A round glass outer wall edging device

A glass and edging technology, which is applied to grinding drive devices, machine tools suitable for grinding workpiece edges, grinders, etc. The effect of improving edging efficiency and edging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

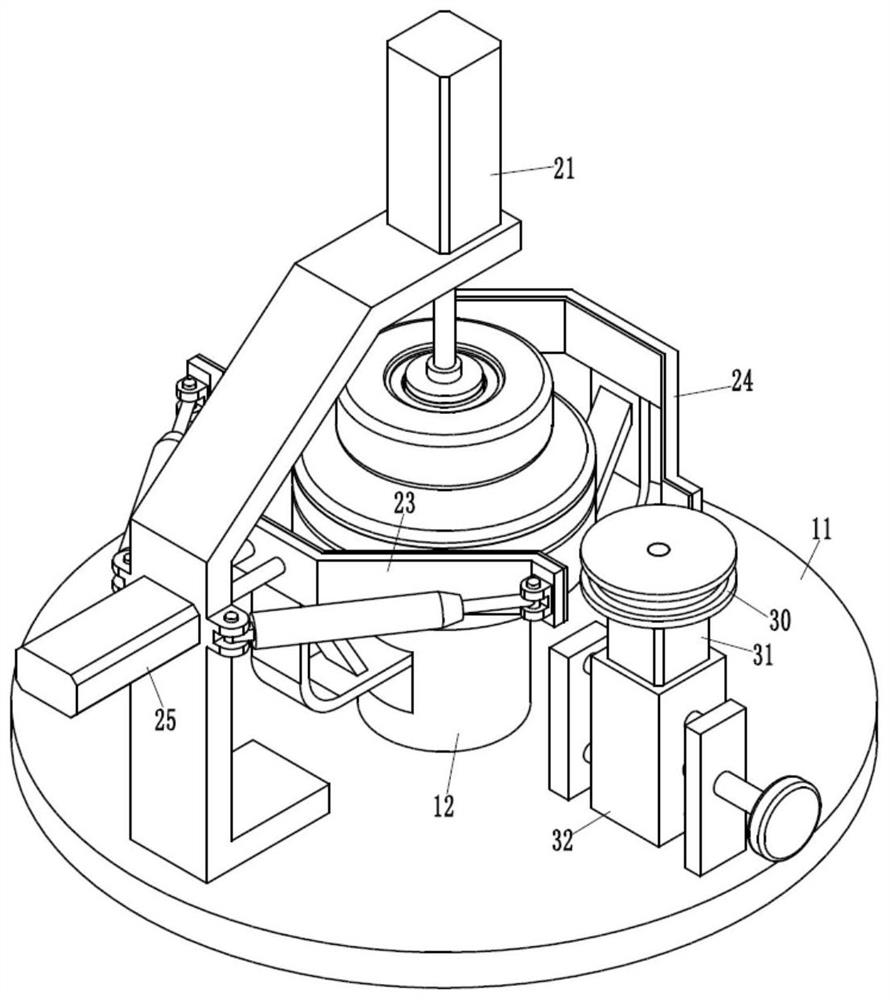

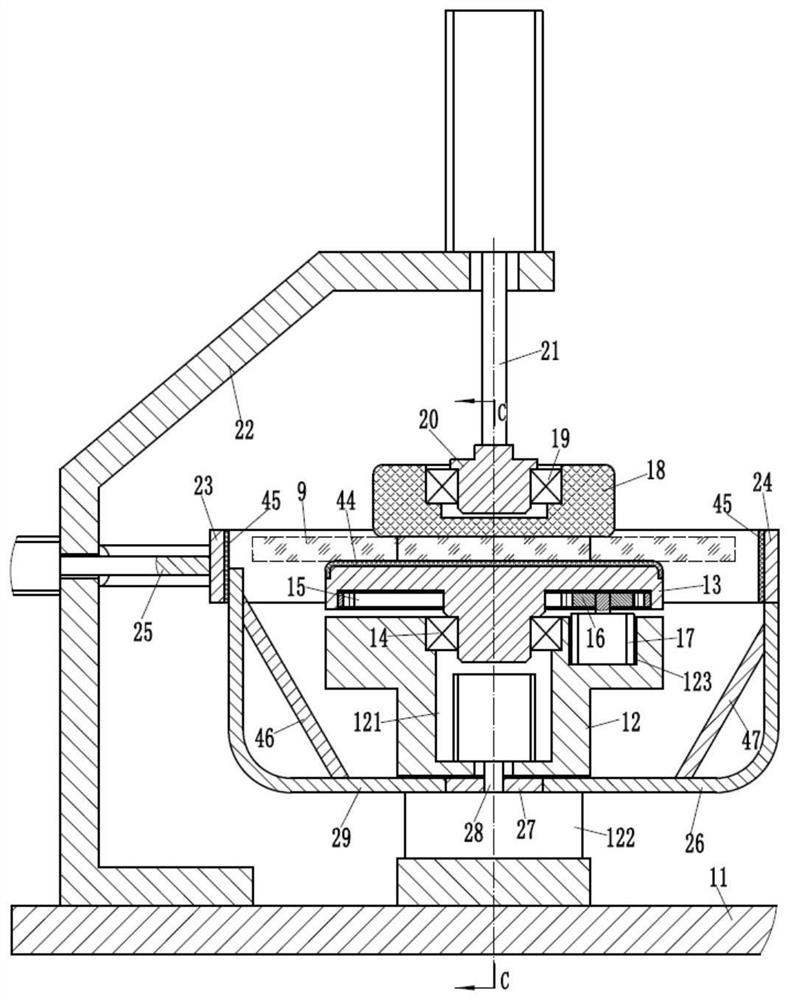

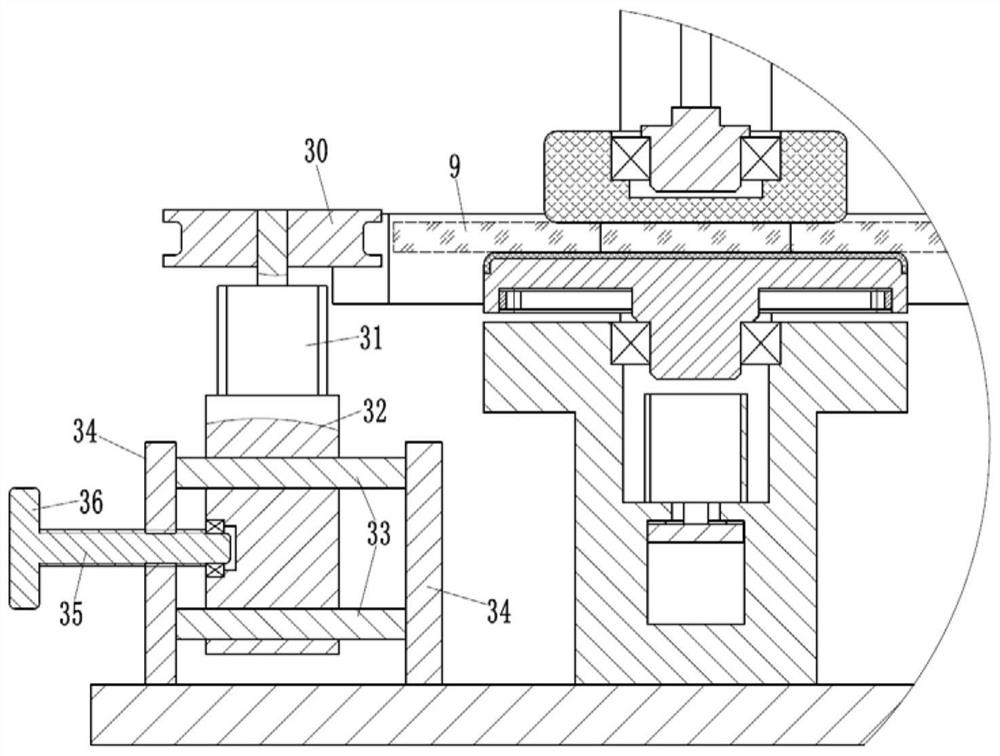

[0015] Examples, see e.g. Figure 1 to Figure 4 As shown, a round glass outer wall edging device includes a bottom plate 11, a base 12 is fixed in the middle of the bottom plate 11, and a stepped hole 121 with a large upper and a smaller bottom is formed in the middle of the base 12 and is located on the lower side of the stepped hole 121. The rectangular hole 122 that runs through the left and right direction of the base 12 is provided with an internal hollow dome platform 13, and the dome platform 13 is hinged in the large hole at the upper end of the step hole 121 through the first bearing 14. The dome An inner ring gear 15 is fixed on the inner wall of the table 13, and the inner ring gear 15 is meshed with a pinion 16, and the pinion 16 is fixed on the motor shaft of the first motor 17, and the first motor 17 is fixed in the motor cavity 123 of the base 12 , the top of the dome table 13 is provided with a briquetting block 18 coaxially arranged with the dome table 13, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com