Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Center positioning is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

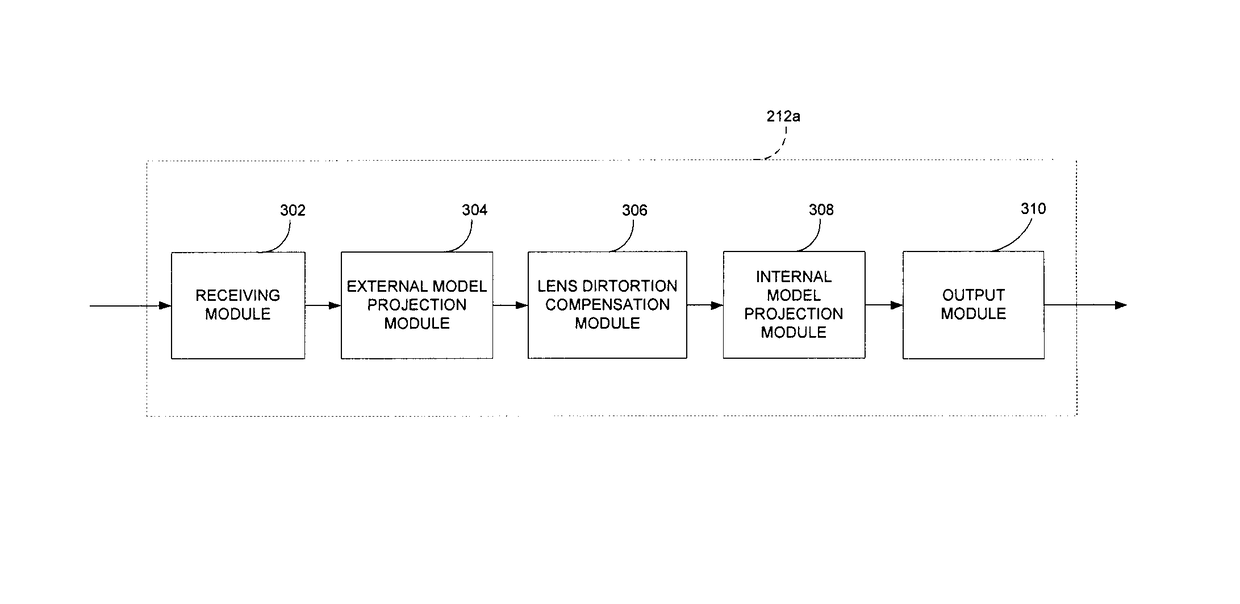

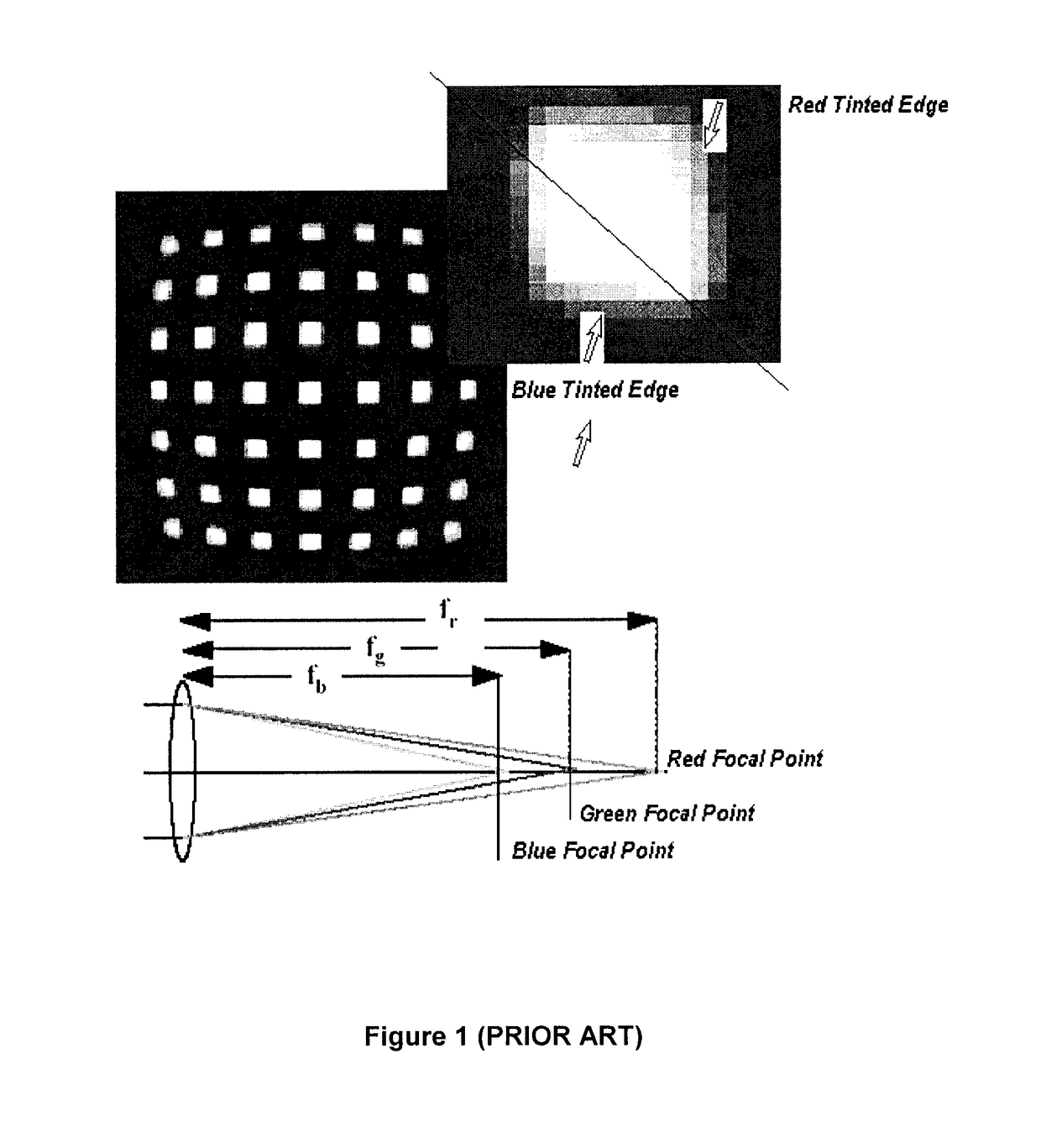

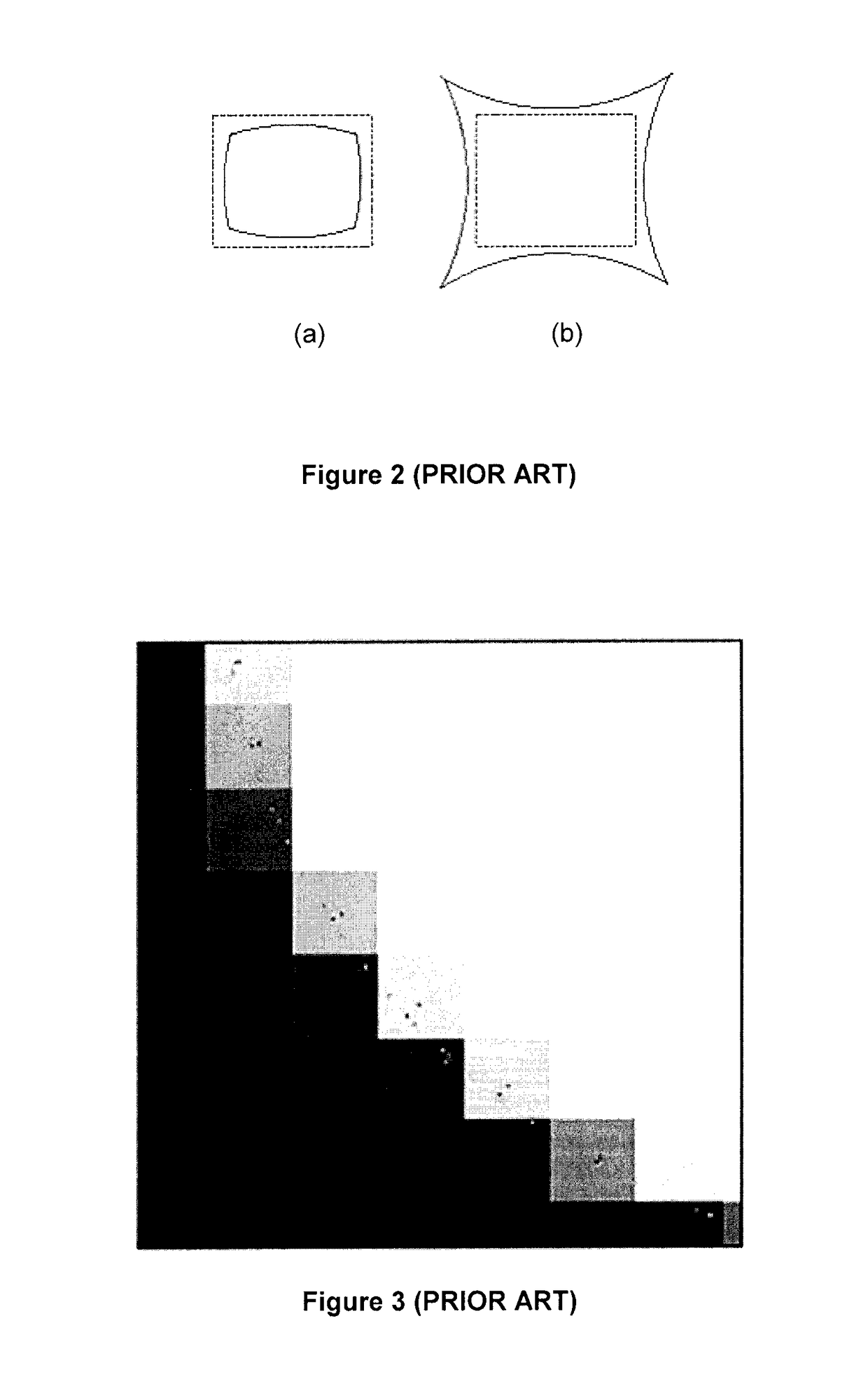

System and method for imaging device modelling and calibration

ActiveUS20160140713A1Exact lengthImprove accuracyImage enhancementImage analysisDistortionVideo camera

The invention relates to a camera modeling and calibration system and method using a new set of variables to compensate for imperfections in line of sight axis squareness with camera plane and which increases accuracy in measuring distortion introduced by image curvature caused by geometric and chromatic lens distortion and wherein the camera image plane is represented from a full 3D perspective projection.

Owner:MARTIN GUY

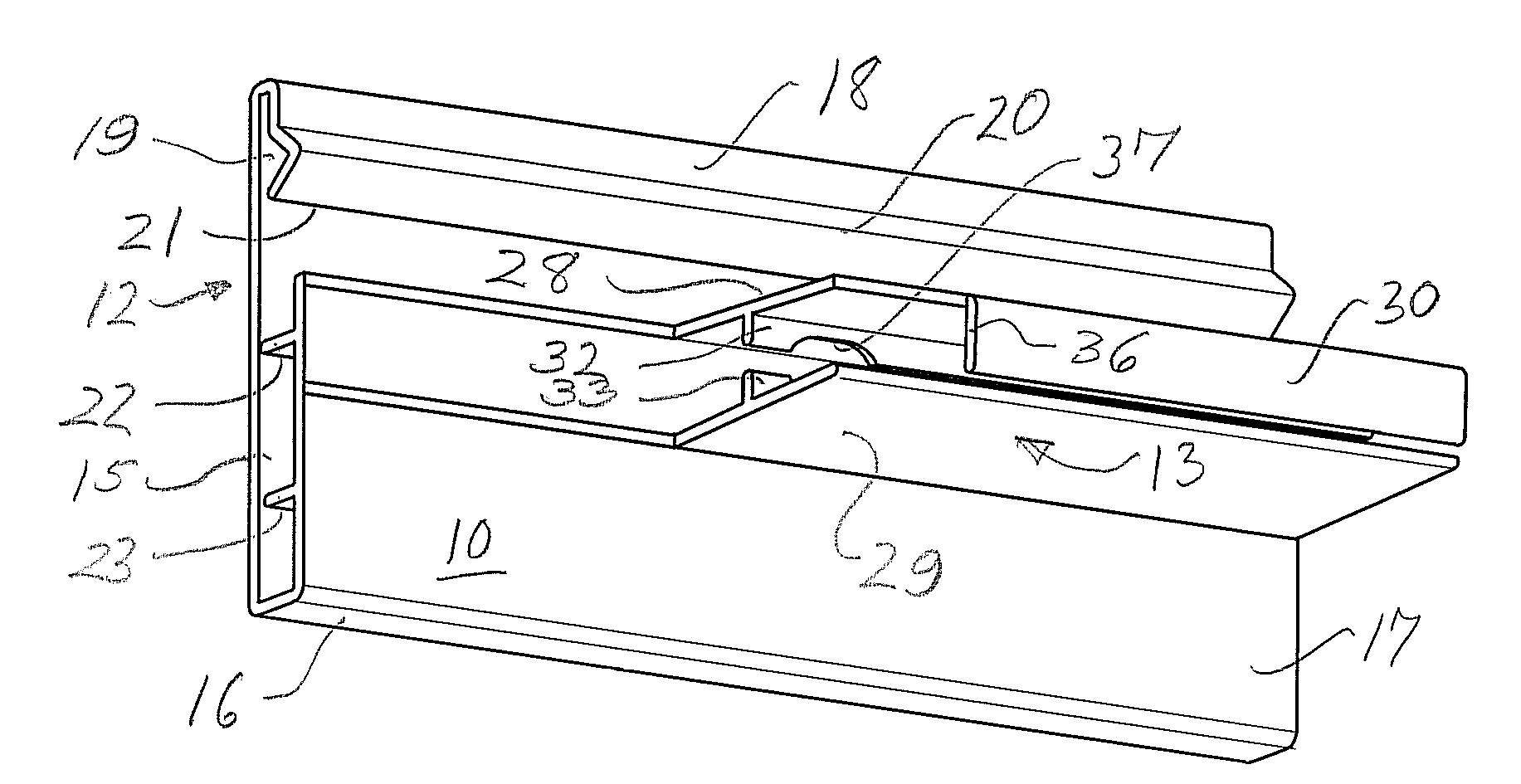

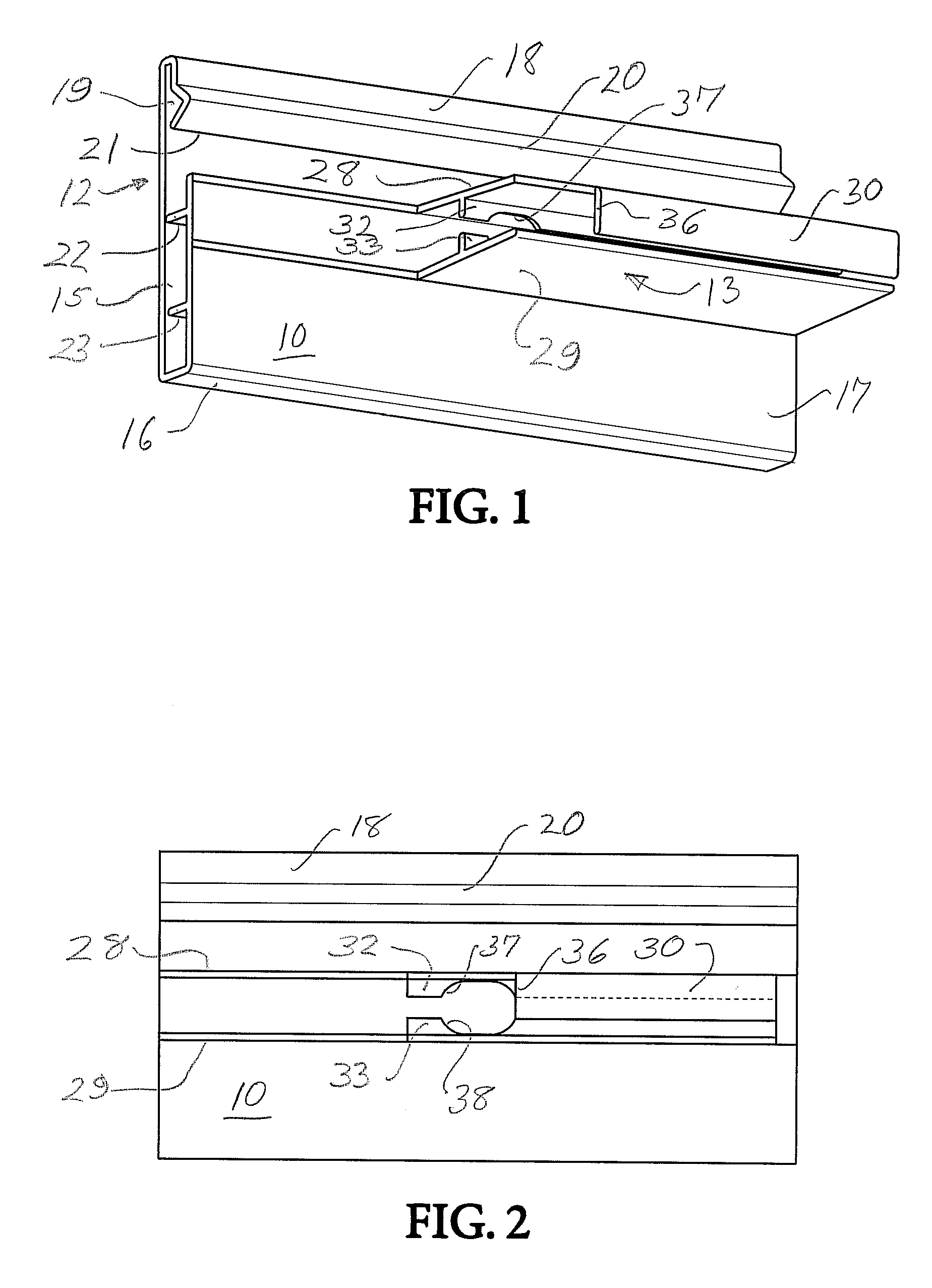

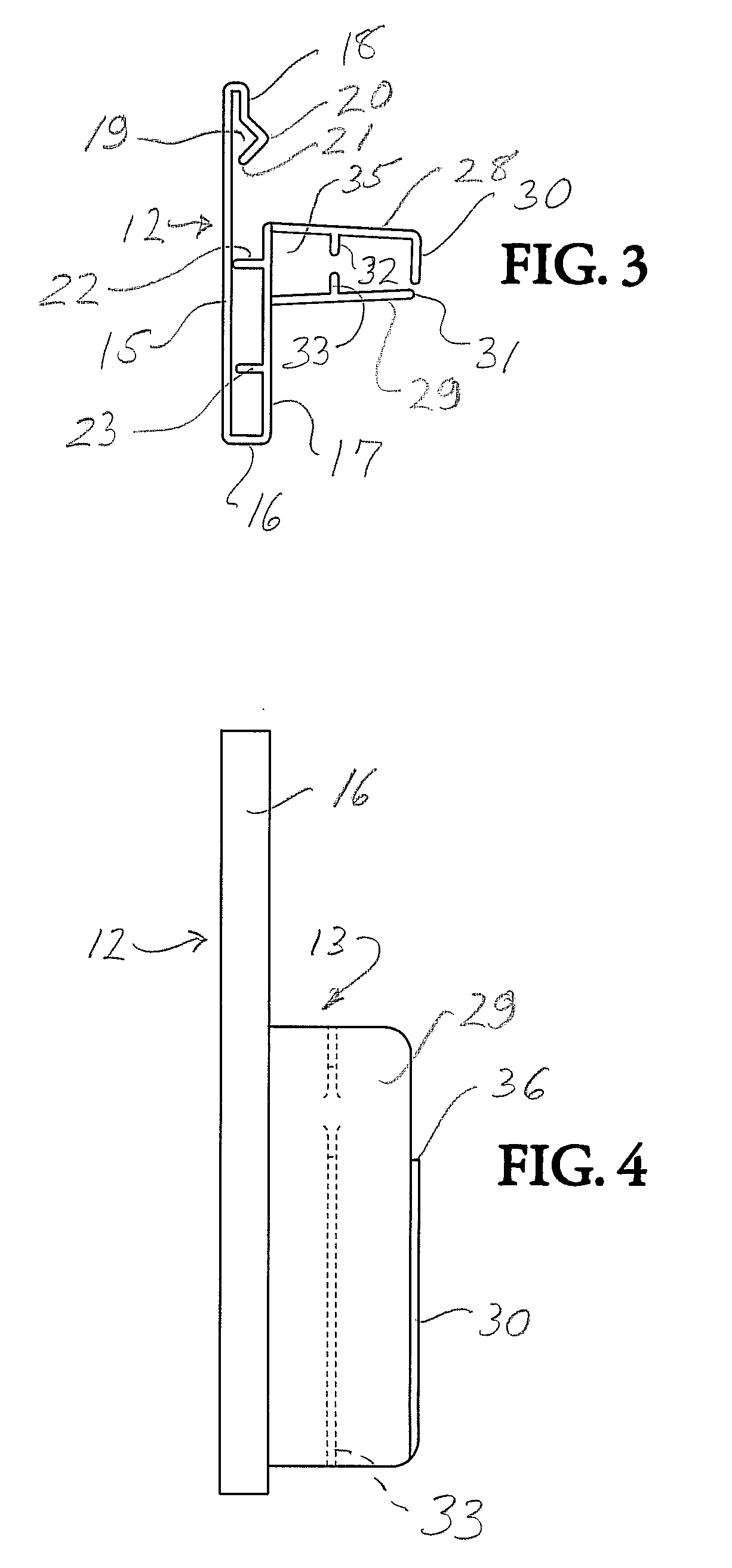

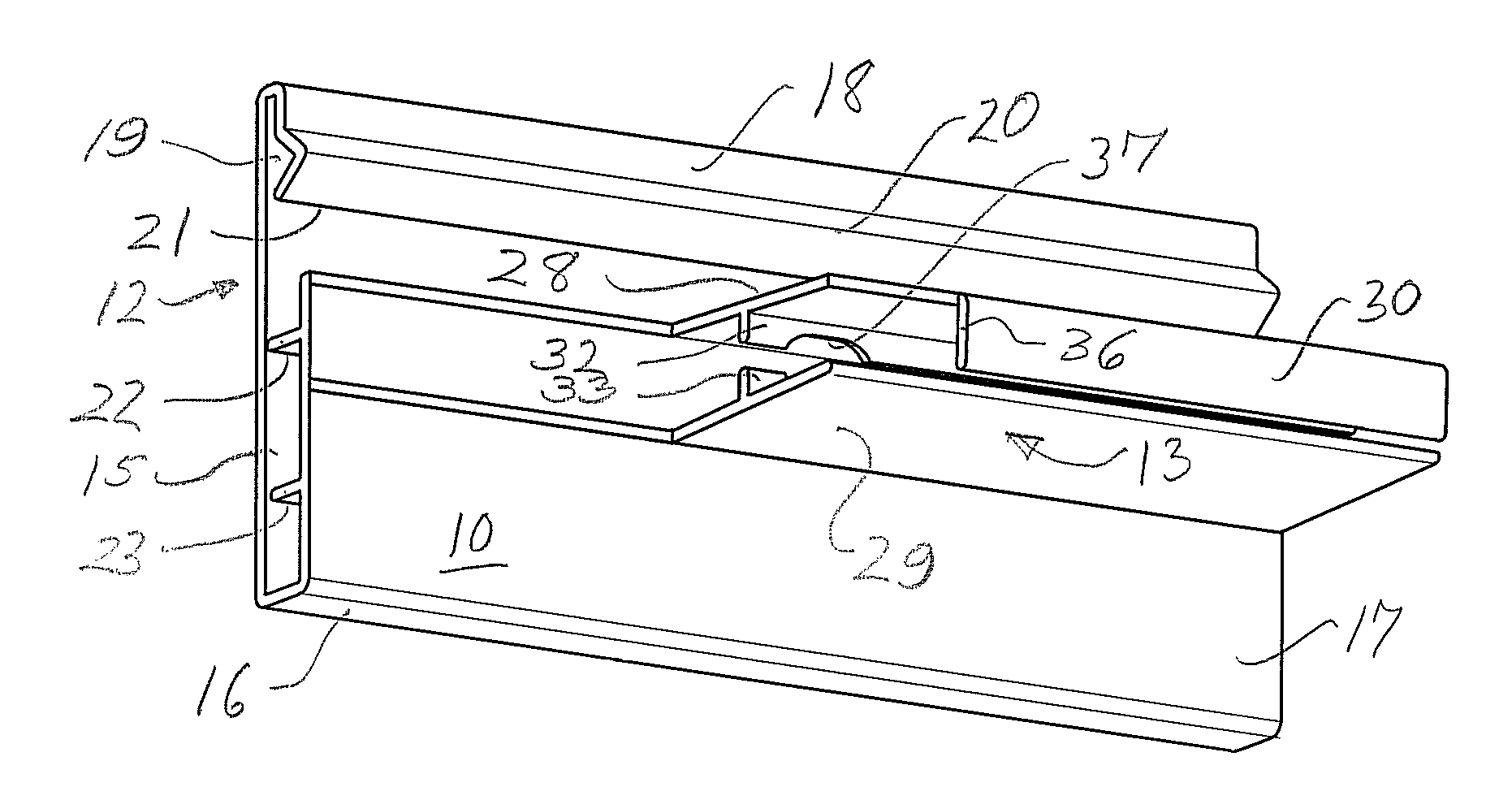

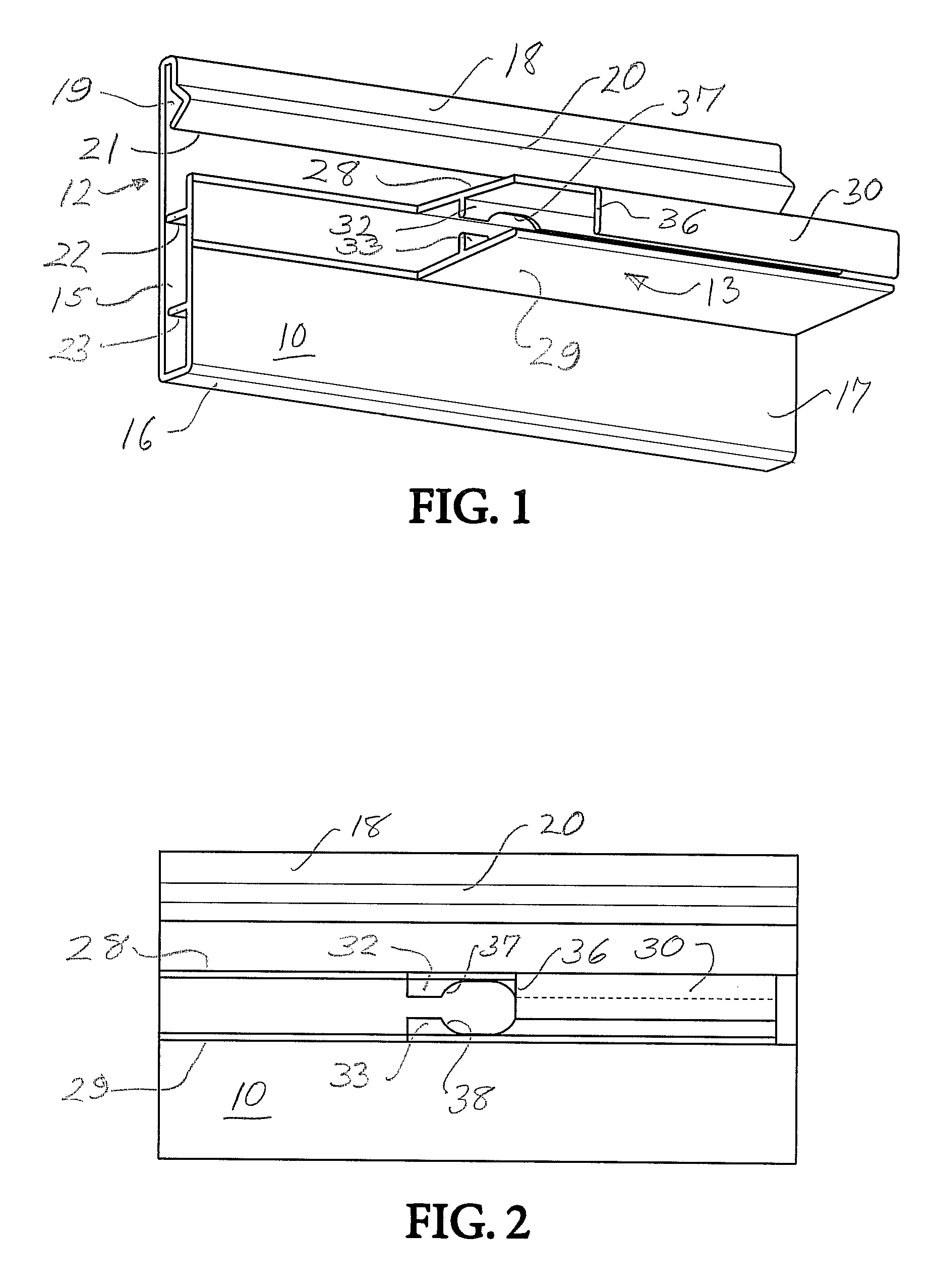

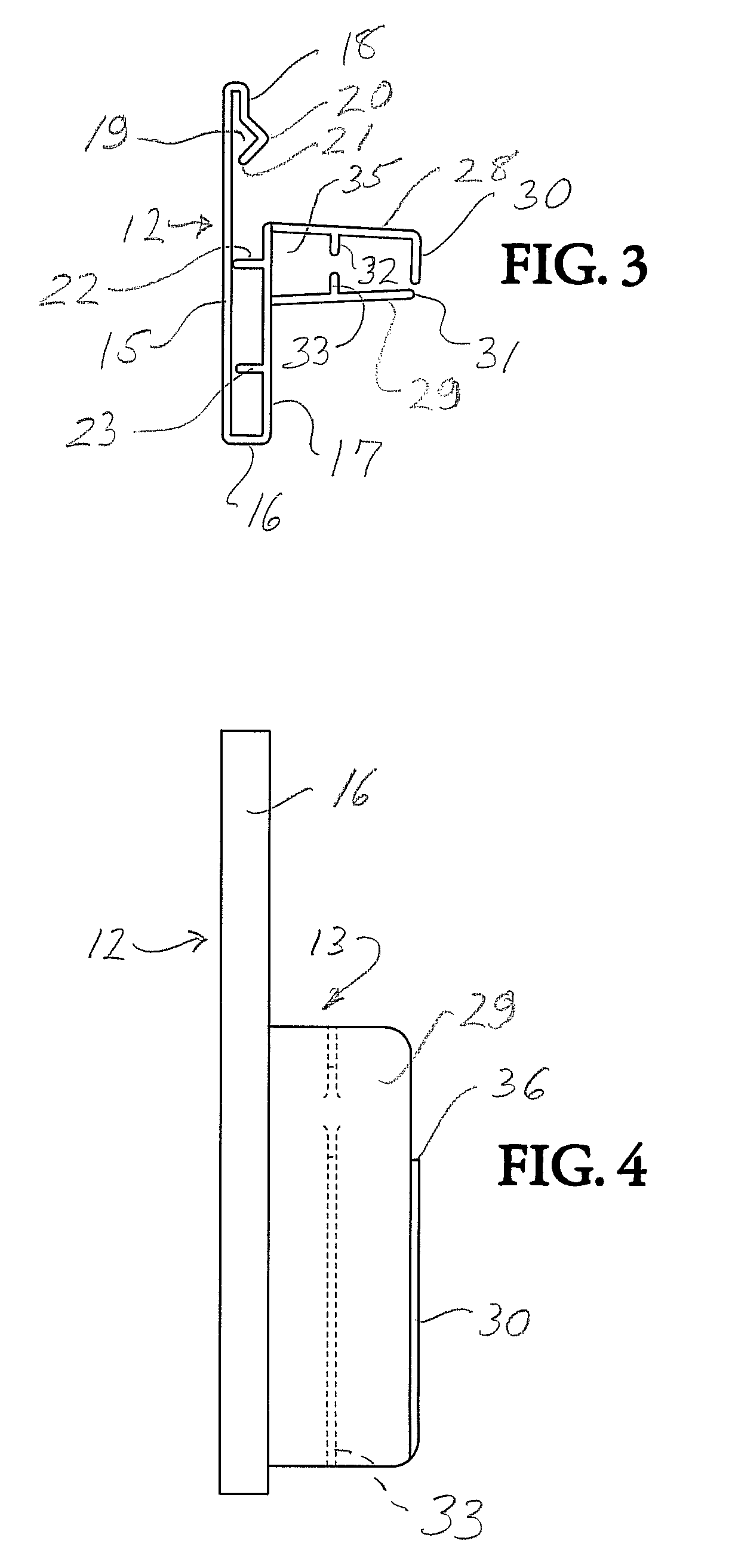

Label holder for merchandise display hooks and method of making same

InactiveUS20080307687A1Low costCenter positioning is accurateStampsMetal rolling stand detailsWire rodEngineering

A label holder for displaying information labels at the front of merchandise display hooks, and method for making the label holder. The label holder is of inexpensive continuously extruded construction, which is inexpensively processed after extrusion to eliminate the typical shortcomings of conventional extruded label holders. The extruded body form is cut to usable length and subjected to a plurality of die cutting operations on the back or mounting portion of the label holder, to form positioning and retention features. The label holder is thus provided with many if not most of the beneficial features of specially molded label holders, without incurring the greater expense involved in the molding process. The label holder is designed to accommodate mounting on label holders of several wire sizes commonly found in use in merchandise displays.

