Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Clear blot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

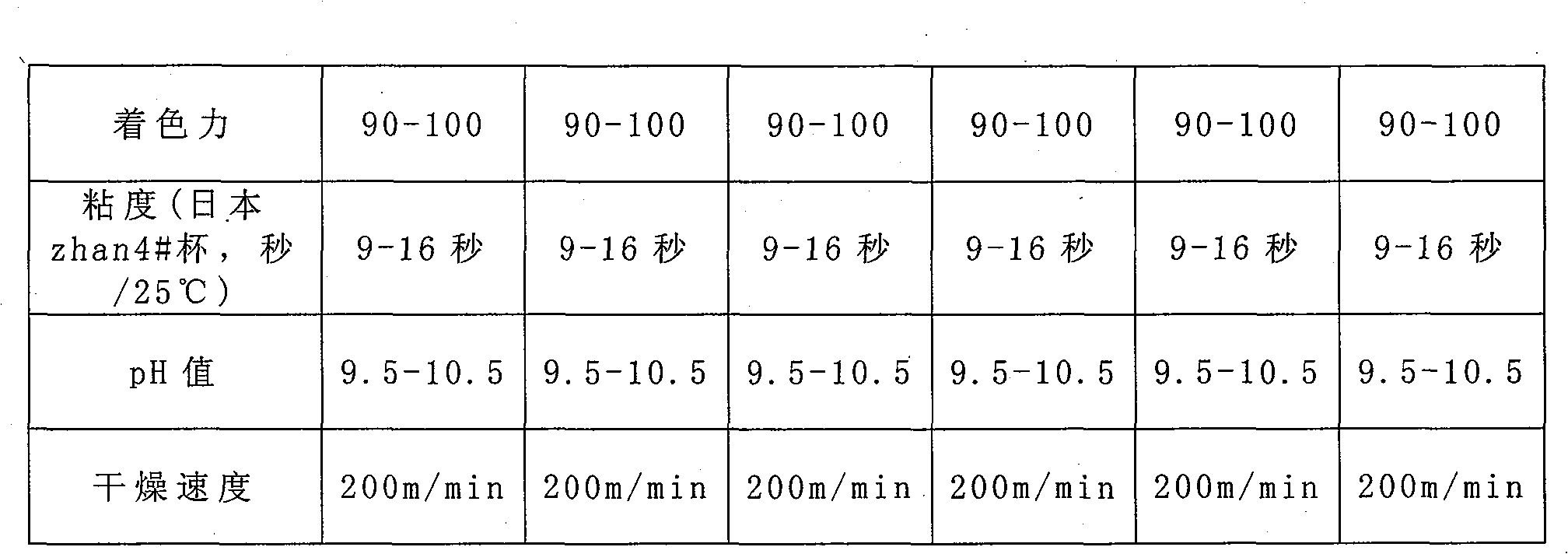

Water flexible painting plate ink and preparing method thereof

The invention relates to a waterborne soft printing ink comprising the components: film-forming resin emulsion of 8.7-47.2wt percent, waterborne acrylic color paste of 40-50wt percent, antifoam agent of 0.1-0.3wt percent, waterborne wax paste of 0.2-2.0wt percent, isopropyl alcohol of 2-8wt percent, ethylene glycol of 10-30wt percent, ethanolamine of 0.5-1wt percent and water of the rest percent. The invention further provides a method to prepare the waterborne soft printing ink. The waterborne soft printing ink of the invention is nontoxic and environmental friendly, has good safety, stable performance and good adaptability to coated art paper printing, and can be continuously used in printing without mackle, has clear printing effect and low production cost.

Owner:GUANGDONG YINGKE GRP CO LTD

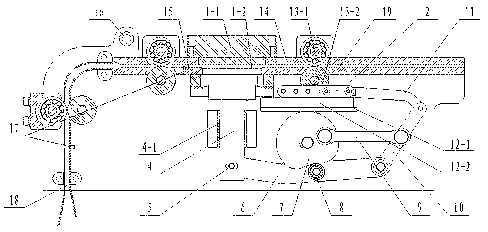

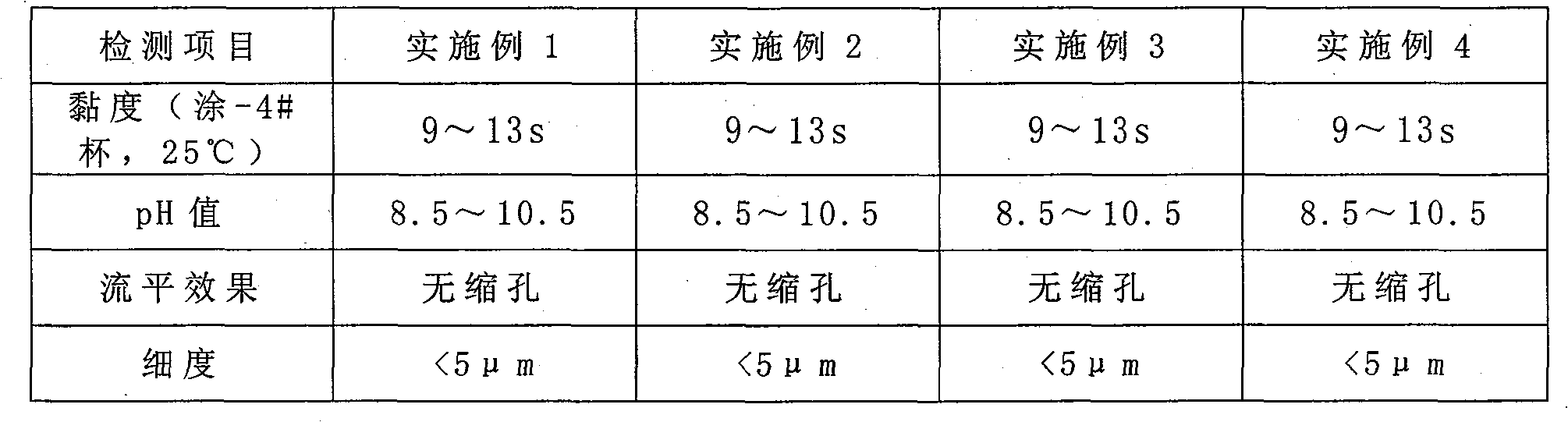

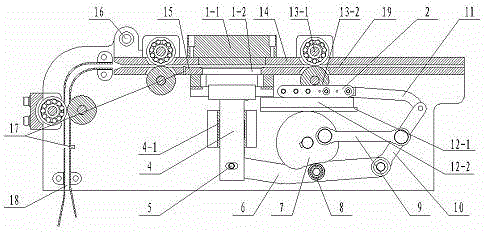

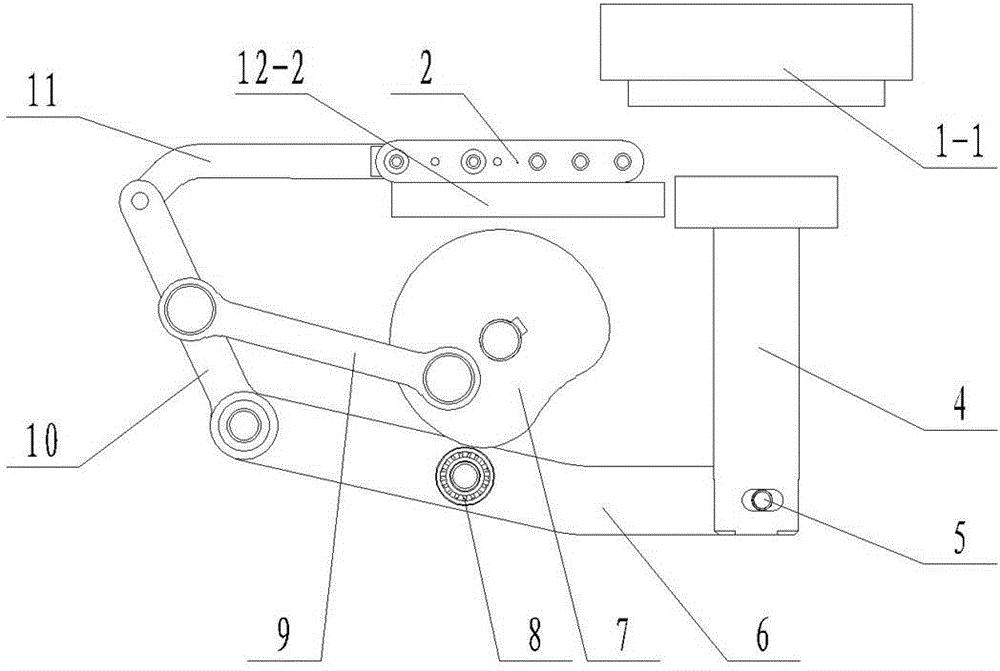

Automatic stamping mechanism based on copper stamp

ActiveCN103129193AMake up for the defect of low service lifeLow failure rateStampingFailure ratePulp and paper industry

An automatic stamping mechanism based on a copper stamp structurally includes a paper feeding channel, a paper outlet channel, a paper conveying driving mechanism, a stamping mechanism and a control management circuit, wherein the paper feeding channel is connected with a paper outlet channel of a printer, and the paper outlet channel is connected with the tail end of the paper feeding channel. The automatic stamping mechanism based on the copper stamp is mainly characterized by further including an automatic replenishing mechanism of stamp-pad ink in structure, the automatic replenishing mechanism of the stamp-pad ink and the stamping mechanism form a matching structure of stamp-retrieval first and oiling second through a compound driving mechanism arranged under the paper outlet channel. The automatic stamping mechanism based on the copper stamp is simple in structure, omits the complex process of manual dipping the stamp-pad ink before stamping, has clear stamp, prolongs the service life of the stamp, and is connected with a specialized paper outlet so that paper jam is not easy to happen and the failure rate is low.

