Round hole inner diameter measuring instrument

A measuring instrument and inner diameter technology, applied in the field of measuring tools, can solve the problems of short mechanical service life, large vibration amplitude, easy wear of the inner wall of the circular hole, etc., and achieve the effects of small mechanical vibration amplitude, long service life and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

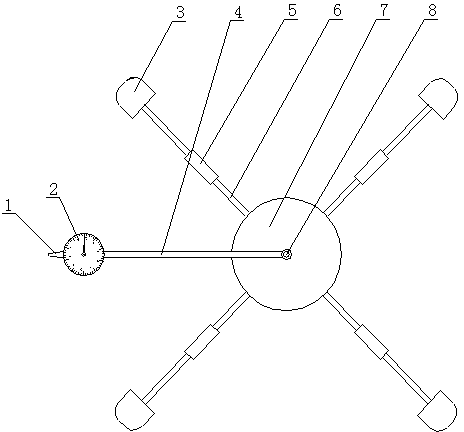

[0009] The inner diameter measuring instrument as shown in the figure is provided with a measuring rod 4, the front end of the measuring rod 4 is provided with a measuring meter head 2, and the measuring meter head 2 is provided with a measuring probe 1. The feature of the present invention is that a positioning seat 7 is also provided. , the positioning seat 7 is evenly provided with at least three positioning rods 6 with adjustable length, as can be seen from the figure, the positioning rod 6 is formed by connecting two screw rods through the adjusting screw sleeve 5, and the positioning can be adjusted by rotating the adjusting screw sleeve 5 The overall length of the rod. The front end of the positioning rod is provided with a positioning block 3, and the positioning block 3 is usually an elastic block made of rubber. The measuring rod 4 is hinged at the center of the positioning seat 7 via the hinge shaft 8 . When in use, place the positioning seat in the round hole of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com