Owner:TRION IND

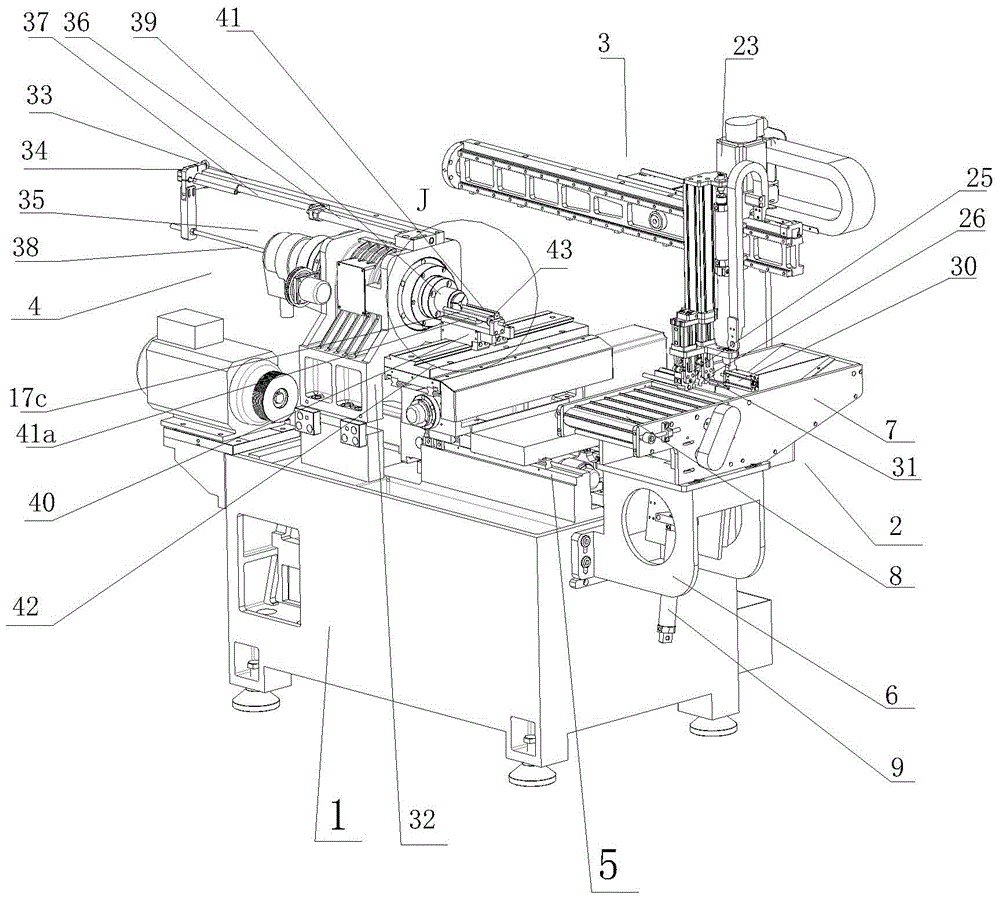

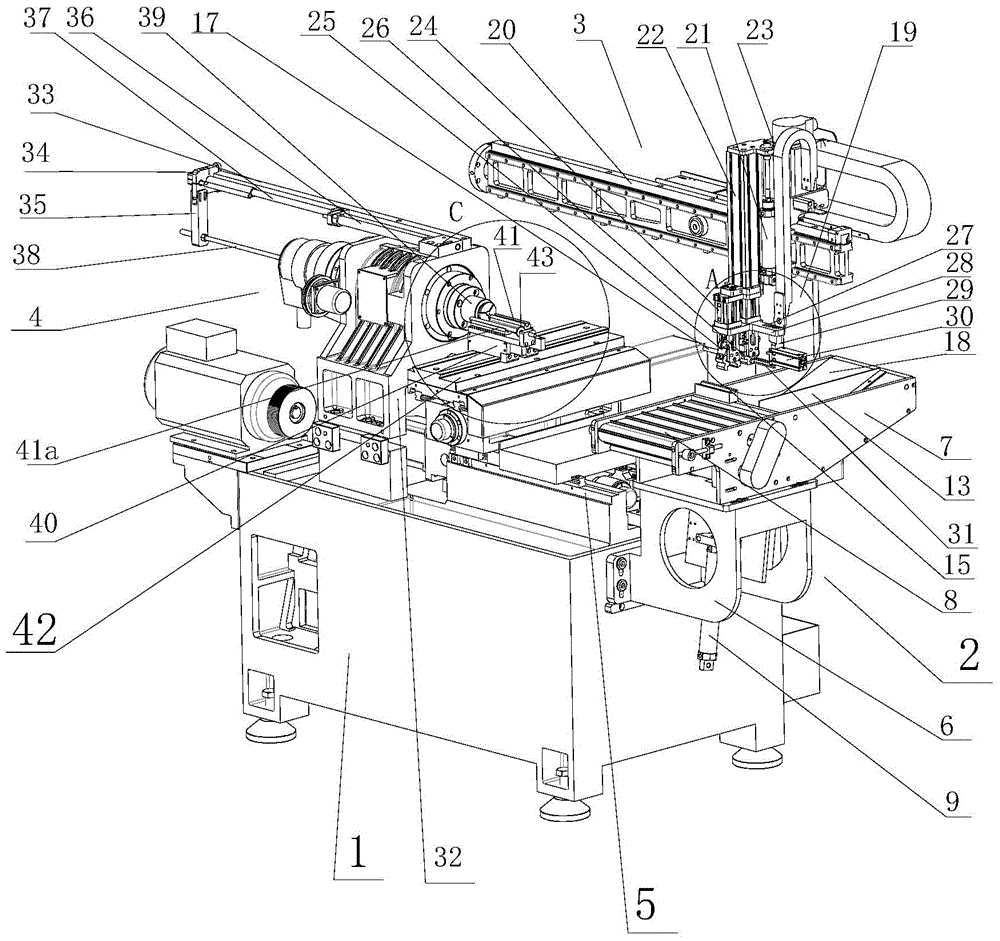

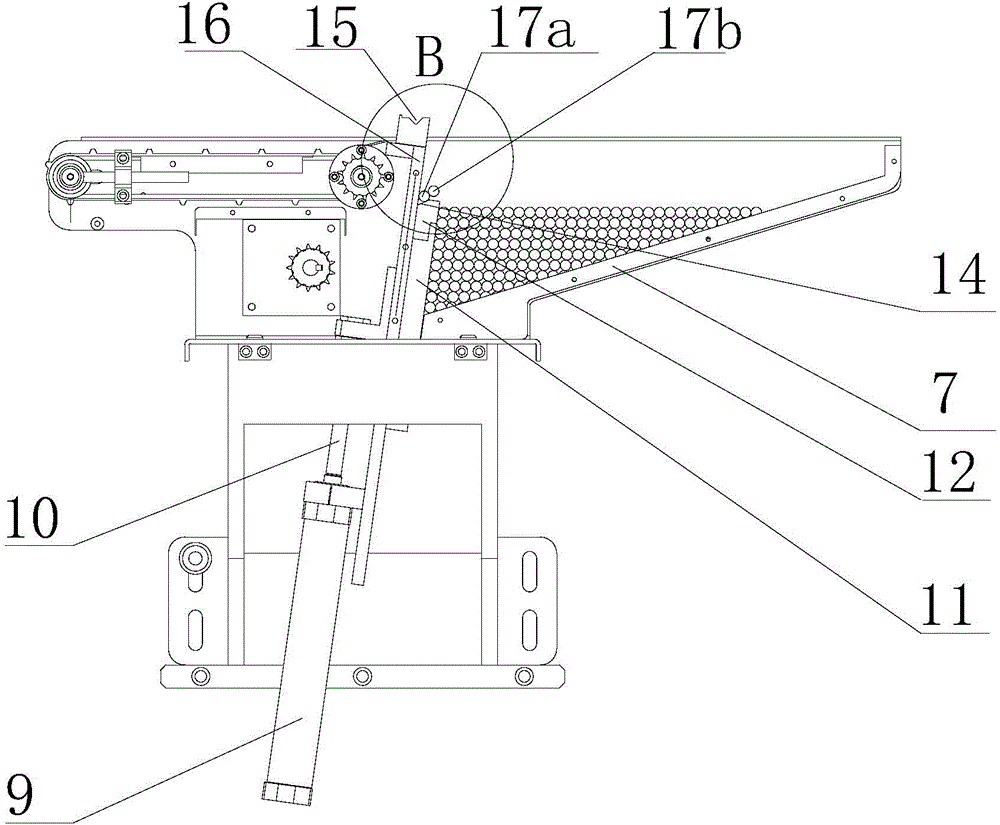

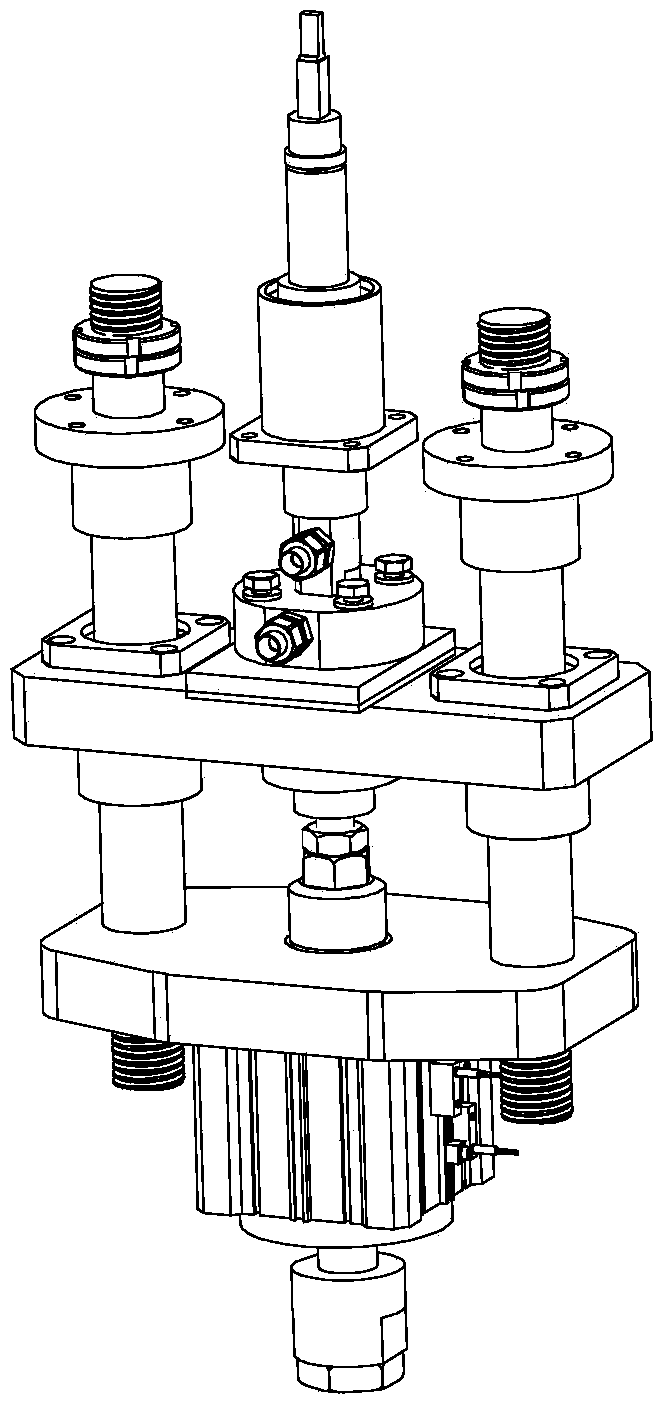

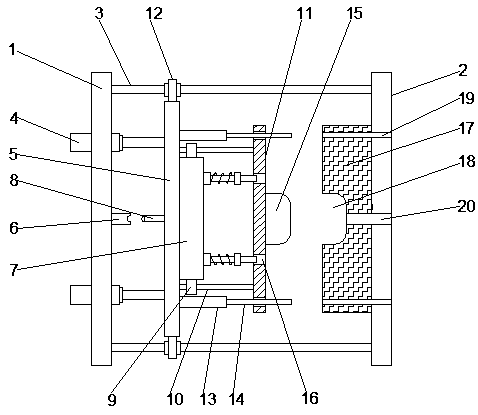

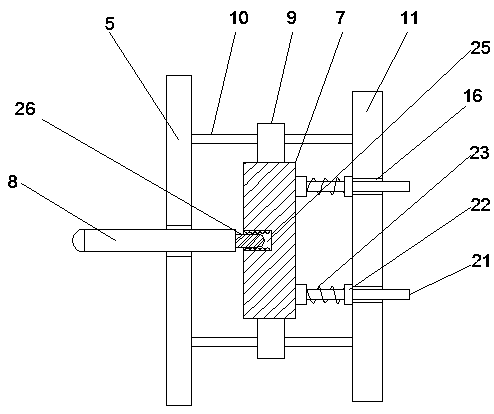

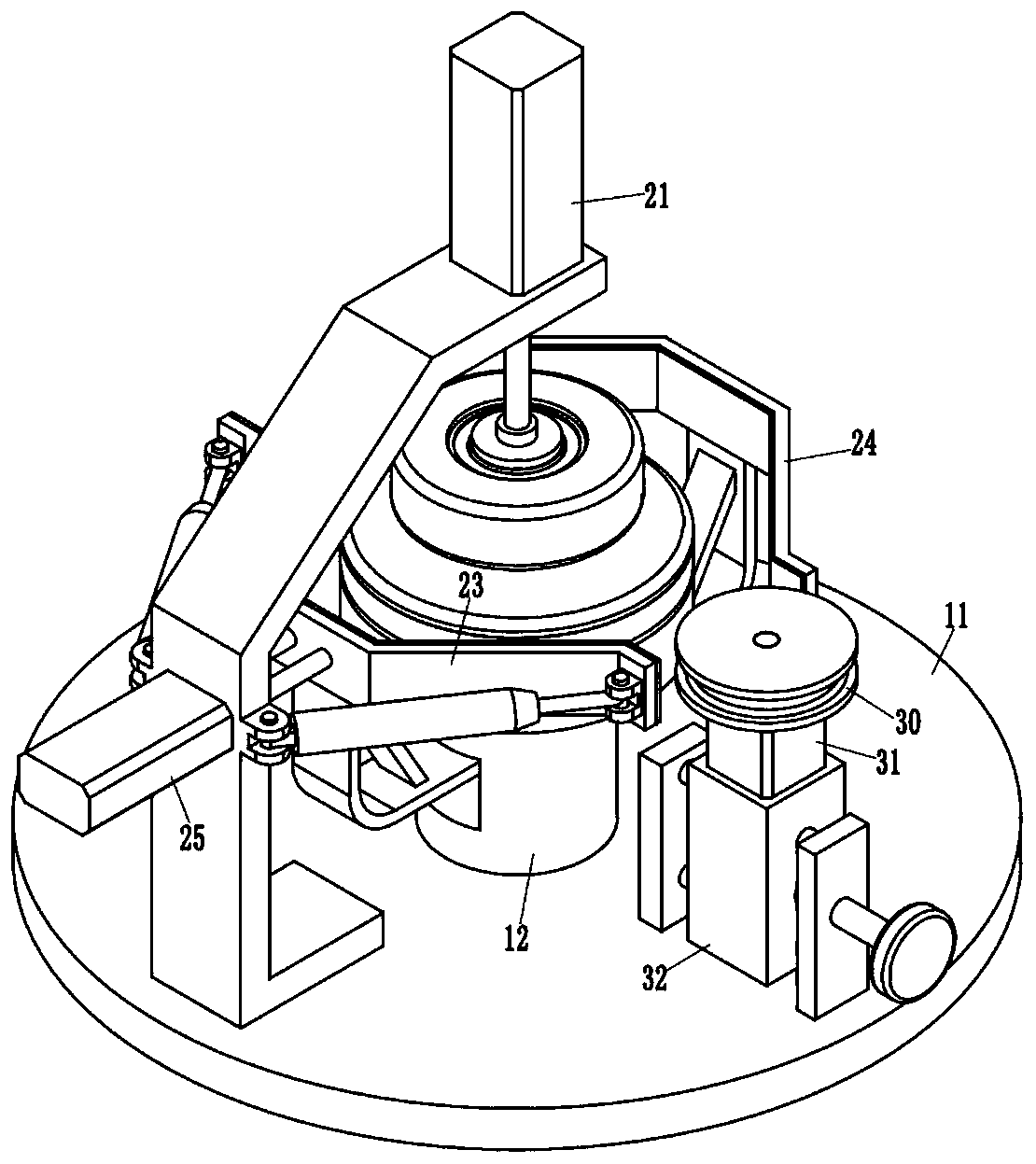

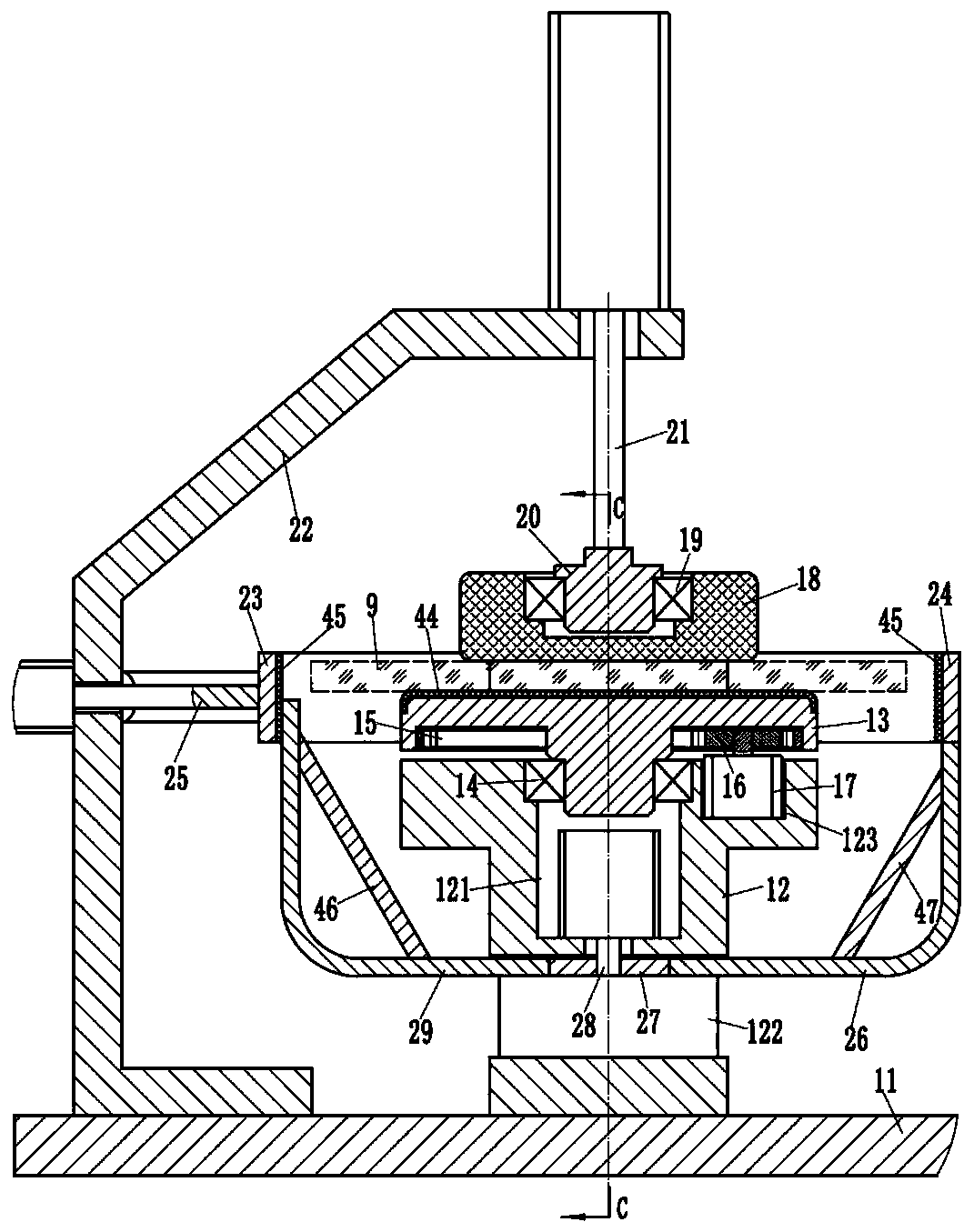

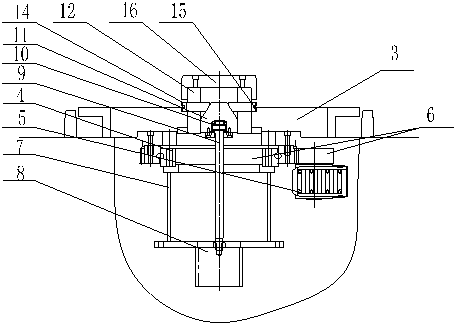

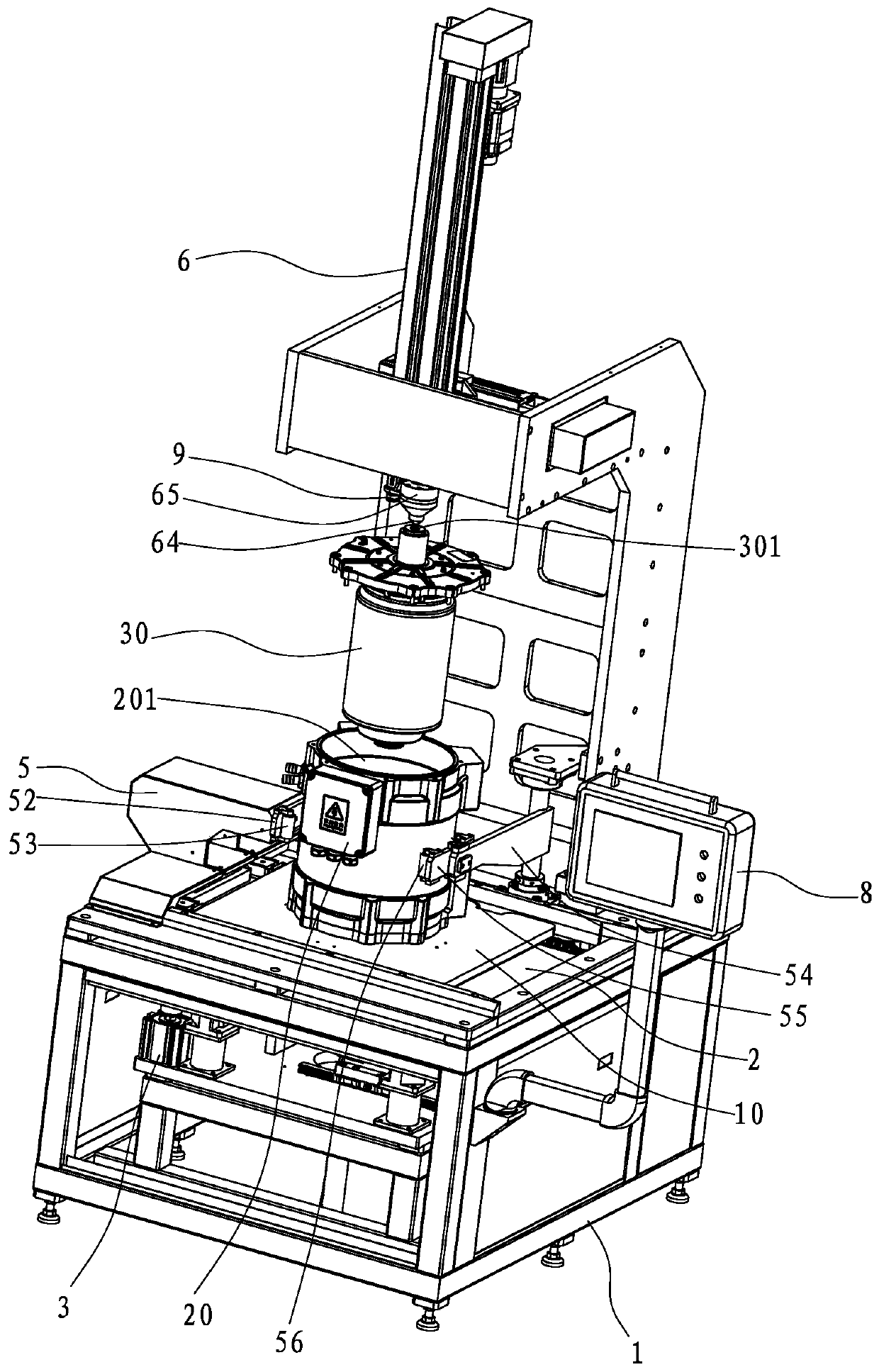

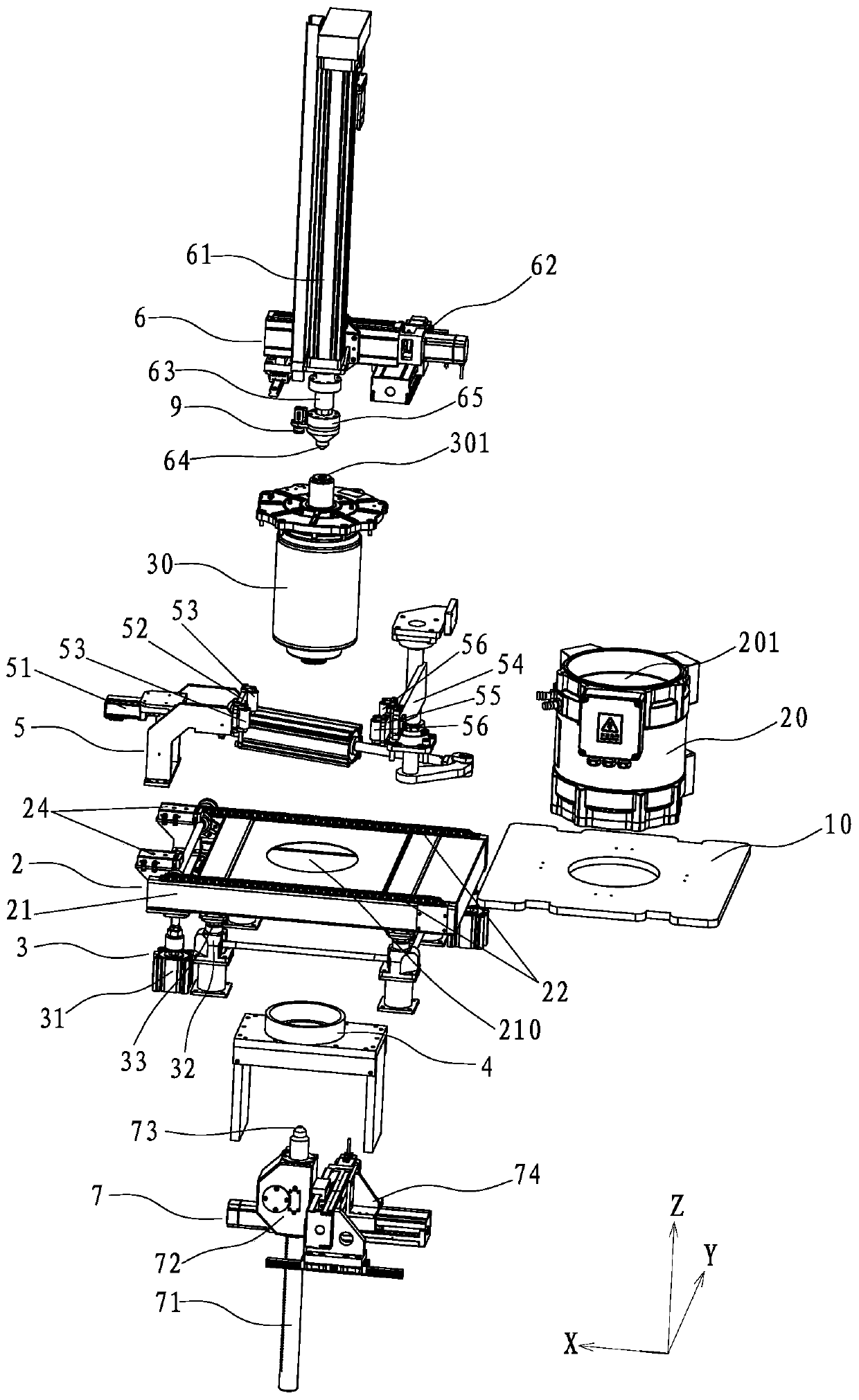

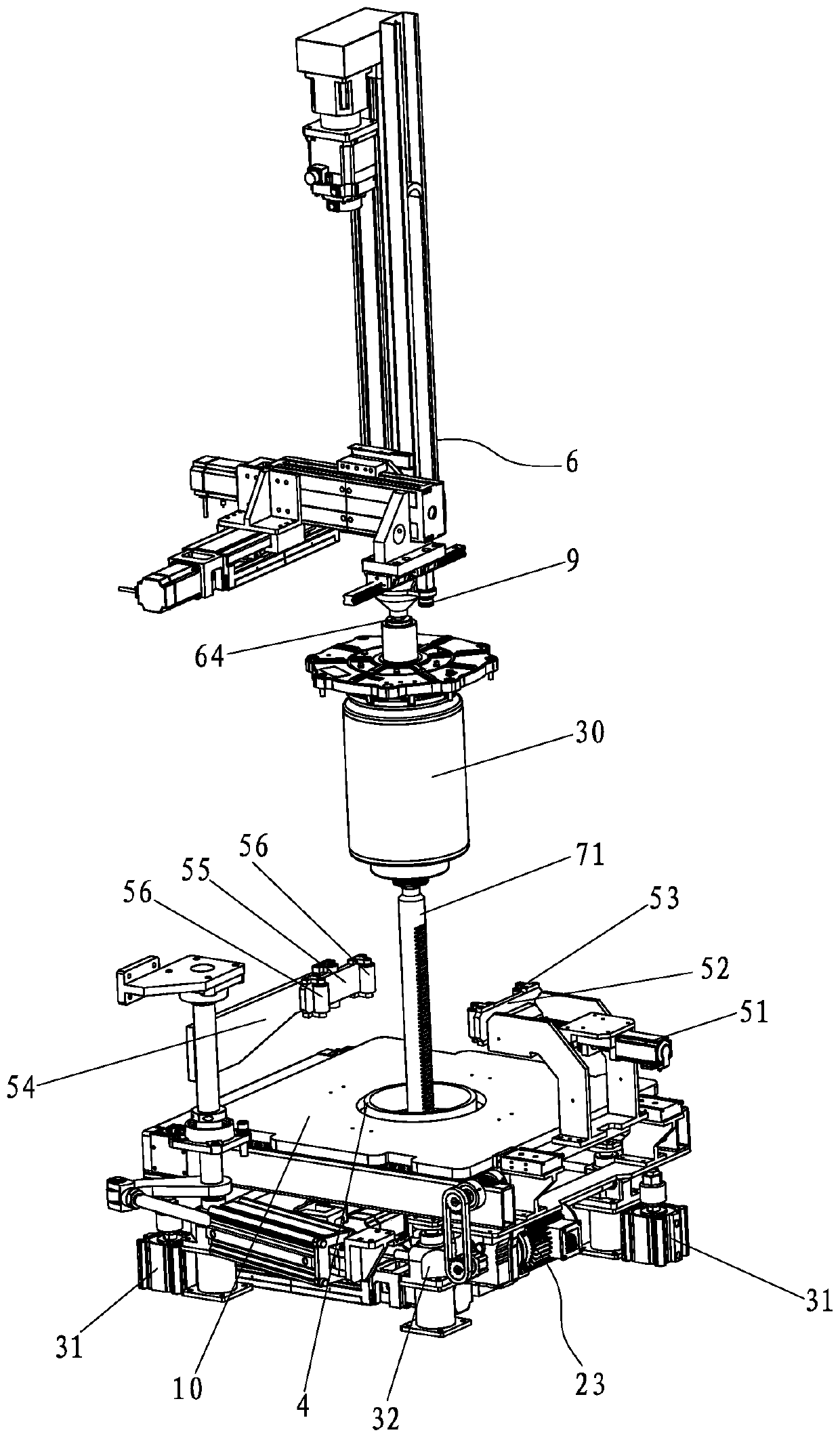

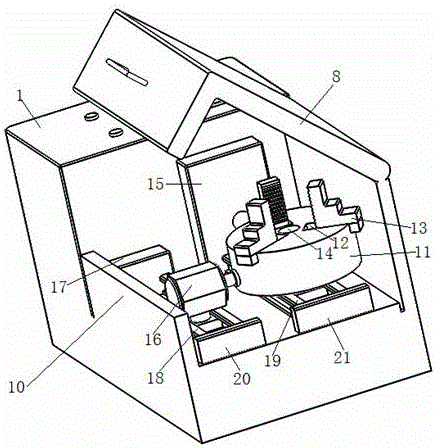

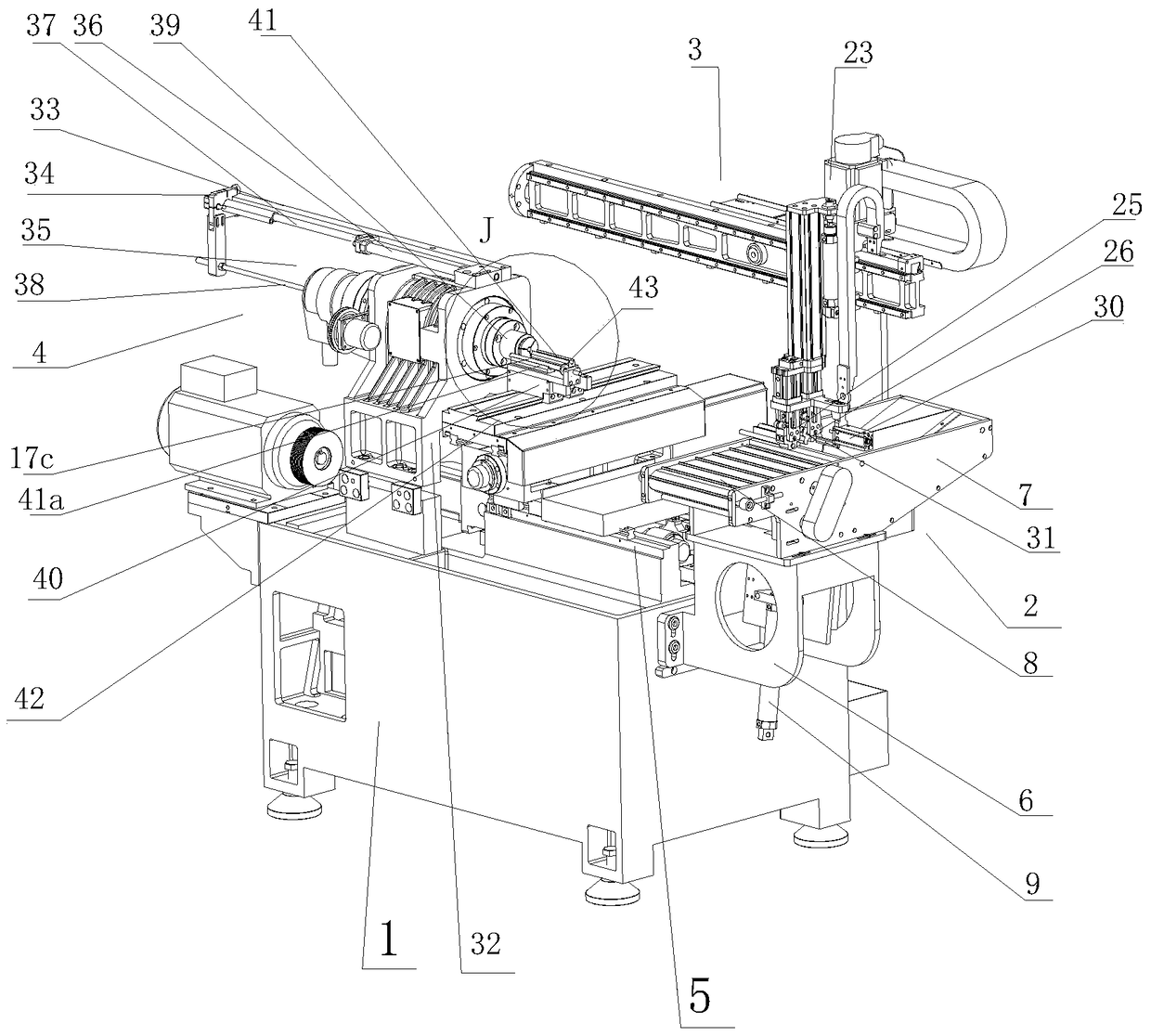

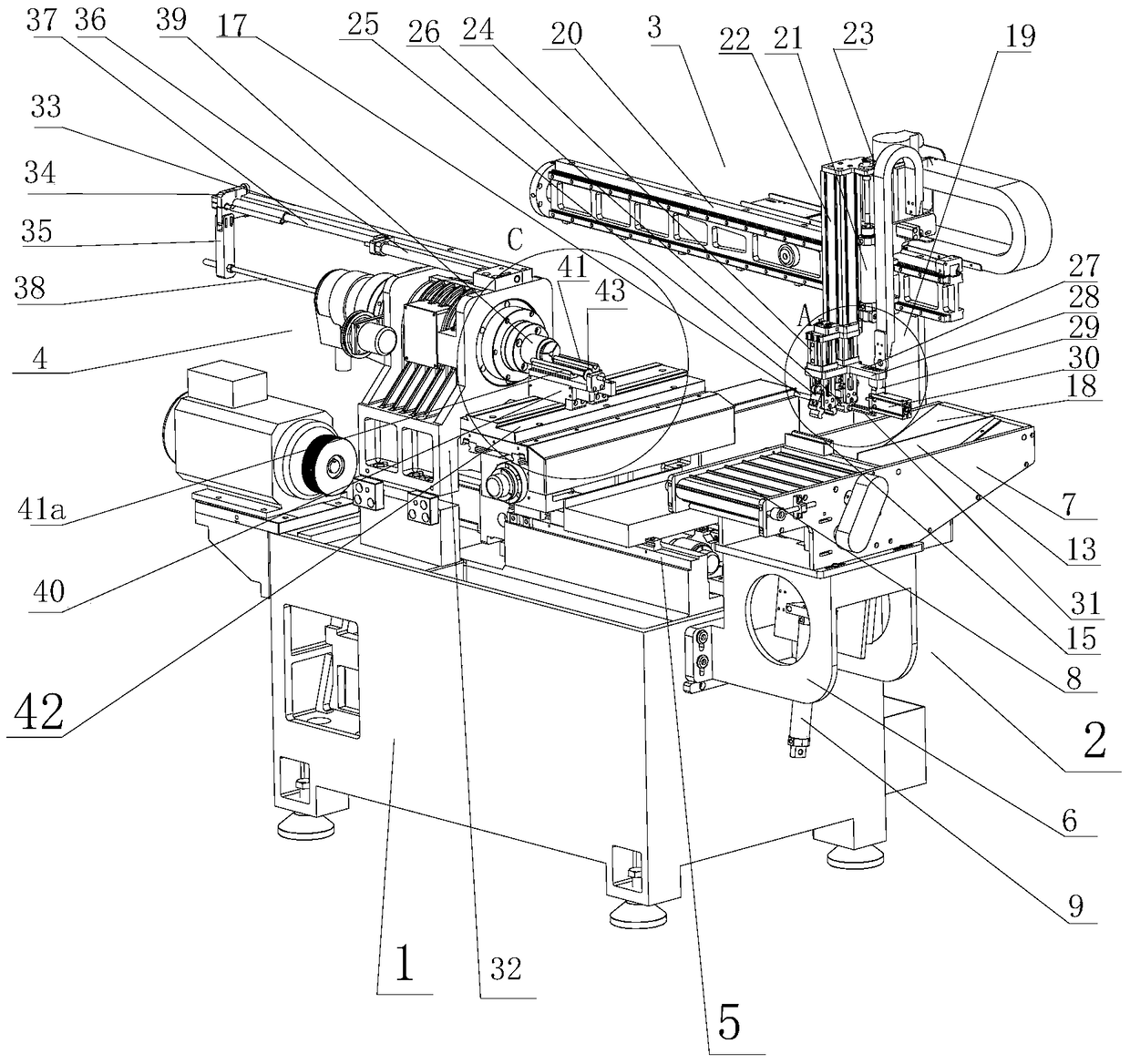

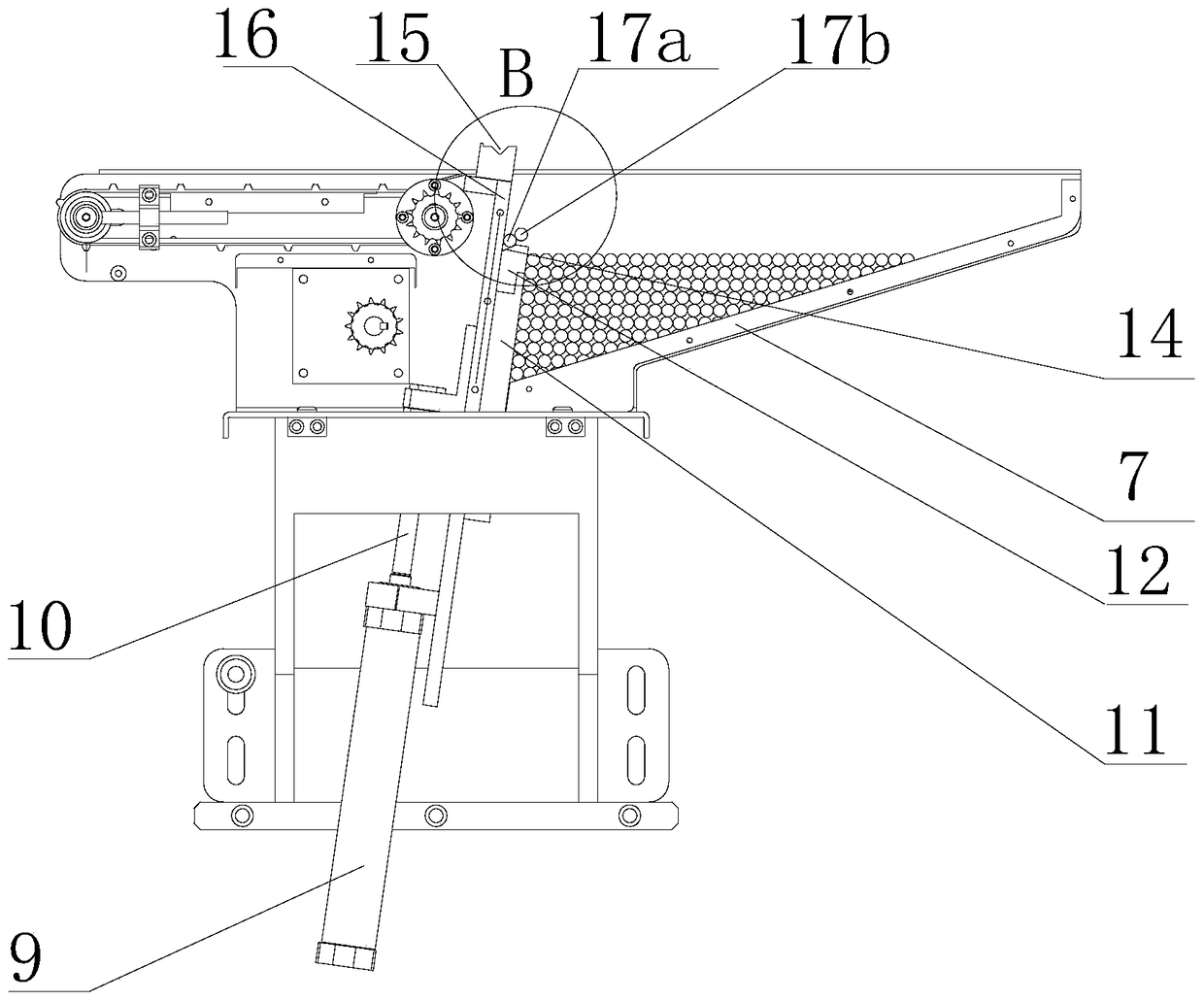

Mechanical arm clamp feeding and ejecting device

InactiveCN105312955ACenter positioning is accuratePrecise positioningMetal working apparatusEngineeringManipulator

The invention provides a mechanical arm clamp feeding and ejecting device which comprises a feeding mechanism and a main shaft ejecting mechanism. The feeding mechanism comprises a rack, a feeding drive device, a grabbing drive device and a pushing drive device. The main shaft ejecting mechanism comprises a device base, an air cylinder, a material rack and a linear guide rail assembly. The rack is provided with a feeding clamp. A baffle is arranged in the feeding clamp. A conveyor belt assembly is arranged at one side of the baffle, and a trough is formed in the other side of the baffle. A discharge V-shaped groove is formed above the baffle. A telescopic rod is arranged at the upper end of the feeding drive device. A feeding ejector rod is arranged at one side of the baffle. A feeding part is arranged above the feeding ejector rod and located in the trough. The feeding part makes contact with the baffle. A slope is arranged at one side, making contact with the baffle, of the top end of the feeding part. An included angle is formed between the slope and the baffle. The material rack is provided with a left V-shaped groove and a right V-shaped groove which are used for placing blanks. The device can solve the problems that excessive blanks are conveyed at a time and can not be conveyed in place.

