Stamp capable of automatically and uniformly applying stamp-pad ink

A printing ink and uniform technology, applied in printing, stamping, etc., can solve the problems of inconvenient carrying and storage, incomplete imprinting, poor uniformity, etc., and achieve the effect of convenient carrying and storage, beautiful imprinting, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

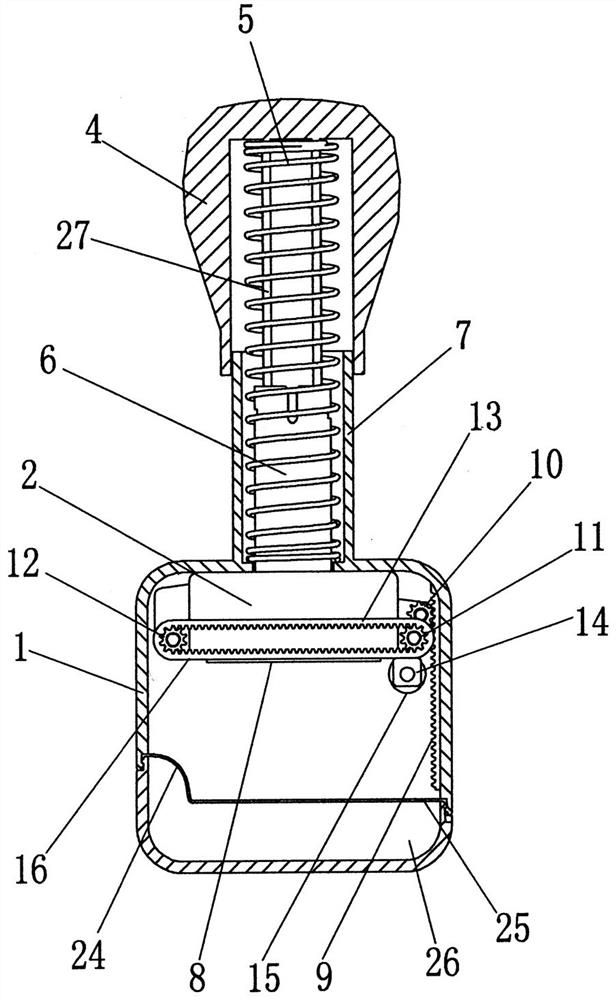

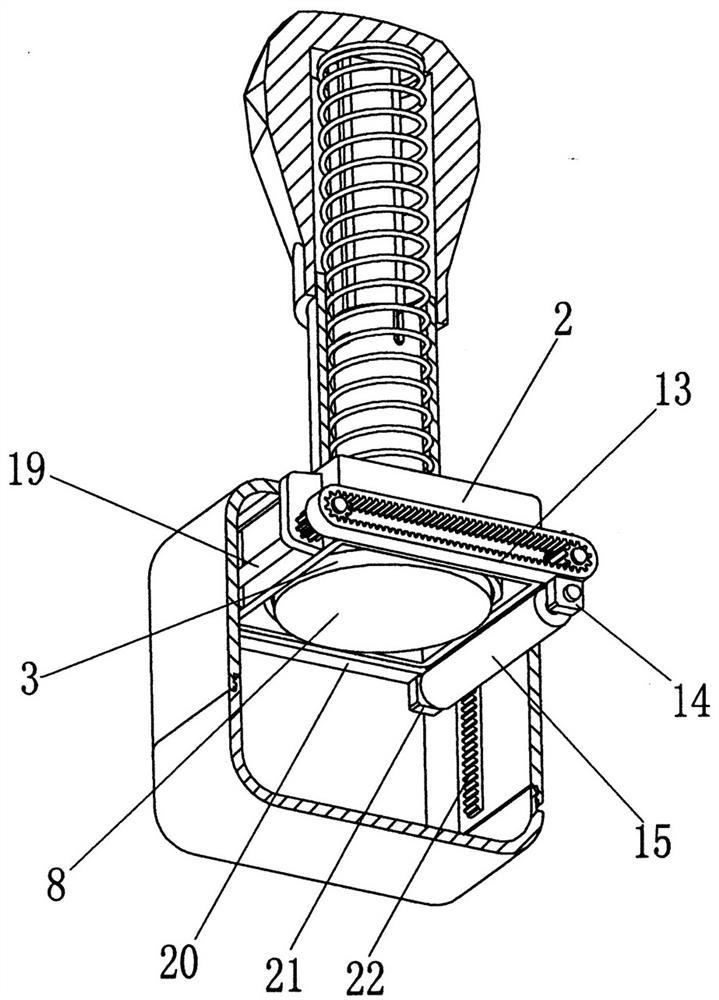

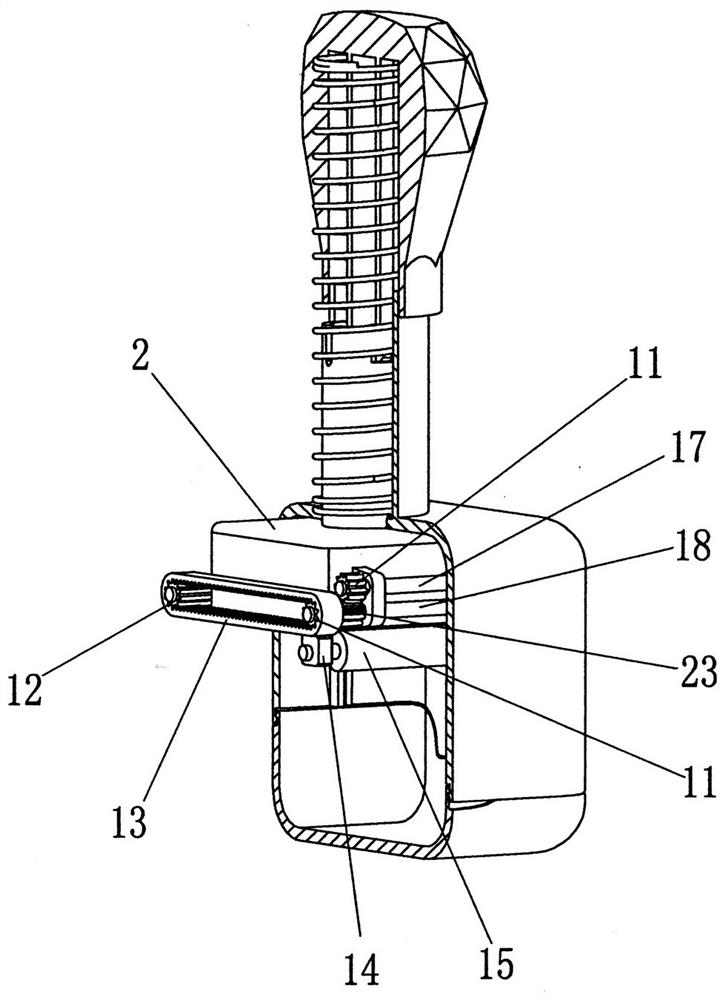

[0025] refer to Figure 1 to Figure 4 , the stamp that is automatically and evenly printed with oil includes a housing 1, a stamp base 2, a print body 3, a handle 4, and a return spring 5, wherein the stamp base 2 is in the housing 1, and the stamp base 2 is formed by its top The sliding rod 6 is slidingly fitted on the housing 1, and the top sliding rod 6 protrudes from the top cylinder 7 of the housing 1, and the printing body 3 is installed and fixed in the printing seat 2 and The stamp surface 8 of the stamp 3 exposes the bottom side of the stamp seat 2, the handle 4 is sleeved and slidably fitted on the outside of the top cylinder 7, and the return spring 5 is located between the top cylinder 7 and In the handle 4, one head is against the top cylinder 7, and the other end is against the handle 4. It is characterized in that: an ink-containing cylinder upper printing mechanism is installed on the outer side of the printing seat 2, so that The ink printing mechanism on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com