Owner:HEBEI HUIJIN ELECTROMECHANICAL

Heat transfer film for soft infusion bag and preparation method thereof

The invention discloses a heat transfer film for a soft infusion bag and a preparation method thereof. The heat transfer film for the soft infusion bag orderly comprises a tape base, a release layer and an ink layer, wherein the release layer is prepared from raw materials in percentage by mass: 5 to 30 percent of binder, and 70 to 95 percent of wax; and the ink layer is prepared from raw materials in percentage by mass: 5 to 50 percent of binder, 10 to 50 percent of pigment, 0 to 50 percent of filler, and 0 to 5 percent of additive. The application of the heat transfer film for the soft infusion bag has the characteristics of quick transfer, no adhesion of the tape base, clear print, firm attachment, cooking sterilization resistance, alcohol resistance, no toxicity, no harm and the like,and can meet the need of the printing of surface marks of medical PVC film bags and non-PVC co-extruded films.

Owner:ZHUOLI IMAGING TECH

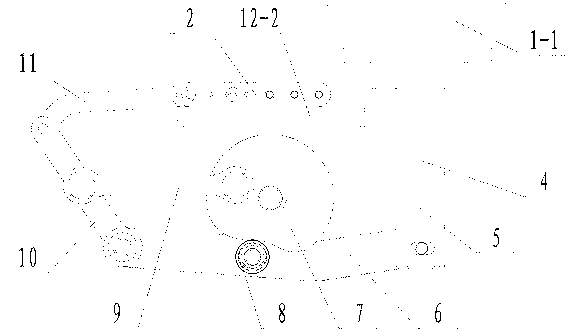

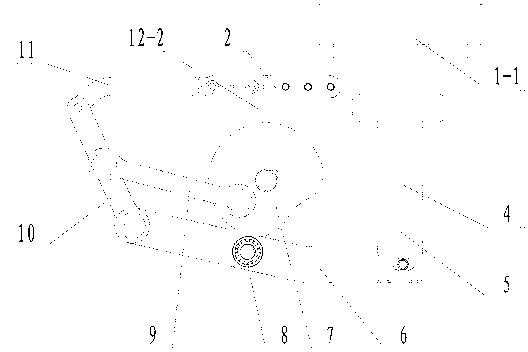

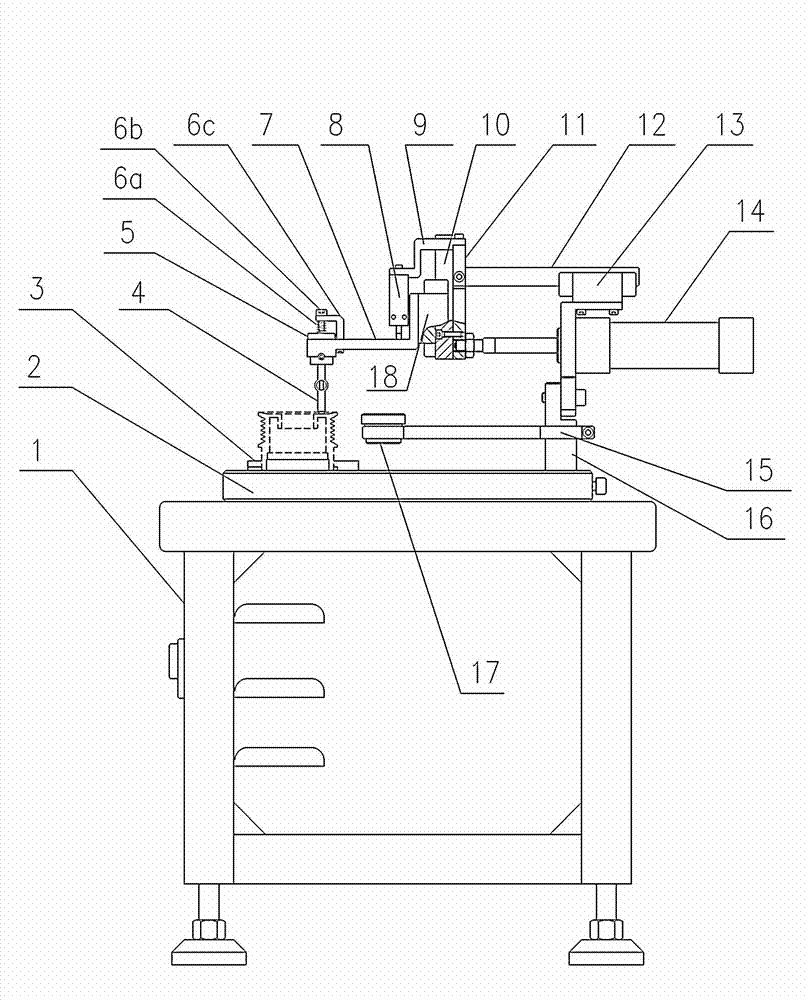

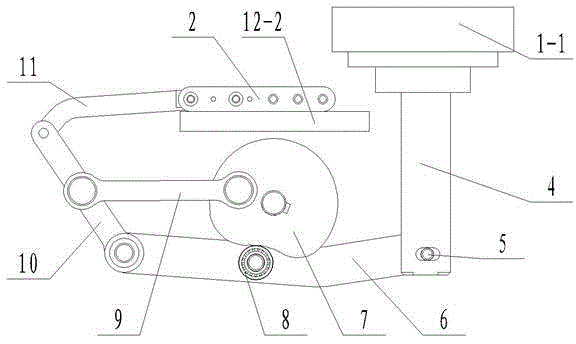

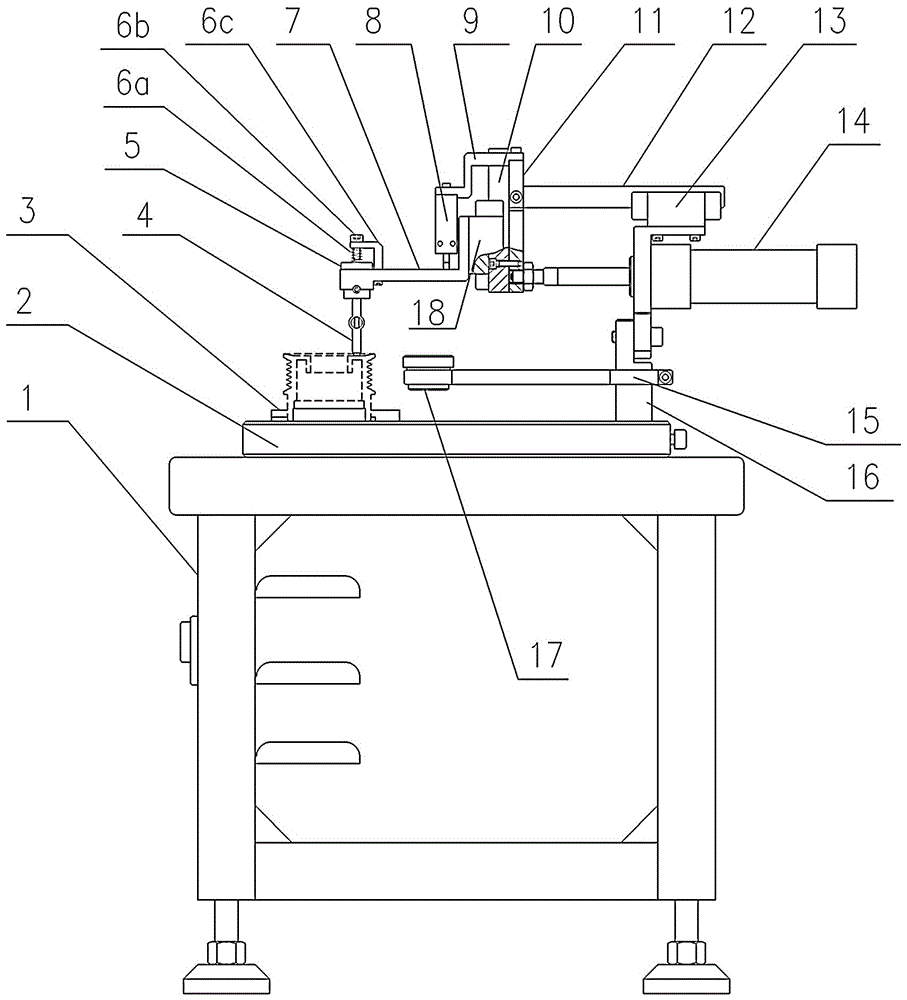

Automatic stamping machine for stamping pulley assemblies

ActiveCN103753986AReduce labor intensitySimple structureStampingEngineeringUltimate tensile strength