Owner:宁波宫铁智能科技有限公司

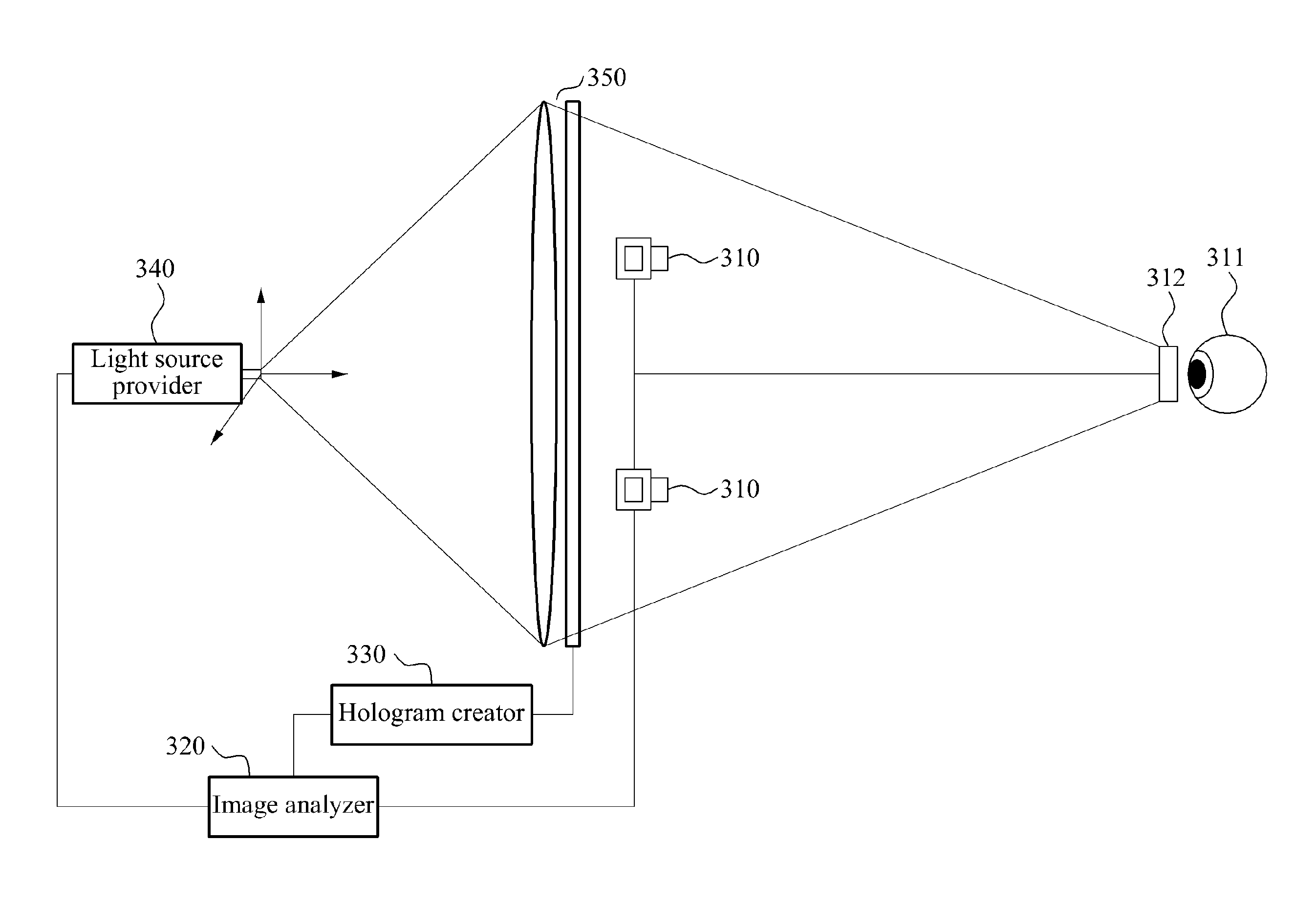

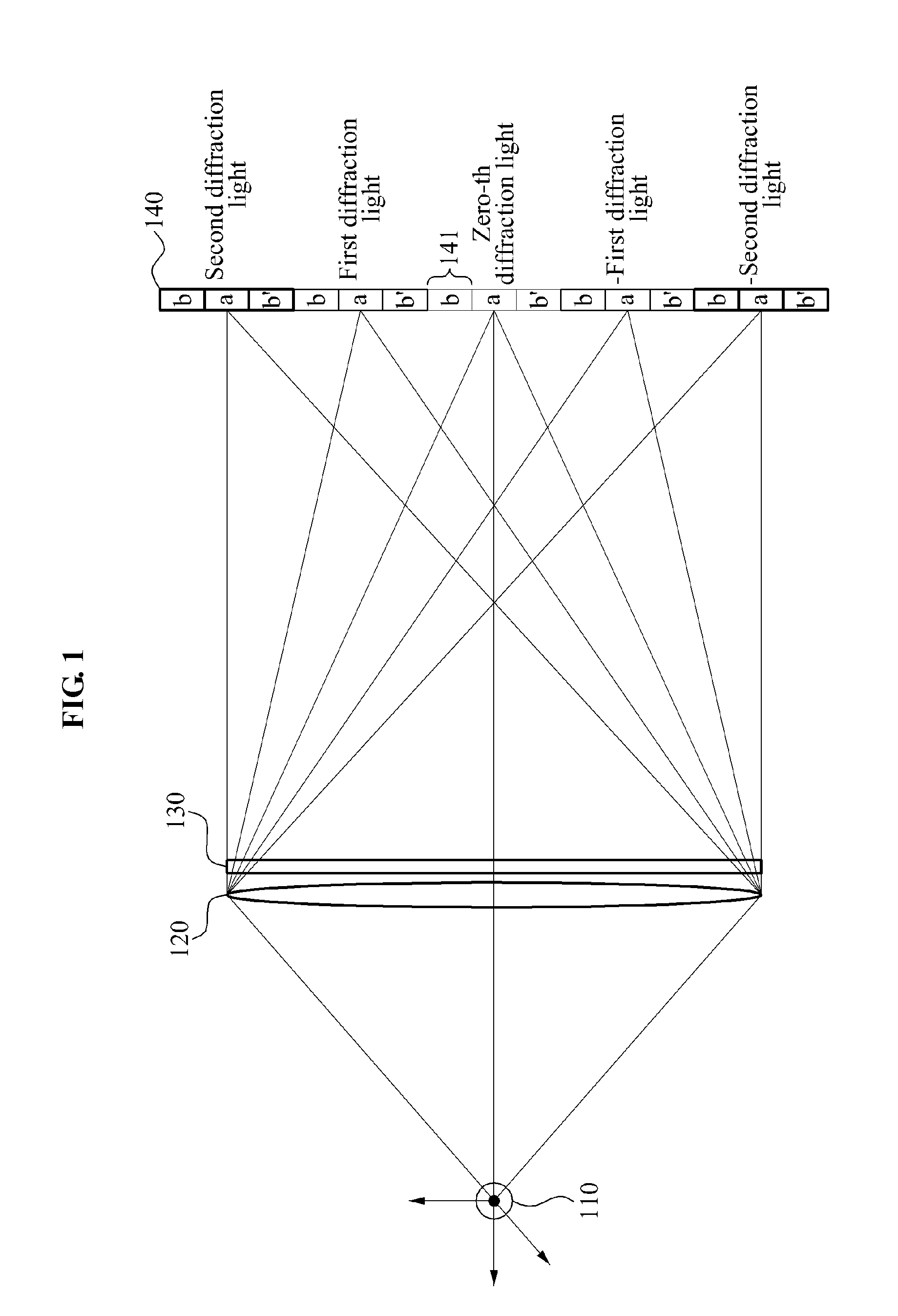

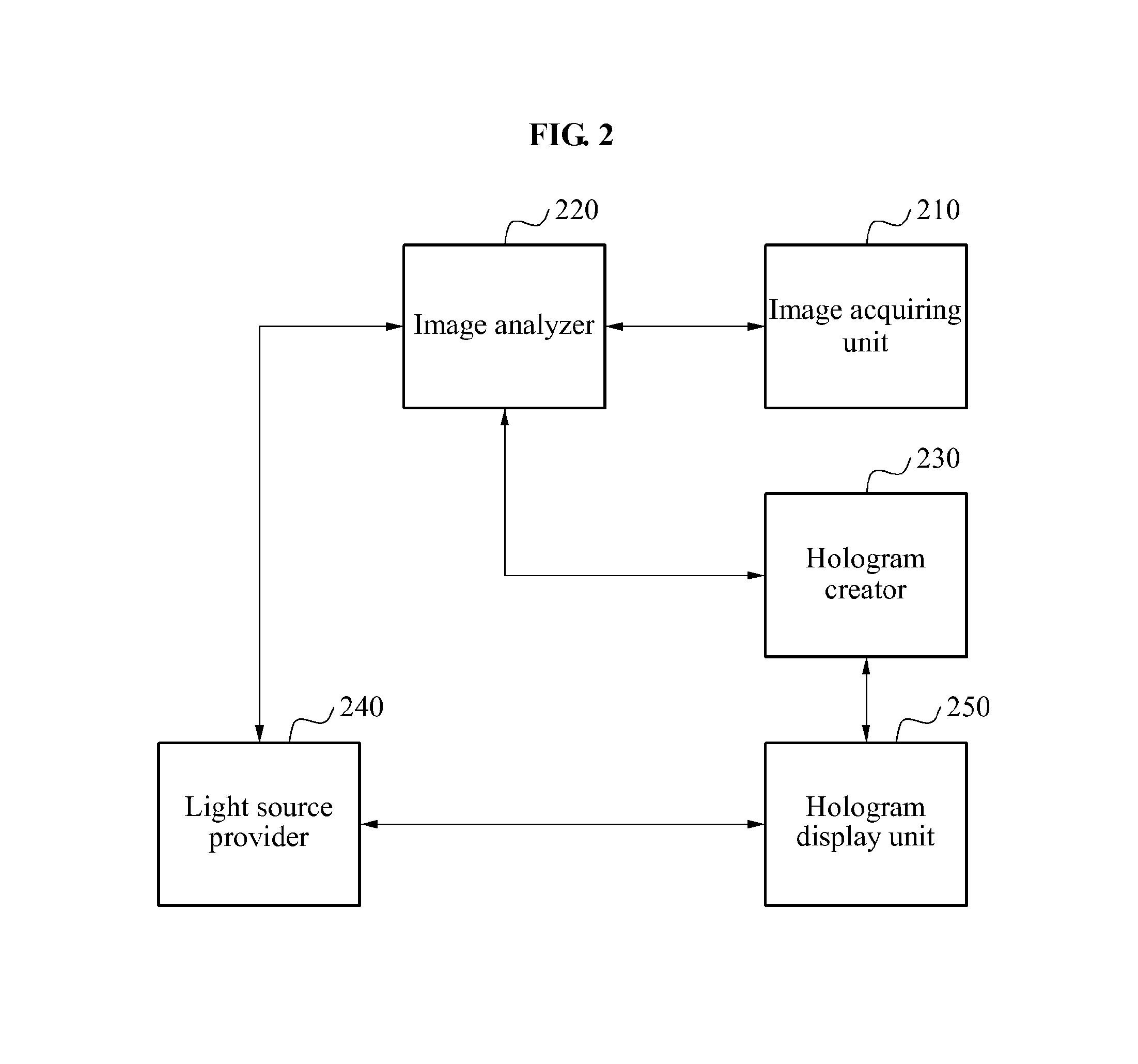

Apparatus and method for displaying hologram image

InactiveUS20140192146A1Center positioning is accurateTelevision system detailsColor television detailsImage tracingImage based

Provided is an apparatus and method for displaying a hologram image that may display a hologram image created by tracking a position of a pupil of a user using an acquired user image, tracking a position of a light source of a reflection hologram image that is reflected from appearance of the user, and by correcting a position of a light source of a display hologram image based on the position of the pupil of the user.

Owner:ELECTRONICS & TELECOMM RES INST

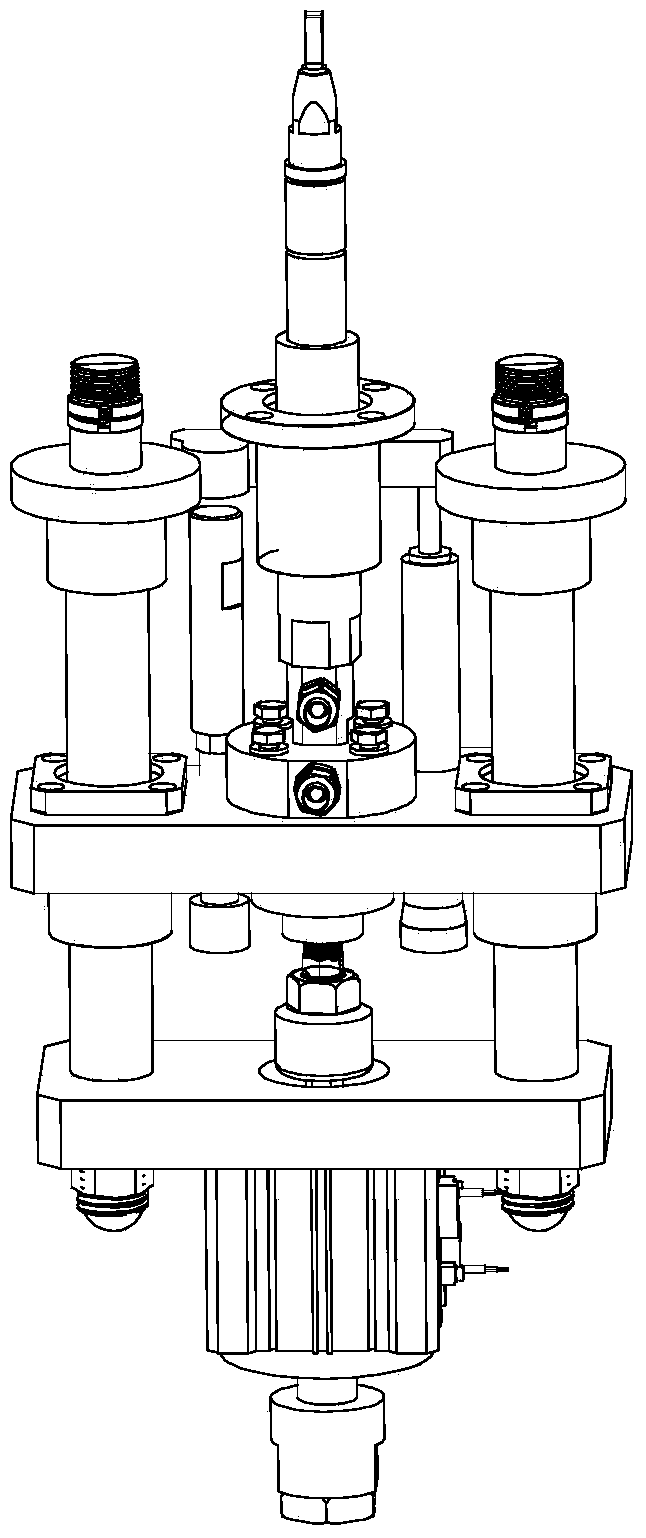

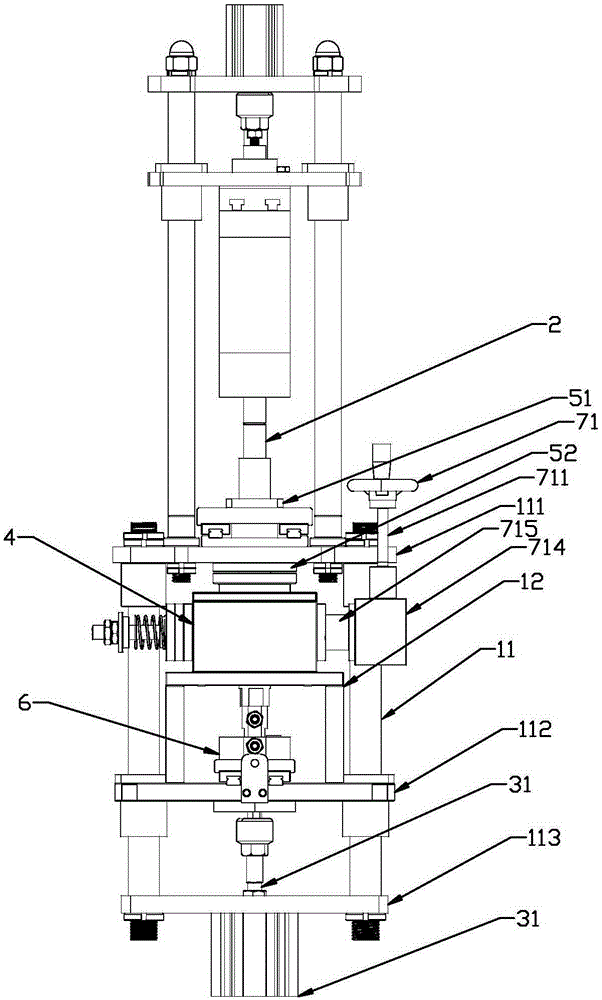

Welding mechanism with lifting device

ActiveCN103962700AHigh adjustment accuracyCenter positioning is accurateResistance electrode holdersMechanical engineeringEngineering

The invention discloses a welding mechanism with a lifting device. The welding mechanism comprises an installation frame, wherein a welding head and the lifting device for driving the welding head to move vertically are arranged on the installation frame, the lifting device comprises a lifting air cylinder and a vernier device, the lifting air cylinder is provided with a piston rod coaxial with the welding head, and the vernier device is arranged between the piston rod and the welding head. The welding mechanism with the lifting device has the advantages of being high in regulation accuracy, accurate in center positioning and convenient to operate.

