Welding mechanism with lifting device

A lifting device, welding mechanism technology, applied in welding equipment, resistance welding equipment, resistance electrode holder and other directions, can solve the problems of reduced adjustment accuracy and easy occurrence of deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

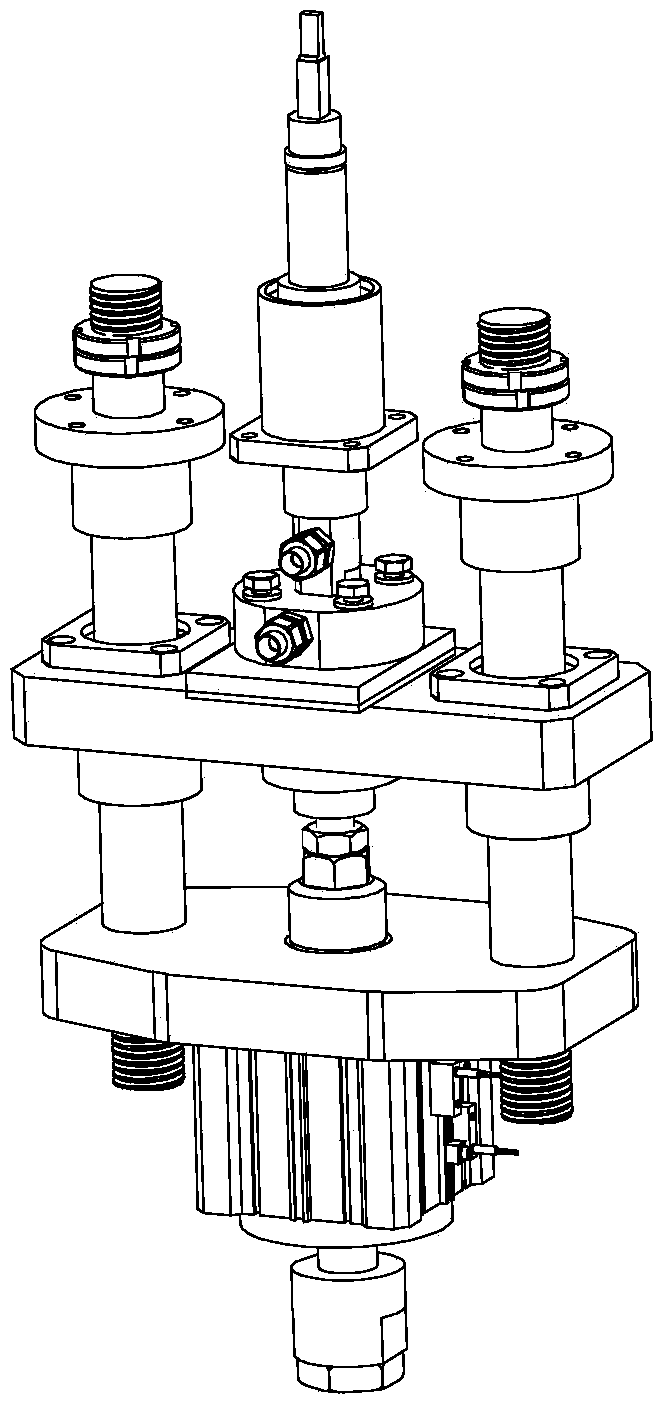

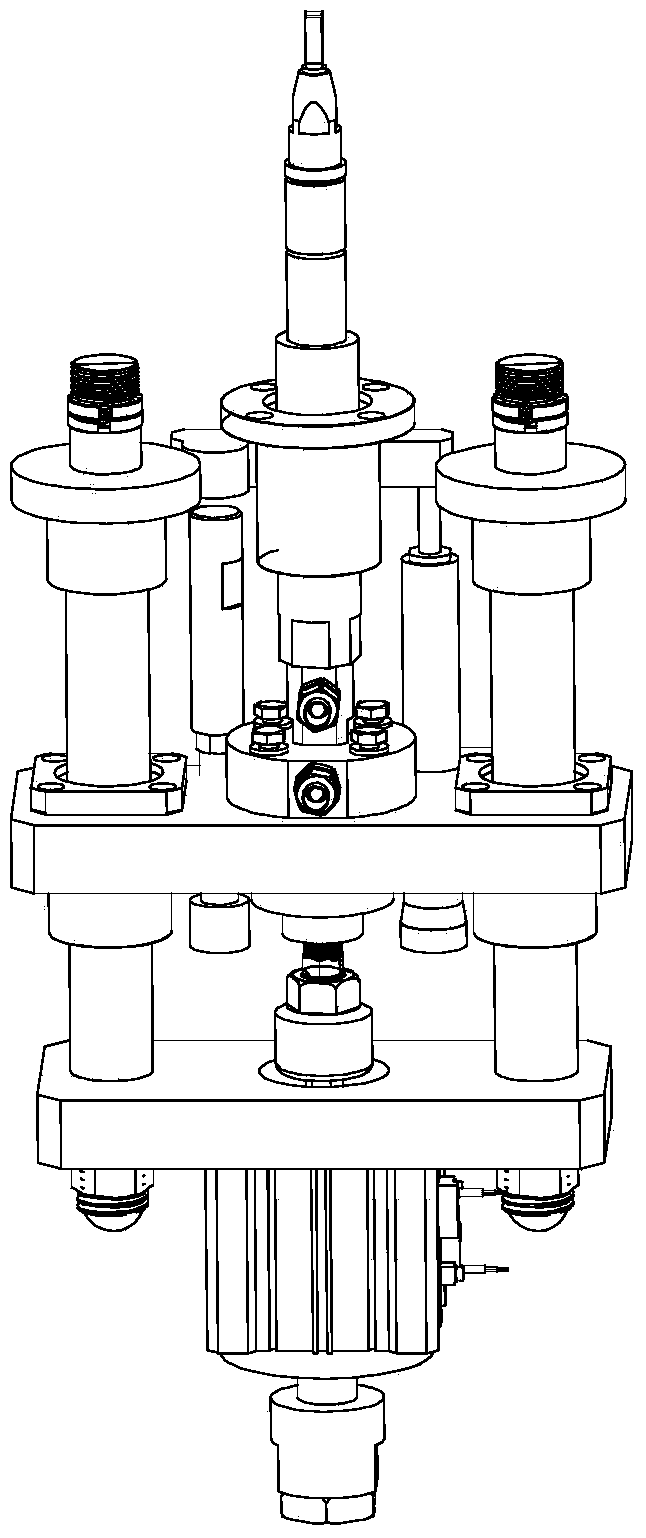

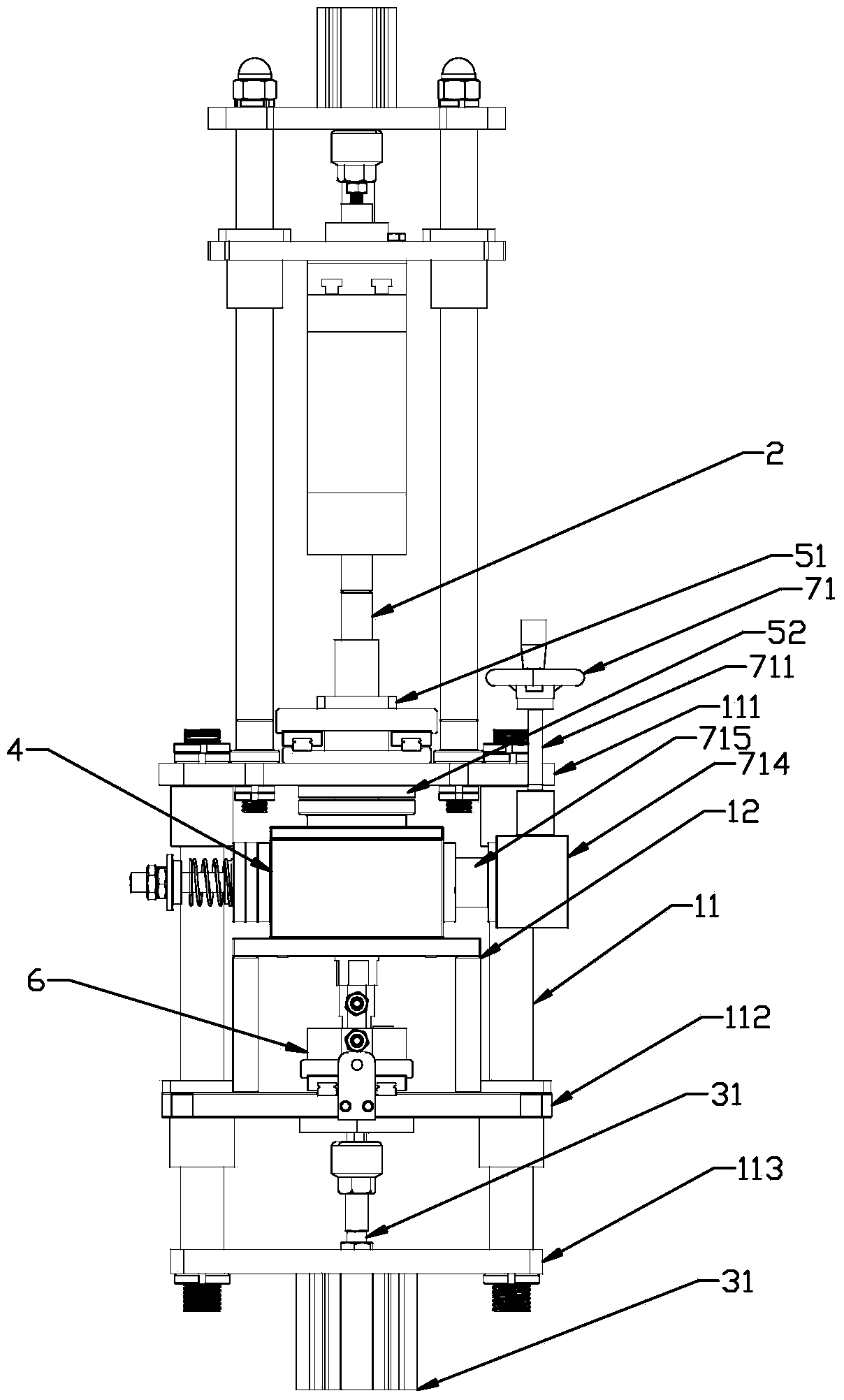

[0032] Specific embodiments of the present invention such as Figure 3-6 Shown is a welding mechanism with a lifting device, which includes a mounting frame, a welding head 2 and a lifting device. The lifting device includes a lifting cylinder 31 and a fine-tuning device 4. The mounting frame includes four columns 11, and the columns 11 are arranged sequentially from top to bottom. There are upper mounting plate 111, middle mounting plate 112 and lower mounting 113, upper mounting plate 111 is provided with positioning sleeve 51, fine-tuning device 4 is arranged on the middle mounting plate 112 by fine-tuning mounting bracket 12, fine-tuning mounting bracket 12 and middle mounting plate Also be provided with horizontal adjusting device 6 between 112, and lifting cylinder 31 is fixed on the lower mounting plate 113.

[0033] Above-mentioned fine-tuning device 4 comprises worm gear and worm transmission assembly, and worm gear 41 and worm screw 42 are mutually meshed and are pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com