The invention relates to an automatic stamping machine for stamping pulley assemblies. The automatic stamping machine comprises a worktable (1), a baseplate (2) is arranged on the worktable, a workpiece clamping seat (3) for clamping pulleys is arranged on the baseplate, a supporting seat (16) is further arranged on the baseplate, a telescopic cylinder (14) is connected on the supporting seat, one end of the telescopic cylinder is connected with a push plate (11), a lifting cylinder (8) is arranged on the push plate, the lower end of the lifting cylinder is connected with a pressing plate (7), a stamp seat (5) is arranged on the pressing plate, and the lower end of the stamp seat is connected with a stamp (4) aligning to the end faces of the pulleys. The automatic stamping machine has the advantages that the automatic stamping machine is simple in structure, convenient to operate and clear in stamp, labor intensity of operators is relieved, and working efficiency is improved.

Owner:ANHUI HAOFANG ELECTROMECHANICS

Environment-friendly printing ink

The invention discloses environment-friendly printing ink which is prepared from the following raw materials in parts by weight: 15-25 parts of polyamide resin, 5-15 parts of acrylic resin, 20-50 parts of a solvent, 5-10 parts of pigment, 2-4 parts of a cationic photo-initiator, 0-1 part of vinyl chloride-vinyl acetate resin, 2-4 parts of an ink enhancer, 1.5-3 parts of polyolefin wax, 1-5 parts of an abrasion-resistant auxiliary, 1-3 parts of a defoaming agent, 0.5-1.5 parts of a dispersing agent and 5-10 parts of a diluent. According to the environment-friendly printing ink provided by the invention, the used materials are benzene-free materials, so that the printing ink does not contain volatile harmful matters, is good in printing effect, high in adhesion fastness, non-inflammable, unexplosive and nontoxic, does not damage the health of printing workers, and is free of pollution to the atmosphere and good in environment friendliness; the abrasion-resistant auxiliary is added, so that the printed ink layer has a relatively small friction coefficient, and the abrasion resistance of the ink is greatly improved; the cost is relatively low, the ink layer firmly adheres, namely, the adhesive force is high, the ink layer is rub resistant, scratch resistant, high in glossiness, good in abrasion resistance and high in drying speed, and the product quality is good.

Owner:桐城市人和包装有限公司

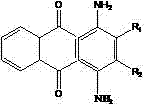

Surfactant for uncoated thermal transfer ink, uncoated thermal transfer ink and preparation method of surfactant

The invention discloses and provides a surfactant for an uncoated thermal transfer ink, the uncoated thermal transfer ink and a preparation method of the surfactant. The surfactant for the uncoated thermal transfer ink is capable of reducing the cost of thermal transfer paper, reducing the usage amount of ink, and improving the heat transfer rate and the color concentration of the ink. The uncoated thermal transfer ink is prepared from the following raw materials in parts by weight: 20-40 parts of non-azo disperse dyes, 5-40 parts of an organic solvent, 1-10 parts of a surfactant, 0.05-1 part of a pH modifier, 0.05-1 part of a buffering agent, 0.01-0.3 part of a preservative, 0.1-1 part of an emulsifier, 0.05-1 part of a chelating agent and 20-50 parts of water; the surfactant is a polyoxyethylene polyoxypropylene copolymer; the preparation method of the uncoated thermal transfer ink comprises the following steps: firstly, stirring an organic solvent mixed with water; adding the surfactant, stirring for 30 minutes to be full and uniform; adding the pH modifier, the buffer agent, the preservative, the emulsifier and the chelating agent, stirring for 30 minutes to be full and uniform; adding the non-azo disperse dyes, stirring for 2 hours to be full and uniform; and filtering with 1.0micron of filter membrane, thus obtaining the thermal transfer ink.

Owner:珠海欣威科技有限公司

High-resolution thermal transfer ribbon and preparation method thereof

The invention discloses a high-resolution thermal transfer ribbon which comprises a ribbon base, a thermal transfer ink layer and a thermal resisting coating. One side of the ribbon base is coated with the thermal transfer ink layer, and the other side of the ribbon base is coated with the thermal resisting coating. The thermal transfer ink layer is prepared from, by weight, 28-32 parts of lignite wax, 45-50 parts of carnauba wax, 14-17 parts of carbon black, 12-15 parts of soldering iron black, 4-8 parts of kaolin, 1-3 parts of montmorillonoid, 2.5-3.5 parts of aluminum phosphate, 4-6 parts of DCPD resin, 1-2 parts of methyl silicone oil and 1-5 parts of ethyl acetate. The thermal resisting coating is prepared from, by weight, 9-15 parts of acrylic resin and 85-90 parts of polyimide. The invention further discloses a preparation method of the high-resolution thermal transfer ribbon. The high-resolution thermal transfer ribbon is good in adhesive force, clear in print, resistant to scraping and wide in market prospect.

Owner:POMA IND SHANGHAI

Printing ink

InactiveCN105315776ALong storage timeReduce coefficient of frictionInksFrictional coefficientPrinting ink

The invention discloses printing ink which is prepared from the following raw materials in parts by weight: 20-40 parts of polyamide resin, 40-60 parts of a solvent, 5-10 parts of pigment, 1-5 parts of a viscosity conditioning agent, 0-1.5 parts of vinyl chloride-vinyl acetate resin, 1-3 parts of a printing ink reinforcing agent, 1-5 parts of a wear-resisting auxiliary, 1-3 parts of active monomer, 1-3 parts of hollow glass bead, 1-3 parts of an antifoaming agent and 5-10 parts of a diluent. According to the printing ink, the active monomer is added, so that the surface tension of the prepared printing ink is equal to or less than that of the printed surface; the wear-resisting auxiliary is added, so that the printed printing ink layer has a very small frictional coefficient, and the wear resistance of the printing ink is greatly improved; the printing ink contains no volatile toxic solvent, is good in printing effect, strong in adhesion fastness, incombustible, unexplosive and nontoxic, cannot damage health of printing workers, has no environmental pollution on atmosphere, and is lower in cost; an ink layer is high in adhesion fastness, namely adhesive force, rub-resistant, scratch-resistant, high in glossiness, good in wear resistance, quick in drying rate and good in product quality.

Owner:桐城市人和包装有限公司

High-temperature-resistant ink containing modified resin

InactiveCN104804551AImprove high temperature resistanceImprove adhesionInksAcetic acidPolyethylene vinyl acetate

The invention discloses high-temperature-resistant ink containing modified resin. The high-temperature-resistant ink comprises components in parts by weight as follows: 20-30 parts of modified resin, 1-10 parts of polyethylene vinyl acetate, 3-8 parts of vinyl chloride-vinyl acetate resin, 2-6 parts of ethylene glycol monostearate, 1-5 parts of ethyl acetate, 5-10 parts of an antifoaming agent, 3-7 parts of an adhesion promoter, 1-6 parts of a matting agent, 1-10 parts of high-temperature-resistant aids and 30-40 parts of a solvent. The high-temperature-resistant ink is prepared from the modified resin, is applicable to a spraying printing technology and has good adhesion on products, clear print marks and good high-temperature resistance, cannot shed, fade or release substances harmful to a human body in the high-temperature steaming process and is applicable to the fields of food and medicine packaging.

Owner:陈良伢

Cinnabar seal ink and preparation method thereof

The invention provides a cinnabar seal ink and a preparation method of the cinnabar seal ink. The cinnabar seal ink is prepared from cinnabar, moxa, bamboo leaf powder, white carbon black, propyl p-hydroxybenzoate, yellow soft paraffin, and flavoring rose essence. The seal ink is high in drying speed, bright in color, and stable in chemical properties, is light-resistant, can be stored for a long period of time, and does not fade.