Owner:浙江华亿电气有限公司

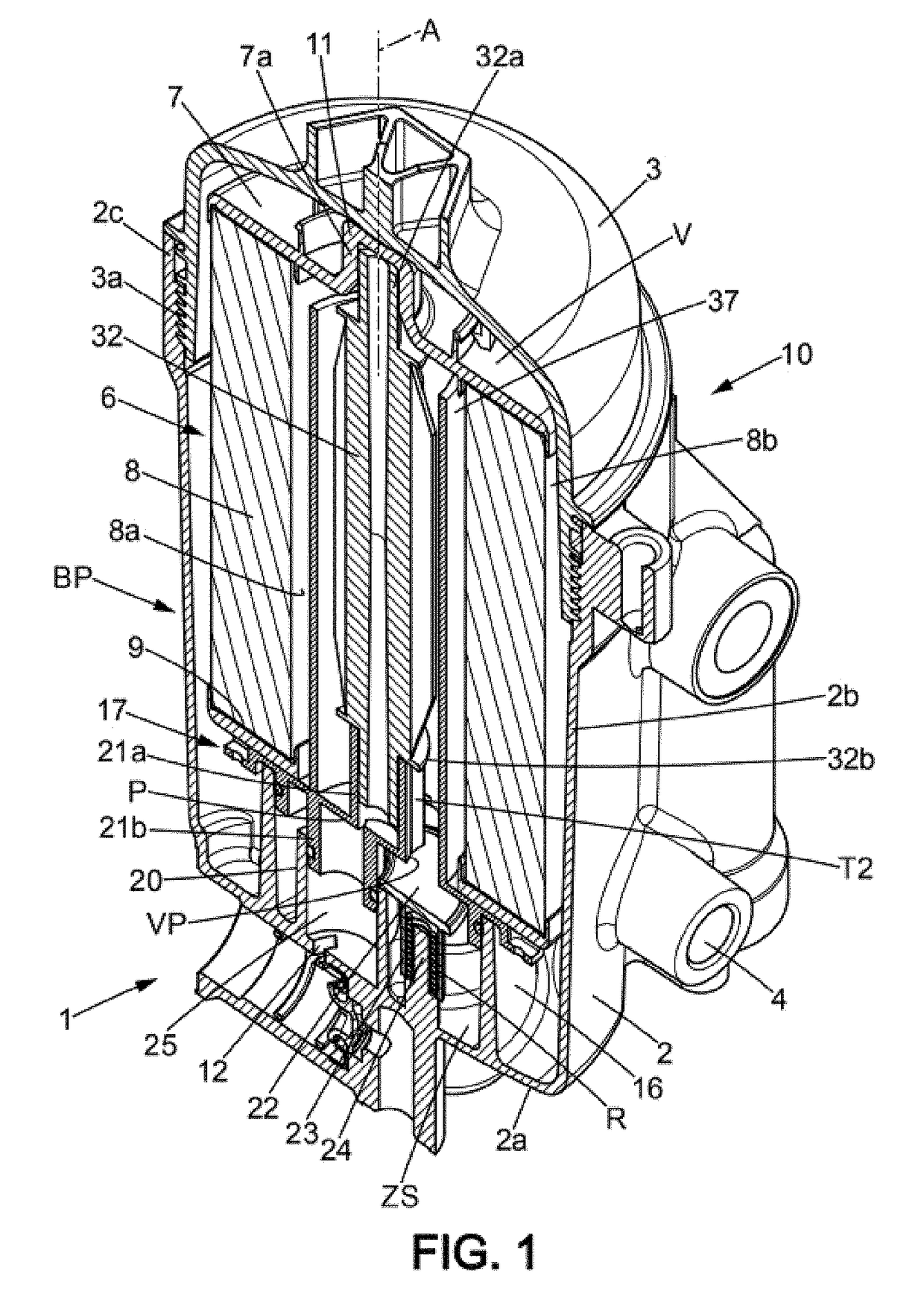

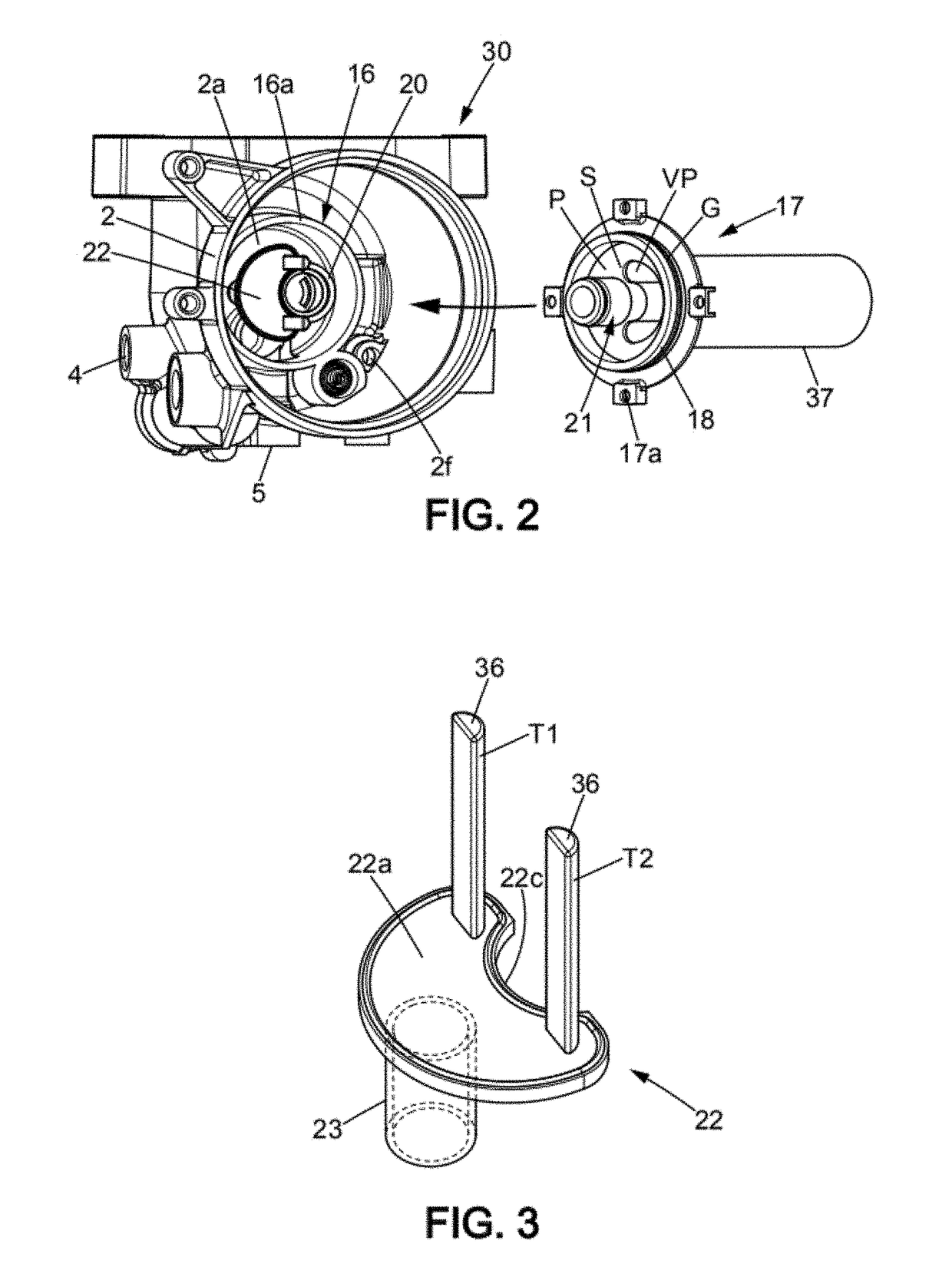

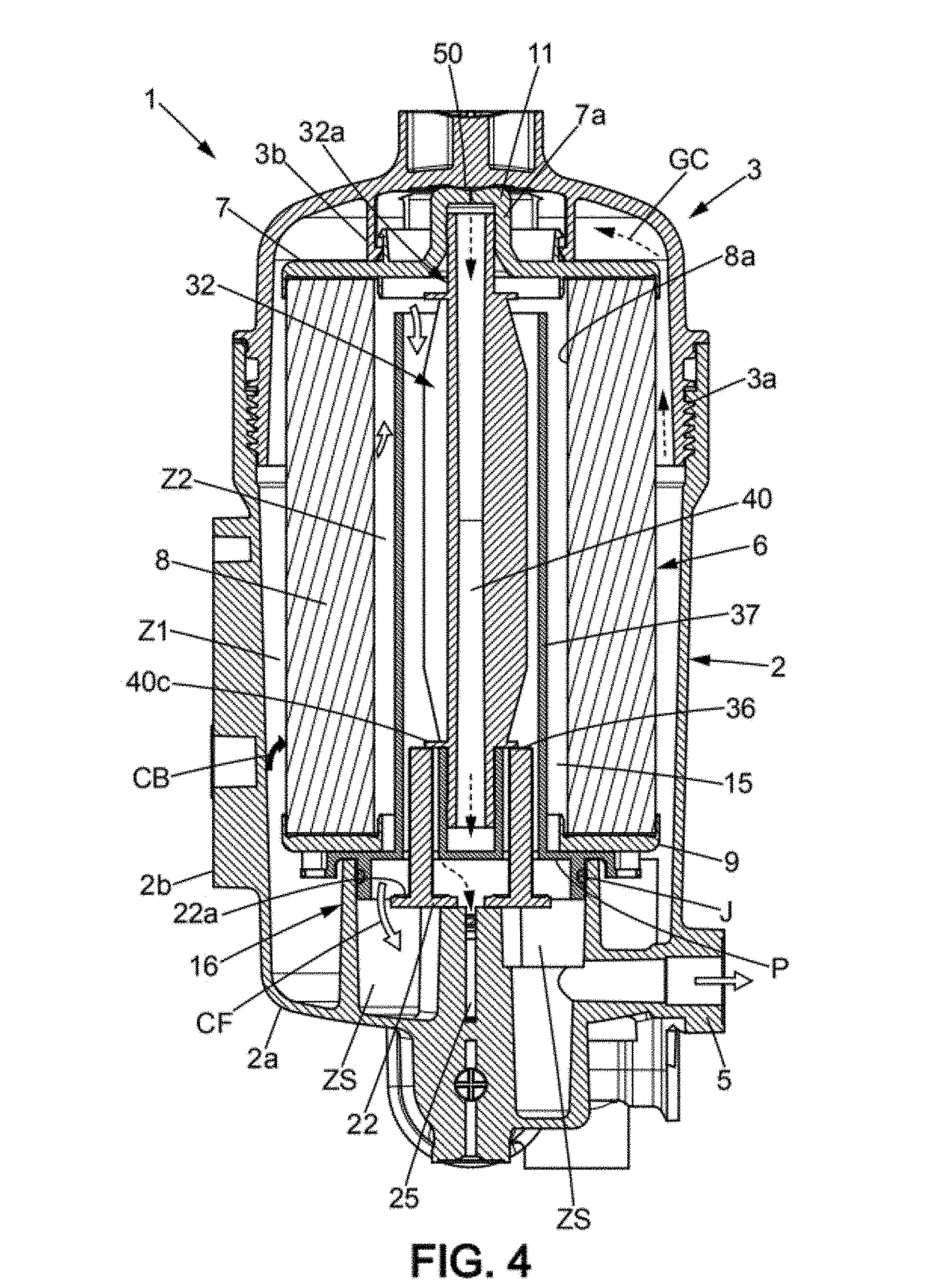

Fuel filter and mounting support of which the outlet is sealed by a valve in case of removal of a filter insert

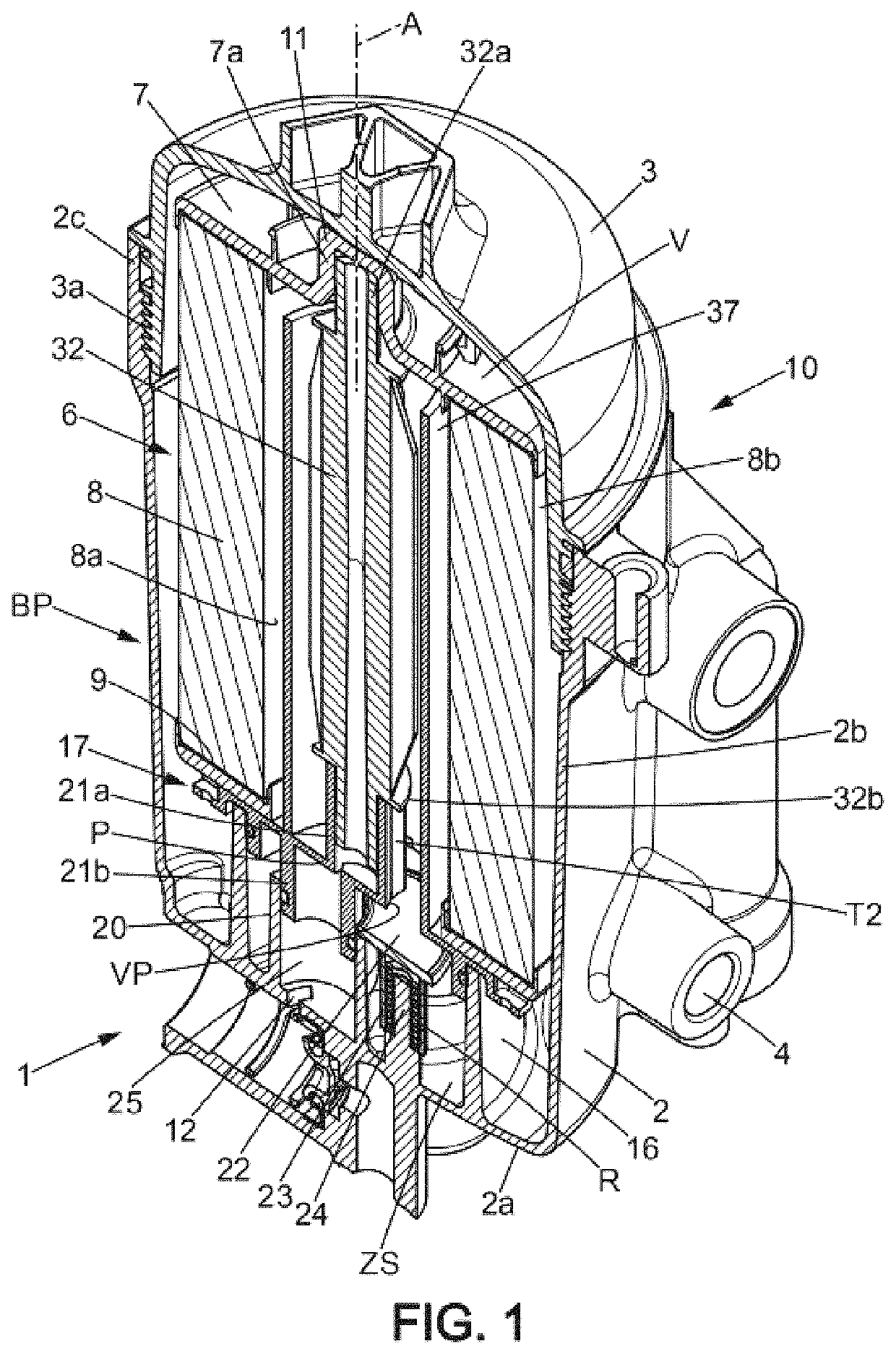

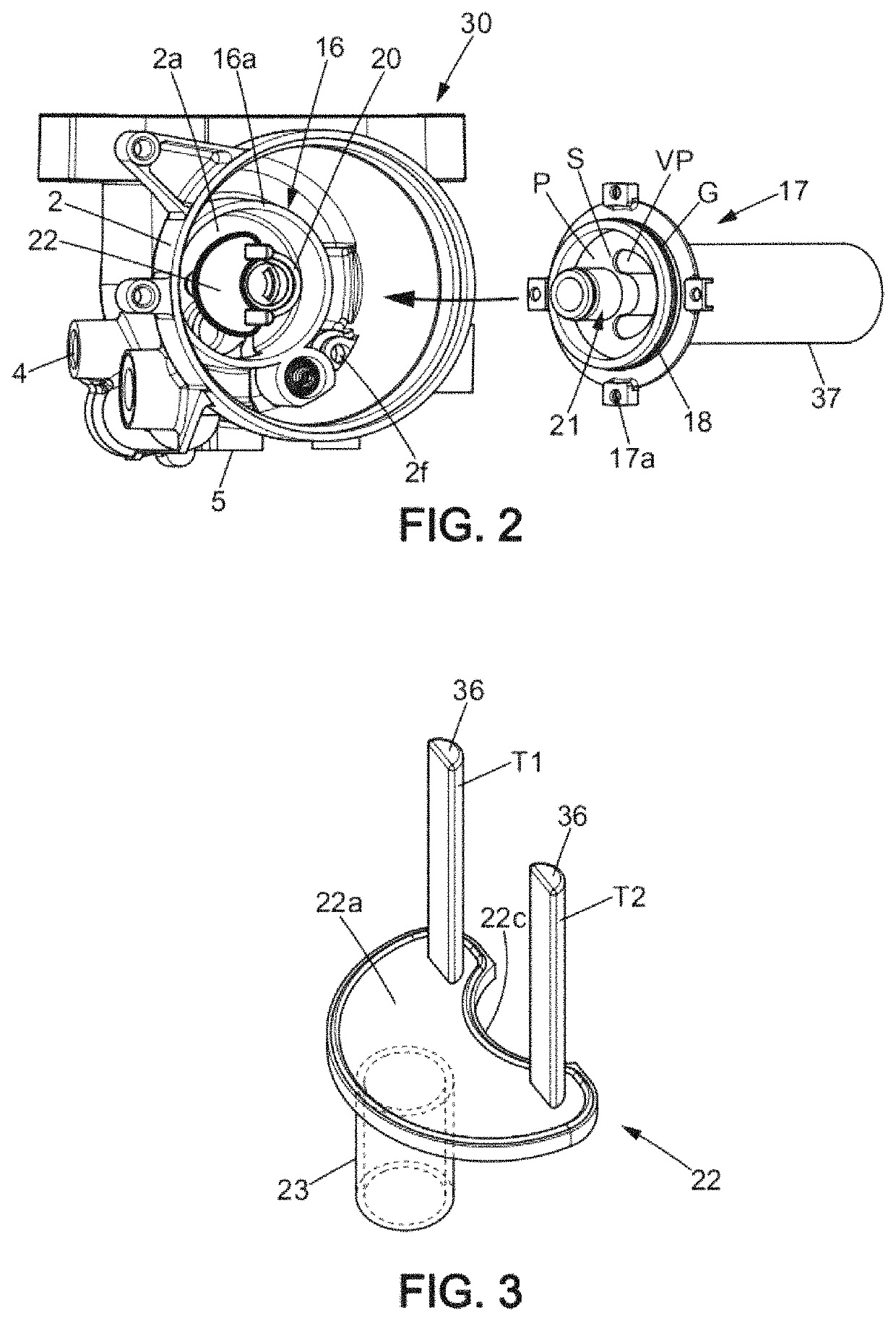

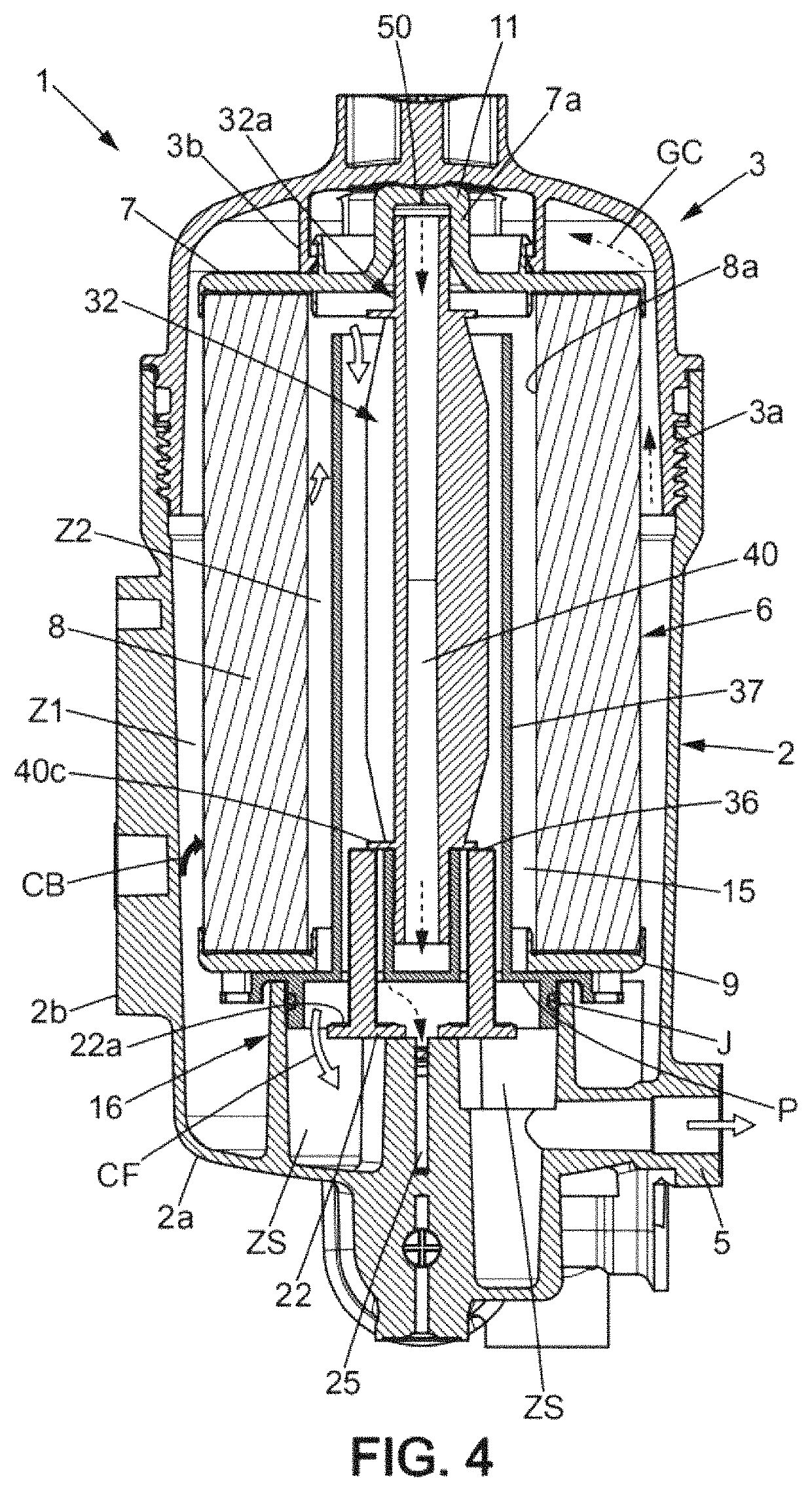

ActiveUS20190030471A1Improve the situationEliminating and minimizing riskMembrane filtersFiltration circuitsFuel filterEngineering

The fuel filter has an outlet for the filtered fuel in a lower base portion of a casing, and a valve associated with the outlet. The filter insert has an internal space in which filtered fuel flows and that accommodates a central member capable of moving the valve to an open position when the insert is in an operational configuration in the casing. The valve is urged, by default, to a sealed position cutting off the flow to the outlet, for example by resilient return arranged between the bottom of the filter and a wall of an interface that guides the lower end of the central member. The central member and the filter insert form a removable unit, and it is therefore possible, typically by way of a cover / removable unit fastening, to automatically obtain the sealed position after opening the top cover.

Owner:SOGEFI FILTRATION

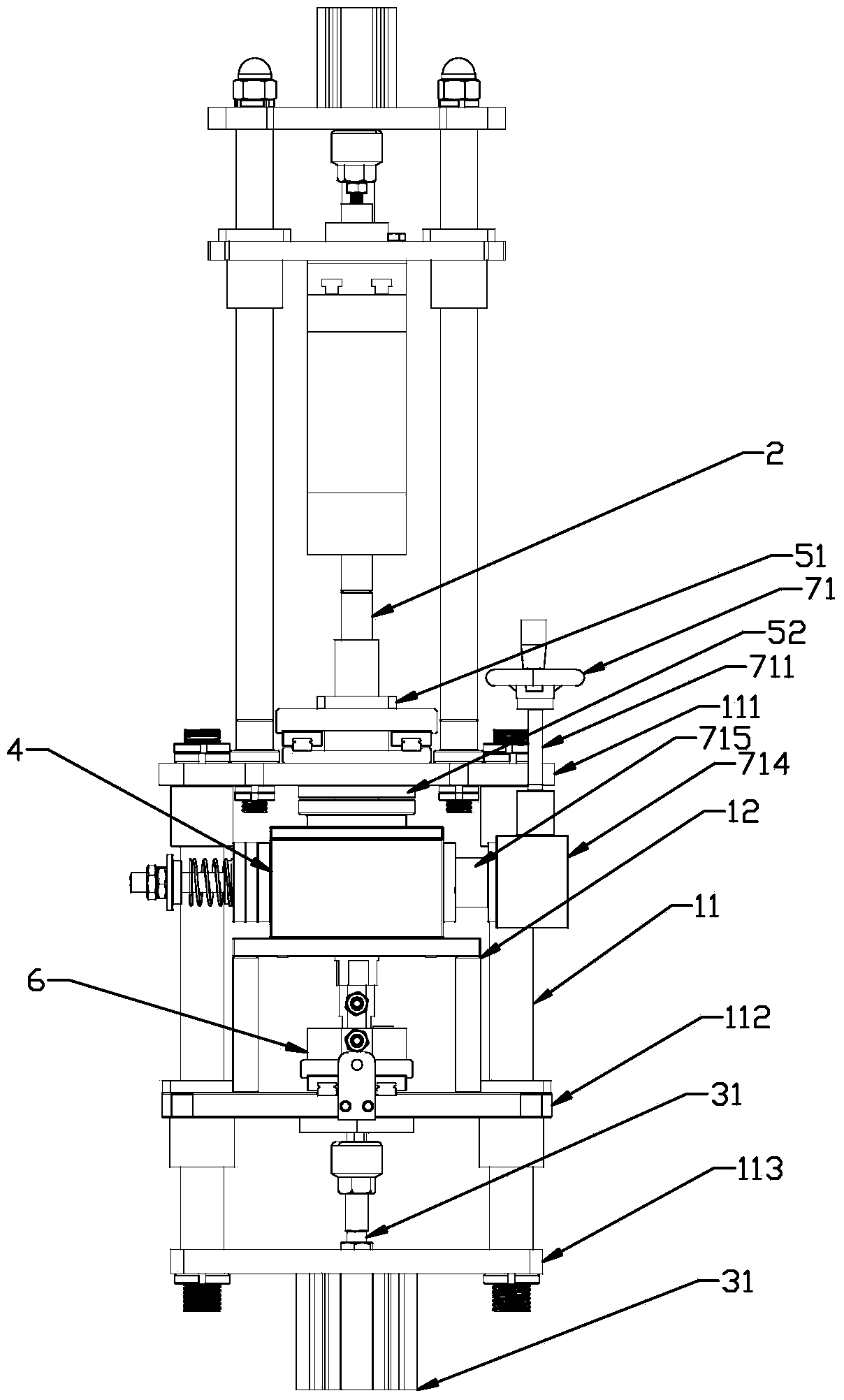

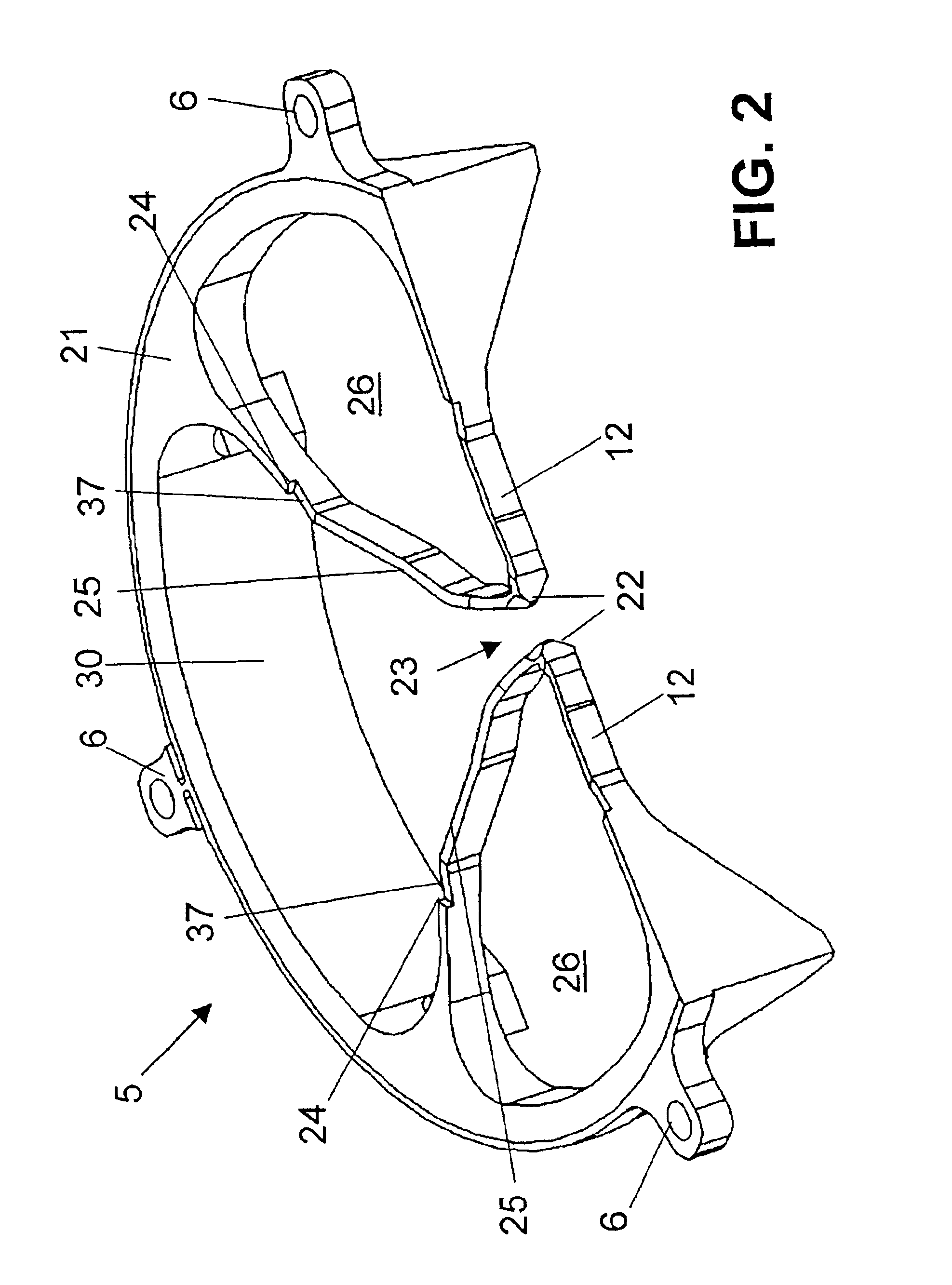

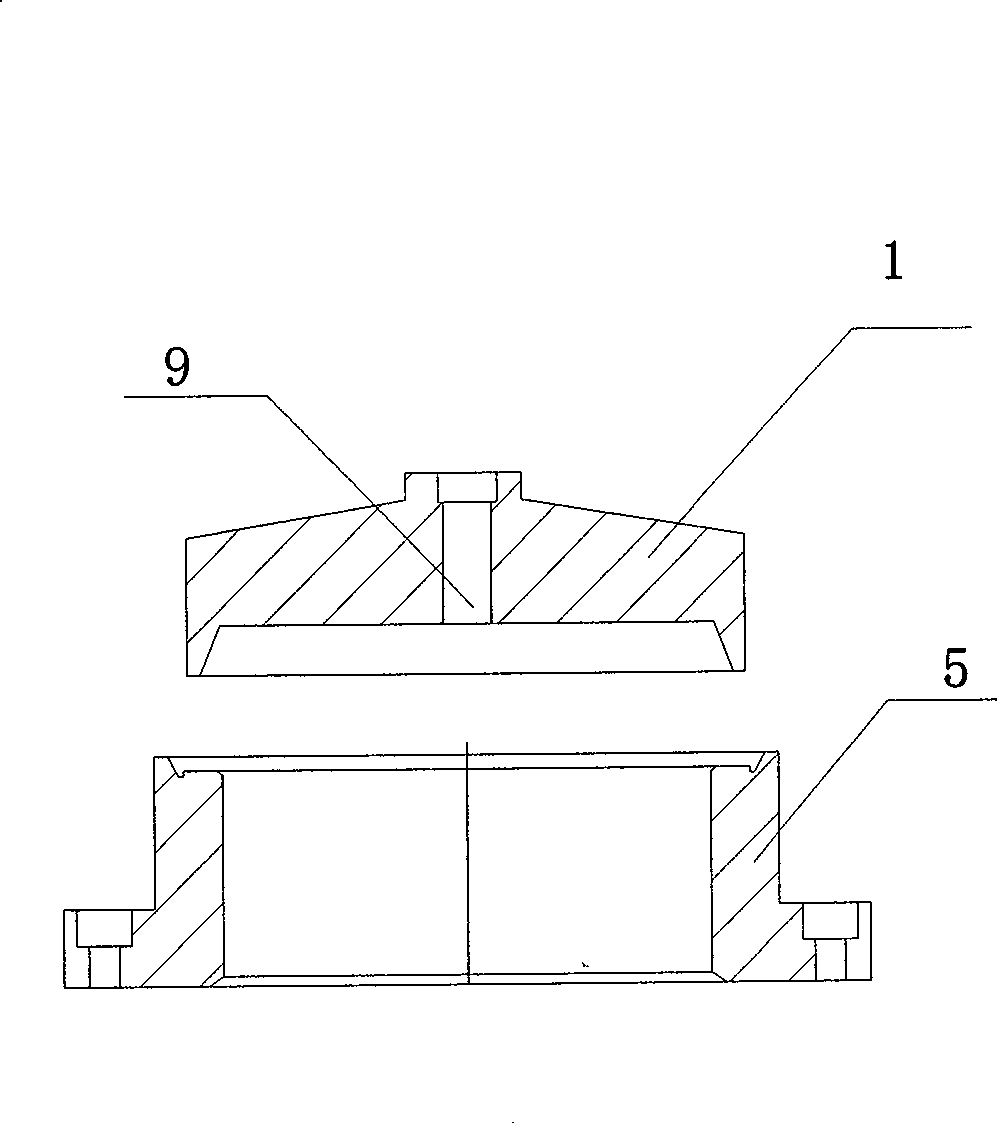

Load receiver and loading stage for a balance, and mass comparator equipped with the load receiver and loading stage

InactiveUS6864438B2Raised and loweredAutomate processingWeighing apparatus using counterbalanceWeighing apparatus testing/calibrationSlope angleEngineering

A load receiver (10) for a balance with arms (11) is designed to support weights of various shapes and sizes (13, 14, 15, 16) by cradling the weights in a depression sloped at a variable slope angle towards the middle of the load receiver. A loading stage (1) arranged to cooperate with the load receiver (10) has one or more weight-placement devices (5) designed so that the load receiver (10) can reach through the weight-placement device (5) without touching the latter. The loading stage (1) and the load receiver (10) are moveable up and down in relation to each other. The weight-placement device (5) is suitably configured to support the different weights (13, 14, 15, 16). The load receiver (10) and loading stage (1) are used in a mass comparator for testing weight standards with a high degree of precision.

