Vacuum preloading and electroosmosis combined testing device and vacuum preloading and electroosmosis combined testing method

A test device and vacuum technology, which is applied in the field of vacuum preloading combined with electroosmosis test, can solve the problems of weakening the sealing performance, aggravating the air leakage on the surface of the sealing film, and the vacuum degree of the soil cannot meet the expected requirements, and achieves convenient operation and simple structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

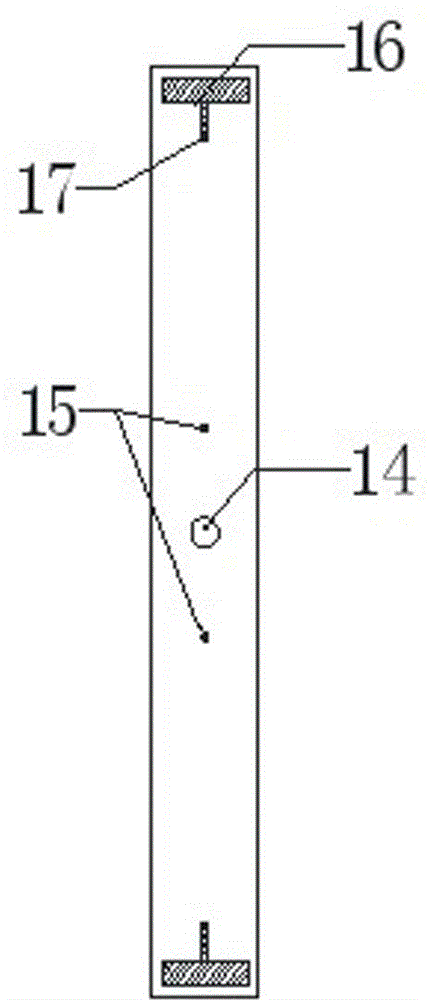

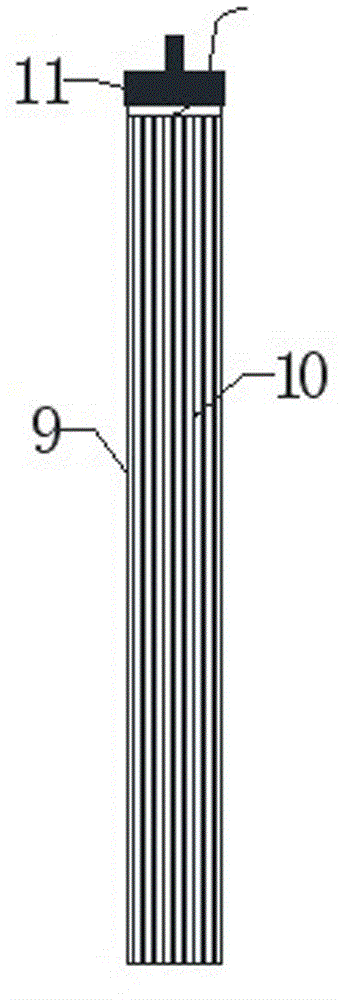

[0015] refer to Figure 1~5 As shown, the vacuum preloading combined electroosmotic test device provided by the present invention includes a tempered glass model box 1, and a measuring hole 2 is opened along the height direction on the tempered glass model box 1, and a miniature pore water pressure gauge 7 is arranged on the tempered glass model The inside of the box 1 is connected to the external instrument through the information line through the measuring hole 2. A plastic drainage board 9 is vertically inserted in the middle of the tempered glass model box 1, and a steel bar 12 is vertically inserted in the tempered glass model box 1. , the steel bar 12 is connected with the anode terminal 17, the plastic drainage board 9 is provided with a conductive copper wire 10 along the height direction, the conductive copper wire 10 is connected with the cathode terminal 15, and the cathode terminal 15 and the anode terminal 17 are connected by a wire To the external DC power supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com