Owner:铜仁市万山区丹凤朱砂工艺品研发检测鉴定中心有限公司

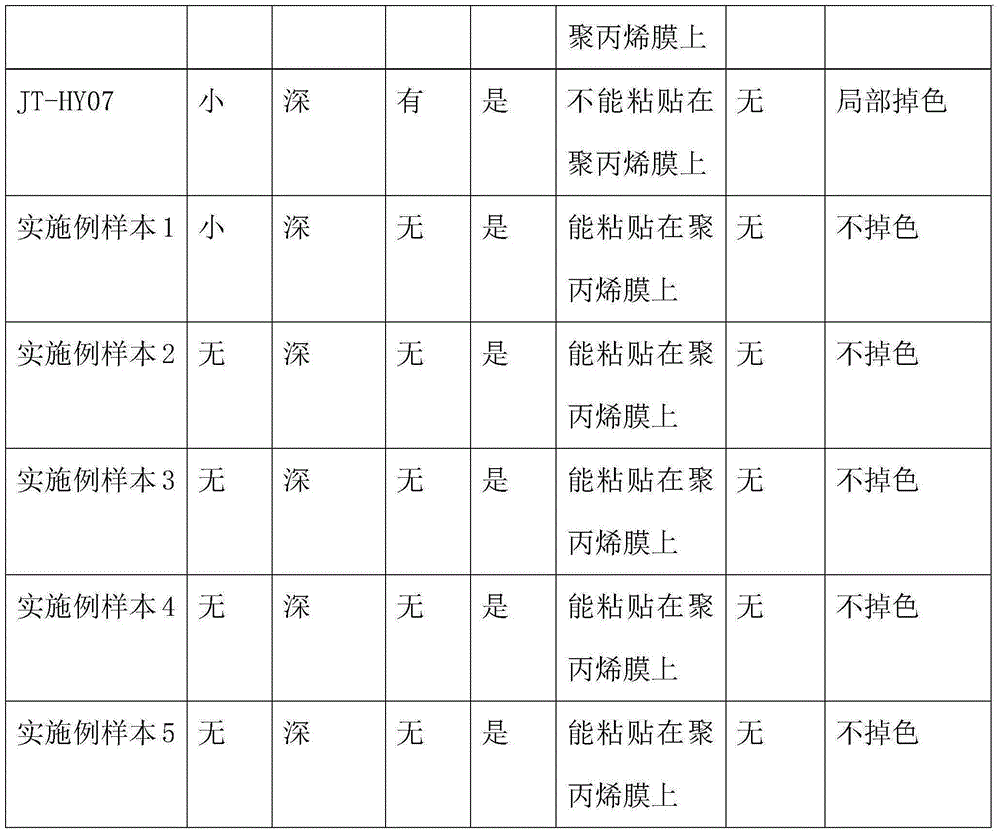

Screen printing ink for polypropylene plastic and method of producing the same

InactiveCN101469151BLow costGood continuous printingInksOther printing apparatusScreen printingPolymer science

Owner:海宁市盐官工业投资有限公司

Super-slip easily-flowing acrylic-resin printing ink

The invention relates to the field of printing ink, and concretely relates to super-slip easily-flowing acrylic-resin printing ink. The printing ink is prepared from the following raw materials in parts by weight: 5-8 parts of acetyl tributyl citrate, 3-4 parts of corn starch, 2-4 parts of 1,6-hexanediol, 1-3 parts of octyltrimethylammonium chloride, 28-32 parts of acrylic resin, 6-8 parts of talcum powder, 10-12 parts of an organic pigment, 12-15 parts of isopropanol, 20-25 parts of 1-methoxy-2-propyl acetate, and 2-4 parts of an auxiliary agent. The printing ink is low in content of toxic volatile organics and small in harm to environment and human body; corn starch processed by an isopropanol aqueous solution is well dispersed in resin and a solvent and helps to improve the printing adaptability, and by combining octyltrimethylammonium chloride, the auxiliary agent and the other raw materials for assisting printing ink to be dry and improve the printing quality, the prepared printing ink is low in surface tension, strong in adhesive force with a base material, good in levelling property, easy to transfer, clear and firm in printing traces, high in printing quality and efficient in printing.