Owner:METTLER TOLEDO GMBH

System and method for imaging device modelling and calibration

ActiveUS9792684B2Exact lengthImprove accuracyImage enhancementTelevision system detailsCamera imageImage plane

The invention relates to a camera modeling and calibration system and method using a new set of variables to compensate for imperfections in line of sight axis squareness with camera plane and which increases accuracy in measuring distortion introduced by image curvature caused by geometric and chromatic lens distortion and wherein the camera image plane is represented from a full 3D perspective projection.

Owner:MARTIN GUY

Die for seal piece processing production

PendingCN110696296AAvoid manual handlingImprove securityDomestic articlesHydraulic cylinderEngineering

The invention discloses a die for seal piece processing production. The die for seal piece processing production comprises a first fixed plate and a second fixed plate, wherein two connecting rods arearranged on one side of the first fixed plate; a second fixed plate is arranged at one ends, far away from the first fixed plate, of the two connecting rods; two hydraulic cylinders are arranged on one side of the first fixed plate, penetrate through the first fixed plate and are connected with a movable plate; connecting blocks are arranged on the upper side and the lower side of the movable plate and are slidably connected with the connecting rods; through the cooperation of an ejector column and an ejector rod, when a die is closed, an ejector block is separated from the movable plate, andthe ejector block pushes a push rod to move rightwards so as to penetrate through a first through hole formed in a moving die, so that a seal piece on the moving die is pushed out so as to fall, theoccurrence of the phenomenon that plastic parts are manually taken is avoided, the safety is improved, the automation degree is high, the manpower is saved, and the working efficiency is greatly improved.

Owner:镇江联创机械配件有限公司

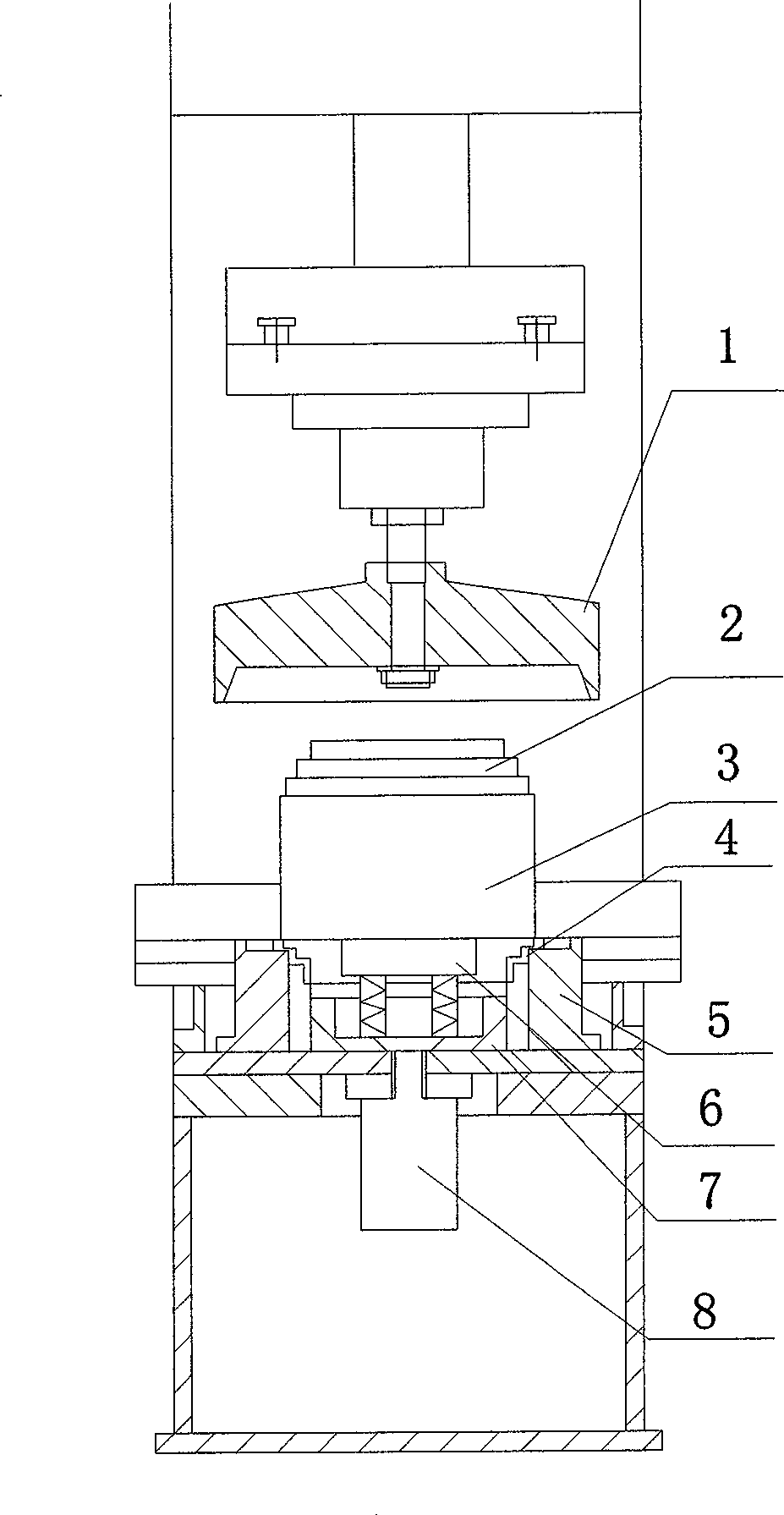

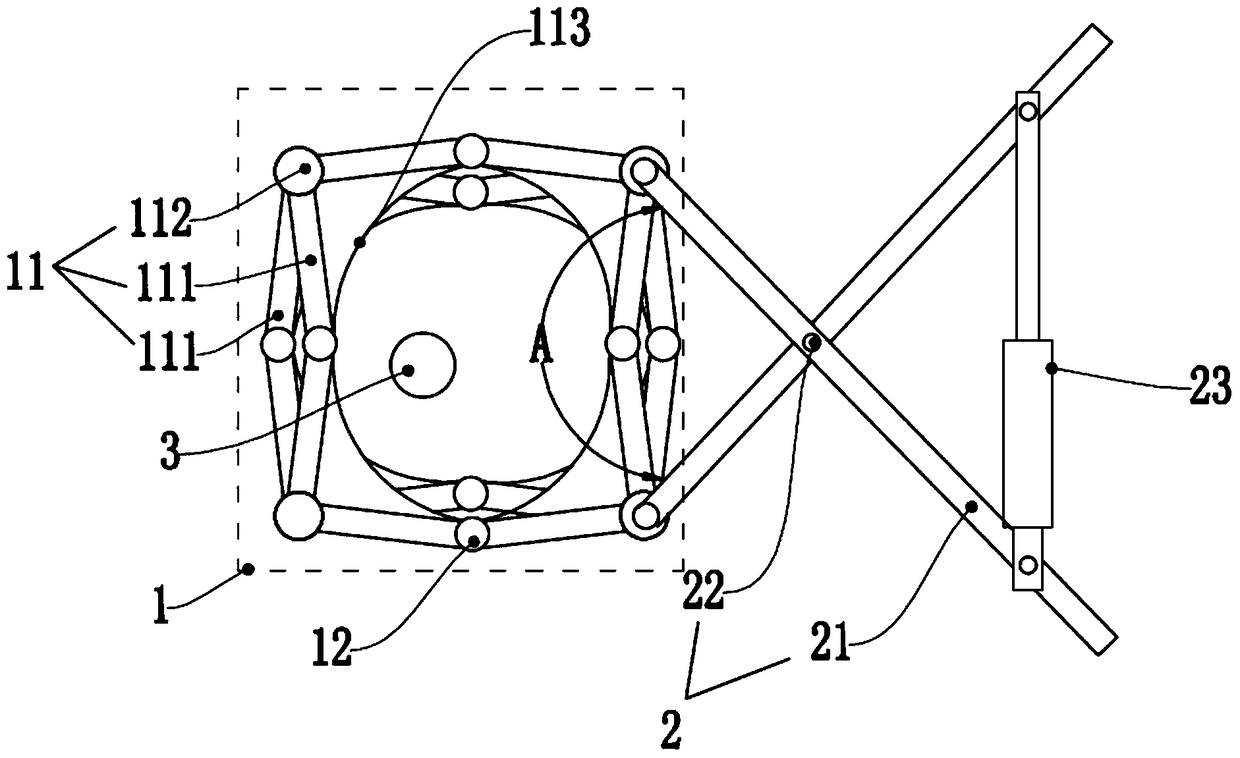

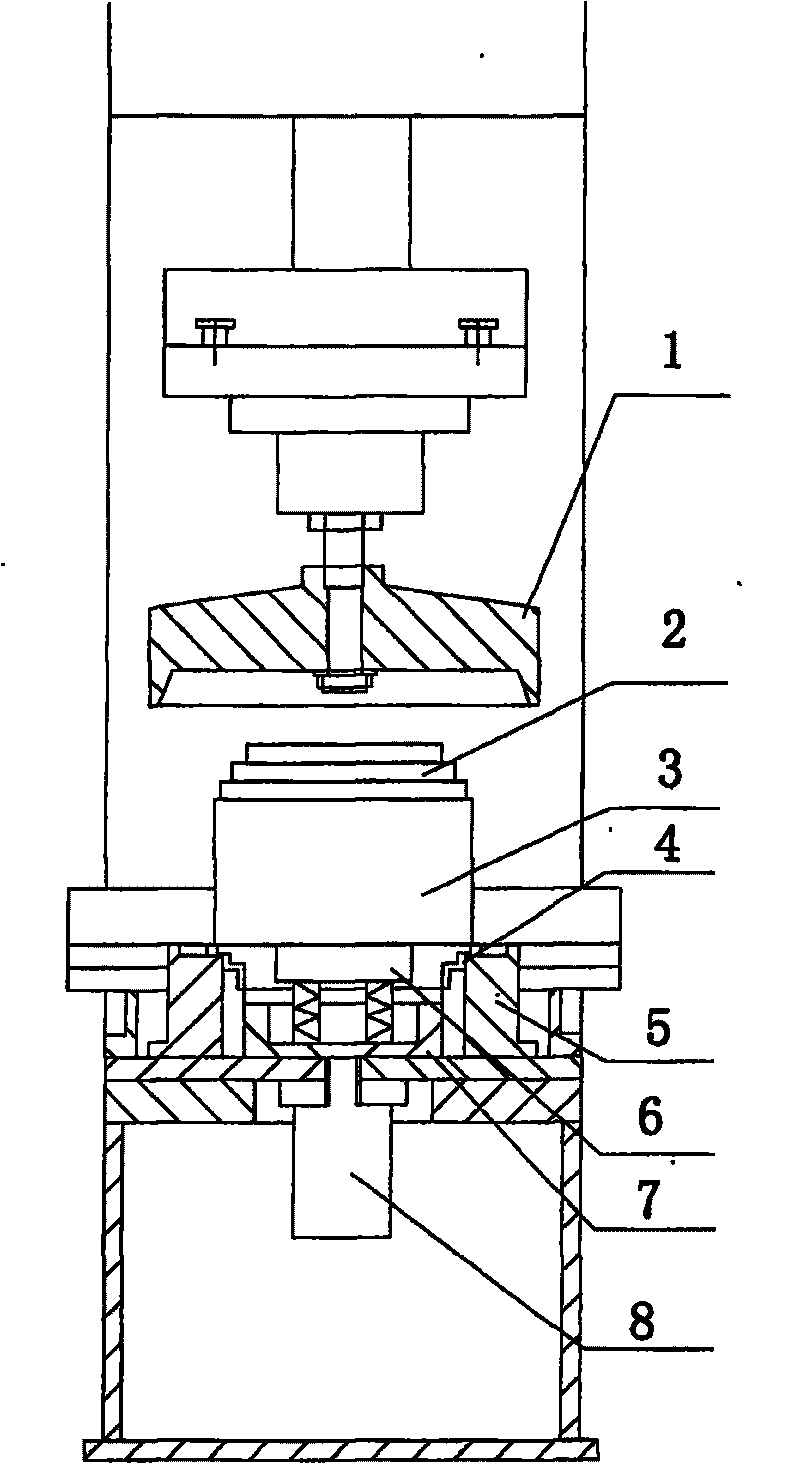

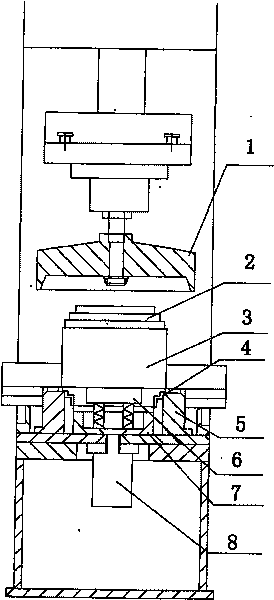

Bearing capper

The present invention relates to a bearing manufacture equipment, particularly relates to a bearing capping machine. The capping machine includes a hydrostatic press, an air cylinder, an inner lane locater, an upper mould and a lower mould, wherein the upper mould connects with the screw rod of the hydrostatic press; the lower mould connects with the working table of the hydrostatic press; the inner lane locater locates above the lower mould in central position of the lower mould; the air cylinder locates below the lower mould and can pass the lower mould to contact with the inner lane locater and push-out the bearing work piece; the lower mould holds the outer lane of the bearing; the inner lane locater holds the inner lane of the bearing. The present invention characterized in that the shape and size of the intersecting surface of the upper and lower mould matches the outer lane of the bearing, and the upper and lower mould are provided with a T-shaped groove to adjust the central position of the upper and lower mould to align the upper and lower mould. By adopting above technical solution, the center locating of the upper and lower mould is accurate, operation is easy, hence capping speed and percent of pass are improved significantly.

