High-performance emulsion type water-based code-spraying printing ink for polyethylene and preparation method thereof

A polyethylene, high-performance technology, applied in the field of high-performance emulsion type water-based coding ink, can solve the problems of low adhesion, unenvironmental protection, and reduced ink, and achieve the effect of stable system performance, good adhesion performance and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

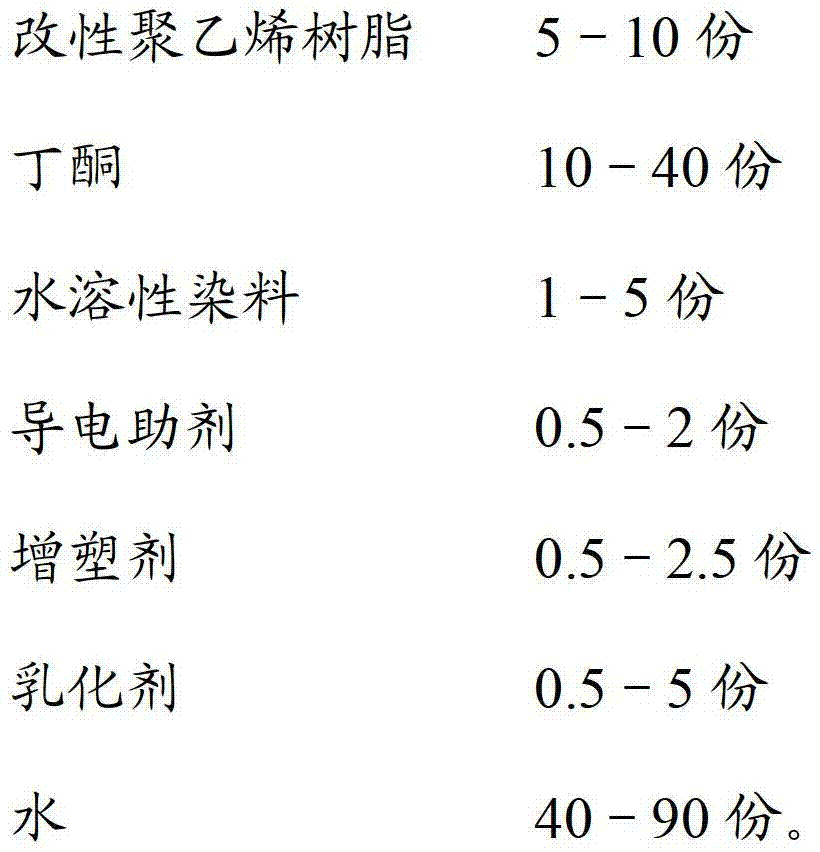

[0029] A high-performance emulsion type water-based inkjet ink for polyethylene, its raw material formula is as follows by weight:

[0030]

[0031] Preparation:

[0032] According to the above raw material ratio, weigh 6 parts by weight of highly chlorinated modified polyethylene resin, put it into 20 parts of butanone, stir at room temperature until the resin is completely dissolved, and obtain solution A. At the same time, dissolve 1 part of Tween-20 with 50 parts of water to obtain solution B. Dissolve 2 parts of water-soluble dye reduction direct black RB with 19 parts of water to obtain solution C. Under the stirring condition that the stirring speed is not lower than 1000RPM, slowly drop the solution A into the solution B for emulsification, and continuously stir vigorously for 4~10h. Finally, add 1 part of dibutyl phthalate, 1 part of dimethylamine hydrochloride and solution C in sequence, and stir well at room temperature to prepare a high-performance emulsion-ty...

Embodiment 2

[0035] A high-performance emulsion-type water-based inkjet ink for polyethylene, its raw material formula is as follows by weight:

[0036]

[0037] Preparation:

[0038] According to the above raw material ratio, weigh 5 parts of chlorosulfonated polyethylene resin, put it into 25 parts of butanone, stir at room temperature until the resin is completely dissolved, and obtain solution A. At the same time, dissolve 0.5 part of Tween-60 and 1 part of Span-40 with 50 parts of water to obtain solution B. Dissolve 1.5 parts of water-soluble dye Direct Black 168 with 15 parts of water to obtain solution C. Under the stirring condition that the stirring speed is not lower than 1000RPM, slowly drop the solution A into the solution B for emulsification, and continuously stir vigorously for 4~10h. Finally, 1 part of dibutyl phthalate, 1 part of tetrabutylammonium bromide and solution C were added in sequence, and stirred thoroughly at room temperature to obtain a high-performance e...

