A motor rotor and stator automatic centering mechanism

A motor rotor and centering technology, applied in the field of motor rotor and stator automatic centering mechanism, can solve the problems of inaccurate rotor and stator center positioning, easy fatigue of staff, high labor intensity, etc., to achieve stable clamping, Simple structure, realize the effect of automatic positioning and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

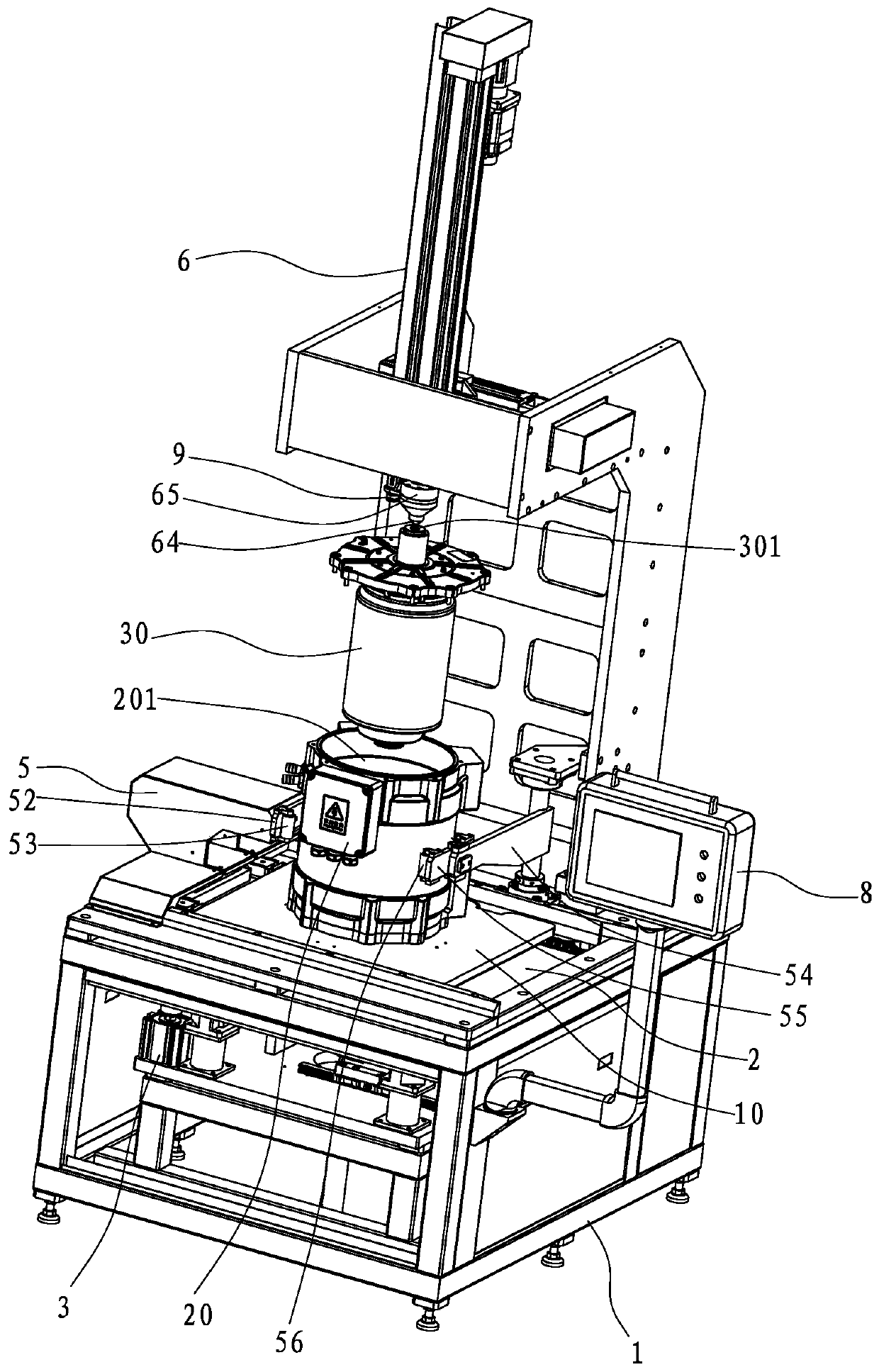

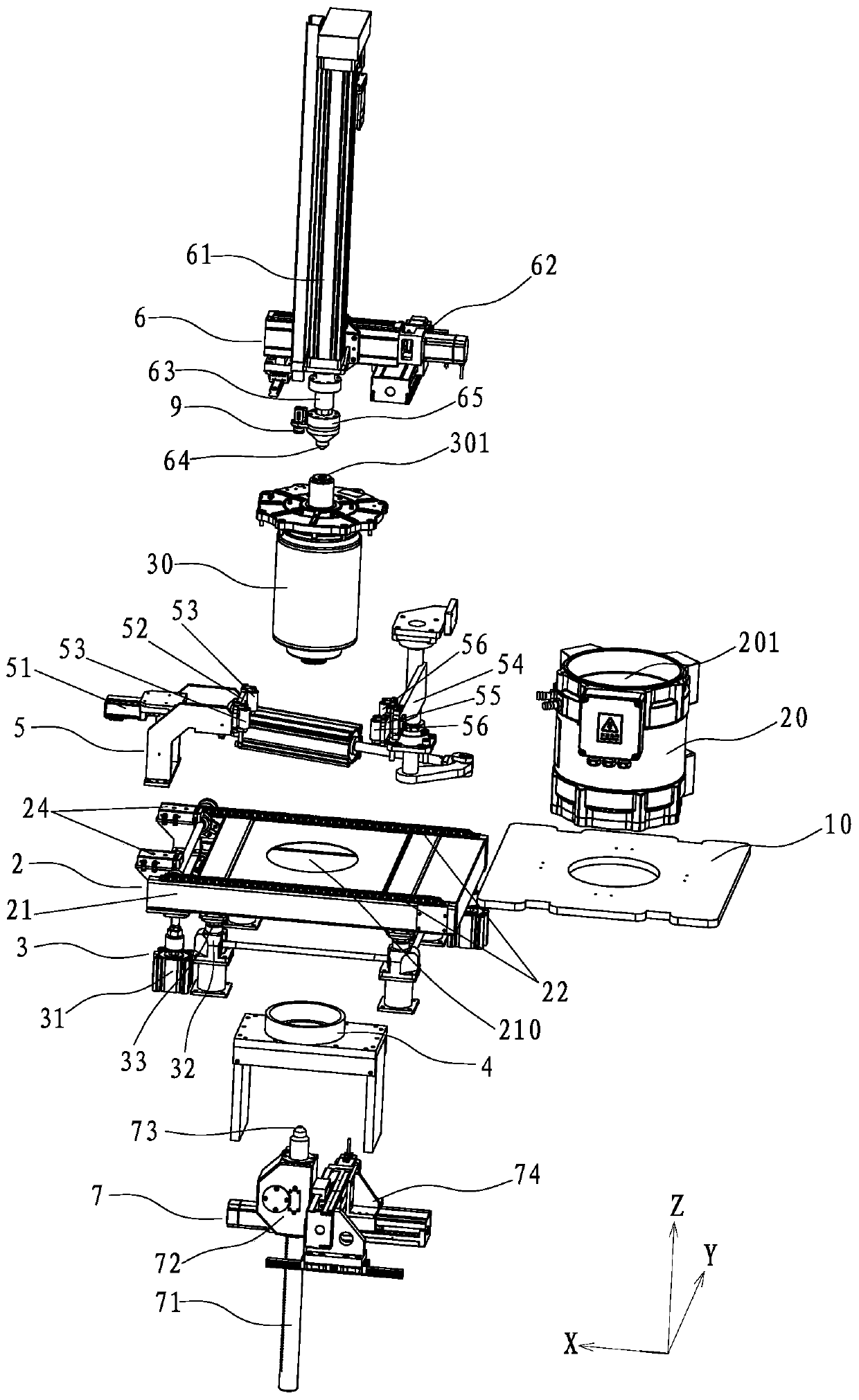