Owner:BENGBU PIONEER FILTER

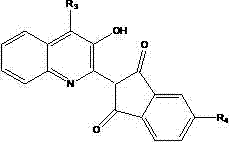

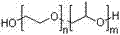

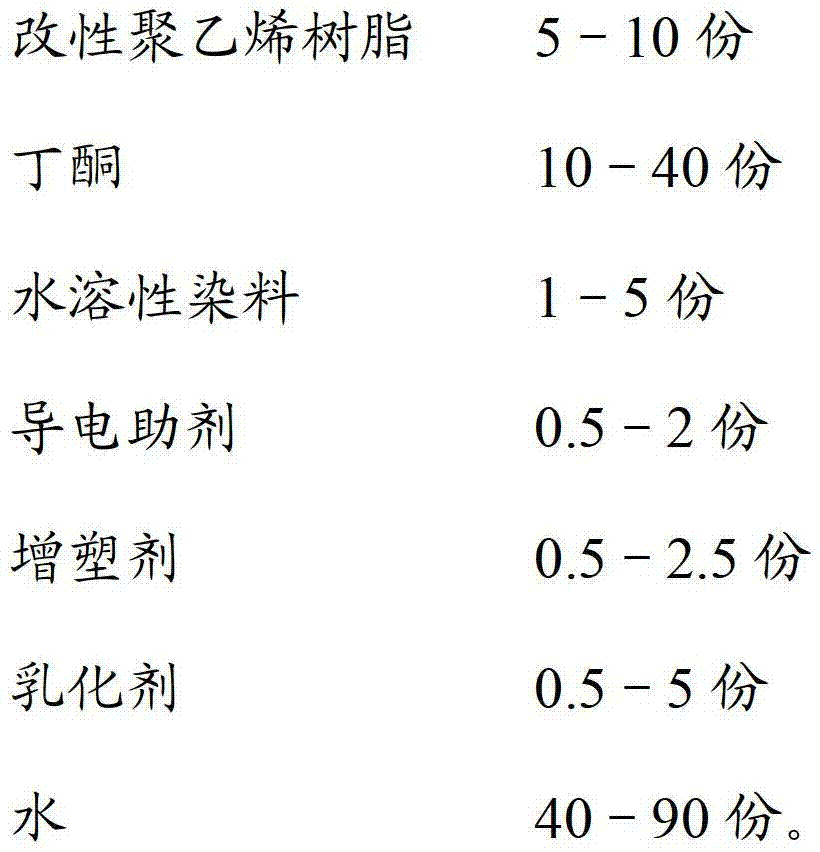

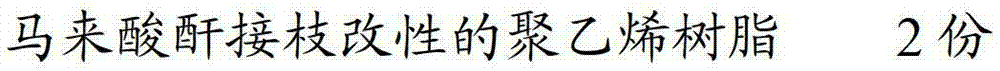

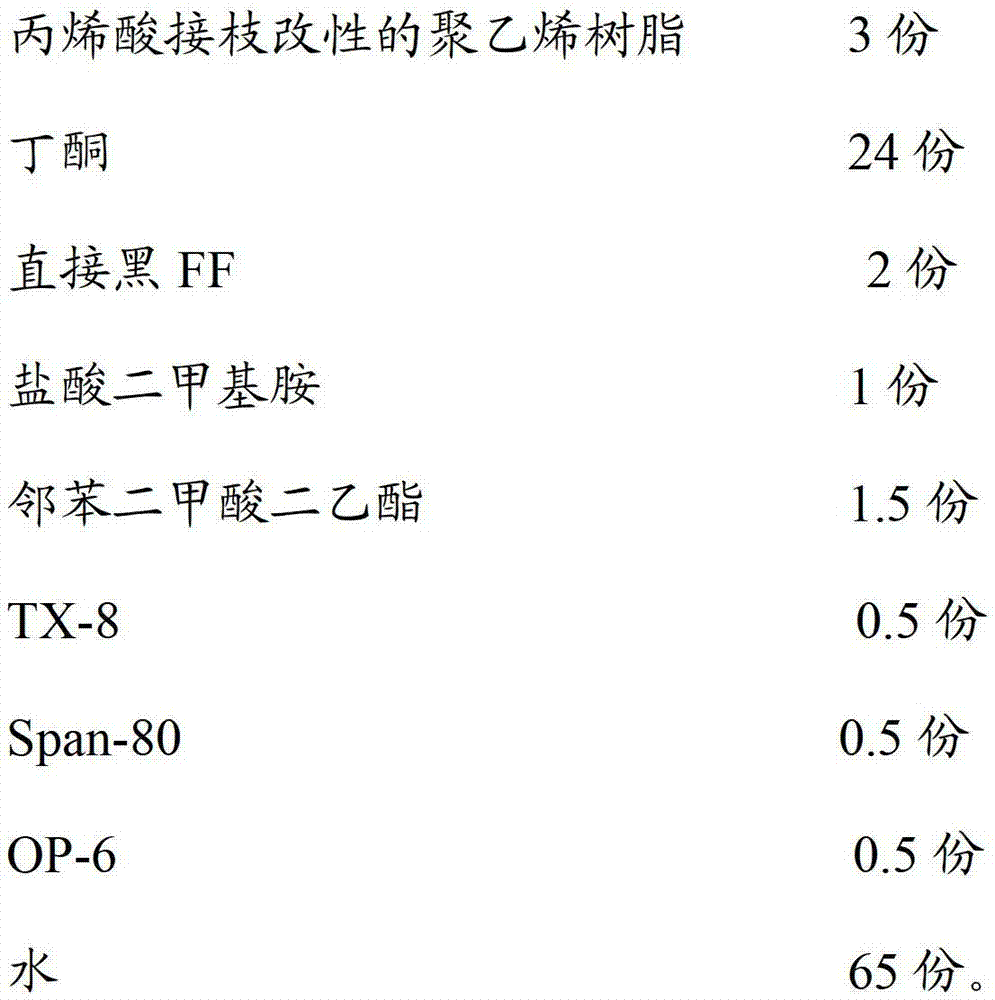

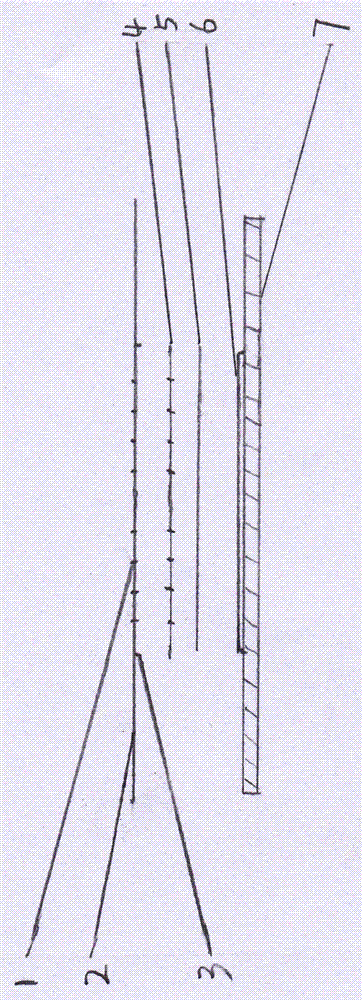

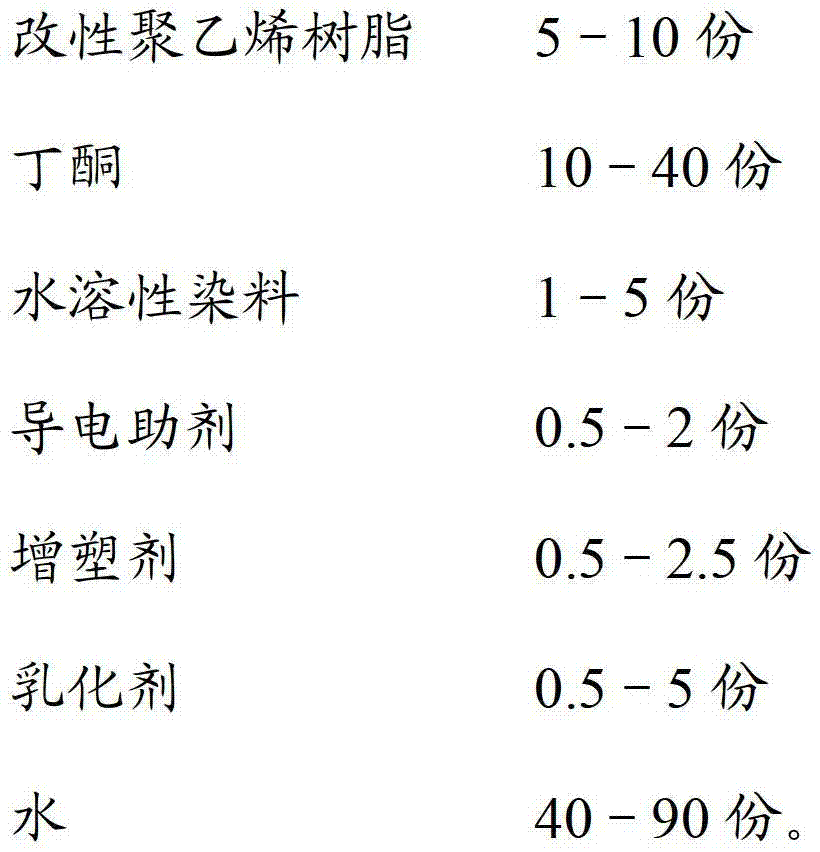

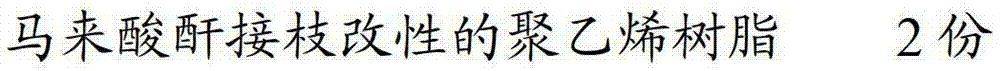

High-performance emulsion type water-based code-spraying printing ink for polyethylene and preparation method thereof

The invention discloses a high-performance emulsion type water-based code-spraying printing ink for polyethylene, which is prepared from the following components in parts by weight: 5-10 parts of modified polyethylene resin, 10-40 parts of butanone, 1-5 parts of a water-soluble dye, 0.5-2 parts of a conductivity improver, 0.5-2.5 parts of a plasticizer, 0.5-5 parts of an emulsifying agent, and 40-90 parts of water. According to the invention, through selecting an appropriate connecting material and an additive matched with the connecting material, the adhesion property of the code-spraying printing ink on a PE material in the process of spray printing is better, the system performance is stable, and prints are clear; and in addition, the utilization of organic solvents is completely abandoned in an code-spraying printing ink formulation disclosed by the invention, thereby greatly reducing the harm of the code-spraying printing ink to the human body and the environment in the processes of preparation and utilization.

Owner:河北慧彩油墨科技有限公司

Processing technology of aseptic package with metallic luster

InactiveCN106393881AGood metallic lusterGood printing adaptabilityLamination ancillary operationsSynthetic resin layered productsCardboardCompound a

The invention discloses a processing technology of an aseptic package with metallic luster. The technology includes the steps of: (1) compounding an aluminum plated film, PE and a paperboard together to prepare a composite aluminum plated card paper; (2) employing ink to perform printing on the surface of the composite aluminum plated card paper, wherein the ink comprises: 10-28% of pigment, 45% of polyurethane, 8.5-26.5% of n-propyl acetate, 8% of propylene glycol methyl ether, 2% of a leveling agent, 3.5% of a wetting agent, and 5% of a chelating agent; (3) compounding a PE layer and an aluminum foil layer on the other side of the paperboard; (4) compounding a PE layer on the other side of the aluminum foil layer; (5) compounding functional resin on the printed aluminum plated film surface by a multi-layer coextrusion technology; (6) cutting the obtained composite material into a coiled material; and (7) conveying the coiled material into a filling machine, and carrying out sterilization, filling, sealing and molding; and (8) sealing a drinking port. The package has metallic luster, the aesthetic properties of the aseptic package is greatly improved, and the overall value of the aseptic package is increased.

Owner:苏州普丽盛包装材料有限公司

Target capable of recording touch marks

The invention provides a target capable of recording touch marks. White paper where a circular ring target body is drawn is arranged under surface target paper, circular rings and circular rings on the surface target paper are in the same positions, carbon paper is arranged under the white paper, and a rough bottom plate with a file-like surface is arranged on the lowest layer. When a ball or other objects touch the target, clear marks are generated by the carbon paper due to pressure on the white paper where the circular ring target body is drawn, and the ring number and scores are calculated according to the position, on the target, of the center of the marks.

Owner:长沙深蓝未来智能技术有限公司

Fluorescent stamp-pad ink with anti-counterfeiting function and preparation method thereof

InactiveCN105176197AStable blotting performanceQuick identification of authenticityInksSolventChemistry

The invention relates to the field of printing ink of anti-counterfeiting label, especially to fluorescent stamp-pad ink with an anti-counterfeiting function and a preparation method thereof. The fluorescent stamp-pad ink with the anti-counterfeiting function is composed of a film-forming material and a fluorescent liquid, and is characterized in that the fluorescent liquid comprises the following ingredients, by weight, 15-20 parts of castor oil, 10-15 parts of terbium nitrate, 25-30 parts of 2,4-dihydroxy-benzoic acid, 150-200 parts of triethylamine, 150-200 parts of industrial alcohol solvent and 250-300 parts of n-butyl alcohol. The fluorescent stamp-pad ink prepared by the preparation method has stable print performance, is rapid and accurate in distinguishing true-false, and has good stability and adhesiveness. Print is clear and uniform and has little diffusion. The print can emit fluorescence under ultraviolet illumination, and the fluorescent color is obvious and clear and has good differentiability. Anti-counterfeiting identification can be achieved according to the fluorescent color.

