates to a novel semi-automatic screw gauge integrated measuring instrument. The front end and the rear end of a vertical air floatation guide rail support column 8 are connected with a vertical raster 7, the vertical air floatation guide rail support column 8 is connected with a longitudinal slide rack 6 in a sleeved mode, the longitudinal slide rack 6 is connected with an upright column 3, the top surface of the upright column 3 is connected with a vertical driving servo motor module 2, the central line of the front surface of the upright column 3 is connected with an upright raster 1, the top end of the longitudinal slide rack 6 is provided with a longitudinal slide rack groove 41, the upright column raster 1 is installed in the longitudinal slide rack groove 41, the front surface of the longitudinal slide rack groove 41 is provided with a longitudinal slide rack port 42, the bottom surface of the upright column 3 is connected with a transverse slide block, the transverse slide block cooperates with a vertical raster 7 for application, the upright column 3 is connected with a vertical slide rack 5 in a sleeved mode, the vertical slide rack 5 is connected with a slide shaft 43, the slide shaft 43 cooperates with the upright column raster 1 for application, and the front surface of the vertical slide rack 5 is connected with a measuring module. The novel semi-automatic screw gauge integrated measuring instrument is applied to screw gauge integrated measurement.

Owner:HARBIN FU RUIDA AIRLINE MACHINERY CO LTD

Valve lock clamping groove profiling clamping plate

PendingCN112985217AImprove detection efficiencyIncrease the frequency of self-inspectionMechanical measuring arrangementsEngineeringGauge (instrument)

The invention discloses a valve lock clamping groove profiling clamping plate, which comprises a clamping plate body, a no-go gauge is arranged at one end of the clamping plate body, a go gauge is arranged at the other end of the clamping plate body, the no-go gauge is a rectangular groove, the two sides of a notch of the no-go gauge are each provided with a semicircular protrusion, and the go gauge is in the shape of a rectangular groove. The two sides of the go gauge notch are respectively provided with a semicircular protrusion. The novel profiling clamping plate for the valve collet groove is convenient to use and can be used by training common operators slightly without professional training guidance; the clamping plate is placed on a testing fixture table beside production equipment, so that the size of a product lock clamping groove can be measured at any time, and convenience and rapidness are achieved. The detection efficiency is improved, the production efficiency is also improved, the self-inspection detection frequency of an operator can be improved, and the risk of batch rejection in the machining process can be prevented. By using the novel valve collet groove profiling clamp, the use frequency of a high-precision instrument universal mirror in a laboratory can be reduced, and the cost is saved to a certain extent.

Owner:江苏沃得机电集团有限公司

Temperature-controlled type unsaturated soil consolidometer

InactiveCN102221601BReal-time monitoring of lateral deformationImprove sealingEarth material testingMaterial strength using repeated/pulsating forcesSoil scienceSuction stress

The invention discloses a temperature-controlled unsaturated soil consolidation instrument, which can be used in the manufacture of geotechnical engineering measuring instruments. The device includes a combined pressure chamber with a bidirectional motion loading pressure piston, a flow guide system, a displacement gauge and a laser measuring device, and heat-conducting oil is injected into the interlayer chamber between the outer side of the combined pressure chamber and the outer transparent sleeve. , and equipped with thermocouples and heating rods to control the temperature inside the pressure chamber. The instrument can be used to measure the suction of unsaturated samples at different temperatures by using the filter paper method to measure the suction; it can carry out the unsaturated soil dry-wet cycle test under suction control and the compression test under constant suction to obtain the temperature effect on unsaturated soil. Influence law of water characteristics and mechanical characteristics; water immersion expansion deformation test and expansion pressure test can be carried out at different temperatures, and the expansion deformation and expansion force of unsaturated soil can be obtained through displacement meters or load sensors respectively. The device has complete functions, simple structure, convenient operation and high testing accuracy.

