Shaft length and inner bore size detection device in shaft detection equipment

A technology for detecting equipment and inner hole size, applied in the field of measurement, can solve problems such as low efficiency and errors in manual detection, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

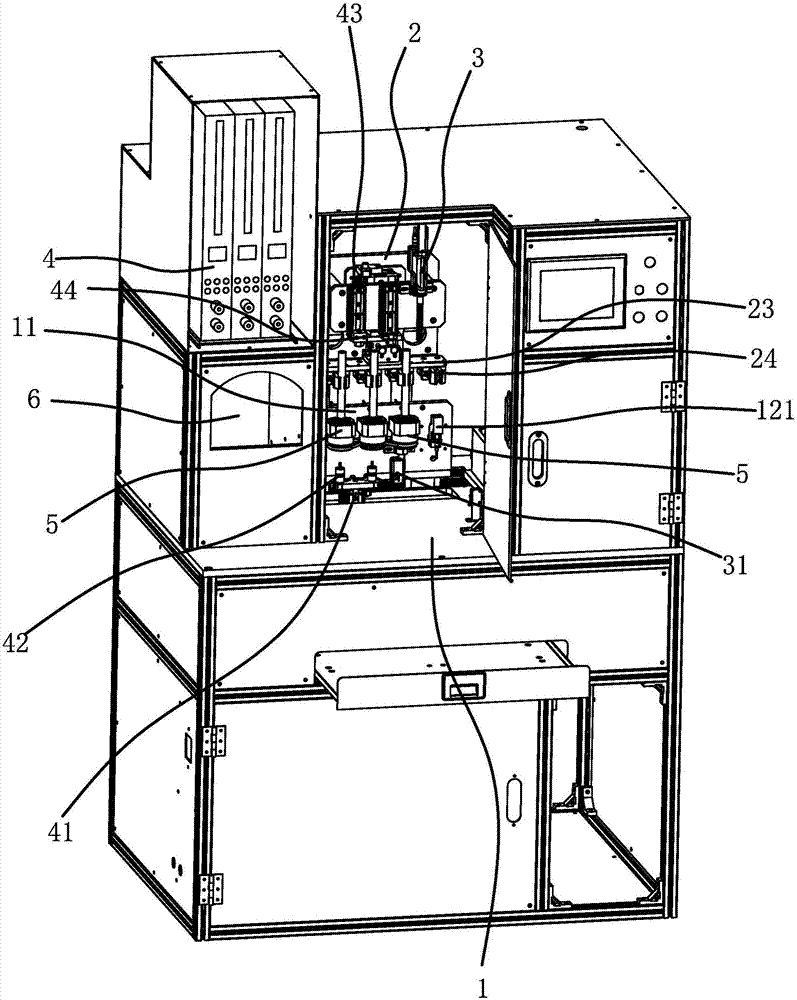

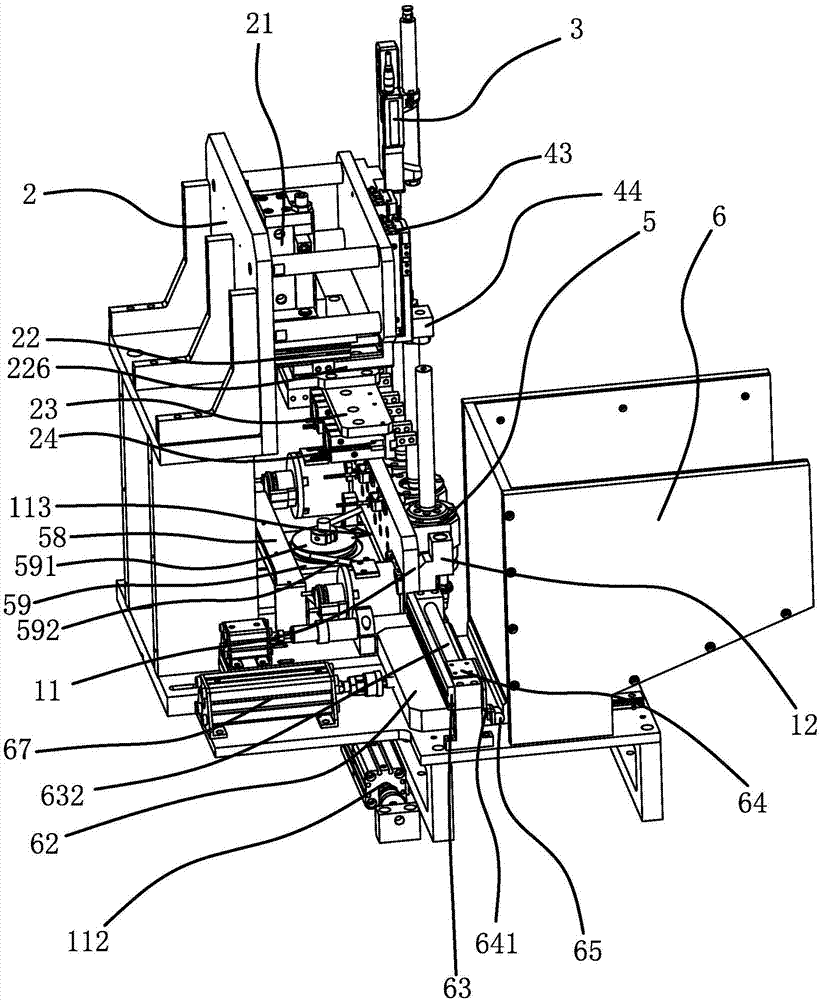

[0031] Such as Figure 1 to Figure 10 As shown, the testing equipment for the length of the shaft and the size of the inner hole includes a housing, a workbench 1 fixed in the housing, and a measuring platform 11 arranged on the workbench 1. The measuring platform 11 is provided with three inspection bases 5 arranged side by side. , The detection base 5 is rotatably connected with a shaft core 51 for positioning the shaft, the shaft core 51 is arranged vertically, the shaft cores 51 of the three detection bases 5 can be rotated synchronously through the rotating structure, and the measuring table 11 is located on the three detection bases. Both ends of the seat 5 are respectively provided with a feeding reversing sleeve 12 and a disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com