A closed ring structure for gripping cylindrical workpieces

A closed annular structure, cylindrical technology, applied in workpiece clamping devices, metal processing machinery parts, manufacturing tools, etc., can solve the problem that the center of the item is aligned with the center of the place where it needs to be placed, affecting the production efficiency of processing, The problem of high labor intensity of workers can achieve the effect of convenient and fast grasping process, improve clamping efficiency, and avoid excessive recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

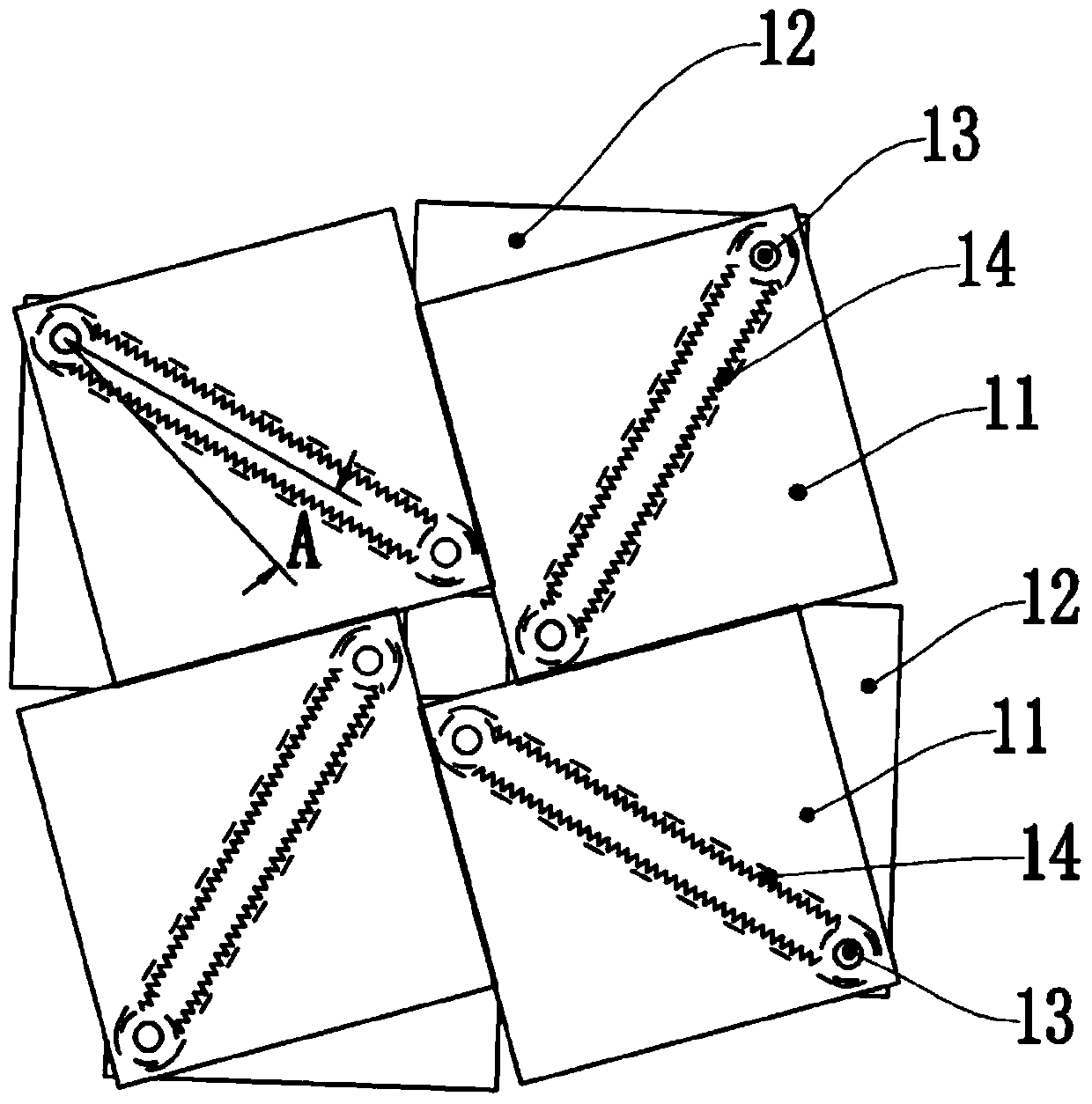

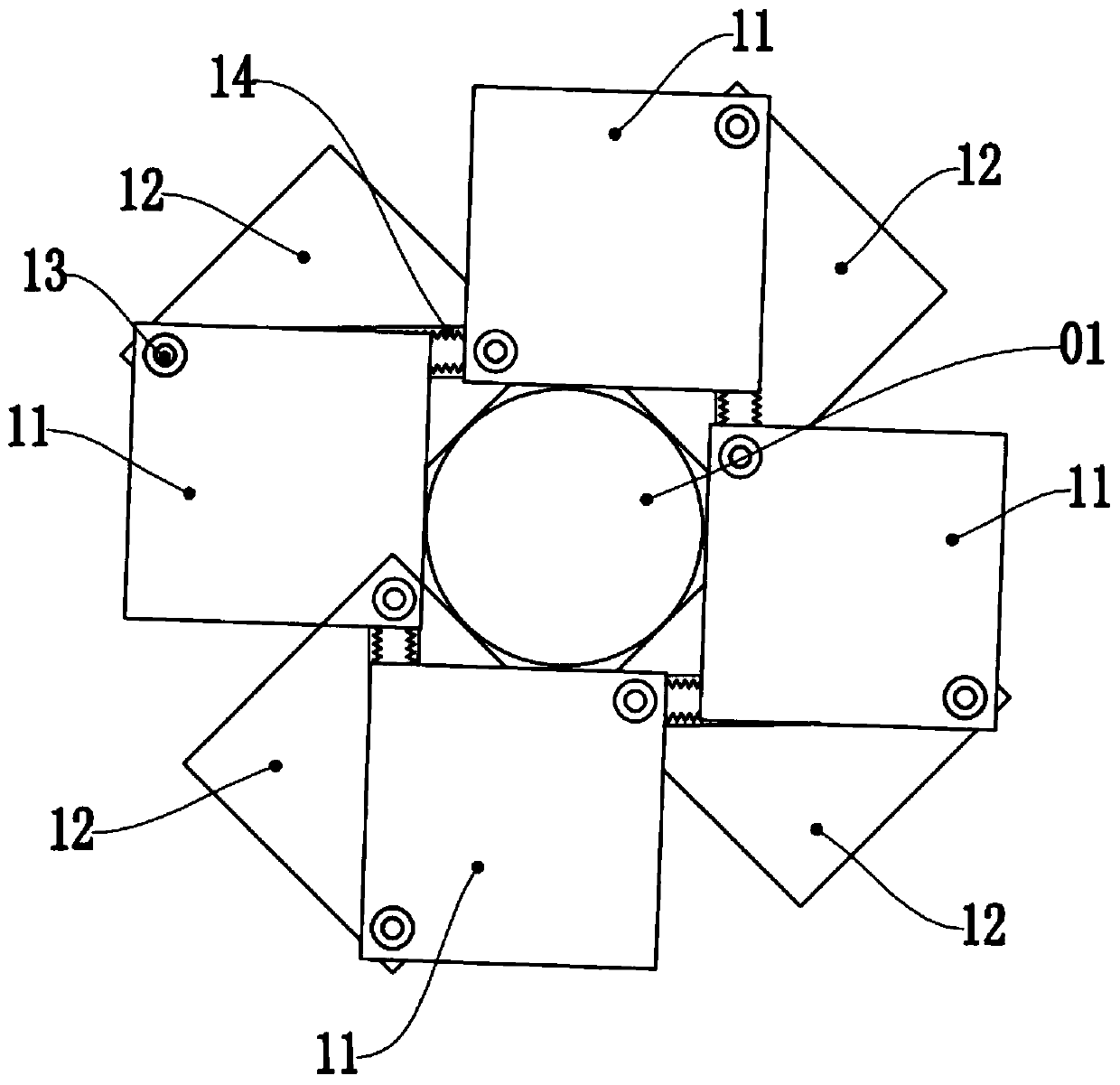

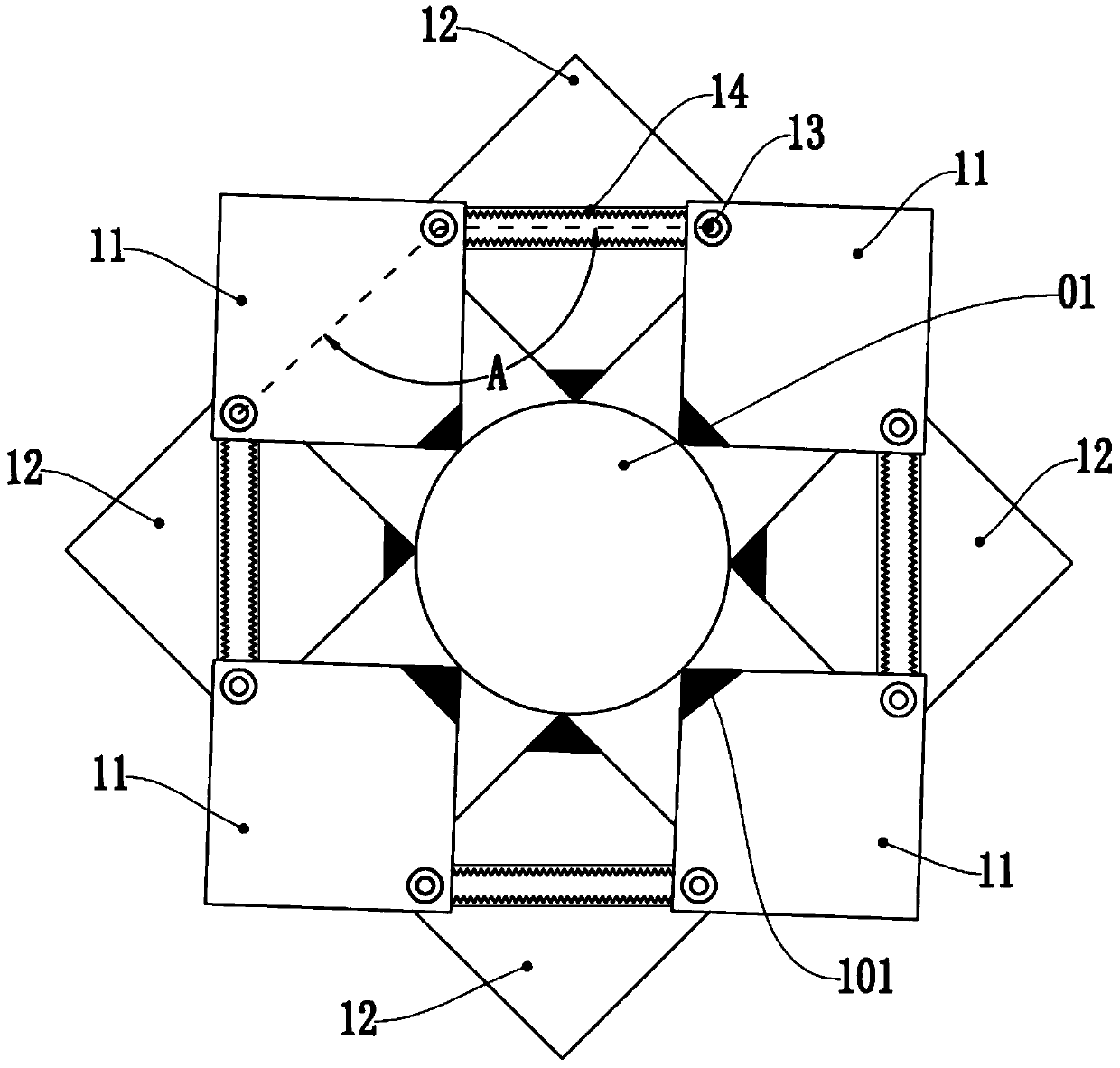

[0038] Example 1, such as image 3 Shown, be provided with 4 groups of square rotating assemblies 1, promptly be provided with 4 upper blocks 11, as Figure 6 As shown, the synchronous transmission assembly 14 is disposed between the upper block 11 and the lower block 12 .

[0039] To further illustrate, the upper block 11 is provided with pulleys 111 at opposite corners of the rotating shaft 13, and the rotating shafts 13 are rigidly connected to the pulleys 111 of the upper block 11 respectively connected to them, so The synchronous transmission assembly 14 is a flexible belt. The upper block 11 is provided with a pulley 111 rigidly connected to the rotating shaft 13, so that the connection between the rotating shaft 13 and the upper block 11 is more stable, the strength of the connection structure becomes larger, and the service life of the entire gripping structure is extended.

[0040] To further illustrate, the pulley 111 is a smooth pulley, and the flexible belt is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com