Owner:SHANGHAI UNIV

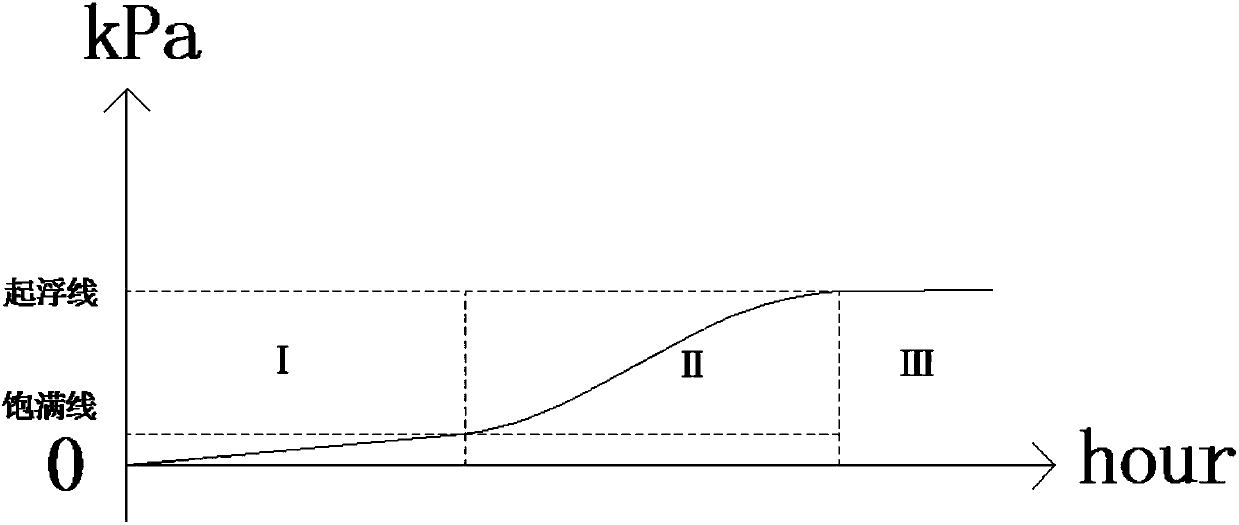

Underwater foundation grouting full weight monitoring system and method

ActiveCN107702740AQuality assuranceImprove practicalityMeasurement devicesWeight monitoringMonitoring system

The present invention discloses an underwater foundation grouting full weight monitoring system and method, wherein by arranging two level instruments of which the monitoring directions are mutually vertical in a structure and respectively arranging two pressure gauges at the highest position and the lowest position of the grouting space, and according to the pressure data monitored by the two pressure gauges and the horizontal data monitored by the two level instruments, whether the grouting in the grouting space is in full weight is determined; by analyzing the change rule of the pressure data on the two pressure gauges, the state of the grouting is determined, and when the change value of the horizontal data monitored by the level instruments reaches a set value, the pressure of the grouting approaches the anti-buoyancy of the structure, thereby representing that the grouting reaches the full weight. Therefore, regardless of the rigid grouting space or the flexible grouting space onthe weak conditions, such as a natural foundation porous condition, etc., to which the monitoring system and the monitoring method are applied, the monitoring system and the monitoring method both can monitor the full weight state of the grouting accurately, thereby guaranteeing the quality of an underwater foundation grouting engineering.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES