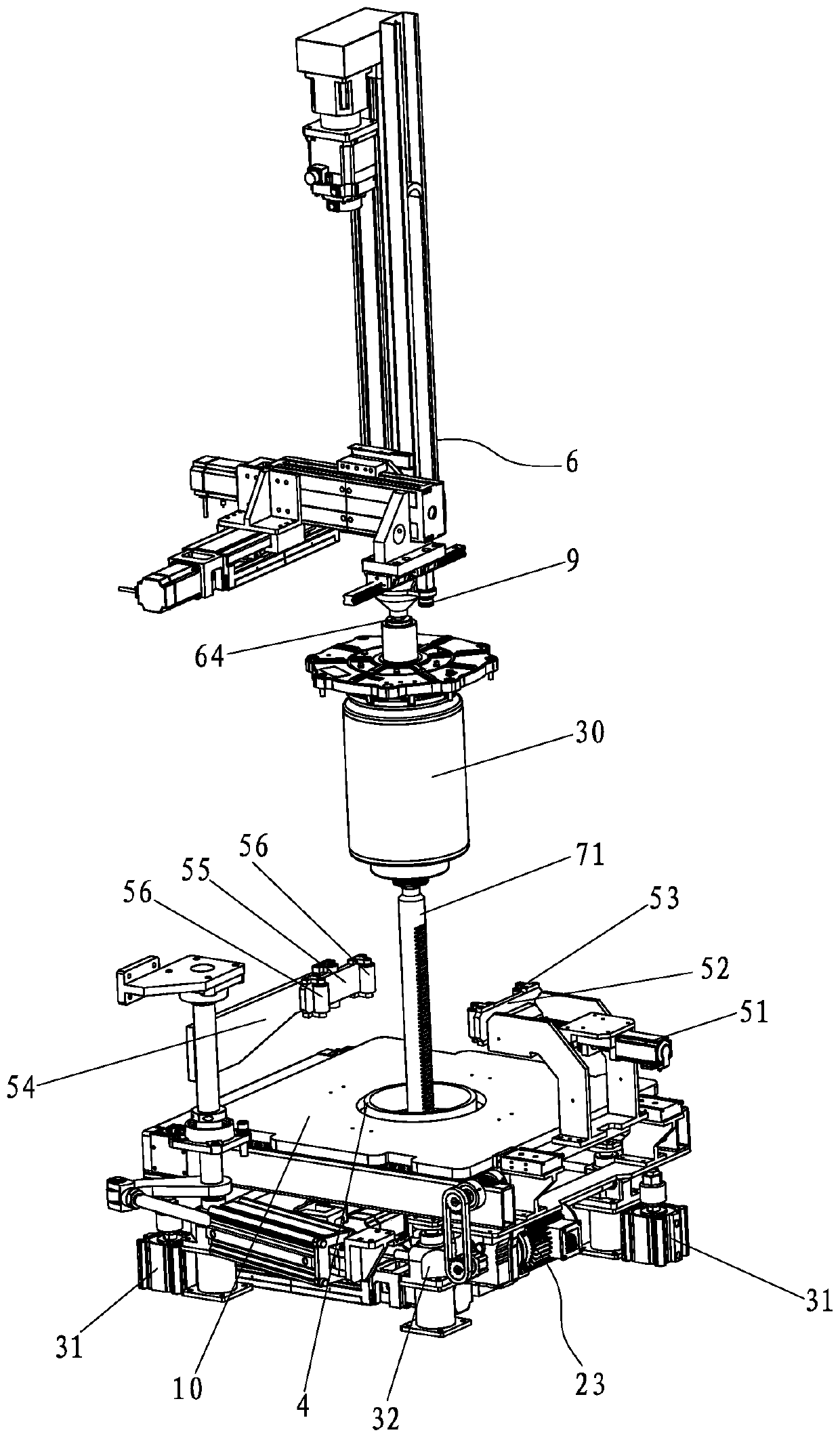

[0028] The present invention will be further described below in conjunction with accompanying drawing:

[0029] Such as Figure 1 to Figure 4 The shown automatic centering mechanism for the rotor and stator of a motor includes a frame 1 on which a support block 4 for supporting and positioning the stator 20 and a clamping block for clamping and fixing the stator 20 are arranged. Device 5, the upper and lower sides of the support block 4 on the frame 1 are respectively provided with an upper pressing assembly 6 and a lower lifting assembly 7 that can move in the horizontal direction and the up and down direction, and the frame 1 is also provided with A control system 8 capable of controlling the movement of the clamping device 5 , the upper pressing assembly 6 and the lower jacking assembly 7 , the upper pressing assembly 6 is provided with an image for grabbing the stator 20 for the control system 8 to calculate the center position of the stator 20 camera9.

[0030] Due to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com