Mechanical arm clamp feeding and ejecting device

A technology of ejecting device and manipulator, which is applied in metal processing and other directions, can solve the problem that the blank is not conveyed in place, and achieve the effects of improving work efficiency, accurate positioning and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

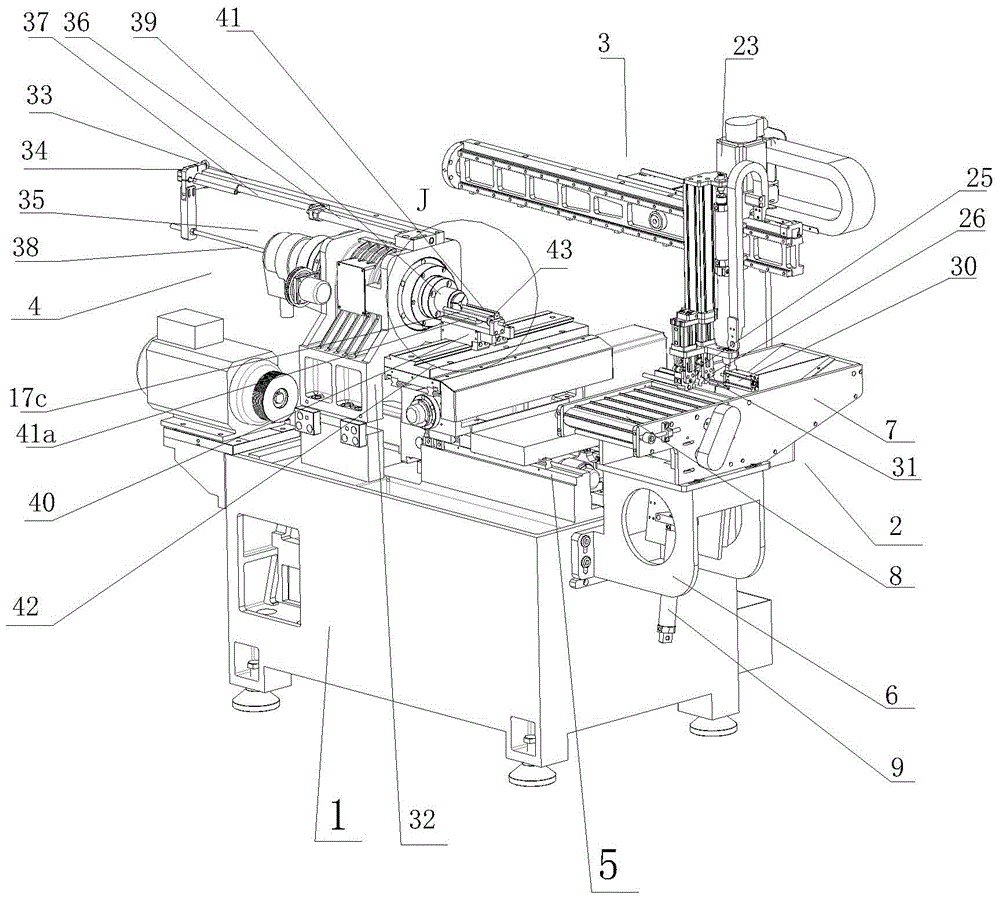

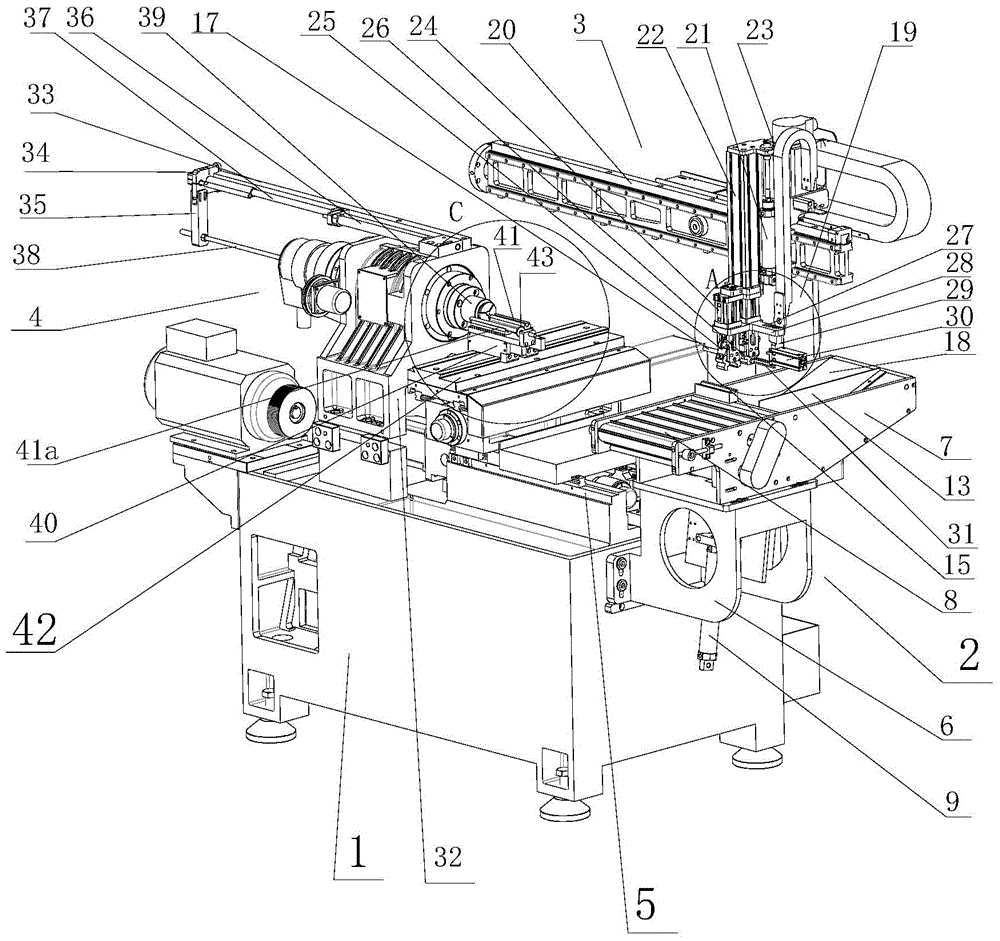

[0045] For ease of understanding, the technical solutions of the present invention are further specifically described below in conjunction with the accompanying drawings and through embodiments:

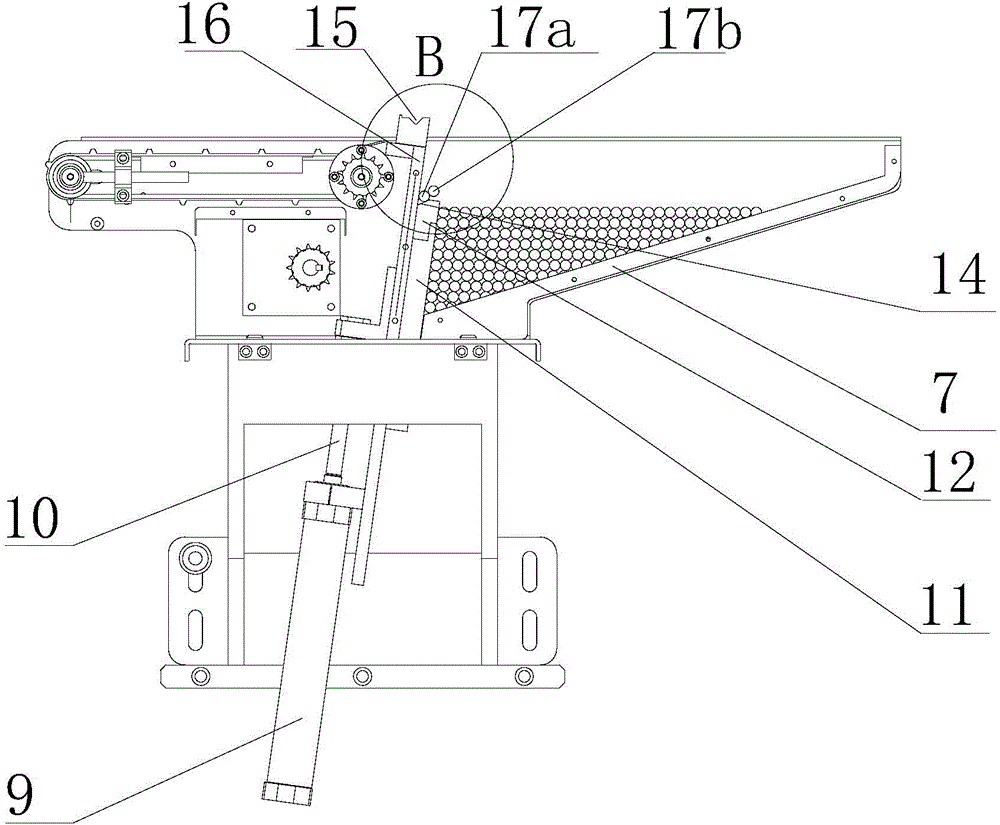

[0046] like Figure 1-Figure 21 As shown, a manipulator clamp feeding and ejecting device includes a feeding mechanism 2 and a spindle ejecting mechanism 4 . The feeding mechanism 2 includes a feeding fixed plate 6, a feeding clamp 7, a conveyor belt assembly 8, a feeding cylinder 9, a feeding cylinder telescopic rod 10, a feeding ejector rod 11 and a discharging V-shaped groove 15; the main shaft ejecting mechanism 4 , including machine base 32, bracket 33, cylinder 36, cylinder expansion rod 37, ejector rod 38, main shaft 39, material rack 40, linear guide rail assembly 42.

[0047] The upper part of feed fixed plate 6 is provided with feed clamp 7, is provided with baffle plate 16 in the feed clamp 7, a side of baffle plate 16 is provided with conveyor belt assembly 8, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com