Owner:FOSHAN HECAI TECH SERVICE

Mixed printing ink

The invention discloses a mixed printing ink. The mixed printing ink is prepared from the following raw materials in parts by weight: 55-65 parts of a water-based ink, 15-25 parts of an oil-based ink and 15-25 parts of a diluent. According to the mixed printing ink, the water-based ink and the oil-based ink are mixed according to a reasonable proportion, so that the glossiness of the ink is increased, and printed patterns are even, smooth and exquisite. The aodpted materials are no-benzene series materials, do not contain volatile poisonous deionized water, has a good printing effect, is strong in attachment firmness, incombustible, unexplosive and nontoxic, causes no harm to printing workers, avoids environmental pollution to the atmosphere and has good environmental protection performance; as a wear-resistant additive is added, a printed ink layer has a very small friction coefficient, and accordingly, the wearing resistance of the ink is greatly improved; the cost is relatively low, the ink layer attachment firmness is strong, and the mixed printing ink can resist rubbing and scratching, and is high in glossiness, good in wearing resistance, quick in drying and excellent in product quality.

Owner:桐城市人和包装有限公司

Novel blending printing ink

The invention discloses a novel blending printing ink. The novel blending printing ink is prepared from the following raw materials in parts by weight: 60 to 70 parts of water-based ink, 10 to 20 parts of oil-based ink, and 15 to 20 parts of diluent. The novel blending printing ink has the advantages that by mixing the water-based ink and the oil-based ink according to reasonable ratio, the glossiness of ink is increased, and the printed pattern is flat, smooth and fine; the used material is a non-benzene material, the volatile and poisonous deionized water is not contained, the printing effect is good, the adhesion firmness is strong, the combustion, explosion, poison and damage to health of printing workers are avoided, the environment pollution to atmosphere is avoided, and the environment-friendly effect is good; by adding an abrasion-resistant additive, the printed ink layer has smaller friction coefficient, and the abrasion-resistant property of ink is greatly improved.

Owner:桐城市人和包装有限公司

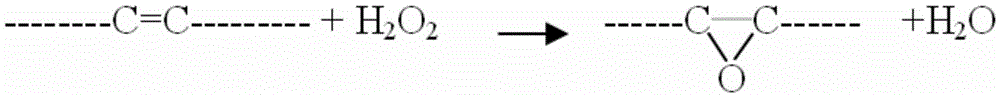

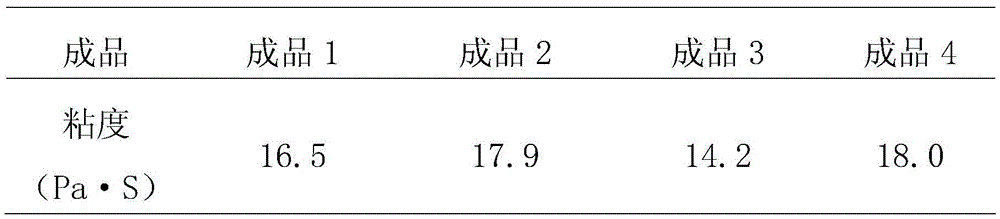

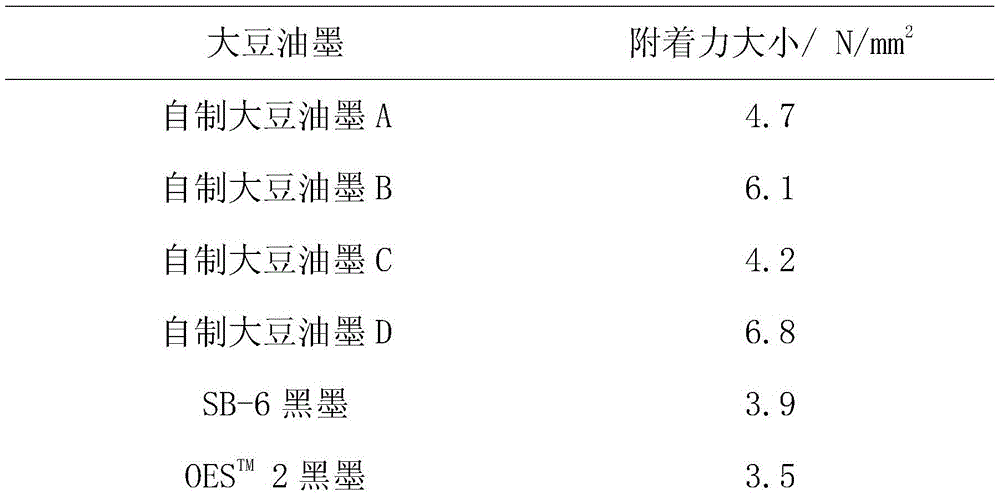

A kind of preparation method of epoxy polymerized soybean oil for printing ink

InactiveCN103865656BImprove adhesionHigh viscosityFatty acid chemical modificationInksEpoxyPolymer science

The invention discloses a preparation method of epoxy polymerized soybean oil for ink. The preparation method comprises the following steps of: firstly preparing thermally polymerized soybean oil by carrying out thermal polymerization on soybean oil under the condition of certain thermal polymerization reaction process parameters; then carrying out epoxidation on the thermally polymerized soybean oil by utilizing a high-efficiency catalyst to prepare the epoxy polymerized soybean oil. The epoxy polymerized soybean oil disclosed by the invention has the advantages of high viscosity, low acid number and good adhesive property, and meets the requirement of a soybean ink connecting material. Soybean ink prepared by taking the epoxy polymerized soybean oil as the soybean ink connecting material is high in volatilizing speed and high in adhesive force on various offset litho printing substrates and can substitute a large quantity of soybean oil ink products on the market.

Owner:瑞柯斯海口技术推广服务合伙企业有限合伙

A kind of ink pad based on supramolecular self-assembly gel and its preparation method

The invention discloses an ink paste based on a super-molecule self-assembled gel, and a preparation method thereof, wherein the ink paste is prepared from the following raw materials by mass: 10-20 parts of cinnabar, 40-60 parts of castor oil, 10-20 parts of moxa punk, 10-15 parts of white clay, 1-2 parts of kaolin, and 0.1-1 part of borneol, and the gel factor is the mixture comprising one or more than two materials selected from C16-C40 amide polymers and derivatives thereof. According to the present invention, the gel factor is easy to obtain, and the yield is high; and in the case of the low gel factor adding amount, the prepared ink paste has characteristics of high stability and clear imprinting mark.

Owner:ZHEJIANG UNIV OF TECH

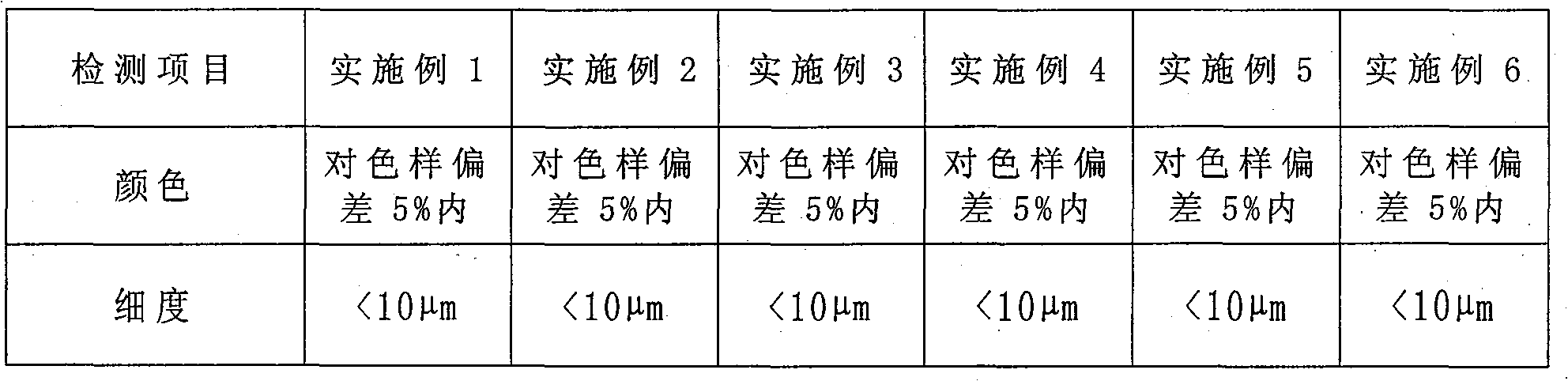

Water flexible painting plate ink and preparing method thereof

The invention relates to a waterborne soft printing ink comprising the components: acrylic resin emulsion of 37-47.2wt percent, waterborne acrylic color paste of 40-50wt percent, antifoam agent of 0.1-0.3wt percent, waterborne wax paste of 0.2-2.0wt percent, isopropyl alcohol of 2-8wt percent, ethylene glycol of 10-30wt percent, ethanolamine of 0.5-1wt percent and water of the rest percent. The invention further provides a method to prepare the waterborne soft printing ink. The waterborne soft printing ink of the invention is nontoxic and environmental friendly, has good safety, stable performance and good adaptability to coated art paper printing, and can be continuously used in printing without mackle, has clear printing effect and low production cost.

