Composite calibration/verification gauge and method of its manufacture

A standard, stepped technology, applied in multi-dimensional length standards, multi-functional fields, and can solve problems such as time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

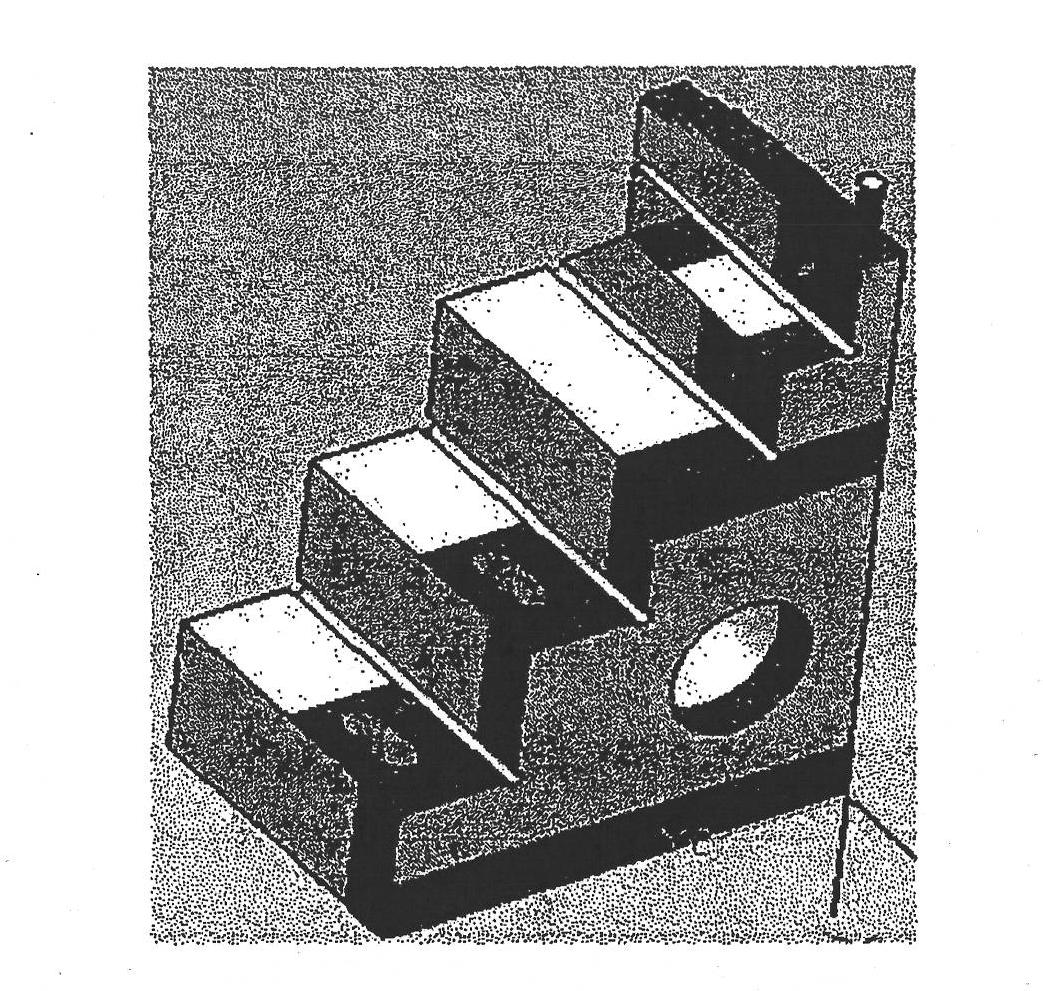

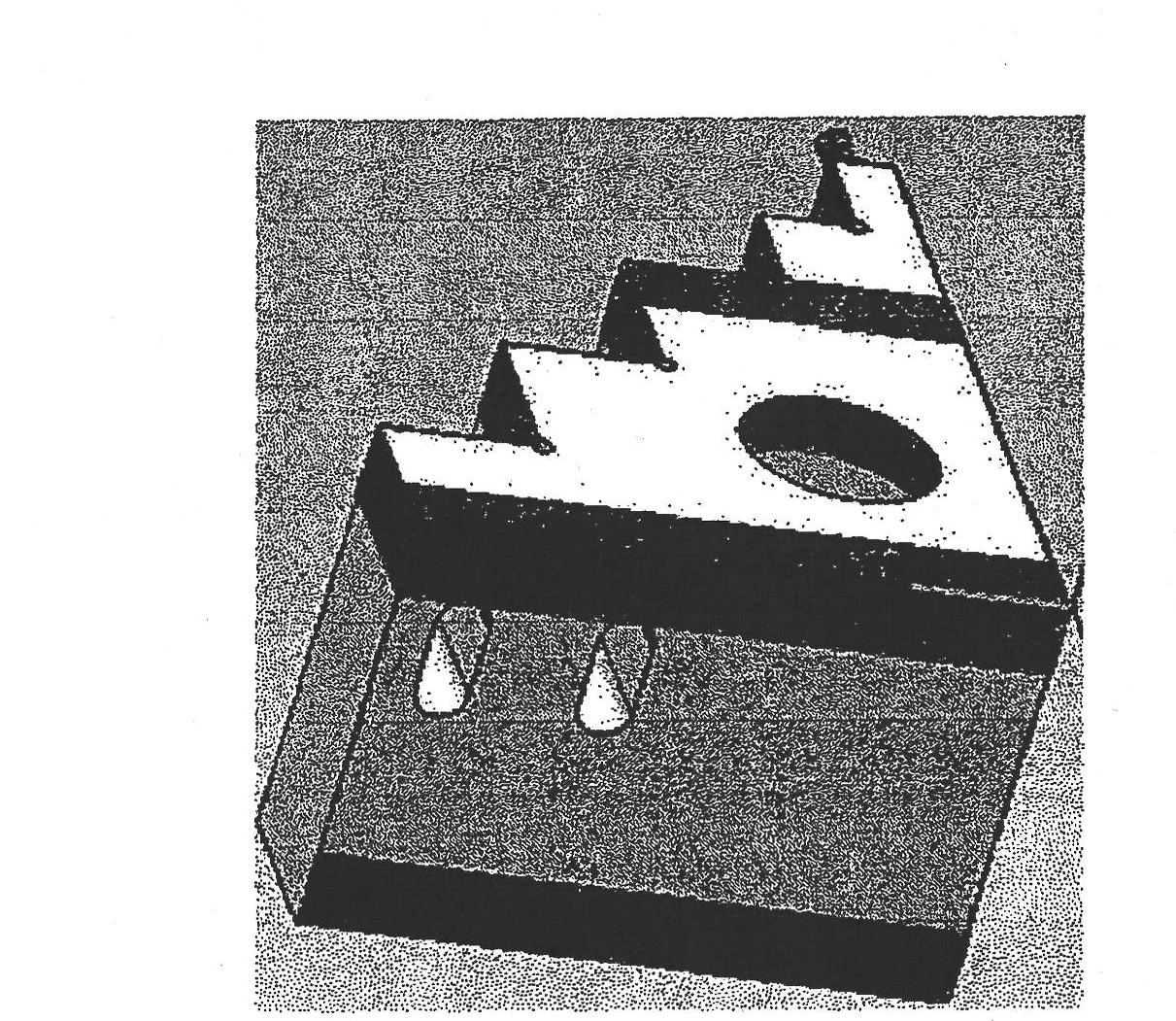

[0053] As described herein, the present disclosure relates to calibration / verification gauges for calibrating measuring instruments as needed in the workplace. refer to figure 1 , which shows the use of multiple calibration gauges for different instruments, which has significant disadvantages, and those skilled in the art will realize that the use of a single calibration gauge with wide and flat parallel surfaces in the workplace is not effective for various measuring instruments. / sub-gauge for the importance of calibration. It is therefore advantageous to use block members with multiple wide support surfaces as well as multiple measurement surfaces and shapes, in which block members can be formed with very small areas or even almost pin-like, or possibly of fixed length Wide surfaces, sharp corners, and multiple holes / steps.

[0054] The gauges disclosed are specifically designed to accommodate some of the usual lengths, apertures, and angles used in a variety of measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com