Automatic stamping machine for stamping pulley assemblies

A technology of automatic stamping machine and identification tape, applied in the field of stamping machines, can solve problems such as low efficiency and unclear imprint, and achieve the effects of clear imprint, simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

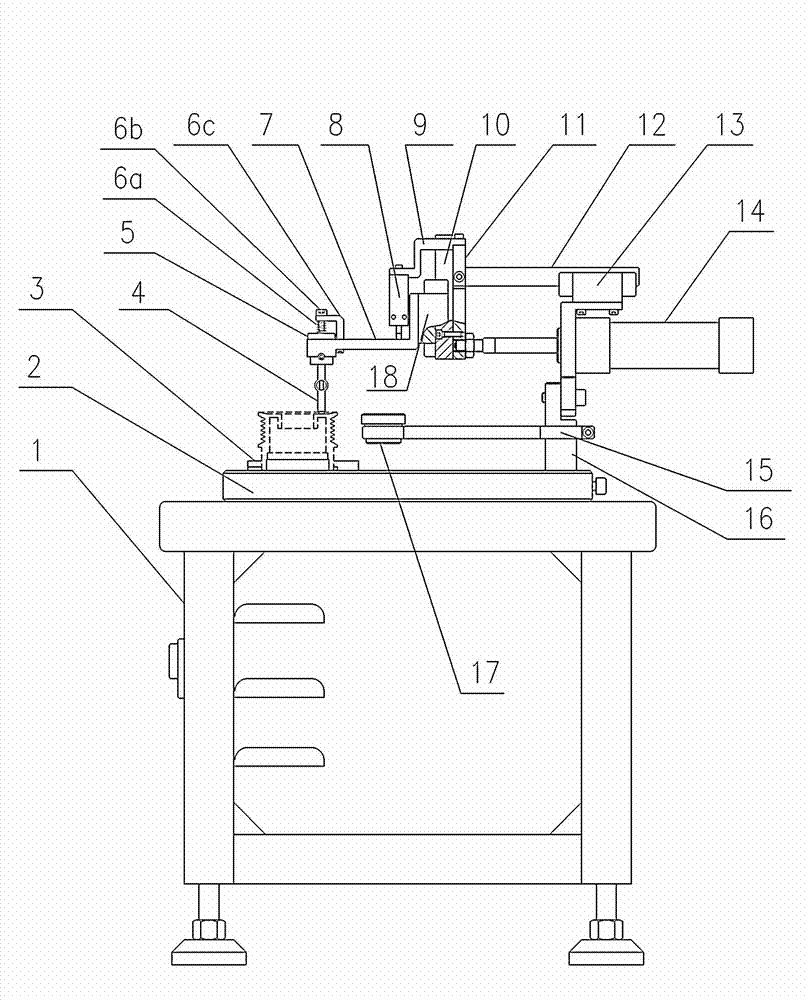

[0014] like figure 1 As shown, it is an automatic stamping machine for identifying a pulley assembly provided by the present invention, comprising a workbench 1, a base plate 2 on the workbench, and a workpiece clamping seat 3 for clamping the pulley on the base plate , the base plate is also provided with a support seat 16, the middle of the support seat is provided with an ink cartridge holder 15, one end of the ink cartridge holder is provided with an ink cartridge 17, the upper part of the support seat 16 is connected with a telescopic cylinder 14, and one end of the telescopic cylinder is provided with a push plate 11, There is also a horizontal slider seat 13 above the telescopic cylinder. The horizontal slider seat is connected with a horizontal slider 12. The horizontal slider is slidably matched with the horizontal slider seat. The upper part of the push plate is connected with a connecting plate 9, the connecting plate is provided with a lifting cylinder 8, the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com