Embodiment 3

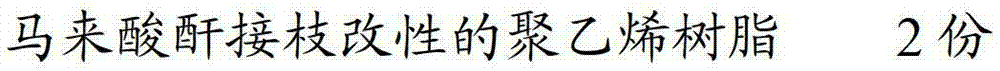

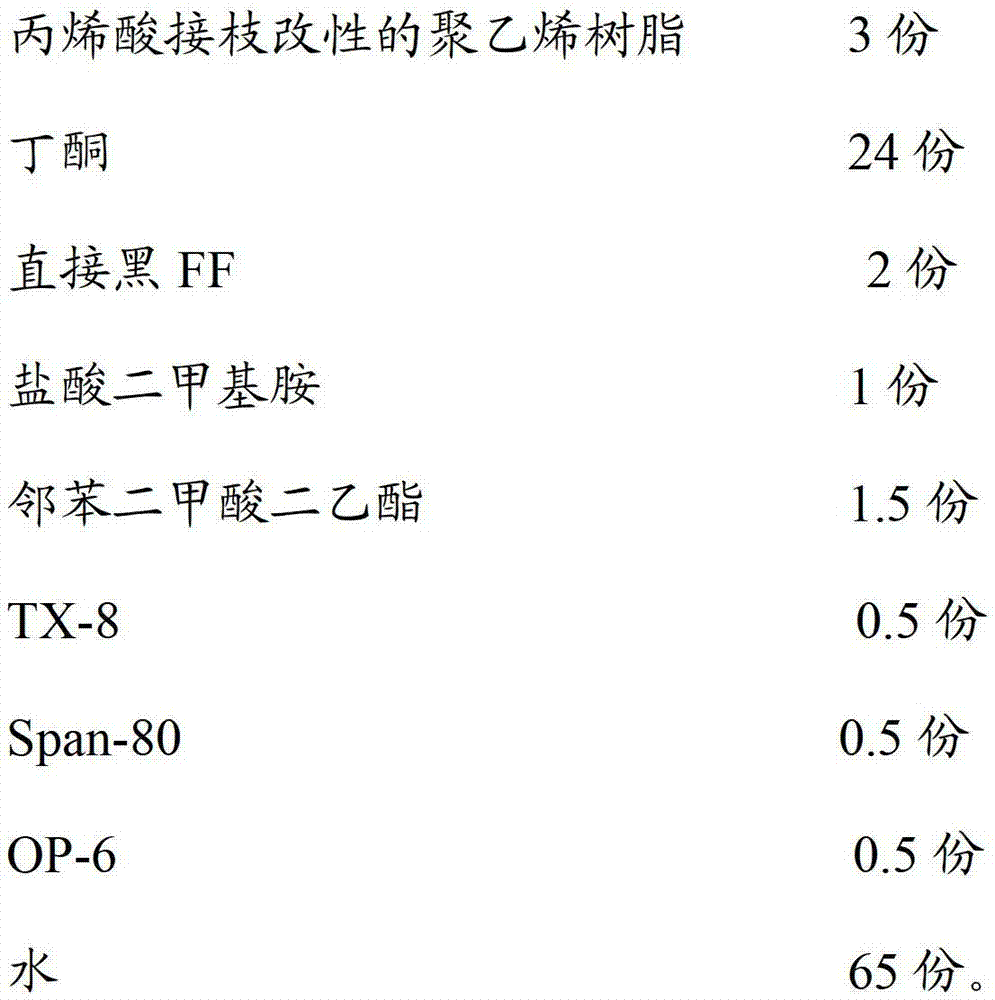

[0041] A high-performance emulsion-type water-based inkjet ink for polyethylene, its raw material formula is as follows by weight:

[0042]

[0043] Preparation:

[0044]According to the above raw material ratio, weigh 6 parts of maleic anhydride graft-modified polyethylene resin, put it into 20 parts of methyl ethyl ketone, stir at room temperature until the resin is completely dissolved, and obtain solution A. At the same time, dissolve 0.5 part of Tween-80, 1 part of Span-60 and 0.5 part of OP-10 with 50 parts of water to obtain solution B. Solution C was obtained by dissolving 2 parts of water-soluble dye C.I. Direct Black 62 with 17 parts of water. Under the stirring condition that the stirring speed is not lower than 1000RPM, slowly drop the solution A into the solution B for emulsification, and continuously stir vigorously for 4~10h. Finally, 1.5 parts of dibutyl phthalate, 1.5 parts of tetrabutylammonium bromide and solution C were added in sequence, and stirred t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com