Underwater foundation grouting full weight monitoring system and method

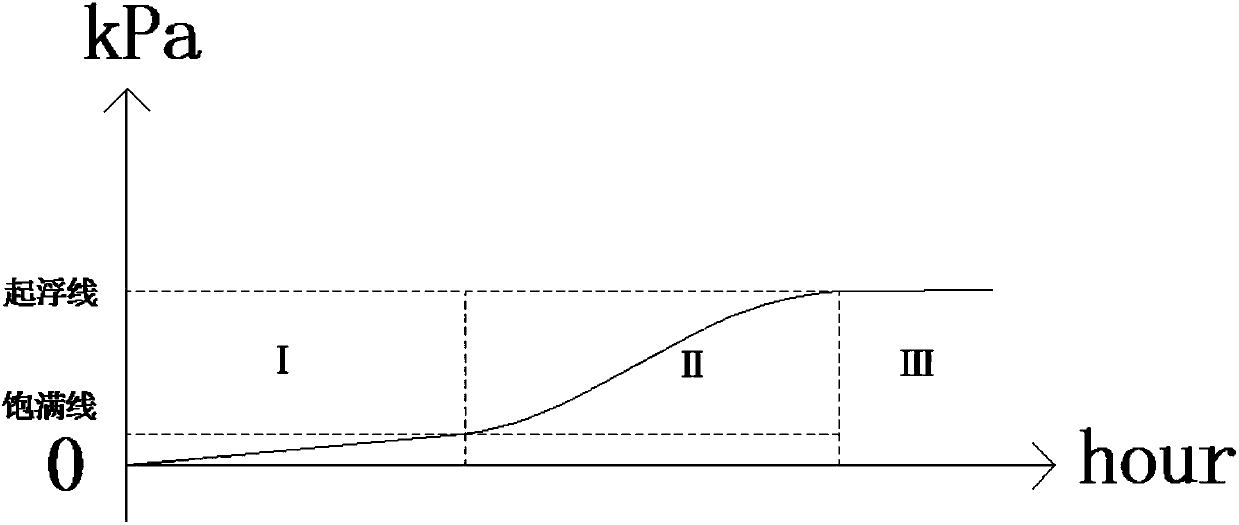

An underwater foundation and monitoring system technology, applied in measuring devices, instruments, etc., can solve the problems of insufficient grouting, unguaranteed engineering quality, and inability to accurately detect the fullness of underwater foundation grouting. Practicality and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

[0026] Such as figure 1 The underwater grouting structural schematic diagram shown; wherein, the underwater foundation grouting plumpness monitoring system of the present invention includes a monitoring host, an X-direction level 3, a Y-direction level 4, a top pressure gauge 1 and a bottom pressure gauge 2. Wherein, the X-direction level 3 and the Y-direction level 4 are arranged inside the structure 8, and the monitoring directions of the X-direction level 3 and the Y-direction level 3 are perpendicular to each other.

[0027] After the structure 8 is placed on the natural foundat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com