Owner:SHANGHAI UNITED BEARING

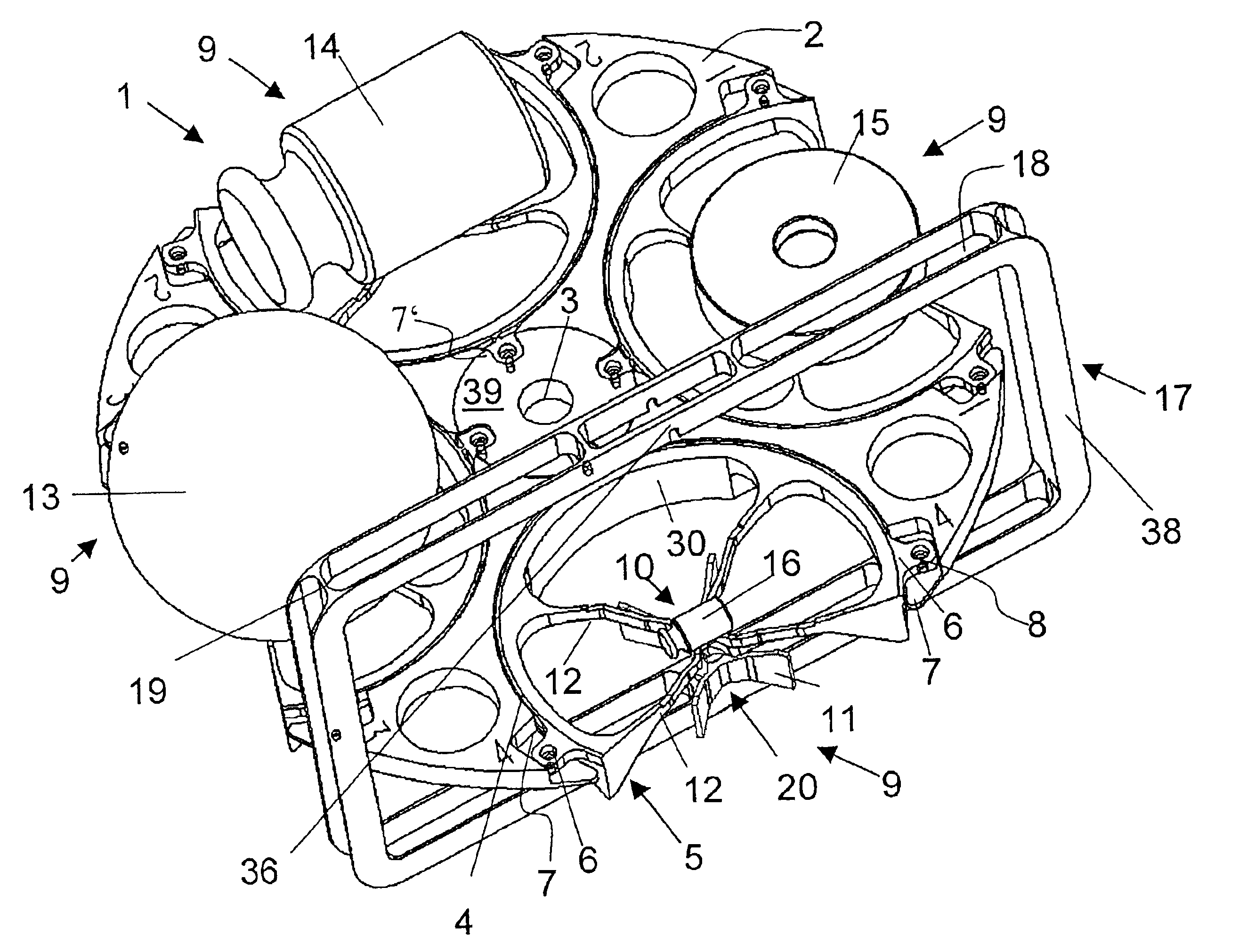

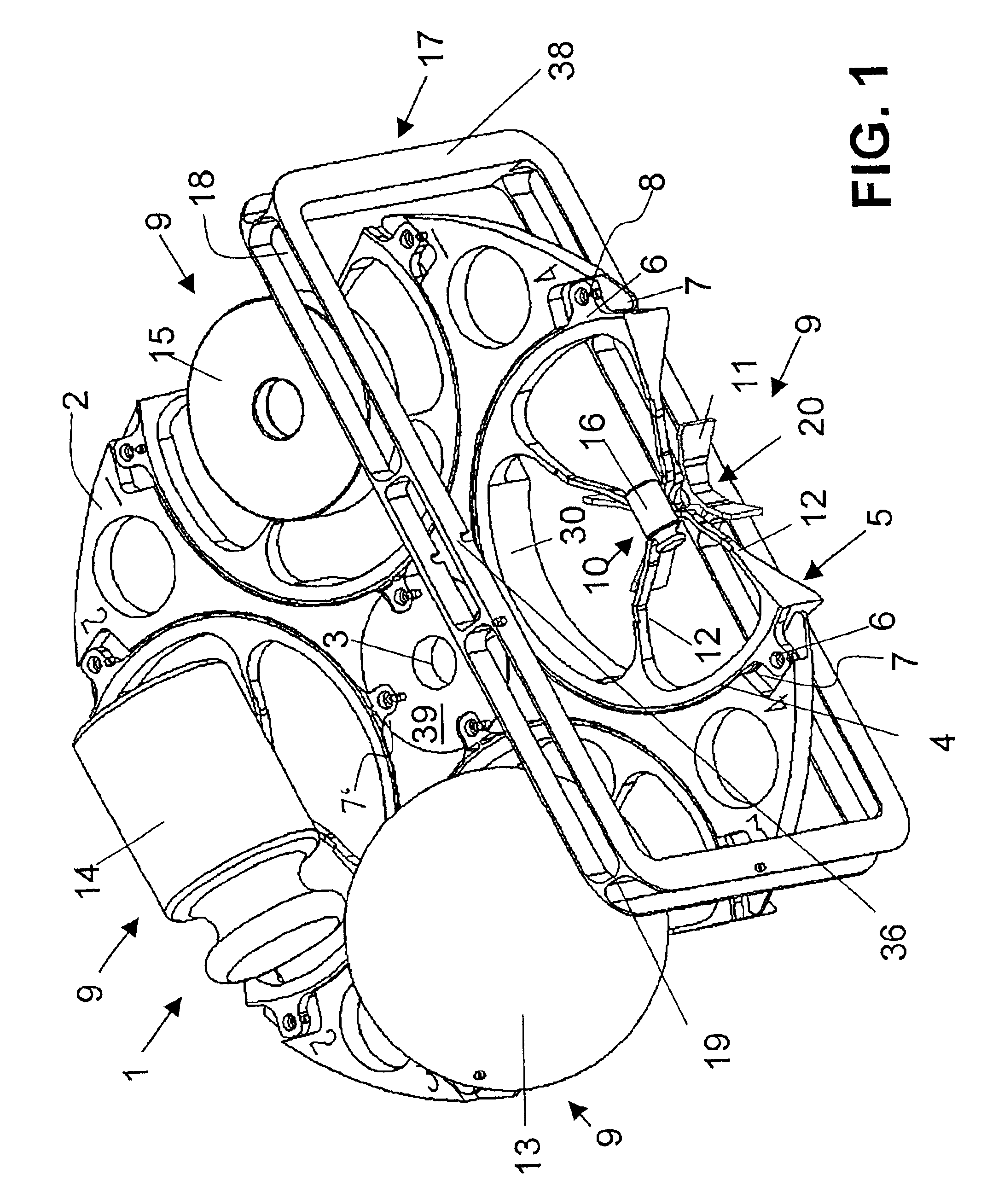

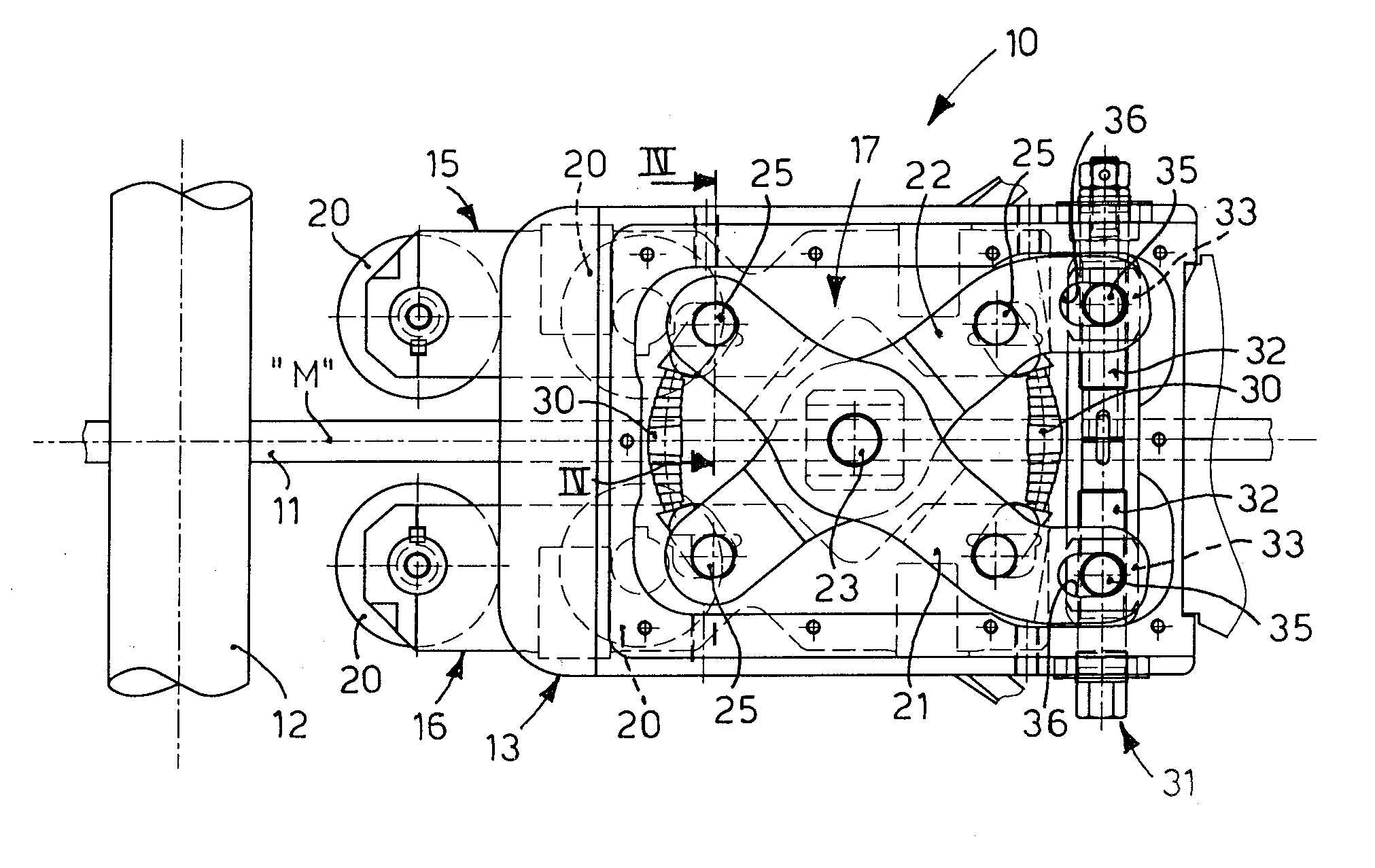

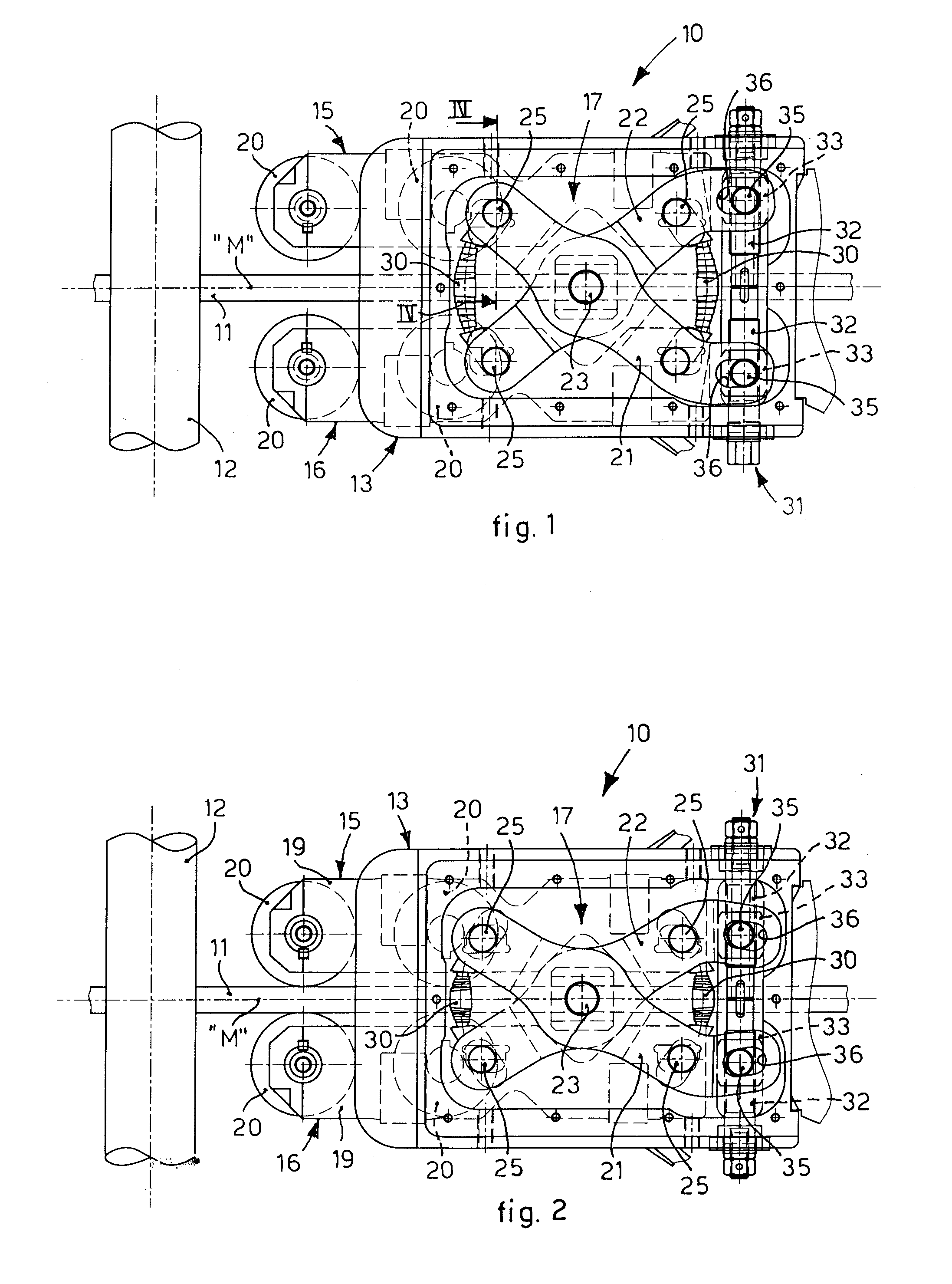

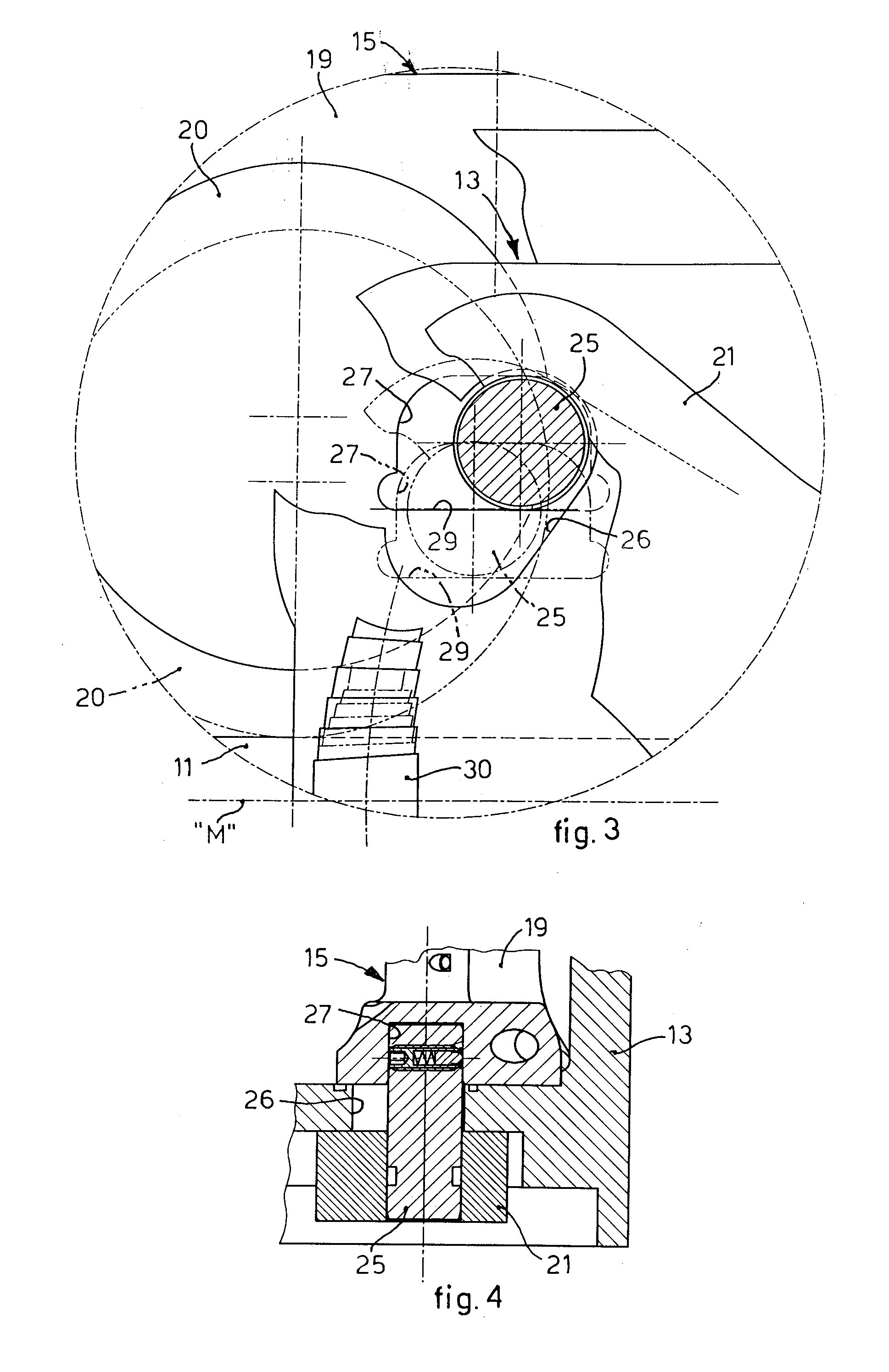

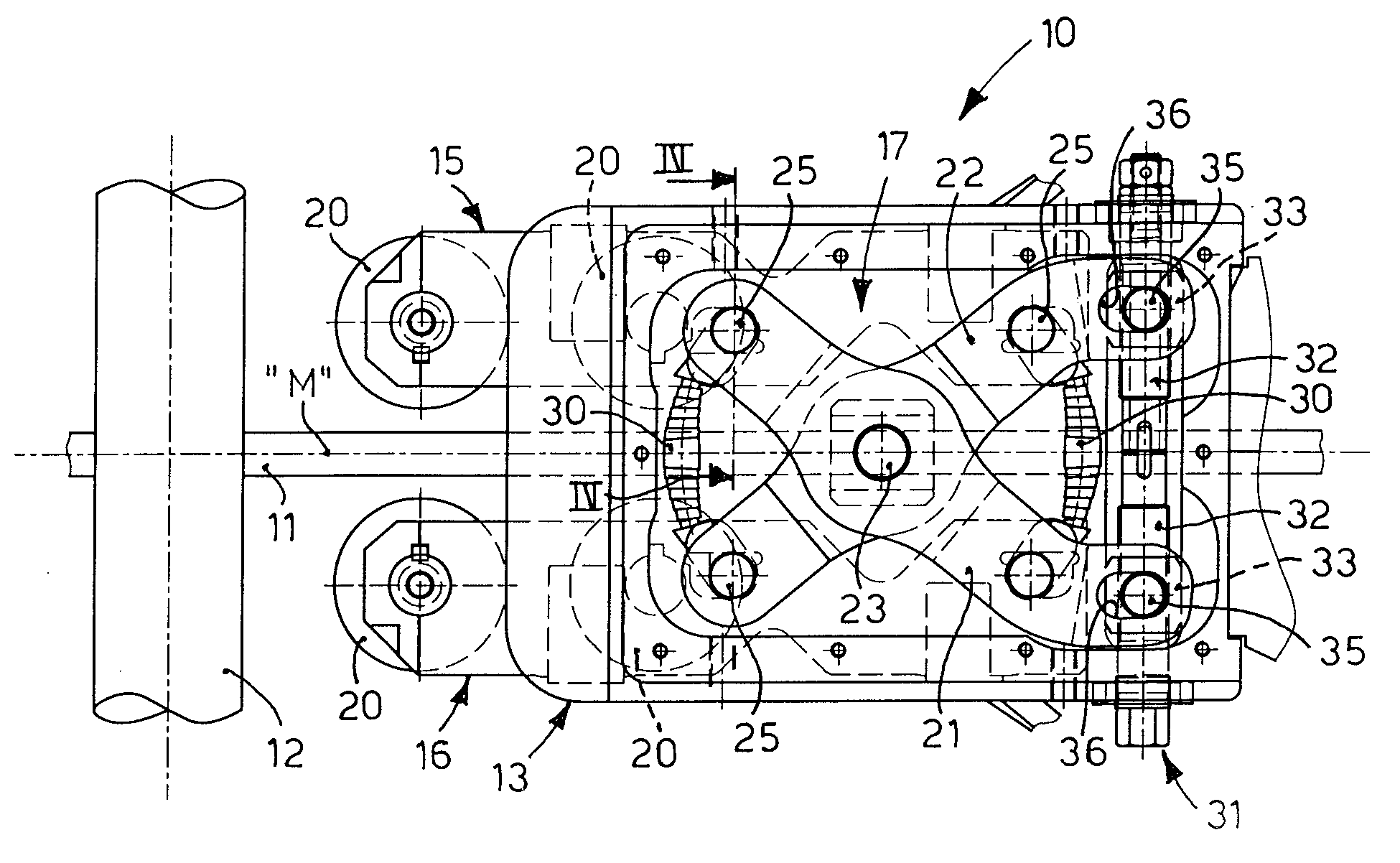

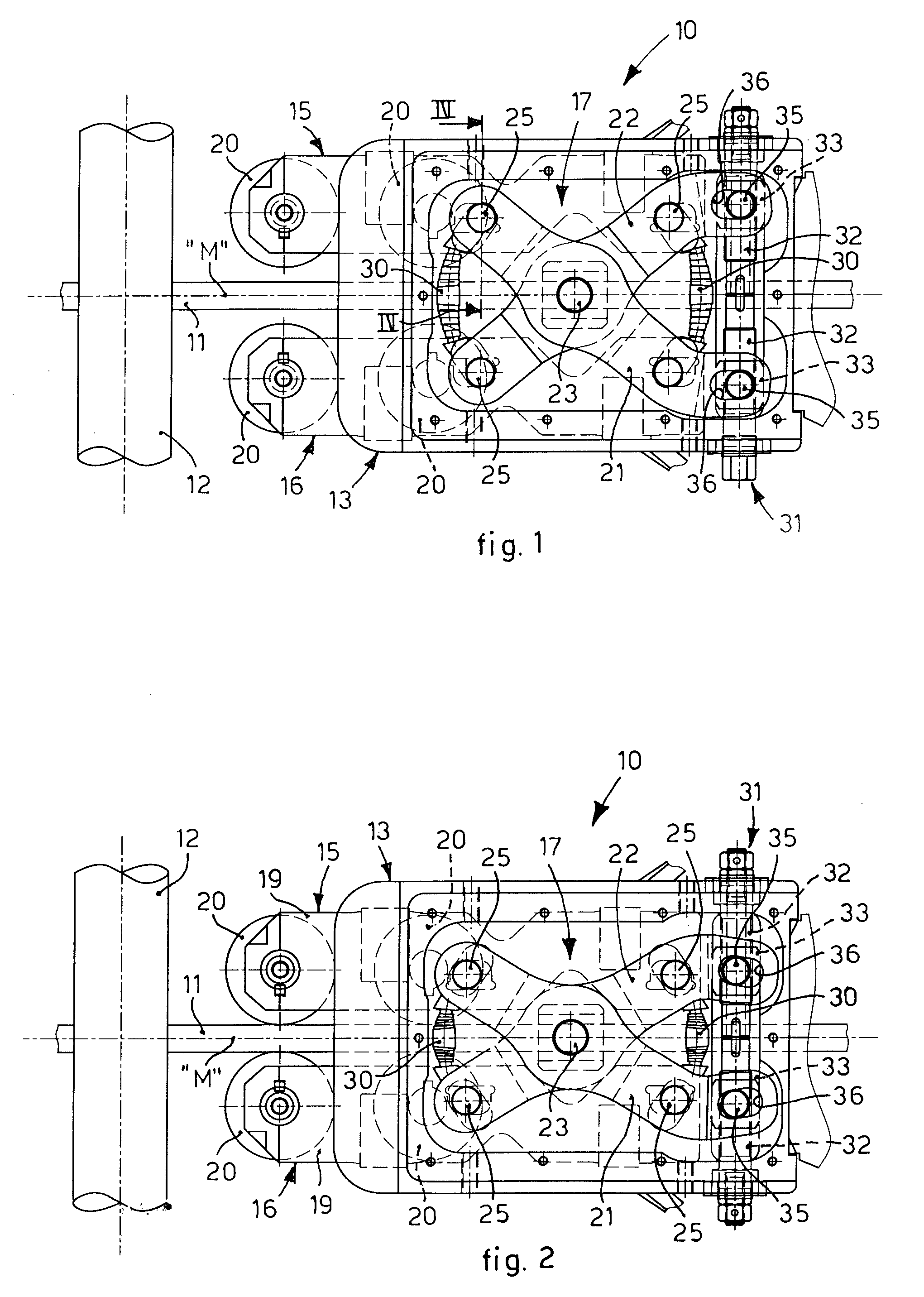

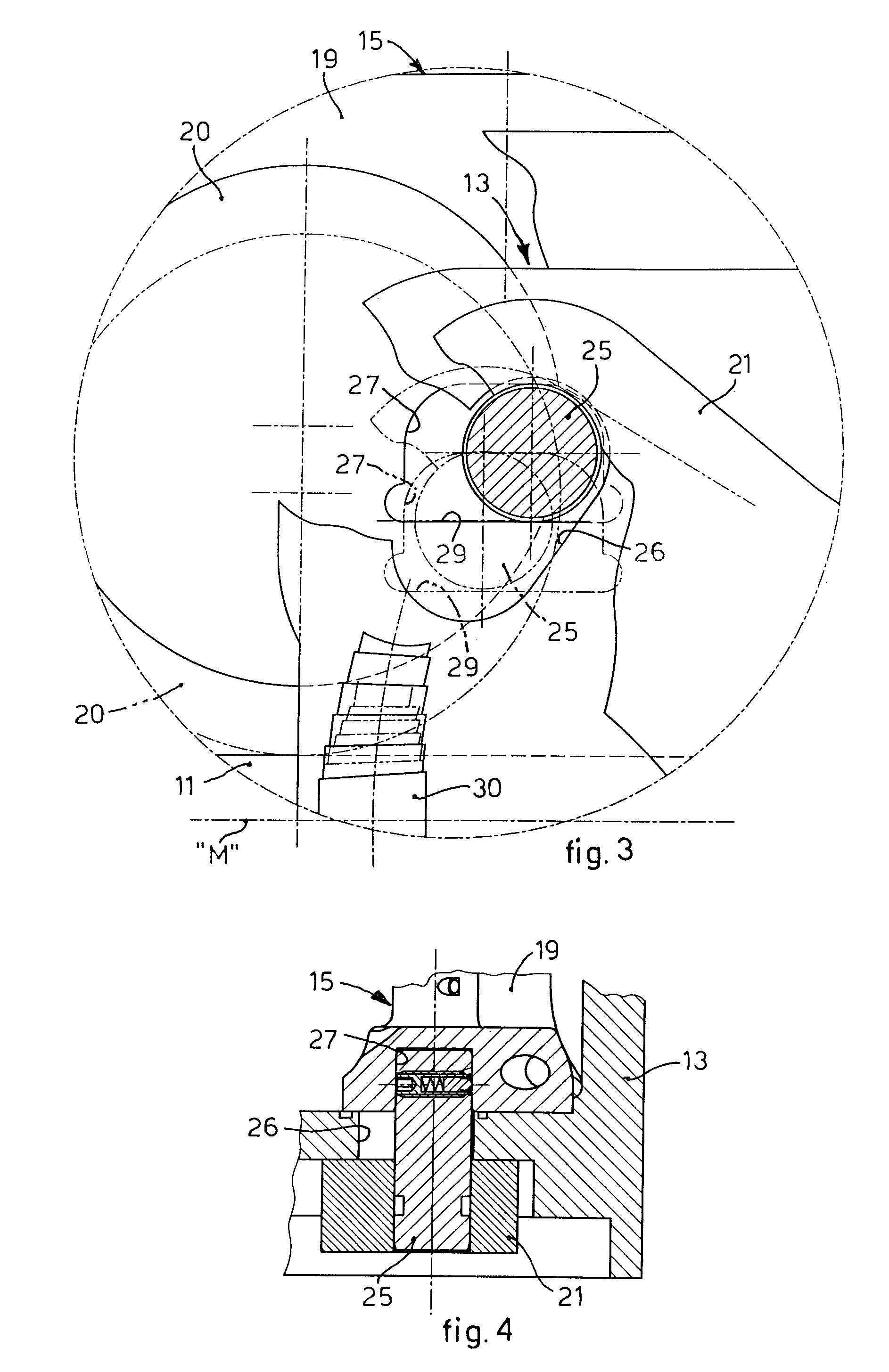

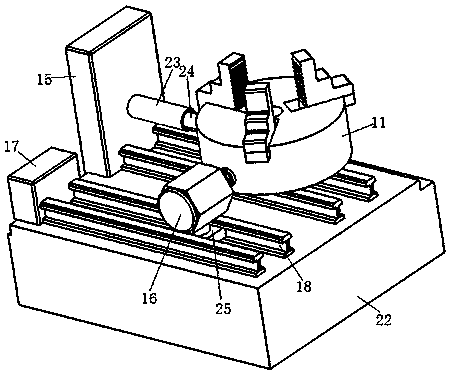

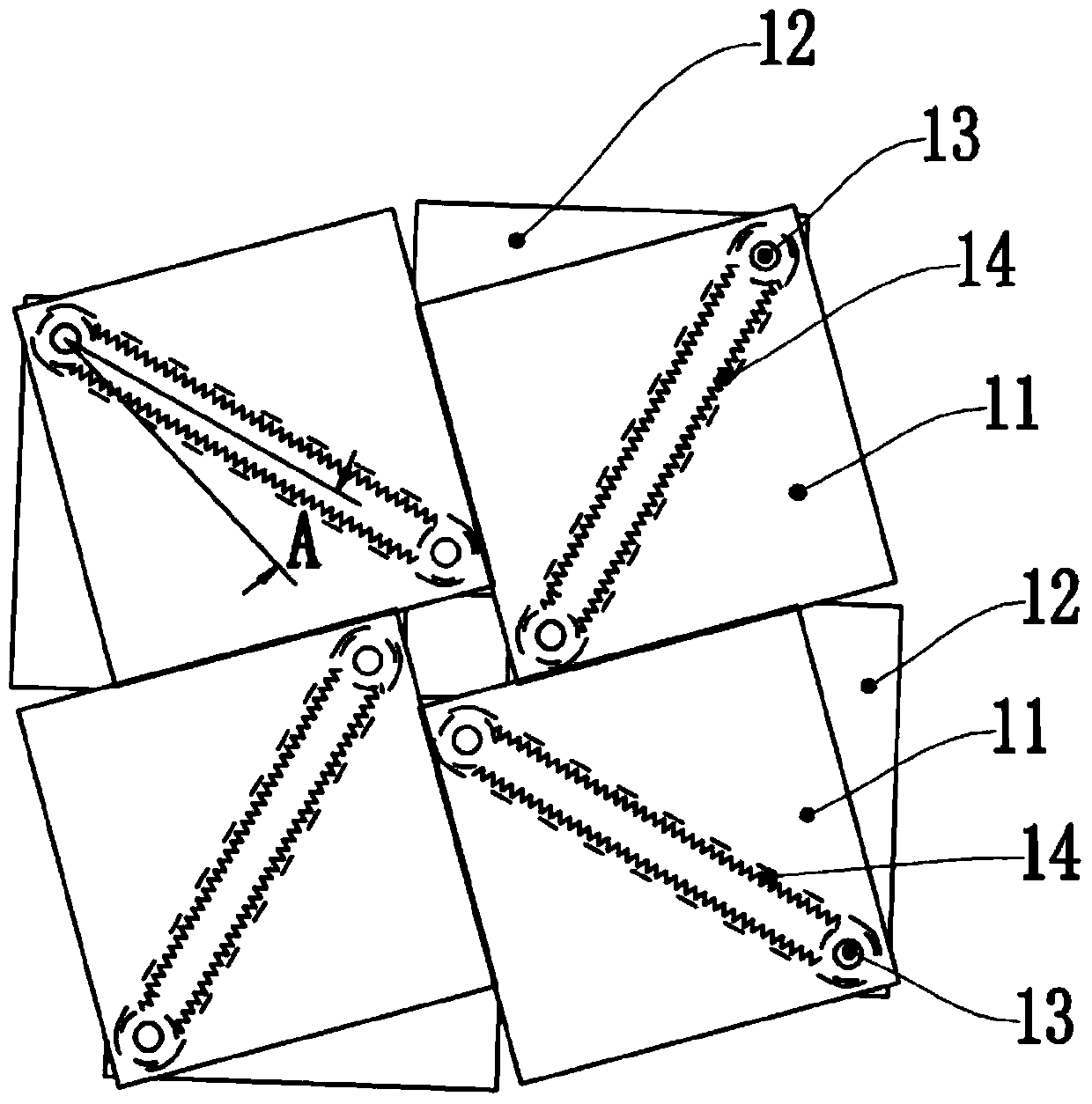

Adjustment device for guide rollers and relative adjustment method

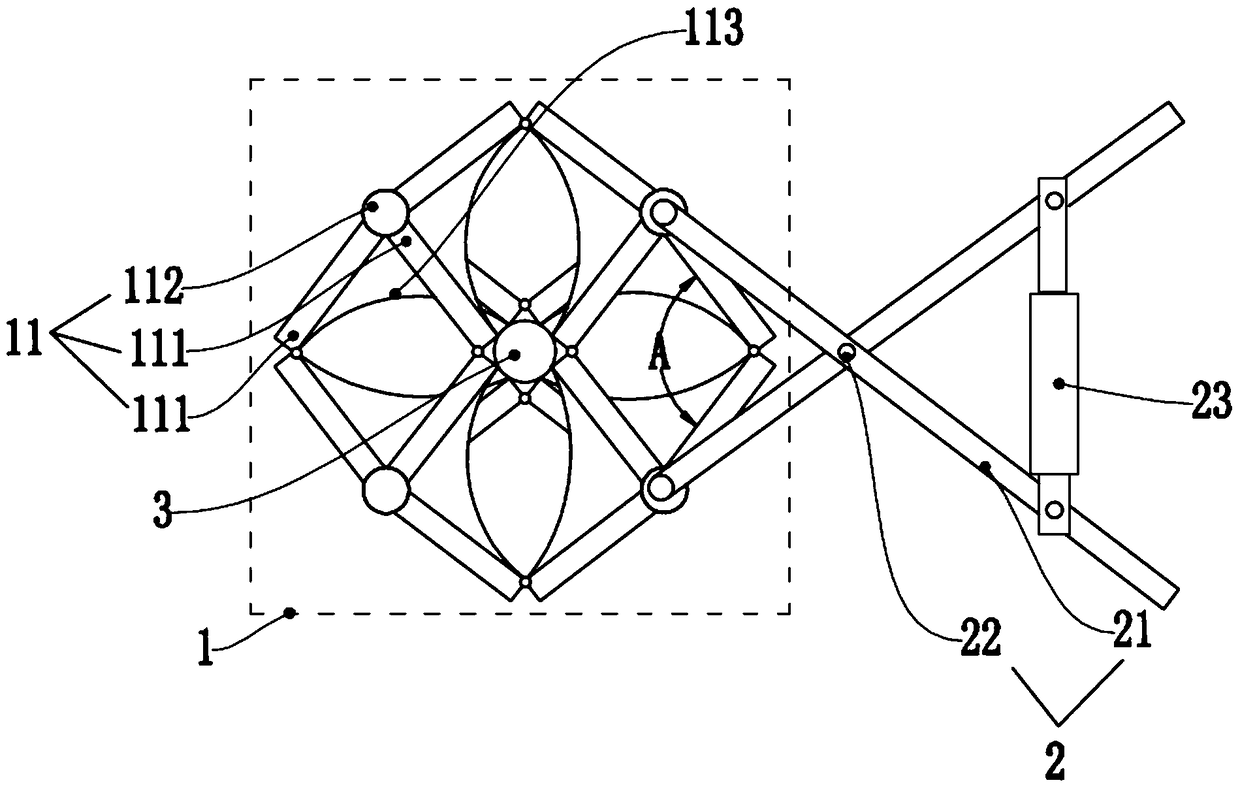

InactiveUS20110259071A1Function increasePrecise functionGuiding/positioning/aligning arrangementsWork manipulationEngineeringPantograph

An adjustment device and method to guide a metal product along a determinate nominal rolling axis. The device comprises a central body disposed astride the rolling axis, two guide units mounted movable on the central body, opposite each other with respect to the rolling axis and each provided with at least a guide roller for the metal product, and an adjustment mechanism mounted on the central body and operatively connected to both the guide units, in order to actuate the selective movement thereof with respect to the central body at least in an approach toward the rolling axis. The adjustment mechanism comprises a system of pantograph levers having two levers pivoted to each other and to the central body in correspondence to the rolling axis by means of a pin, and first constraint means disposed on each lever on opposite sides to the pin, so as to connect each lever to both the guide units.

Owner:DANIELI & C OFF MEC SPA

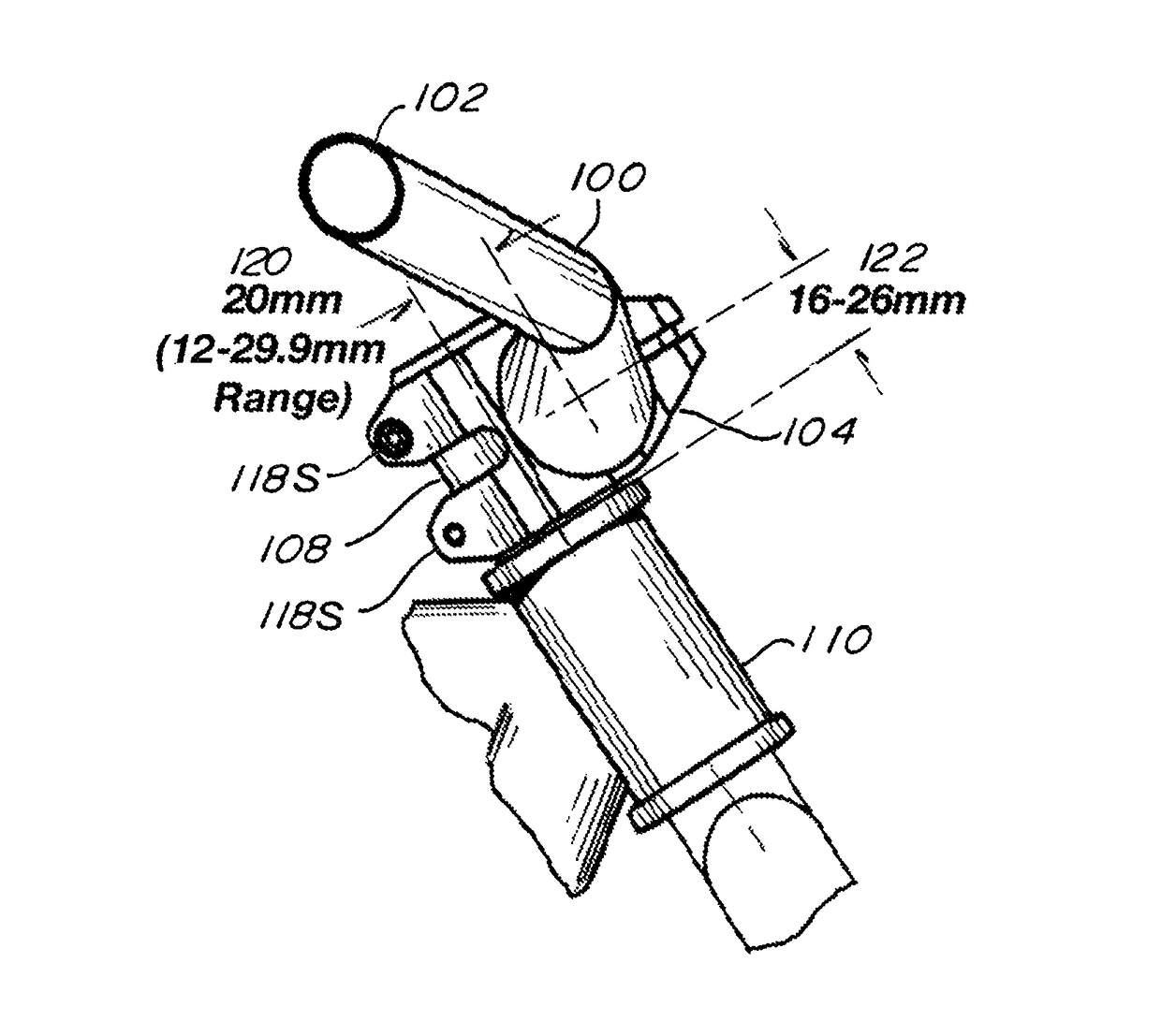

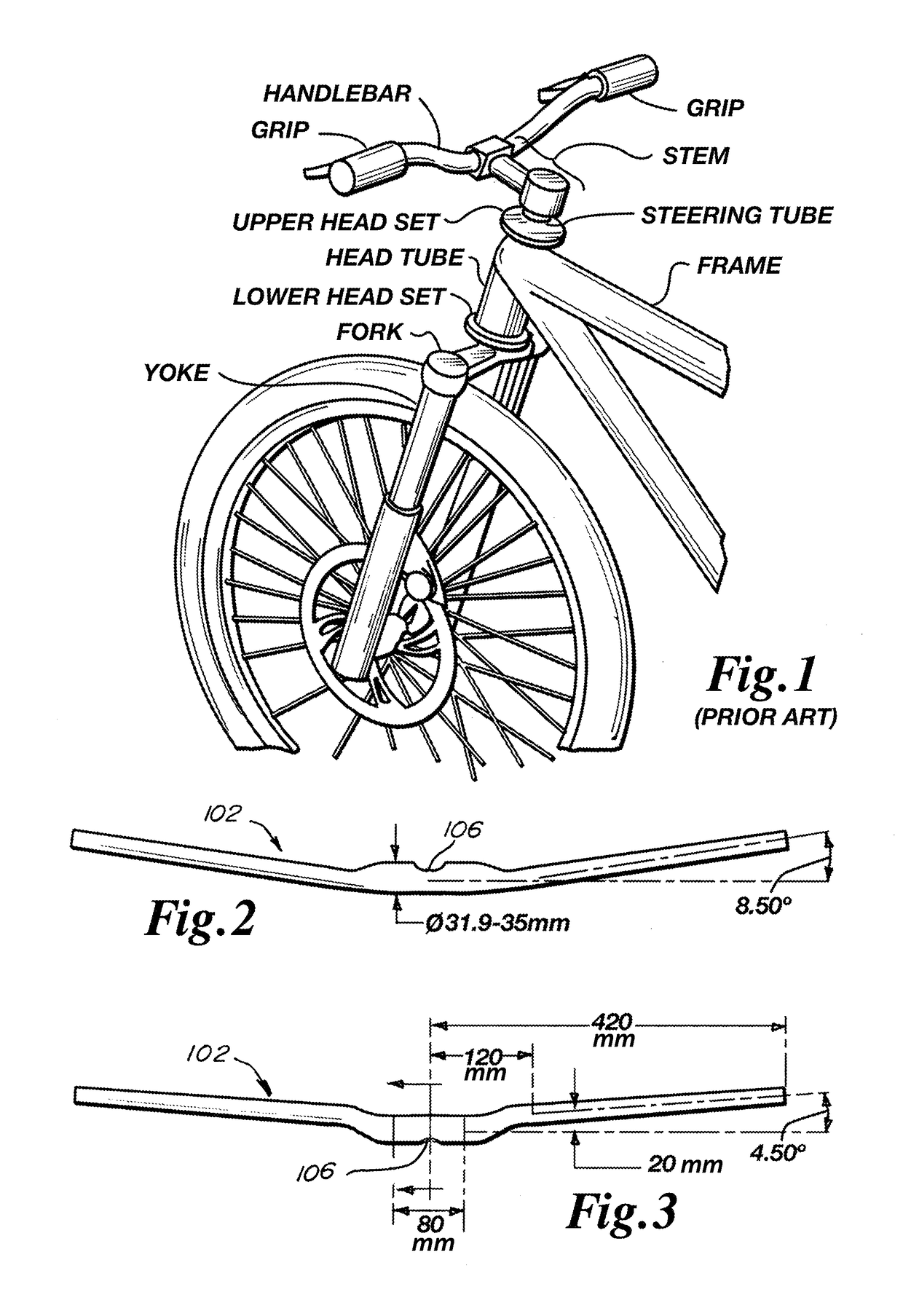

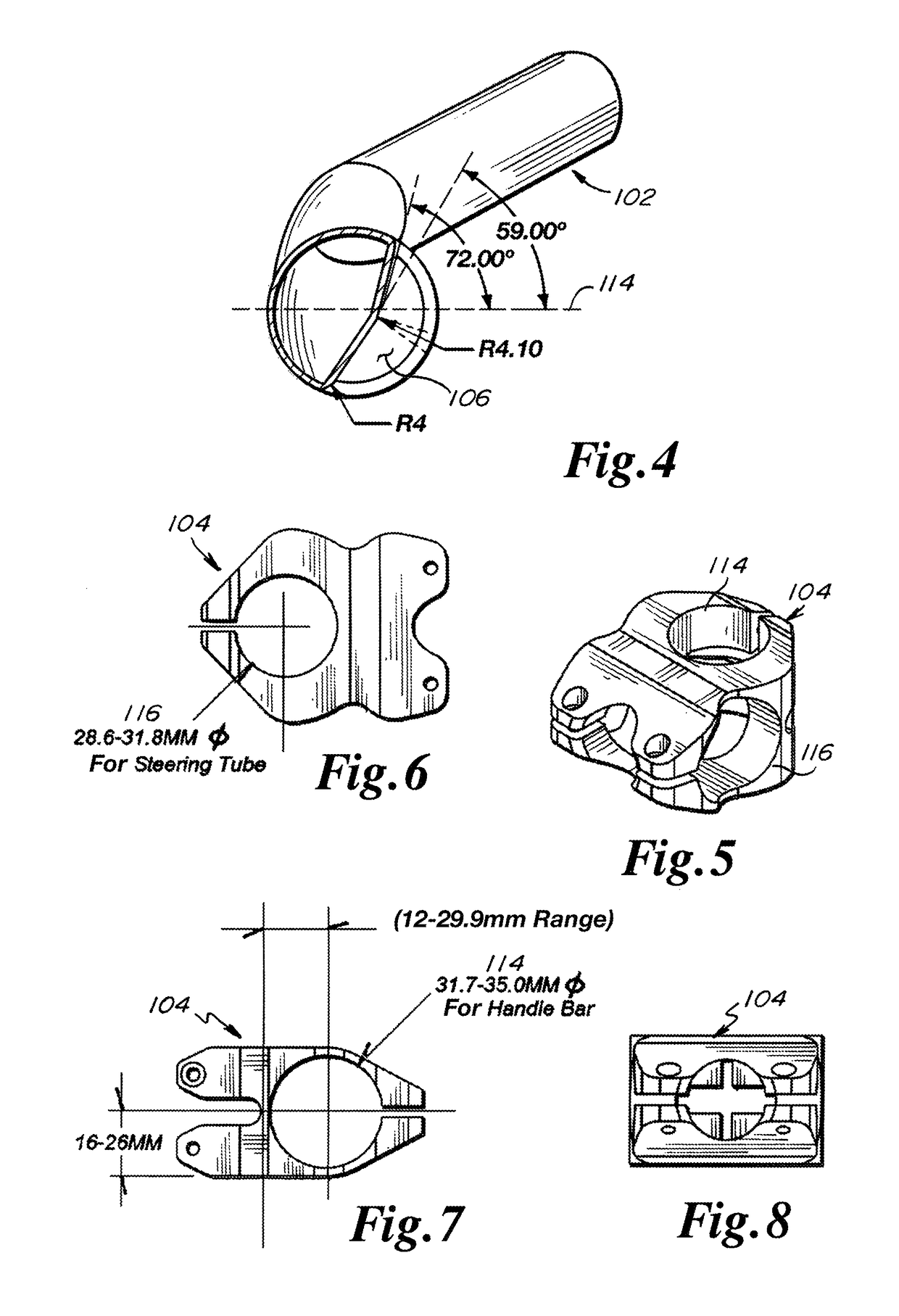

Bicycle handlebar, stem, and fork arrangement

InactiveUS9764792B2Center positioning is accurateSteering device% diameter reductionMechanical engineering

A bicycle handlebar / stem / steering tube assembly has a handle bar diameter and a steering tube diameter there-within. One or both of the steering tube and the handlebar includes one of a depression, a diameter-reduction, and a through-hole configured to mate rigidly against the other of the steering tube and the handlebar and be affixed thereto by the stem at a handlebar / steering tube interface such that a stem offset is created of a dimension that is less than either the handlebar diameter and the steering tube diameter at the handlebar / steering tube interface.