Owner:GUANGDONG YINGKE GRP CO LTD

Automatic stamping mechanism based on copper stamp

ActiveCN103129193BMake up for the defect of low service lifeLow failure rateStampingFailure ratePulp and paper industry

An automatic stamping mechanism based on a copper stamp structurally includes a paper feeding channel, a paper outlet channel, a paper conveying driving mechanism, a stamping mechanism and a control management circuit, wherein the paper feeding channel is connected with a paper outlet channel of a printer, and the paper outlet channel is connected with the tail end of the paper feeding channel. The automatic stamping mechanism based on the copper stamp is mainly characterized by further including an automatic replenishing mechanism of stamp-pad ink in structure, the automatic replenishing mechanism of the stamp-pad ink and the stamping mechanism form a matching structure of stamp-retrieval first and oiling second through a compound driving mechanism arranged under the paper outlet channel. The automatic stamping mechanism based on the copper stamp is simple in structure, omits the complex process of manual dipping the stamp-pad ink before stamping, has clear stamp, prolongs the service life of the stamp, and is connected with a specialized paper outlet so that paper jam is not easy to happen and the failure rate is low.

Owner:HEBEI HUIJIN ELECTROMECHANICAL

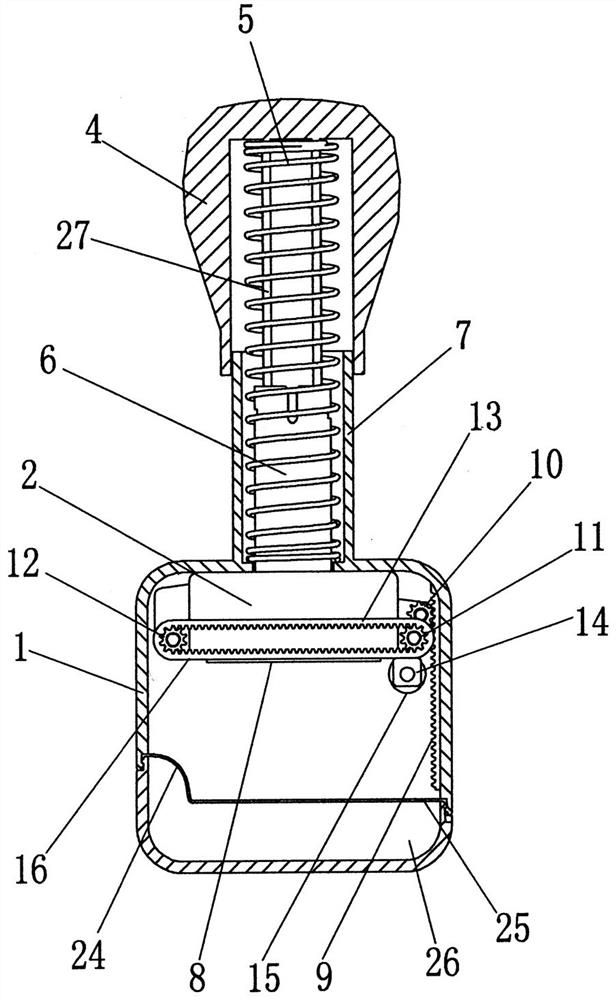

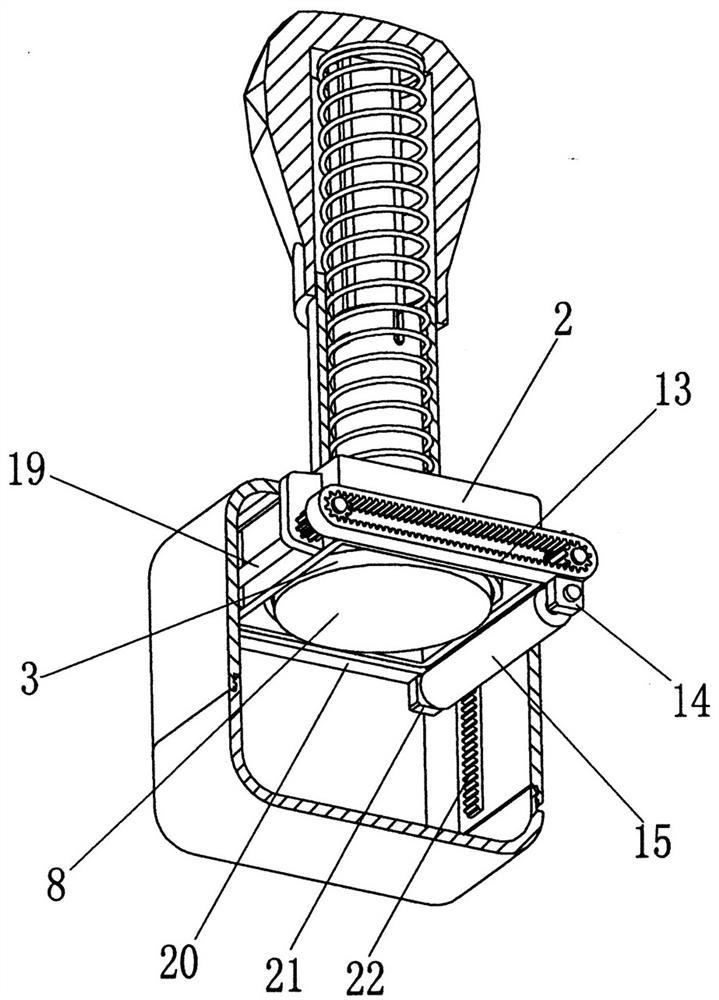

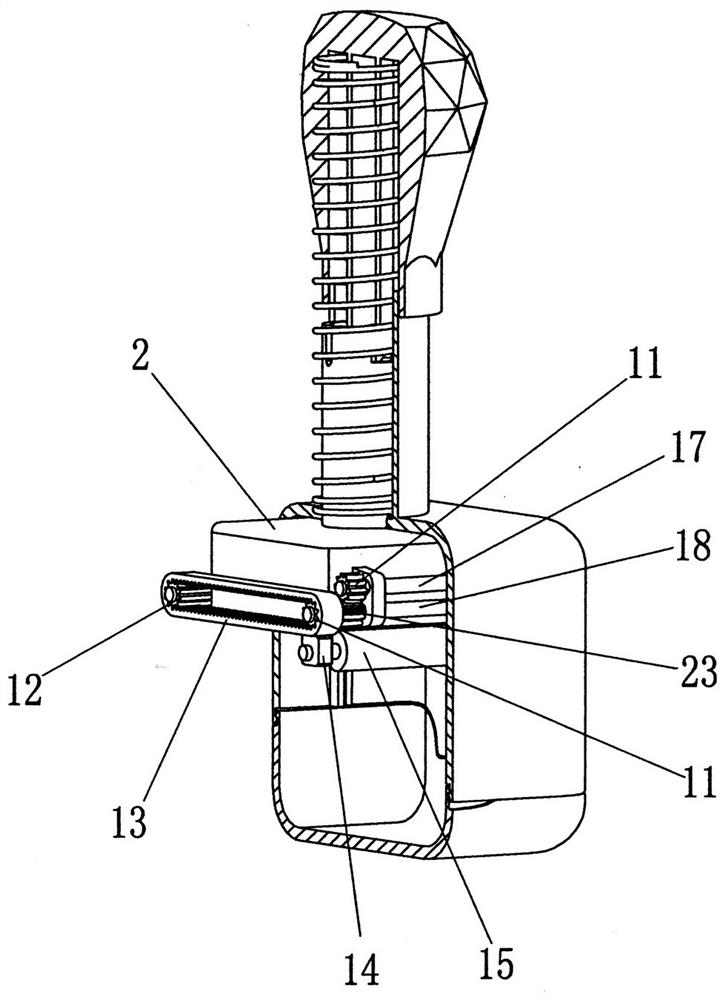

Stamp capable of automatically and uniformly applying stamp-pad ink

The invention discloses a seal capable of automatically and uniformly applying stamp-pad ink. The invention aims to solve the problems of incomplete, unclear and unbeautiful imprint, complex structure, high price, large size and the like in the prior art. According to the technical scheme, the stamp-pad ink mechanism comprises a shell, a stamp base, a stamp body, a handle and a return spring, the stamp base is arranged in the shell in a sliding fit mode, the stamp body is installed in the stamp base, the stamp face of the stamp body is exposed out of the bottom side of the stamp base, the handle is arranged on a top cylinder of the shell in a sliding fit mode, one end of the return spring abuts against the top cylinder, and the other end of the return spring abuts against the handle. Comprising a rack on the inner wall of a shell, a gear rotationally assembled on one side of a printing seat and meshed with the rack, a first belt wheel fixed on a gear shaft, a second belt wheel rotationally assembled on the other side of the printing seat, a transmission belt sleeved on the first belt wheel and the second belt wheel, a roller frame on the bottom surface of the lower side section of the transmission belt, and a roller containing stamp-pad ink rotationally assembled on the roller frame, and the stamp-pad ink-containing roller is lifted to a position higher than the printing surface after being in contact with and rolling over the printing surface.

