Novel semi-automatic screw gauge integrated measuring instrument

A technology of comprehensive measuring instrument and thread gauge, which is applied in the field of new semi-automatic thread gauge comprehensive measuring instrument, can solve the problems that cannot meet the needs of thread gauge detection, can not give individual indicators, unfavorable energy saving and emission reduction, etc., to achieve constant measuring force, The effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

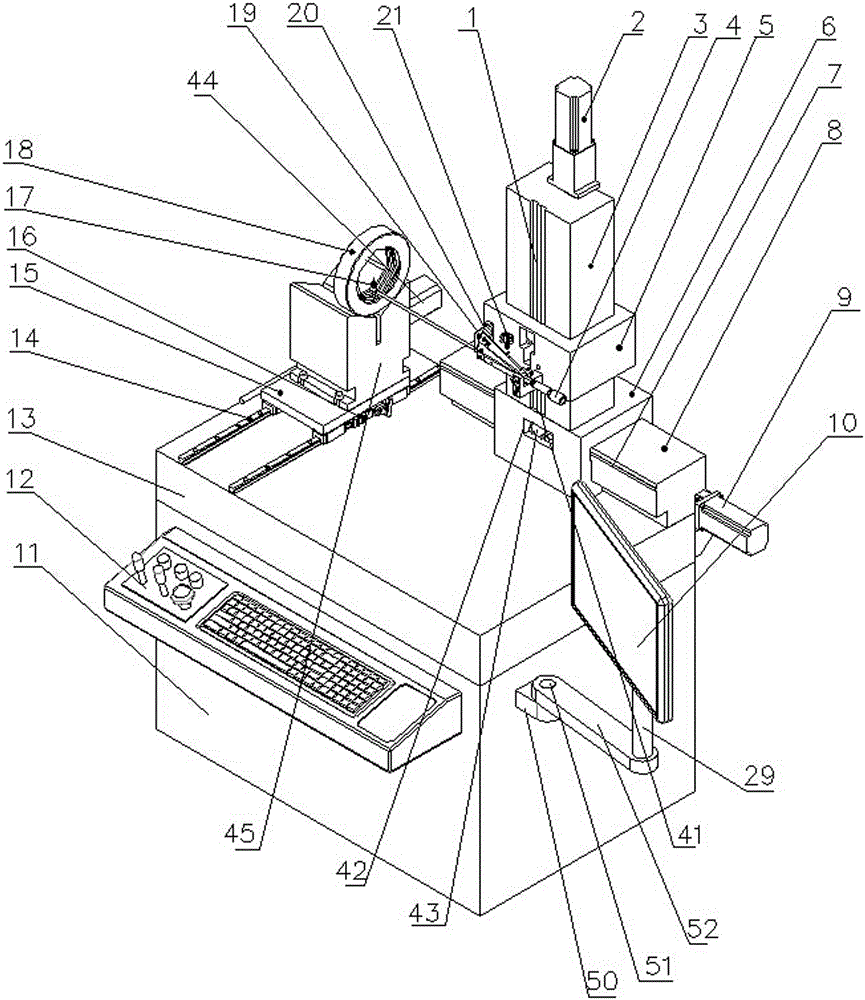

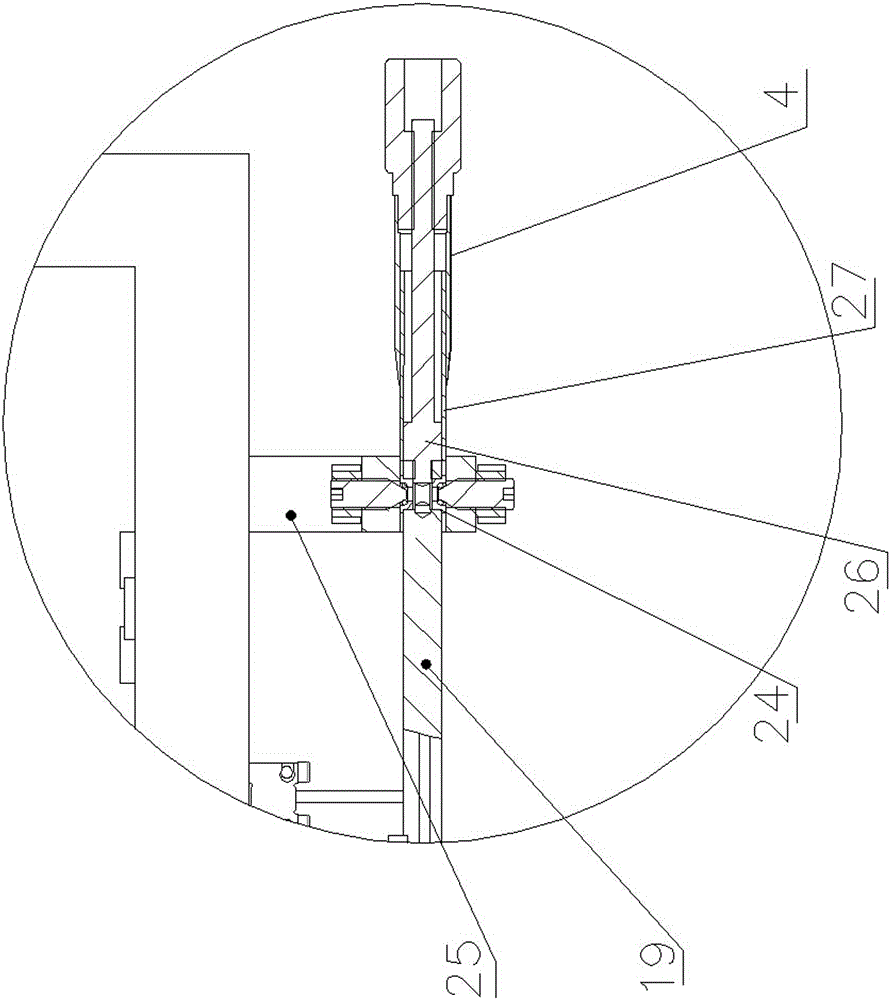

[0033]A new type of semi-automatic thread gauge comprehensive measuring instrument, which consists of: a marble workbench 13, the rear end of the top surface of the marble workbench 13 is connected to the longitudinal air-floating guide rail support column 8, and the longitudinal air-float guide rail support column 8 The rear end is connected to the longitudinal driving servo motor module 9, the front end and the rear end of the longitudinal air-floating guide rail support column 8 are both connected to the longitudinal grating 7, and the longitudinal air-floating guide rail support column 8 is sleeved with the longitudinal carriage 6, The vertical carriage 6 is connected to the column 3, the top surface of the column 3 is connected to the vertical drive servo motor module 2, the front center line of the column 3 is connected to the column grating 1, and the top of the vertical carriage 6 is There is a longitudinal carriage groove 41, and the vertical carriage grating 1 is inst...

Embodiment 2

[0035] In the new semi-automatic thread gauge comprehensive measuring instrument described in Embodiment 1, the left side of the marble workbench 13 is connected with a lateral rolling guide rail 14, and the lateral sliding table 15 slides on the lateral rolling guide rail 14, and the lateral sliding table 15 15 is connected to the lateral drive servo motor module 44, and the bottom end of the lateral sliding table 15 is connected to the lateral locking module 16, and the lateral locking module 16 is used in conjunction with the lateral rolling guide rail 14, and the lateral sliding table 15 is connected with a Y-shaped connection platform 45 with screws, and the top end of the Y-shaped connection platform 45 is connected with the measured thread ring gauge 18.

Embodiment 3

[0037] In the new semi-automatic thread gauge comprehensive measuring instrument described in embodiment 1 or 2, the bottom end of the marble workbench 13 is connected to the base 11, the front of the base 11 is connected to the operation panel 12, and the side of the base 11 passes through The truck is connected to a computer monitor 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com