Owner:PACENTI KIRK A

Label holder for merchandise display hooks and method of making same

InactiveUS7802389B2Low costCenter positioning is accurateStampsMetal rolling stand detailsWire rodEngineering

A label holder for displaying information labels at the front of merchandise display hooks, and method for making the label holder. The label holder is of inexpensive continuously extruded construction, which is inexpensively processed after extrusion to eliminate the typical shortcomings of conventional extruded label holders. The extruded body form is cut to usable length and subjected to a plurality of die cutting operations on the back or mounting portion of the label holder, to form positioning and retention features. The label holder is thus provided with many if not most of the beneficial features of specially molded label holders, without incurring the greater expense involved in the molding process. The label holder is designed to accommodate mounting on label holders of several wire sizes commonly found in use in merchandise displays.

Owner:TRION IND

Edge grinding device for outer wall of round glass

ActiveCN110000654AImprove edging efficiency and edging qualityCenter positioning is accurateEdge grinding machinesGrinding drivesMechanical engineeringGrinding wheel

The invention discloses an edge grinding device for an outer wall of round glass. The edge grinding device comprises a bottom plate, wherein a base is fixed on the bottom plate, a stepped hole and a rectangular hole are formed in the base, a dome table is arranged above the base, the dome table is hinged in the stepped hole, an inner gear ring is fixed on the dome table, a pinion is meshed with the inner gear ring, the pinion is fixed on a first motor, a pressing block capable of ascending and descending is arranged above the dome table, a first V-shaped block and a second V-shaped block whichare symmetrically arranged are arranged on the outer side of the dome table, the first V-shaped block can move left and right, the second V-shaped block can move up and down; a grinding wheel is arranged on the front side of the dome table, the grinding wheel is fixed on a second motor, the second motor is fixed on the sliding block, the sliding block is inserted into a guide rod, and the slidingblock can move back and forth through a screw rod. According to the edge grinding device, the round glass can be accurately and centrally positioned through the first V-shaped block and the second V-shaped block; and the grinding wheel is gradually close to the outer wall of the round glass, so that the edge grinding efficiency and the edge grinding quality can be effectively improved;

Owner:临清市中科建工程有限公司

A round glass outer wall edging device

ActiveCN110000654BCenter positioning is accurateImprove edging efficiencyEdge grinding machinesGrinding drivesRectangular apertureElectric machinery

The invention discloses an edge grinding device for an outer wall of round glass. The edge grinding device comprises a bottom plate, wherein a base is fixed on the bottom plate, a stepped hole and a rectangular hole are formed in the base, a dome table is arranged above the base, the dome table is hinged in the stepped hole, an inner gear ring is fixed on the dome table, a pinion is meshed with the inner gear ring, the pinion is fixed on a first motor, a pressing block capable of ascending and descending is arranged above the dome table, a first V-shaped block and a second V-shaped block whichare symmetrically arranged are arranged on the outer side of the dome table, the first V-shaped block can move left and right, the second V-shaped block can move up and down; a grinding wheel is arranged on the front side of the dome table, the grinding wheel is fixed on a second motor, the second motor is fixed on the sliding block, the sliding block is inserted into a guide rod, and the slidingblock can move back and forth through a screw rod. According to the edge grinding device, the round glass can be accurately and centrally positioned through the first V-shaped block and the second V-shaped block; and the grinding wheel is gradually close to the outer wall of the round glass, so that the edge grinding efficiency and the edge grinding quality can be effectively improved;

Owner:临清市中科建工程有限公司

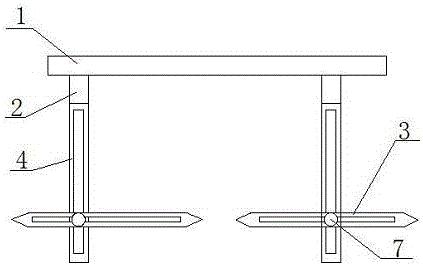

Preoperative designer for nose augmentation surgery

InactiveCN106108908ASimple structureEasy to useDiagnostic recording/measuringSensorsNoseStructural engineering

The invention belongs to the technical field of surgical apparatuses, and in particular relates to a preoperative designer for a nose augmentation surgery. The preoperative designer comprises a transverse beam, vertical beams, longitudinal beams and short rulers, wherein a transverse sliding groove is formed in the side face of the transverse beam; a first vertical sliding groove is formed in one side of each vertical beam; the side, back away from the first vertical sliding groove, of each vertical beam is provided with a second vertical sliding groove; convex sliding blocks are arranged in the first vertical sliding grooves; the convex sliding blocks are matched with the transverse sliding groove; a boss is arranged at one end of each longitudinal beam; the bosses are matched with the second vertical sliding grooves; a longitudinal beam slideway is arranged in each longitudinal beam in a length direction; a short ruler slideway is arranged in each short ruler in a length direction; each longitudinal beam slideway and each short ruler slideway are connected by virtue of an adjusting bolt; and scales are arranged on the transverse beam, the vertical beams, the longitudinal beams and the short rulers. The preoperative designer disclosed by the invention is simple in structure, convenient to use, accurate in center location, precise in measurement, high in making precision, high in design efficiency and low in error, and the preoperative designer is capable of measuring the widths and the heights of various cross sections of a nose, so as to better conduct the nose augmentation surgery.

Owner:大连达美医疗美容门诊有限公司

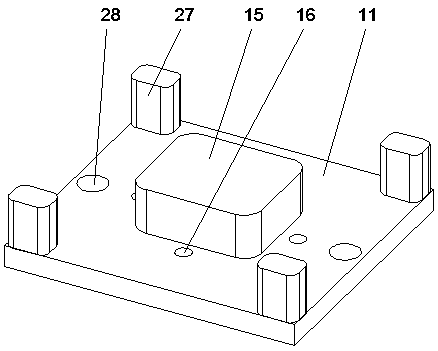

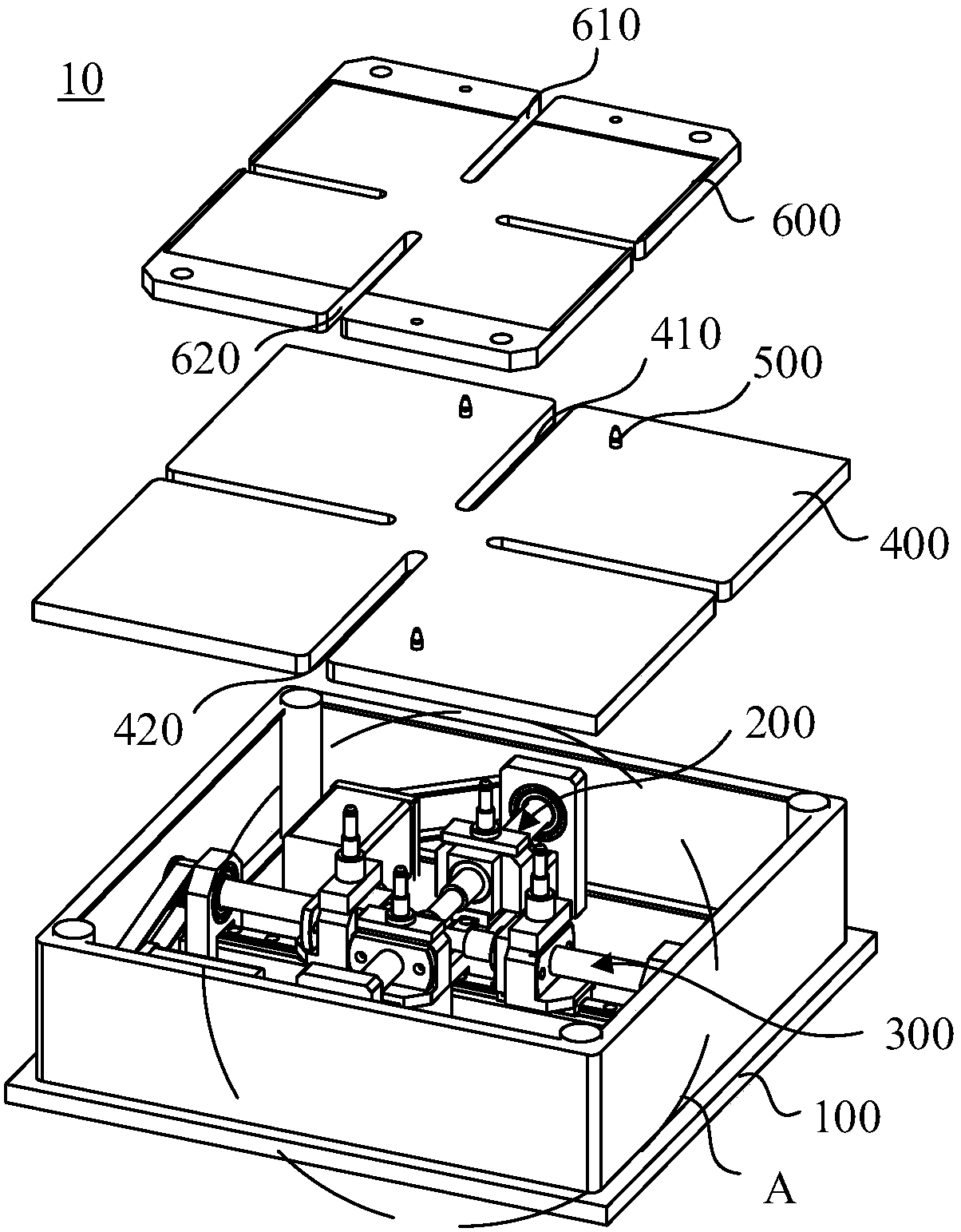

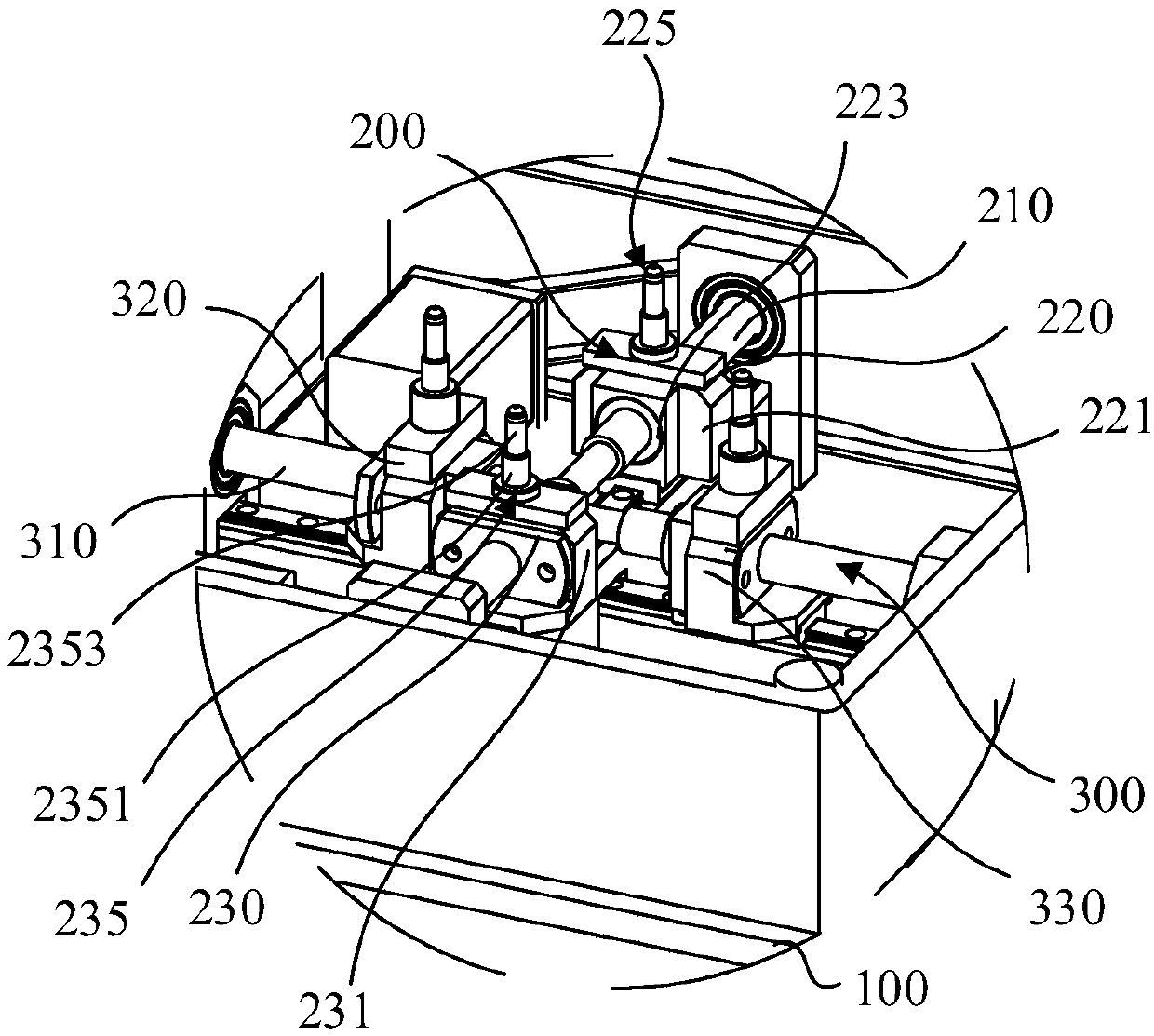

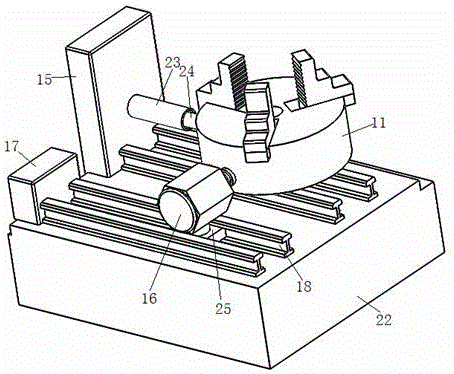

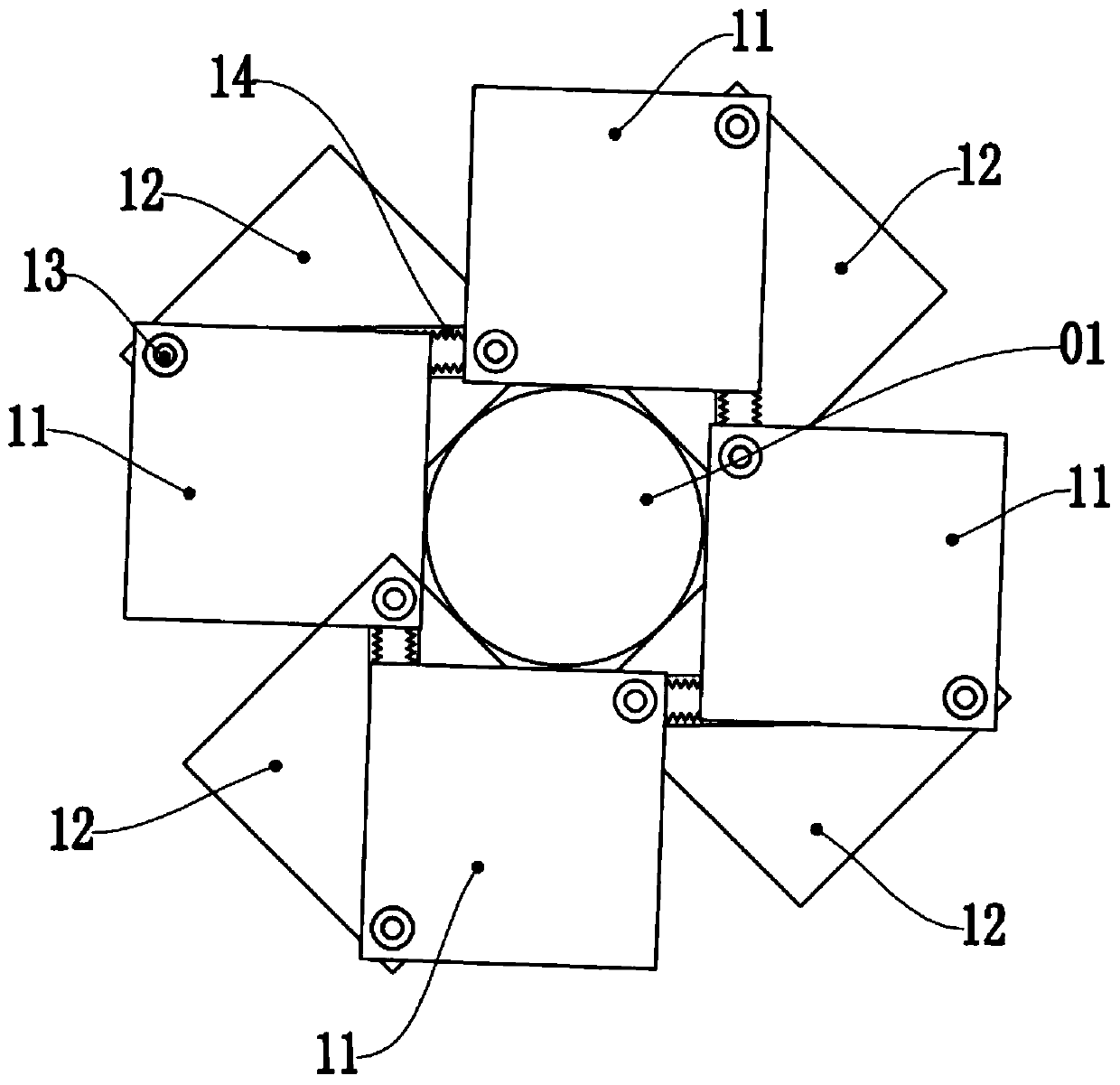

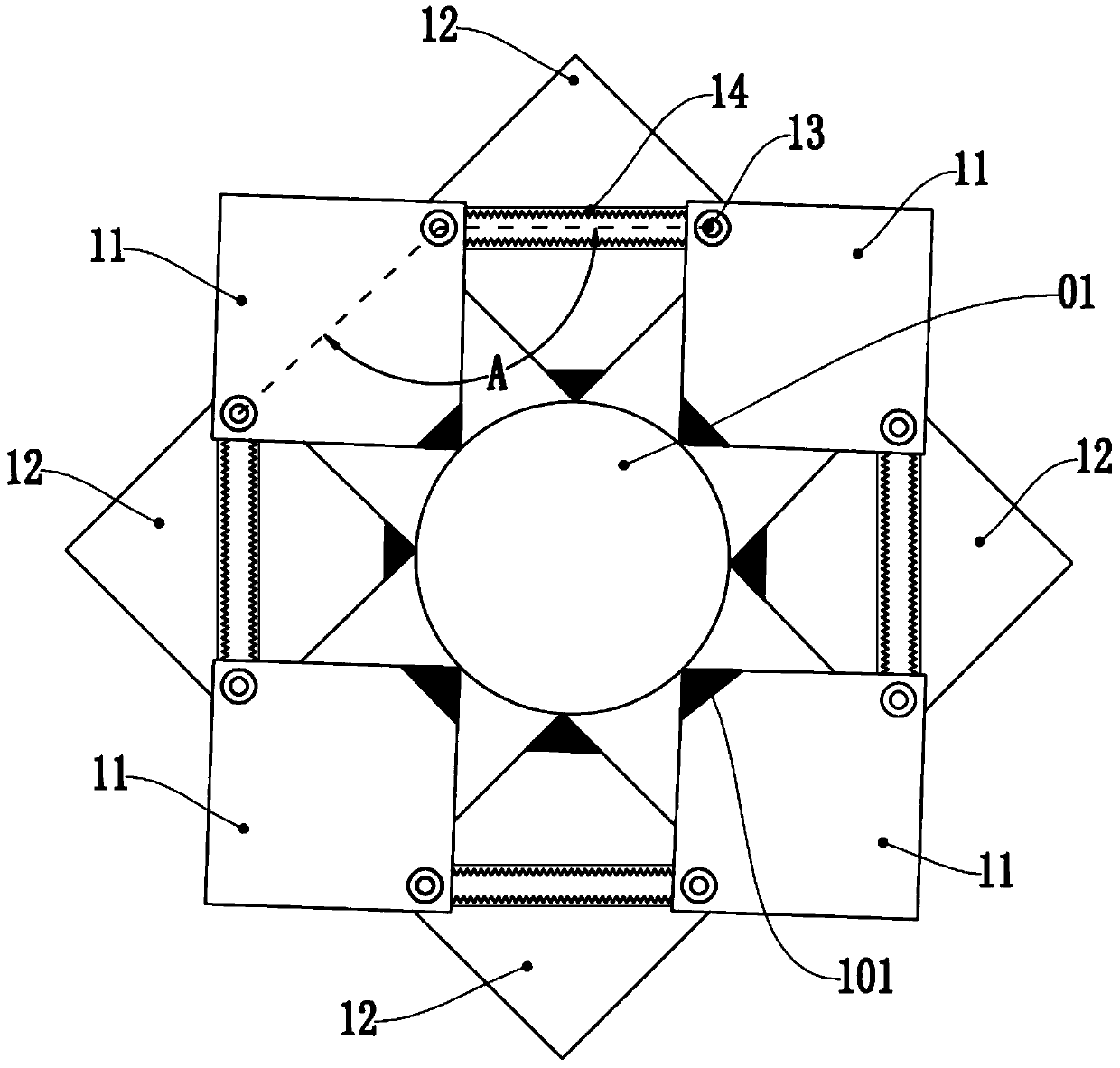

Jig

InactiveCN107584303ASimple structureEasy to operatePositioning apparatusMetal-working holdersMechanical engineeringEngineering

The invention relates to a jig. The jig comprises a supporting member, a first clamping assembly, and a second clamping assembly. A center position is set on the supporting member. The first clampingassembly includes a first transmission bar, a first clamping block, and a second clamping block; the first transmission bar extends in a first direction; when the first transmission bar is rotated, the first clamping block and the second clamping block can move close to or away from each other in the first direction at the same speed. The second clamping assembly includes a second transmission bar, a third clamping block and a fourth clamping block; the second transmission bar extends in a second direction; when the second transmission bar is rotated, the third clamping block and the fourth clamping block can move close to or away from each other in the second direction at the same speed. The jig is simple in structure, easy to operate, and easy to achieve accurate center positioning of products.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD

Adjustment device for guide rollers and relative adjustment method

InactiveUS9132459B2Effective and constant and precise adjustmentCenter positioning is accurateGuiding/positioning/aligning arrangementsWork manipulationEngineeringPantograph

An adjustment device and method to guide a metal product along a determinate nominal rolling axis. The device comprises a central body disposed astride the rolling axis, two guide units mounted movable on the central body, opposite each other with respect to the rolling axis and each provided with at least a guide roller for the metal product, and an adjustment mechanism mounted on the central body and operatively connected to both the guide units, in order to actuate the selective movement thereof with respect to the central body at least in an approach toward the rolling axis. The adjustment mechanism comprises a system of pantograph levers having two levers pivoted to each other and to the central body in correspondence to the rolling axis by means of a pin, and first constraint means disposed on each lever on opposite sides to the pin, so as to connect each lever to both the guide units.

Owner:DANIELI & C OFF MEC SPA

Expansion device of brake disc bolt tightening machine

PendingCN111451755APrecise positioningCenter positioning is accurateWork holdersMetal working apparatusBrakeGear wheel

The invention discloses an expansion device of a brake disc bolt tightening machine. The expansion device is arranged in the center of a workbench seat of the tightening machine and is provided with atable plate, wherein a rotating device is arranged below the table plate and is formed by combining a motor and a gear; a support is arranged below the rotating device; an expansion air cylinder is arranged below the support and is connected with an ejector rod; the ejector rod penetrates through the support and the rotating device to enter the center of the table plate; a bearing, a conical topand an expansion seat are arranged on the upper portion of the ejector rod; a through hole is formed in the wall of the expansion seat; an expansion block is arranged in the through hole; a return spring is arranged on the expansion block in a ring mode; and a nylon sleeve is arranged on the expansion seat. The expansion device has the advantages that a brake disc can be accurately positioned in the center on the bolt tightening machine, the nylon sleeve does not need to be replaced due to different inner diameters of the brake disc, time and labor are saved, and dislocation caused by positioning deviation during nut tightening is avoided. The expansion device is reasonable in structure and high in practicability, and meets the requirement for automatic production.