Owner:李嘉善 +1

Printing ink possessing favorable wear-resistance

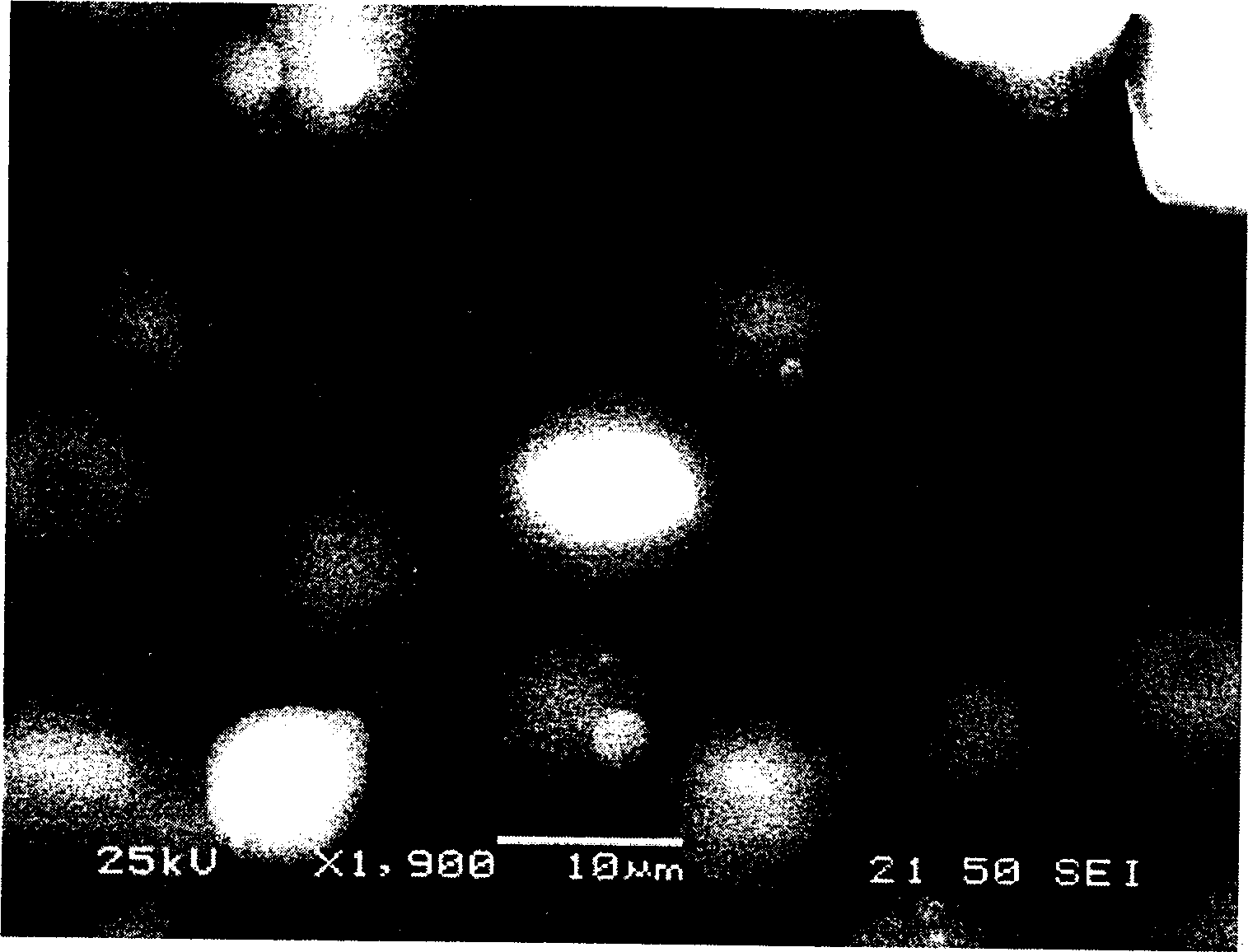

A printing ink with excellent wear-resisting ability is prepared by utilizing wax in which microspherulitized structure is applied. The wax in micro spherulitized structure has comparatively large specific surface area so it is easy to be mixed and dispersed in printing ink to reduce friction coefficient of ink film surface for improving wear-resisting ability of the printing ink.

Owner:CHINA BANKNOTE PRINTING & MINTING +1

Thermal transfer ribbon for near-edge printing and preparation method thereof

ActiveCN106381063BWill not interpenetrateNo pollution in the processInk ribbonsWax coatingsWaxOrganic solvent

The invention discloses a thermal transfer ribbon used for proximal margin printing and a production method thereof. The thermal transfer ribbon comprises a releasing layer, an adhesive coating and a matrix layer; the releasing layer comprises an aqueous wax emulsion, an auxiliary agent and deionized water, the adhesive coating comprises an aqueous resin emulsion, the aqueous wax emulsion, inorganic pigment, an auxiliary agent and deionized water; the emulsions used in the releasing layer and the adhesive coating are aqueous emulsions, an organic solvent is not added; viscosity of the releasing layer and the adhesive coating are different, and cannot be mutually penetrated while transfer printing. The thermal transfer ribbon can realize rapid printing for a proximal margin printer, the printed characters and images are clear, and the wear resistant and scratch resistant effects are good.

Owner:HANGZHOU TODAYTEC DIGITAL

Bronzing transfer film process

ActiveCN105365425BClear blotAngularSynthetic resin layered productsLaminationInformation layerCyclohexanone

The invention discloses a process for a gold-stamped transfer film and relates to the technical field of a gold stamping process. The process comprises the following technological procedures: (1) forming a PET (Polyethylene Terephthalate) base film; (2) forming a release layer; (3) forming an information layer; (4) forming an aluminum plated layer; (5) forming a back glue layer; (6) slitting a finished product; the process comprises the following solvents: ethyl ester, butanone, cyclohexanone and methylbenzene; the process comprises the following raw materials in solid content: 30% of LX-51M-3, 30% of LX-49M, 50% of PET-261, 50% of PET251H and 20% of BJ-30A-1; the PET base film is a PET transfer film; the release layer is an LX-51M-3 release layer; the information layer is a color layer including double components which are namely PET-261 and PET251H; the back glue layer is BJ-302 and 88 glue. The process for the gold-stamped transfer film, disclosed by the invention, has the beneficial effects of being clear in print after stamping, angular, bright, free of pasting, scratch and drop and the like.

Owner:广州市花都恒盛印刷包装有限公司

A kind of high-performance emulsion type water-based coding ink for polyethylene and preparation method thereof

The invention discloses a high-performance emulsion type water-based code-spraying printing ink for polyethylene, which is prepared from the following components in parts by weight: 5-10 parts of modified polyethylene resin, 10-40 parts of butanone, 1-5 parts of a water-soluble dye, 0.5-2 parts of a conductivity improver, 0.5-2.5 parts of a plasticizer, 0.5-5 parts of an emulsifying agent, and 40-90 parts of water. According to the invention, through selecting an appropriate connecting material and an additive matched with the connecting material, the adhesion property of the code-spraying printing ink on a PE material in the process of spray printing is better, the system performance is stable, and prints are clear; and in addition, the utilization of organic solvents is completely abandoned in an code-spraying printing ink formulation disclosed by the invention, thereby greatly reducing the harm of the code-spraying printing ink to the human body and the environment in the processes of preparation and utilization.

Owner:河北慧彩油墨科技有限公司

A kind of cinnabar ink pad and preparation method thereof

The invention provides a cinnabar seal ink and a preparation method of the cinnabar seal ink. The cinnabar seal ink is prepared from cinnabar, moxa, bamboo leaf powder, white carbon black, propyl p-hydroxybenzoate, yellow soft paraffin, and flavoring rose essence. The seal ink is high in drying speed, bright in color, and stable in chemical properties, is light-resistant, can be stored for a long period of time, and does not fade.

Owner:铜仁市万山区丹凤朱砂工艺品研发检测鉴定中心有限公司

An automatic stamping machine for marking pulley assembly

Owner:ANHUI HAOFANG ELECTROMECHANICS

Solvent-based light oil suitable for offset press

InactiveCN103132372BStamping adaptability and stabilityThere will be no problem of incomplete bronzingPaper coatingCoatingsHot stampingVitrification

The invention discloses solvent-based light oil suitable for an offset press. The solvent-based light oil comprises the components by weight percent of: 13-18% of primary connecting material resin, 6-10% of auxiliary resin, 65-80% of a solvent, 4-6% of an auxiliary solvent and 0.5-1% of an auxiliary agent. The Lower glass transition temperature can be obtained after the solvent-based light oil is dried compared with that by using UV (ultraviolet) light oil in the prior art; the solvent-based light oil is stable in the aspect of hot stamping adaptability; the problem of incomplete hot stamping is not generated; the matching characteristic of the solvent-based light oil with silk printing ink after the solvent-based light oil is applied to the offset press can be improved, and the deinking possibility is reduced due to the fact that the resin with low UV tension is selected by the solvent-based light oil.

Owner:SHENZHEN KECAI PRINTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com