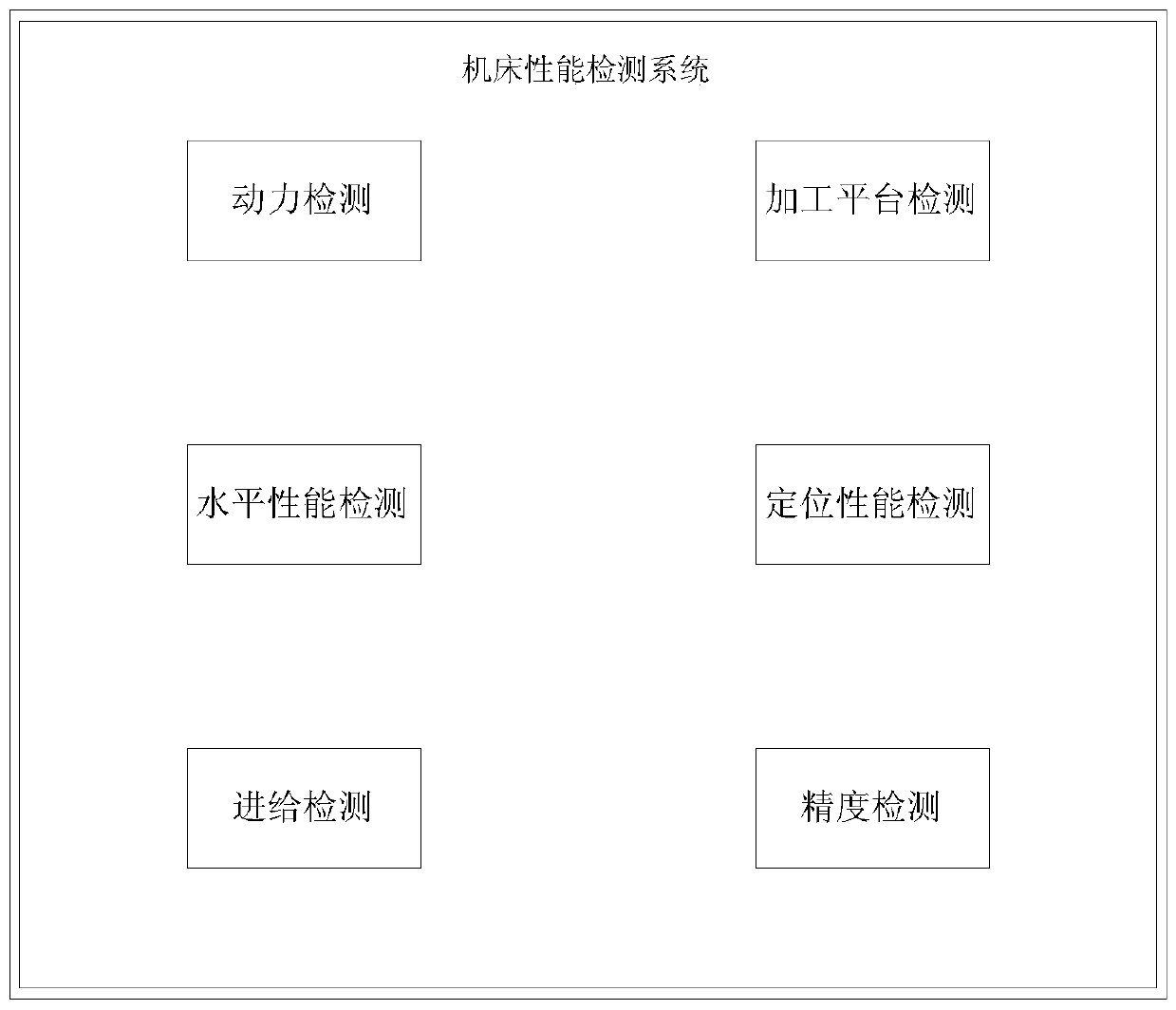

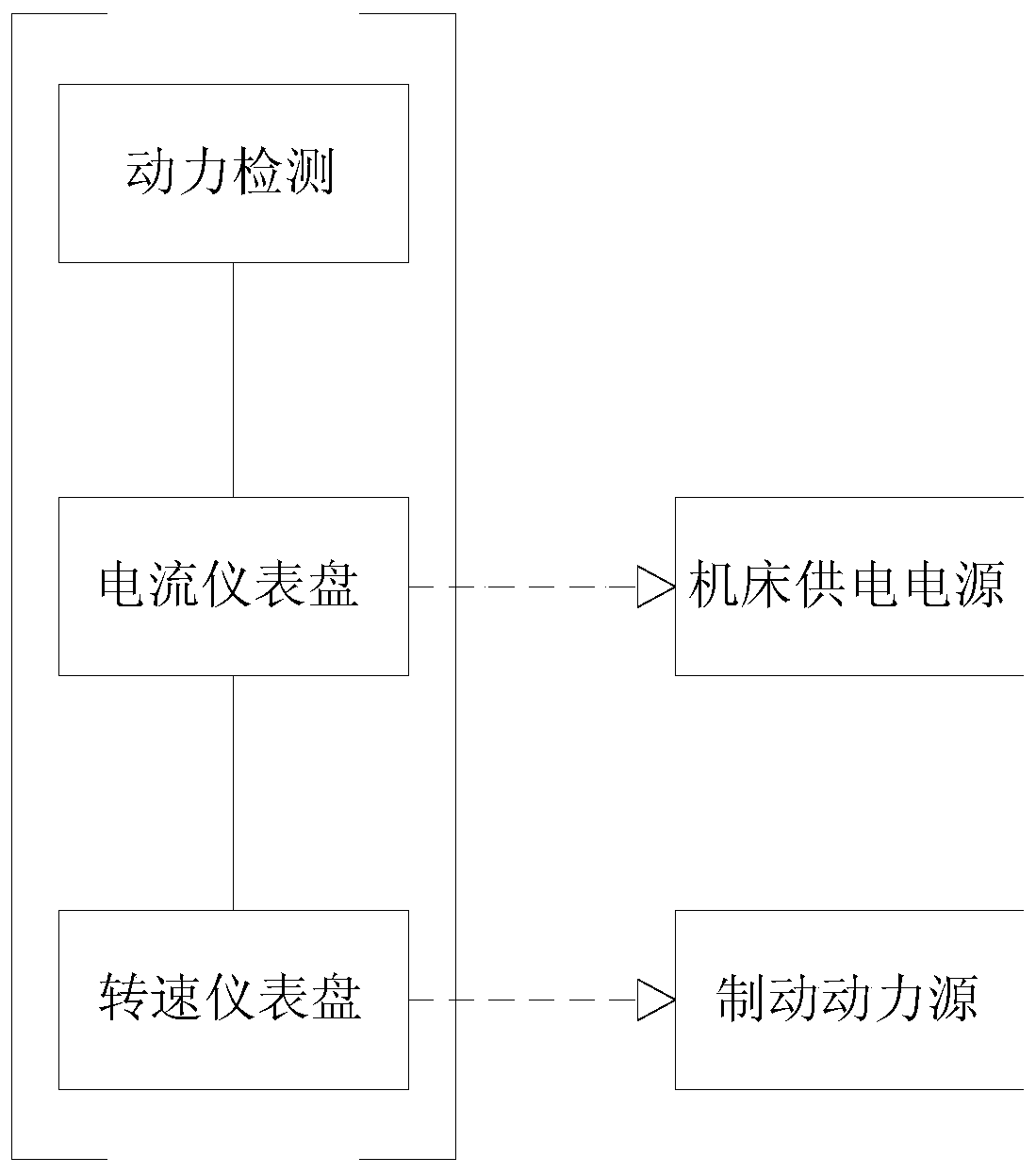

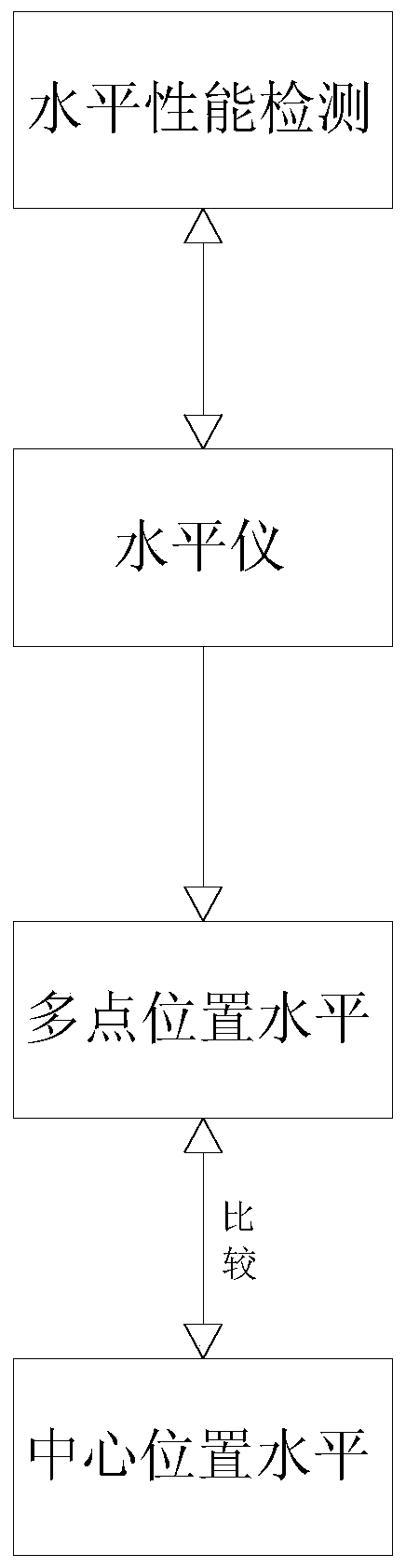

Machine tool performance detection system and method

InactiveCN111069974AImprove performanceConvenient position correctionMeasurement/indication equipmentsControl engineeringMachine

The invention discloses a machine tool performance detection system and method, and belongs to the technical field of industrial detection. The machine tool performance detection system comprises power detection, horizontal performance detection, feed detection, machining platform detection, positioning performance detection and precision detection; and the power detection is used for determiningmachine tool braking power source stability, the power detection comprises a current instrument panel and a rotating-speed instrument panel, the current instrument panel is used for measuring currentdata between a braking power source and a power supply, the rotating speed instrument panel is used for measuring transmission rate data of the braking power source; the horizontal performance detection is used for determining the corners, the local horizontal position and horizontal stability of a machine tool, the horizontal performance detection comprises a level gauge, and the measurement of the reliability, stability and horizontal position of each assembling part of the machine tool is completed through the instrument panels, a dial indicator and the level gauge arranged in a front-and-rear fixed point mode. Comparative analysis can be conveniently carried out by the inspection personnel, the performance of the machine tool is obtained, output data intuitively reflects the performance of the machine tool, and subsequent correcting work can be conveniently carried out on the machine by the workers.

Owner:南京高嘉蕴机械工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com