Owner:HUBEI HEQIANG MACHINERY DEV LIMITED BY SHARE

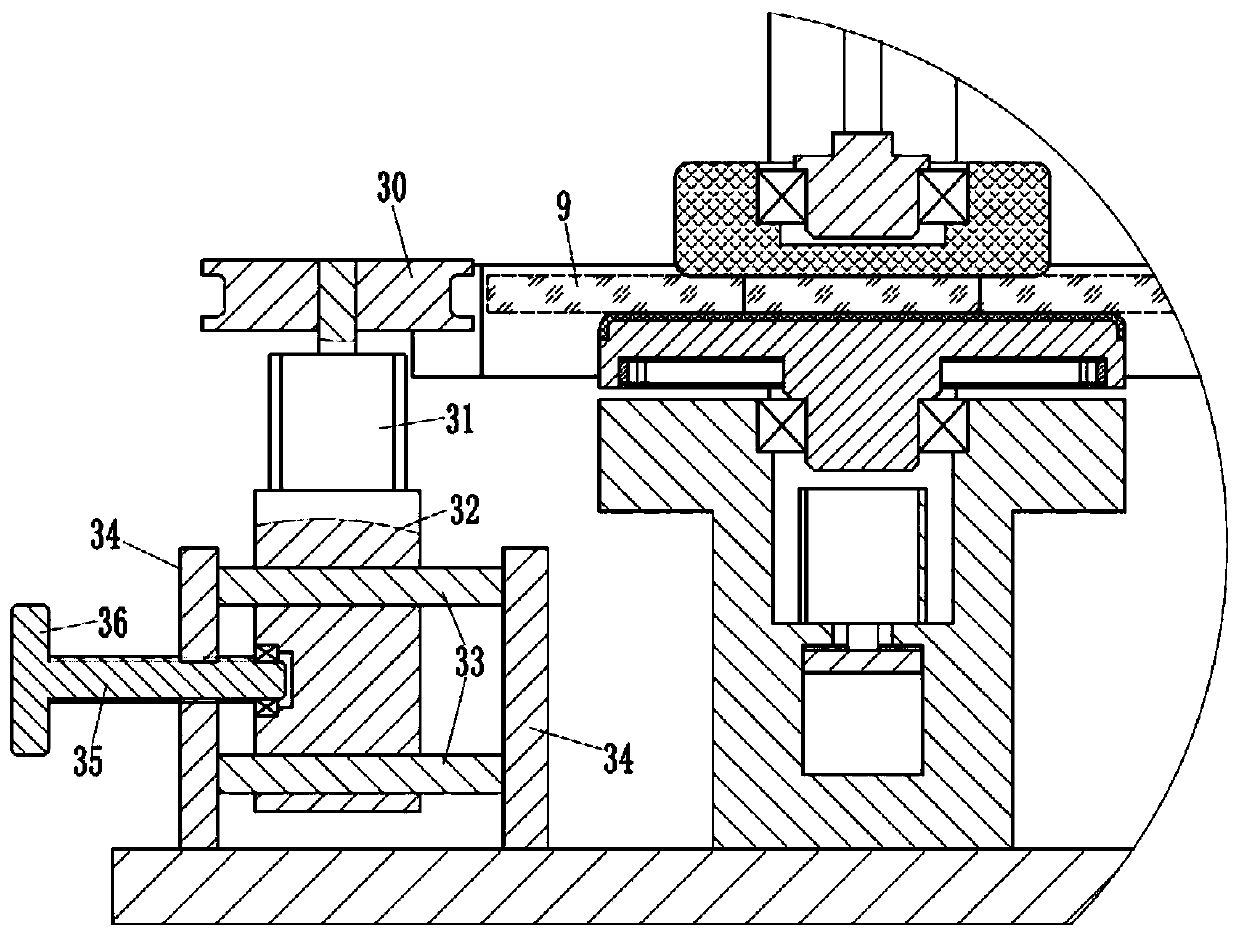

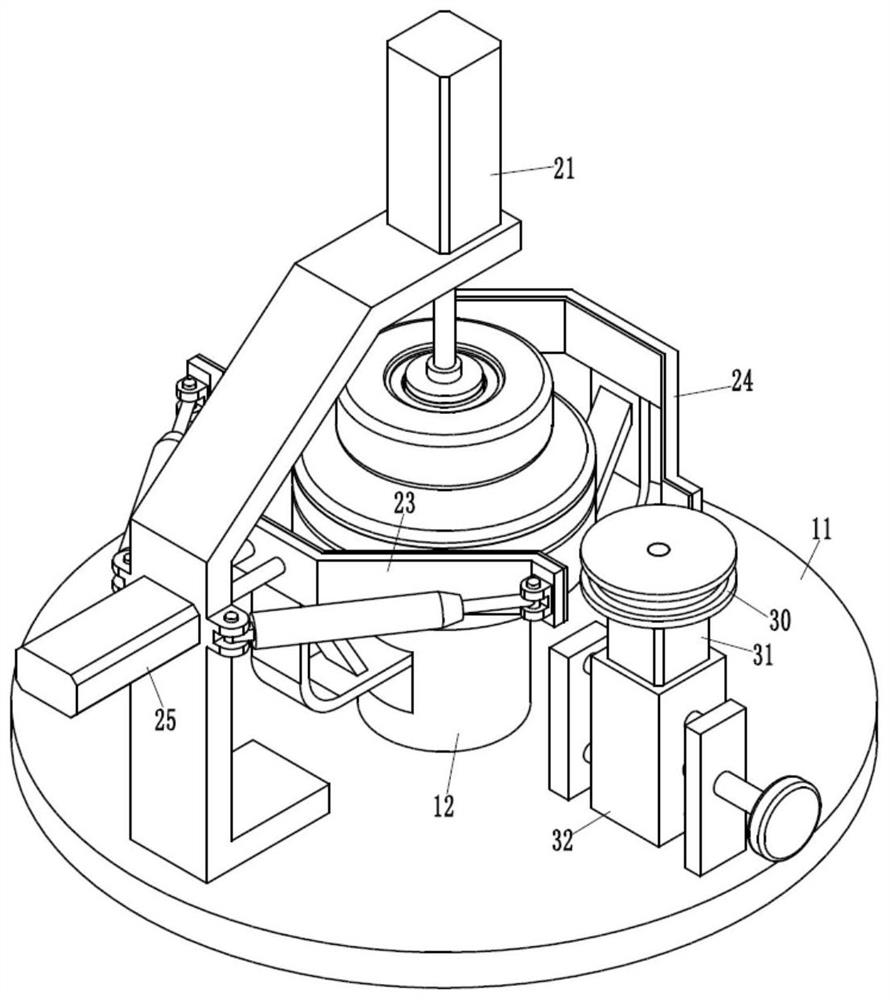

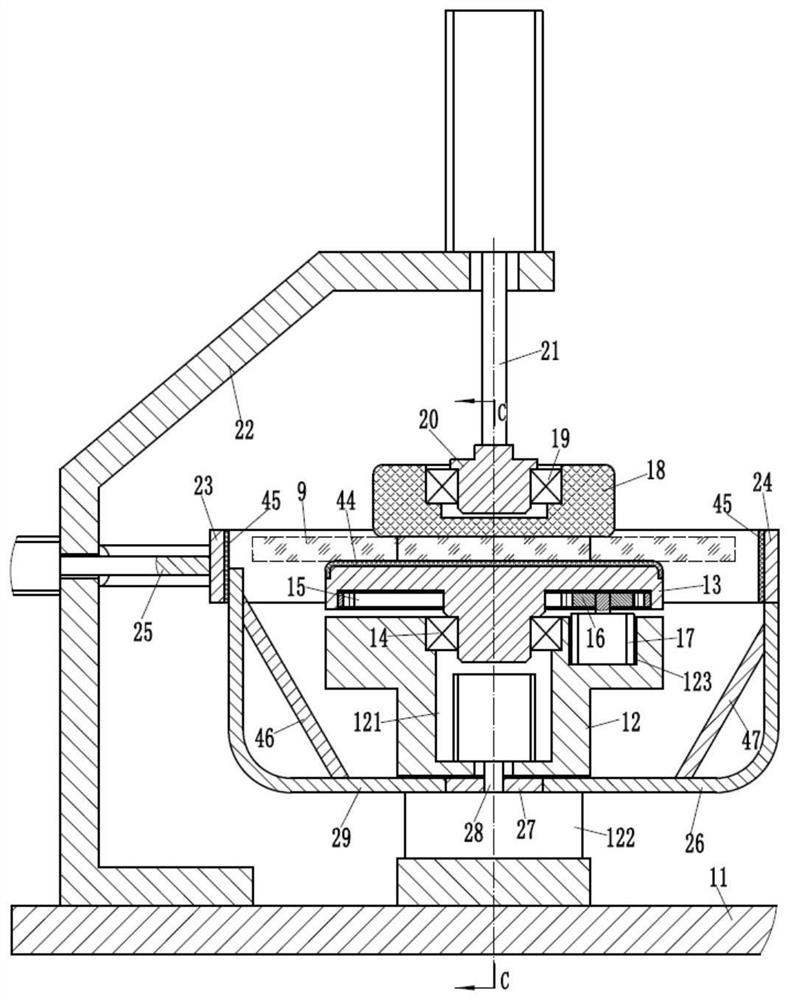

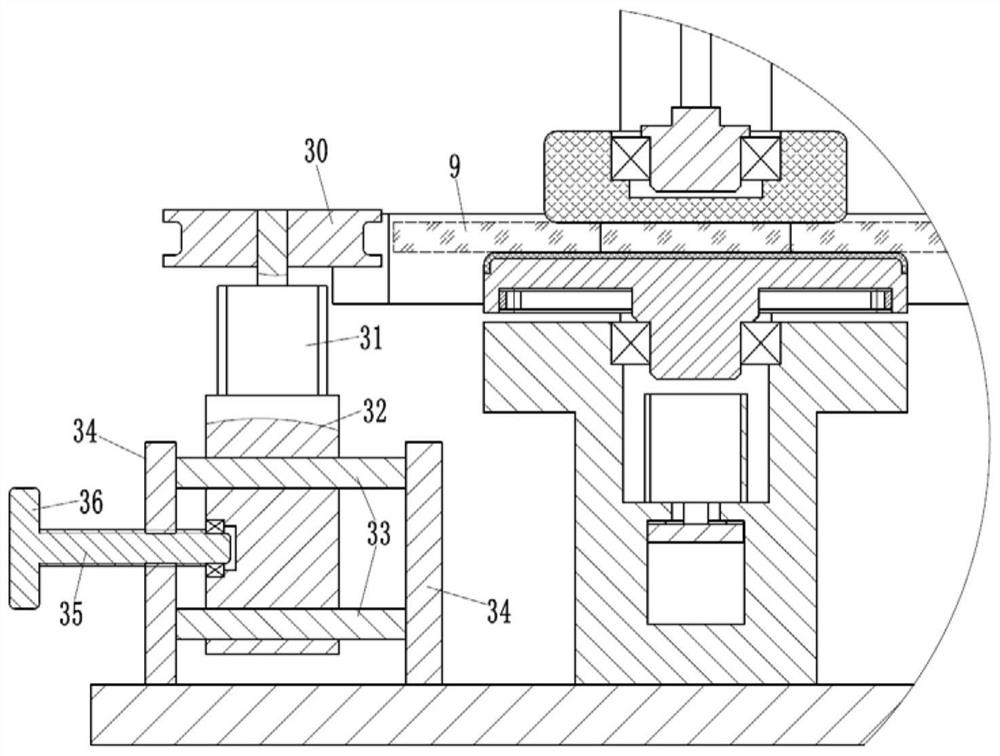

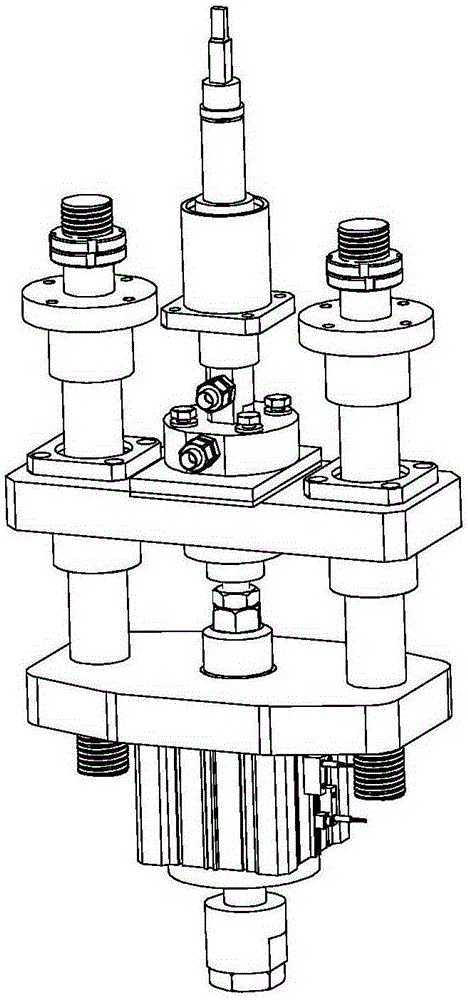

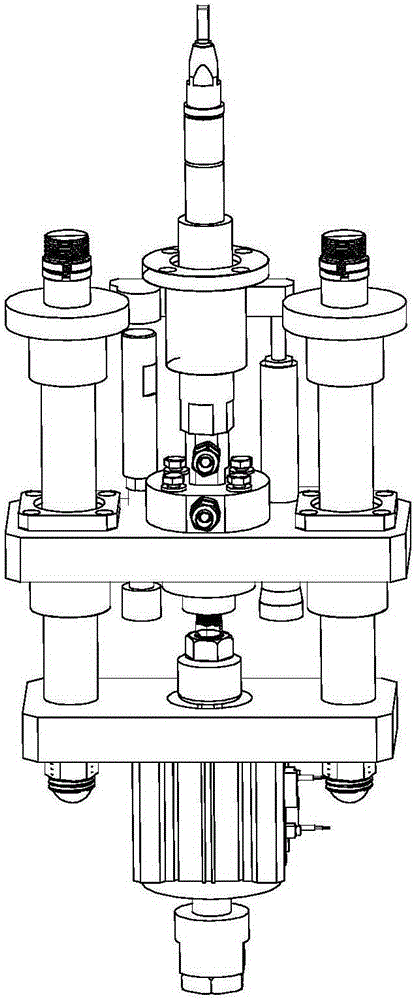

A motor rotor and stator automatic centering mechanism

ActiveCN107769499BAutomatically determineHigh center alignment accuracyCentering/balancing rotorsControl systemMechanical engineering

The invention discloses an automatic centering mechanism for the rotor and the stator of a motor. The automatic centering mechanism comprises a frame equipped with a support block for supporting and positioning the stator, and a clamping device for clamping and fixing the stator. A upper pressing component and a lower lifting component, which can be moved in the horizontal direction and the vertical direction respectively, are arranged on the upper and lower sides of the support block on the frame respectively. The frame is also provided with a control system capable of controlling the movement of the clamping device, the upper pressing component and the lower lifting component. The upper pressing component is provided with a camera for capturing a stator image for a control system to compute the center position of the stator. The automatic centering mechanism is simple in structure and accurate in center positioning.

Owner:GUANGDONG HANDSOME INTELLIGENT EQUIP CO LTD

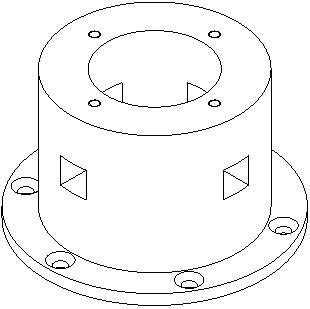

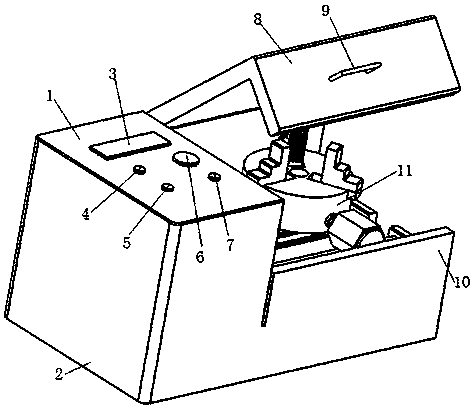

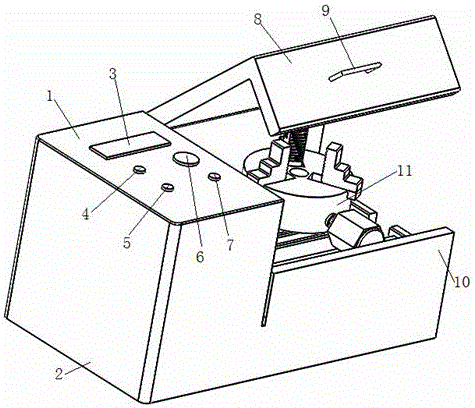

Power Component Lock Mounting Equipment

ActiveCN106231857BEasy to installCenter positioning is accurateSlidable card holdersCard stiffenersHydraulic cylinderEngineering

The invention discloses locking installation equipment for electric power components. The locking installation equipment comprises an enclosure, wherein a control panel is arranged at one side of the top surface of the enclosure and a protective cover is arranged at the other side of the top surface of the enclosure; a side plate is arranged at one side of the front surface of the enclosure; the enclosure is provided with a work bench at the back surface of the side plate; a hydraulic oil tank is arranged at one side of the top surface of the work bench; a bidirectional hydraulic cylinder is connected to the central position of one side surface of the hydraulic oil tank; a hydraulic rod is arranged on the top surface of the other end of the bidirectional hydraulic cylinder; the other end of the hydraulic rod is connected with a chuck base; a central circular hole is formed in the central position of the top surface of the chuck base; three jaw grooves are uniformly distributed in the top surface of the chuck base; a chuck jaw is arranged in each jaw groove; a motor is arranged at the other side of the arc side surface of the chuck base; a sliding rail a is arranged at the bottom side of the motor; and a sliding rail b is arranged at the bottom side of the chuck base. A three-jaw chuck is formed by the chuck base and the chuck jaws, fastening and disassembling are controlled through the motor and locating and locking are convenient and fast.

Owner:PENGLAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

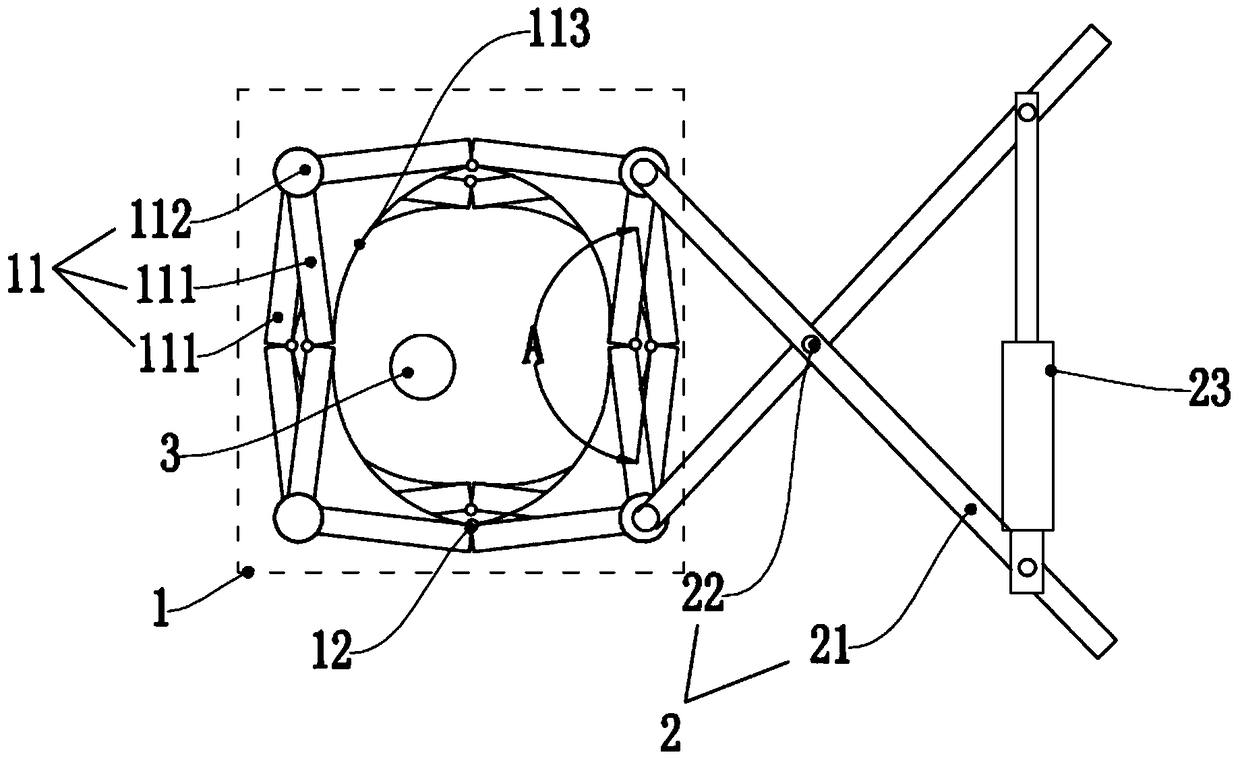

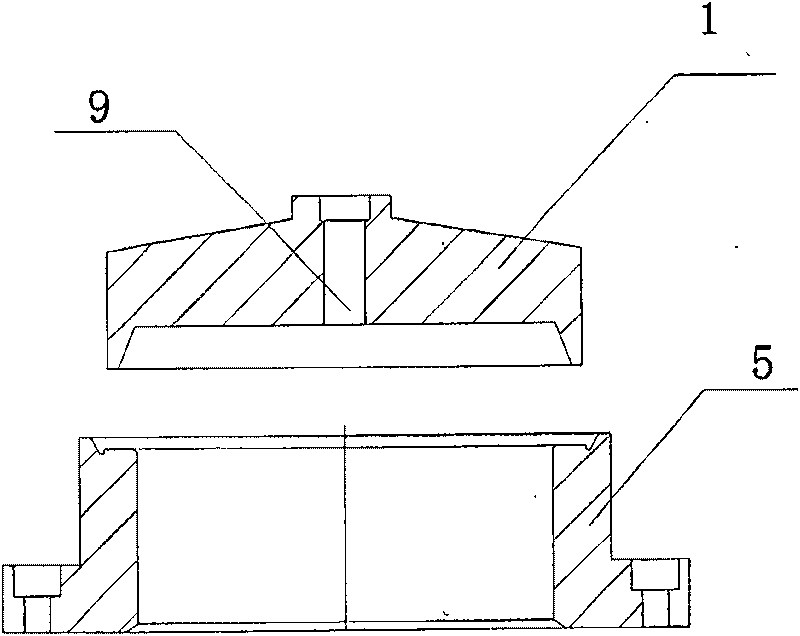

A gripper for gripping a cylindrical workpiece

ActiveCN106695604BChange single clamping functionReduce labor intensityWork holdersEngineeringMechanical engineering

A grasping and holding device for grasping and holding cylindrical workpieces comprises clamping rings and driving assemblies capable of stretching out and drawing back synchronously; the driving assemblies drive the clamping rings to stretch out and draw back synchronously; each clamping ring is of a ring-shaped structure formed by connecting a plurality of hinged connection units end to end through connecting rotation shafts; each hinged plate unit is of a v-shaped structure formed by a <-shaped rod and a rotating shaft, and the middle bent portions of every two <-shaped rods are hinged through the corresponding rotating shaft; the two ends of each <-shaped rod are hinged with the <-shaped rod at the corresponding position in the adjacent hinged connection unit through the corresponding connecting rotation shaft; each driving assembly is of an X-shaped structure formed by driving rods and a driving rotation shaft; and every two driving rods rotate around the corresponding driving rotation shaft; and one ends of every two driving rods are hinged to the two rotating shafts of the adjacent hinged connection units. The grasping and holding device for grasping and holding the cylindrical workpieces changes that an existing clamp only has a singular clamping function, and can perform center alignment positioning on the cylindrical workpieces.

Owner:FOSHAN HECAI TECH SERVICE +1

Bearing capper

The present invention relates to a bearing manufacture equipment, particularly relates to a bearing capping machine. The capping machine includes a hydrostatic press, an air cylinder, an inner lane locater, an upper mould and a lower mould, wherein the upper mould connects with the screw rod of the hydrostatic press; the lower mould connects with the working table of the hydrostatic press; the inner lane locater locates above the lower mould in central position of the lower mould; the air cylinder locates below the lower mould and can pass the lower mould to contact with the inner lane locaterand push-out the bearing work piece; the lower mould holds the outer lane of the bearing; the inner lane locater holds the inner lane of the bearing. The present invention characterized in that the shape and size of the intersecting surface of the upper and lower mould matches the outer lane of the bearing, and the upper and lower mould are provided with a T-shaped groove to adjust the central position of the upper and lower mould to align the upper and lower mould. By adopting above technical solution, the center locating of the upper and lower mould is accurate, operation is easy, hence capping speed and percent of pass are improved significantly.

Owner:SHANGHAI UNITED BEARING

Locking installation equipment for electric power components

ActiveCN106231857AEasy to installCenter positioning is accurateSlidable card holdersCard stiffenersHydraulic cylinderRear quarter

The invention discloses locking installation equipment for electric power components. The locking installation equipment comprises an enclosure, wherein a control panel is arranged at one side of the top surface of the enclosure and a protective cover is arranged at the other side of the top surface of the enclosure; a side plate is arranged at one side of the front surface of the enclosure; the enclosure is provided with a work bench at the back surface of the side plate; a hydraulic oil tank is arranged at one side of the top surface of the work bench; a bidirectional hydraulic cylinder is connected to the central position of one side surface of the hydraulic oil tank; a hydraulic rod is arranged on the top surface of the other end of the bidirectional hydraulic cylinder; the other end of the hydraulic rod is connected with a chuck base; a central circular hole is formed in the central position of the top surface of the chuck base; three jaw grooves are uniformly distributed in the top surface of the chuck base; a chuck jaw is arranged in each jaw groove; a motor is arranged at the other side of the arc side surface of the chuck base; a sliding rail a is arranged at the bottom side of the motor; and a sliding rail b is arranged at the bottom side of the chuck base. A three-jaw chuck is formed by the chuck base and the chuck jaws, fastening and disassembling are controlled through the motor and locating and locking are convenient and fast.

Owner:PENGLAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

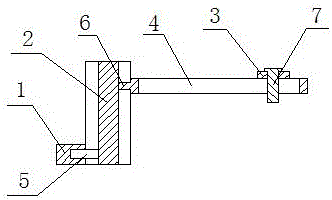

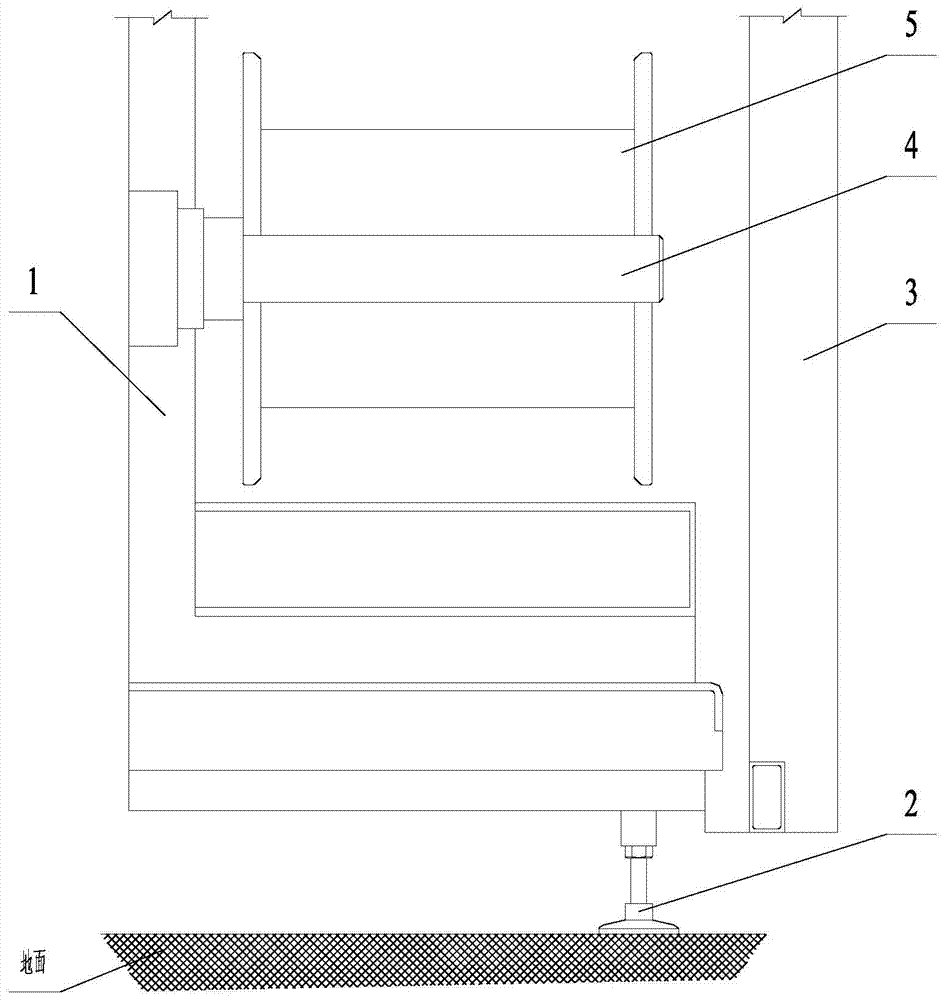

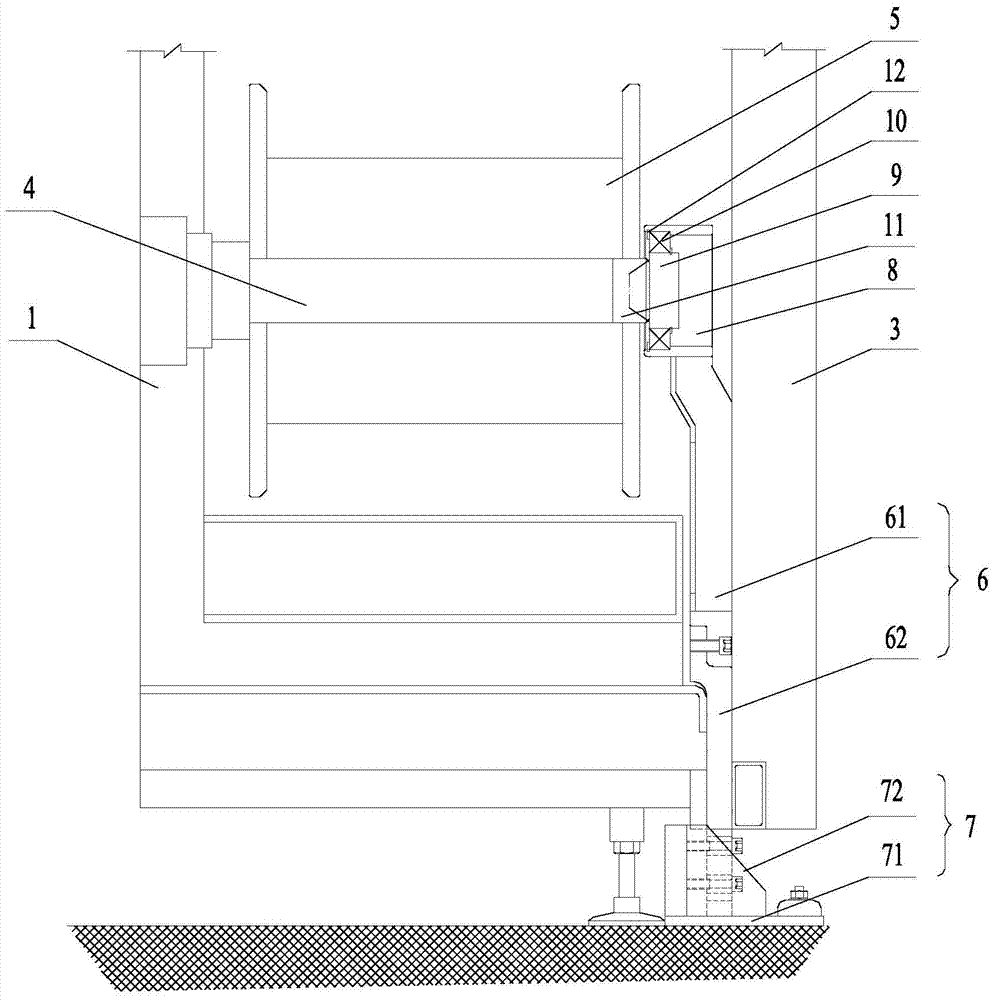

A cantilever shaft reinforcement device of a cantilever optical fiber take-up machine

ActiveCN104816982BImprove bearing capacityReduce axial forceFilament handlingWinding machinePulp and paper industry

The invention discloses a cantilever shaft reinforcing device of a cantilever type optical fiber take-up machine, and relates to the technical field of optical fiber equipment. The cantilever shaft reinforcing device comprises a supporting part vertically arranged on the inner side of a safety door, and the bottom of the supporting part is connected with a fixing part; the supporting part is fixed to the ground through the fixing part, and a connecting part is arranged on the top of the supporting part; a rotating shaft and a bearing are embedded into the connecting part, and the rotating shaft is connected with a locating sleeve arranged at the free end of a cantilever shaft; the rotating shaft and the locating sleeve are located in a conical surface fit manner, and the outer portion of the rotating shaft is sleeved with the bearing; and the position between the inner ring of the bearing and the rotating shaft and the position between the outer ring of the bearing and the connecting part are each provided with a clamping spring. According to the invention, the bearing capacity and the working efficiency of the take-up machine can be effectively improved without replacement of original cantilever type optical fiber take-up machine equipment, and the cantilever shaft reinforcing device is economical and practical.

Owner:FENGHUO COMM SCI & TECH CO LTD

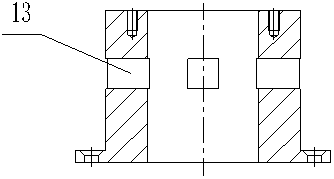

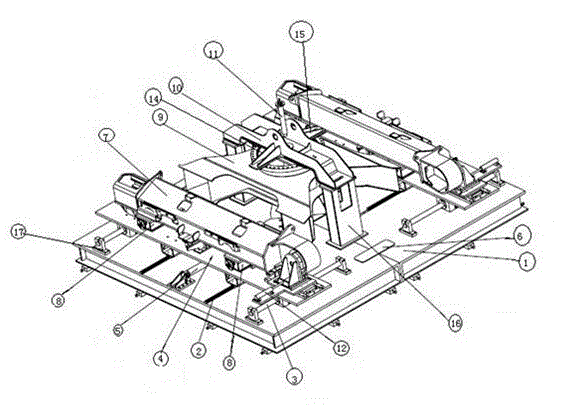

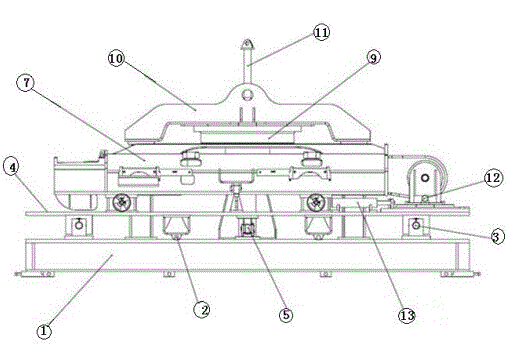

Fuzzy-positioning rapid mounting and clamping device for lower frame of excavator

InactiveCN104439847AQuick open repairCenter positioning is accurateWelding/cutting auxillary devicesAuxillary welding devicesSlide plateUltimate tensile strength

The invention discloses a fuzzy-positioning rapid mounting and clamping device for a lower frame of an excavator. The fuzzy-positioning rapid mounting and clamping device comprises two identical pairing platforms (1), wherein the two pairing platforms (1) are fixed together through a platform connecting plate (6). The fuzzy-positioning rapid mounting and clamping device is characterized in that linear guide tracks (2) are symmetrically mounted on the two pairing platforms (1); sliding plates (4) are mounted on the linear guide tracks (2); two rapid mounting and clamping bases (8) are fixed on each sliding plate (4); a sliding plate cylinder (5) is mounted below the middle of each sliding plates (4); a central positioning cylinder (12) and a front / rear positioning cylinder (13) are mounted at the right end of each sliding plate (4); an X rack (9) is mounted between two X rack positioning hoisting base vertical rods (16). When faults happen in assembling, the lower frame can be rapidly opened to repair; the central positioning is precise, alarms are available during mounting, clamping and positioning, the lower frame is prevented from being closed when problems happen, the production efficiency is high, and the working intensity is low.

Owner:DALIAN DONGTUO ENG MACHINERY MFG

Fuel filter and mounting support of which the outlet is sealed by a valve in case of removal of a filter insert

ActiveUS11338230B2Eliminating and minimizing riskEfficient ventingMembrane filtersFiltration circuitsInterior spaceEngineering

The fuel filter has an outlet for the filtered fuel in a lower base portion of a casing, and a valve associated with the outlet. The filter insert has an internal space in which filtered fuel flows and that accommodates a central member capable of moving the valve to an open position when the insert is in an operational configuration in the casing. The valve is urged, by default, to a sealed position cutting off the flow to the outlet, for example by resilient return arranged between the bottom of the filter and a wall of an interface that guides the lower end of the central member. The central member and the filter insert form a removable unit, and it is therefore possible, typically by way of a cover / removable unit fastening, to automatically obtain the sealed position after opening the top cover.

Owner:SOGEFI FILTRATION

A closed ring structure for gripping cylindrical workpieces

ActiveCN106695363BAvoid destructionChange single clamping functionWork clamping meansWork holdersEngineeringThrough transmission

A closed ring structure for grabbing a cylinder workpiece comprises upper square blocks, lower square blocks, rotation shafts and synchronous transmission assemblies. The multiple upper square blocks and the multiple lower square blocks are arranged at intervals, conduct surrounding along any one of respective diagonal lines in an end-to-end manner and are rotationally connected at the opposite angle positions through the rotation shafts, and accordingly the closed ring structure is formed. The two rotation shafts arranged on the same lower square block are in rigidity connection to the upper square blocks connected with the rotation shafts, wherein the two rotation shafts are connected through the corresponding synchronous transmission assembly. Rotation of any rotation shaft drives same-direction rotation of the other corresponding rotation shaft through transmission of the corresponding synchronous transmission assembly, unfolding or folding movement of the whole closed ring structure is achieved, and the cylinder workpiece is grabbed in the inner circumference of the closed ring structure. The closed ring structure for grabbing the cylinder workpiece is provided and can change the situation that existing clamps only have a single clamping function, and center alignment positioning can be conducted on the cylinder workpiece.

Owner:FOSHAN HECAI TECH SERVICE +1

A welding mechanism with a lifting device

ActiveCN103962700BHigh adjustment accuracyCenter positioning is accurateResistance electrode holdersMechanical engineering

The invention discloses a welding mechanism with a lifting device. The welding mechanism comprises an installation frame, wherein a welding head and the lifting device for driving the welding head to move vertically are arranged on the installation frame, the lifting device comprises a lifting air cylinder and a vernier device, the lifting air cylinder is provided with a piston rod coaxial with the welding head, and the vernier device is arranged between the piston rod and the welding head. The welding mechanism with the lifting device has the advantages of being high in regulation accuracy, accurate in center positioning and convenient to operate.

Owner:浙江华亿电气有限公司

A manipulator clip feeding and ejecting device

InactiveCN105312955BCenter positioning is accuratePrecise positioningMetal working apparatusFeed driveEngineering

The invention provides a mechanical arm clamp feeding and ejecting device which comprises a feeding mechanism and a main shaft ejecting mechanism. The feeding mechanism comprises a rack, a feeding drive device, a grabbing drive device and a pushing drive device. The main shaft ejecting mechanism comprises a device base, an air cylinder, a material rack and a linear guide rail assembly. The rack is provided with a feeding clamp. A baffle is arranged in the feeding clamp. A conveyor belt assembly is arranged at one side of the baffle, and a trough is formed in the other side of the baffle. A discharge V-shaped groove is formed above the baffle. A telescopic rod is arranged at the upper end of the feeding drive device. A feeding ejector rod is arranged at one side of the baffle. A feeding part is arranged above the feeding ejector rod and located in the trough. The feeding part makes contact with the baffle. A slope is arranged at one side, making contact with the baffle, of the top end of the feeding part. An included angle is formed between the slope and the baffle. The material rack is provided with a left V-shaped groove and a right V-shaped groove which are used for placing blanks. The device can solve the problems that excessive blanks are conveyed at a time and can not be conveyed in place.

Owner:宁波宫铁智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com