Printing ink possessing favorable wear-resistance

A technology of wear resistance and ink, applied in the direction of ink, household utensils, applications, etc., can solve the problems of poor ink performance, achieve the effect of improving leveling, smooth and wrinkle-free ink film surface, easy to mix and disperse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

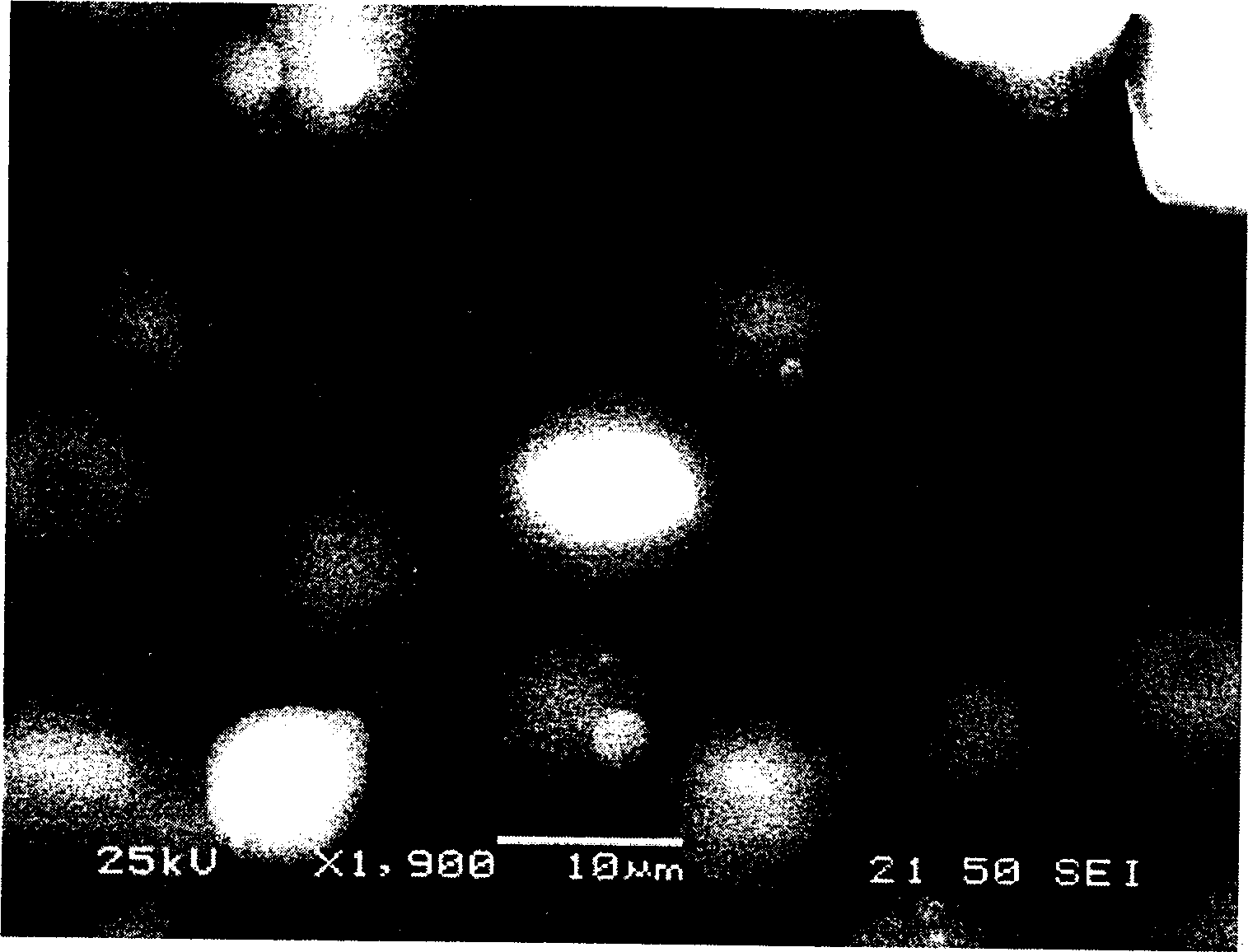

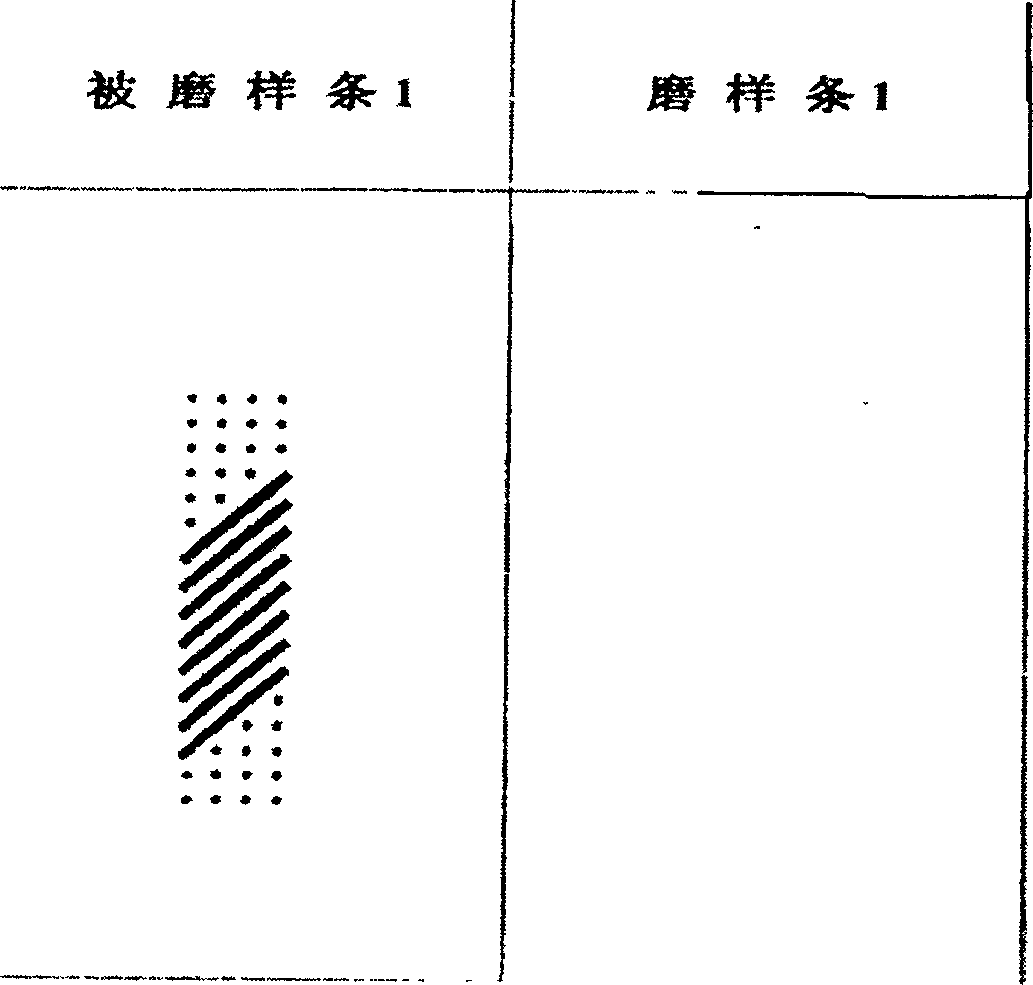

[0042] Weigh 20 kg of phenolic resin, 20 kg of alkyd resin, 30 kg of calcium carbonate, and 8 kg of organic toner according to their weight, put them into the material bucket, and then stir for 30 minutes. The three-roller ink machine is rolled to make its fineness≤15 μm; then add 8 kilograms of particle size distribution and be the microspherical structure of Canaba wax of 10-20 μm, 10 kilograms of solvents (4 kilograms of diethylene glycol monoethyl ether And 6 kilograms of boiling points are the petroleum solvent of 200-280), 2 kilograms of manganese octoates, 2 kilograms of potassium dodecylbenzenesulfonate are stirred together with the rolled material, and the stirring time is 20 minutes, after stirring evenly. The electron micrograph of the canaba wax with microsphere structure is shown in figure 1 . Adopt above-mentioned abrasion resistance detection method to detect, its result sees figure 2 . In the figure, the ground spline 1 refers to the tested spline, and the ...

Embodiment 2

[0044] Weigh 40 kg of phenolic resin, 8 kg of alkyd resin, 30 kg of calcium carbonate, and 8 kg of organic toner according to their weight, put them into the material bucket, and then stir for 30 minutes. The three-roller ink machine is rolled to make its fineness≤15 μm; then add 3 kilograms of polyethylene wax and 2 kilograms of beeswax and 7 kilograms of solvent (3 kilograms of diethylene diethylene glycol) with a microspherical structure of 20-35 μm in particle size distribution. Alcohol monoethyl ether and 3 kilograms of petroleum solvents with a boiling point of 200-280), 2 kilograms of zirconium naphthenate, are stirred together with the rolled material, and the stirring time is 20 minutes, after stirring evenly. Test result is identical with embodiment 1.

Embodiment 3

[0046] Using the same formula and process as in Example 2, but adding 1.5 kg of zirconium naphthenate and 0.5 kg of nonylphenol polyoxyethylene ether, the detection result is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com