Timing method three phase metering separator

A technology of measuring separators and timing methods, which is applied in the direction of material inspection products, etc., can solve the problems of high cost and complex technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

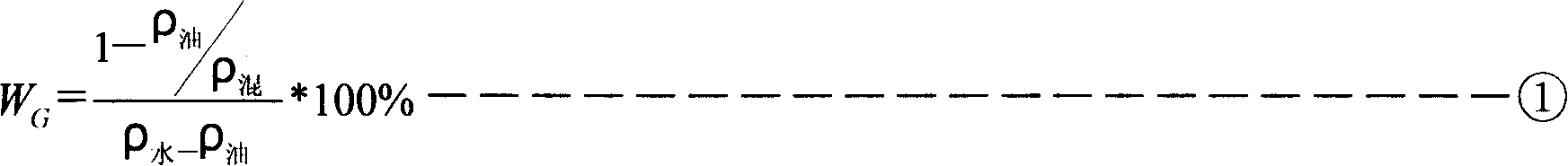

[0032] (2) Measurement principle and calculation formula of gas production test

[0033] Gas measurement is carried out by using the existing gas measurement technology of liquid drainage method in the oil field. Under this process condition:

[0034] The weight of the mixture after each measurement is fixed: q g =S*H*ρ 水 (Ton)

[0035] Its corresponding volume is:

[0036] Based on this known volume and the time t required to drain 3 (see five implementation modes), find the total liquid discharge speed of the three-phase fluid and the total volume of daily production of the three-phase fluid:

[0037] Measured daily liquid volume

[0038]

[0039] (Note H=H 1 =H 2 )

[0040] Formula ⑥ is the calculation formula for gas measurement by liquid drainage method under this process condition.

[0041] From the formula ⑥, it can be clearly seen that the three-phase metering of oil, gas and water is an organic metering whole, and the three metering parameters t 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com