Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Avoid sticking together" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

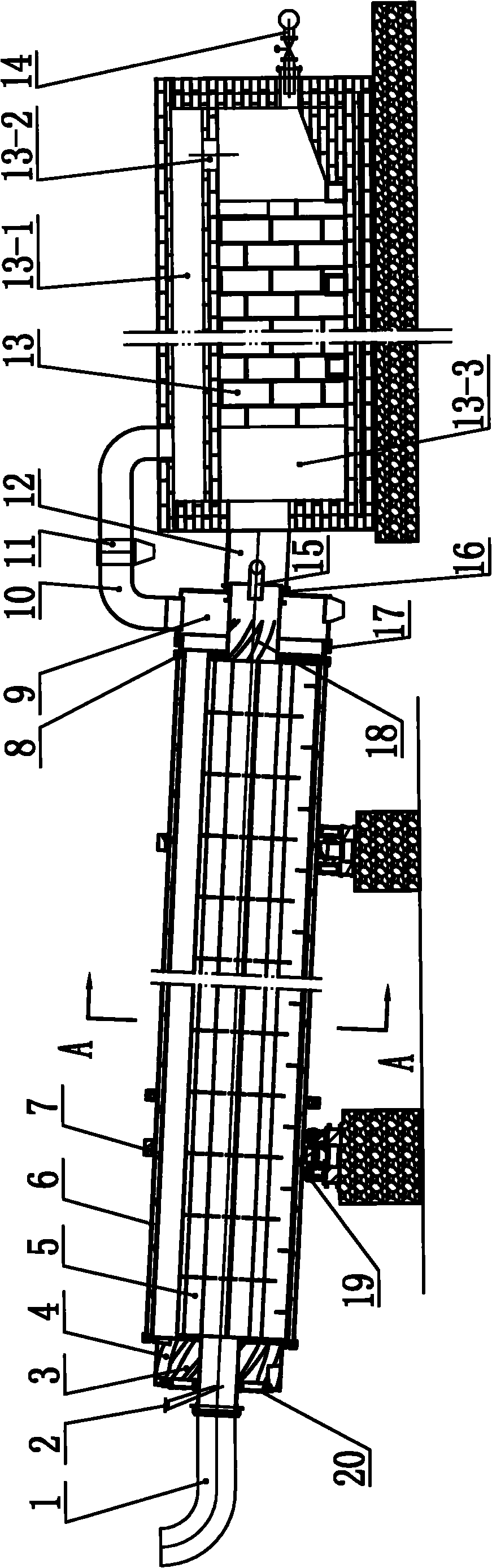

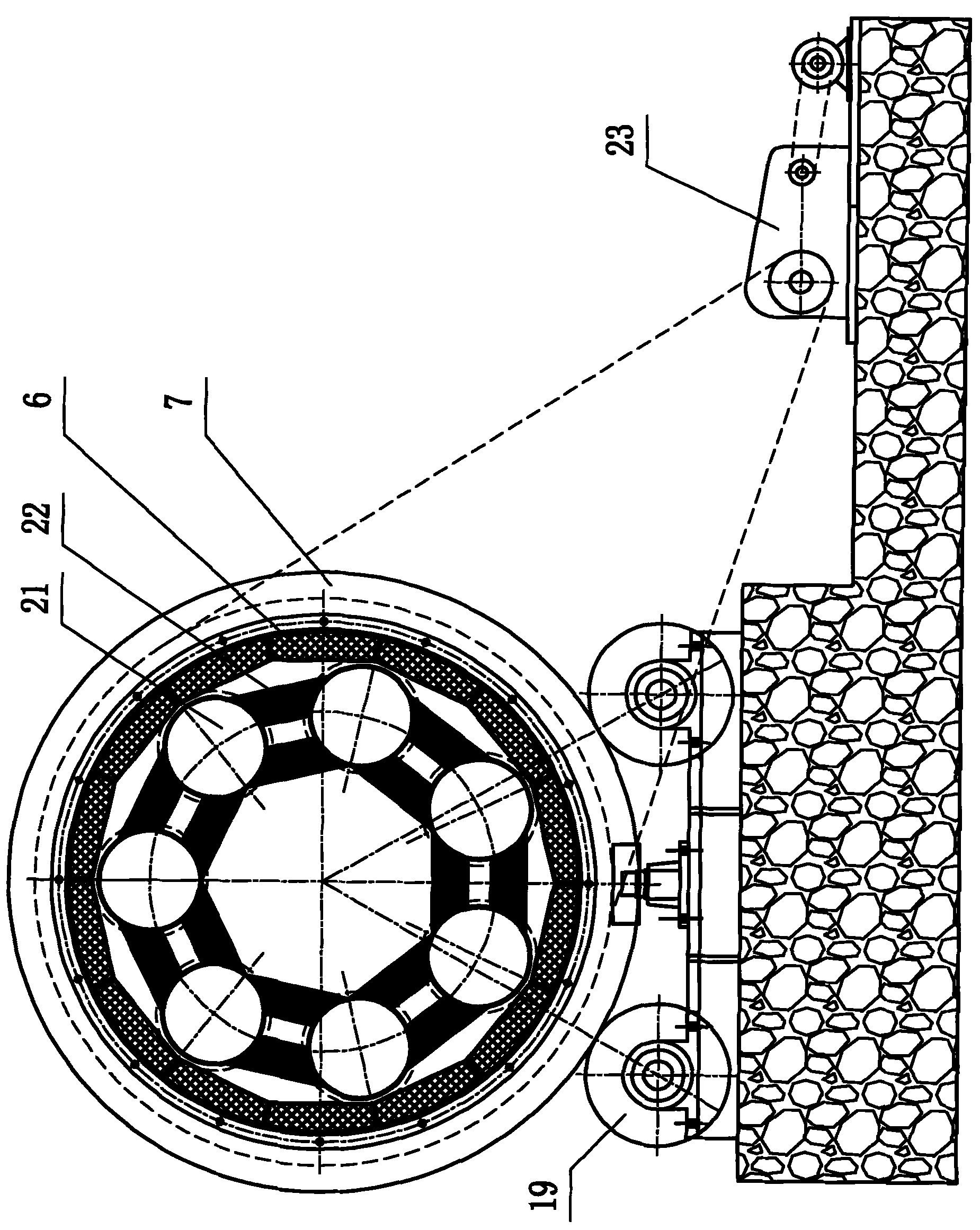

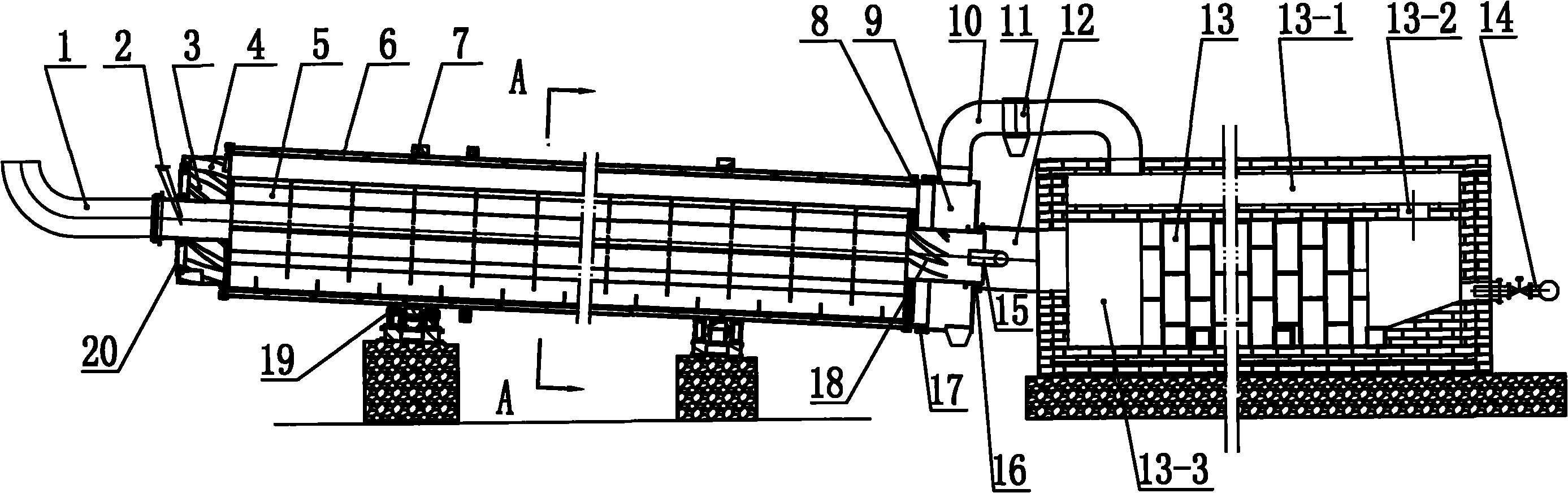

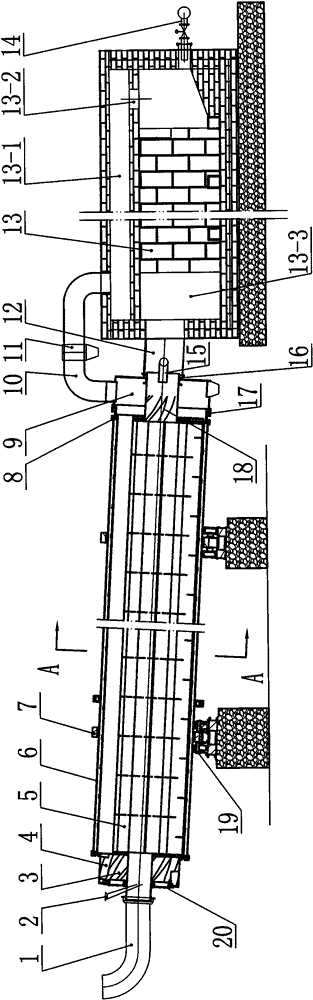

External-heating energy-saving and environment friendly rotary carbonization furnace

InactiveCN102092706AImprove qualityHigh mechanical strengthChemical industryCombustion chamberCarbonization

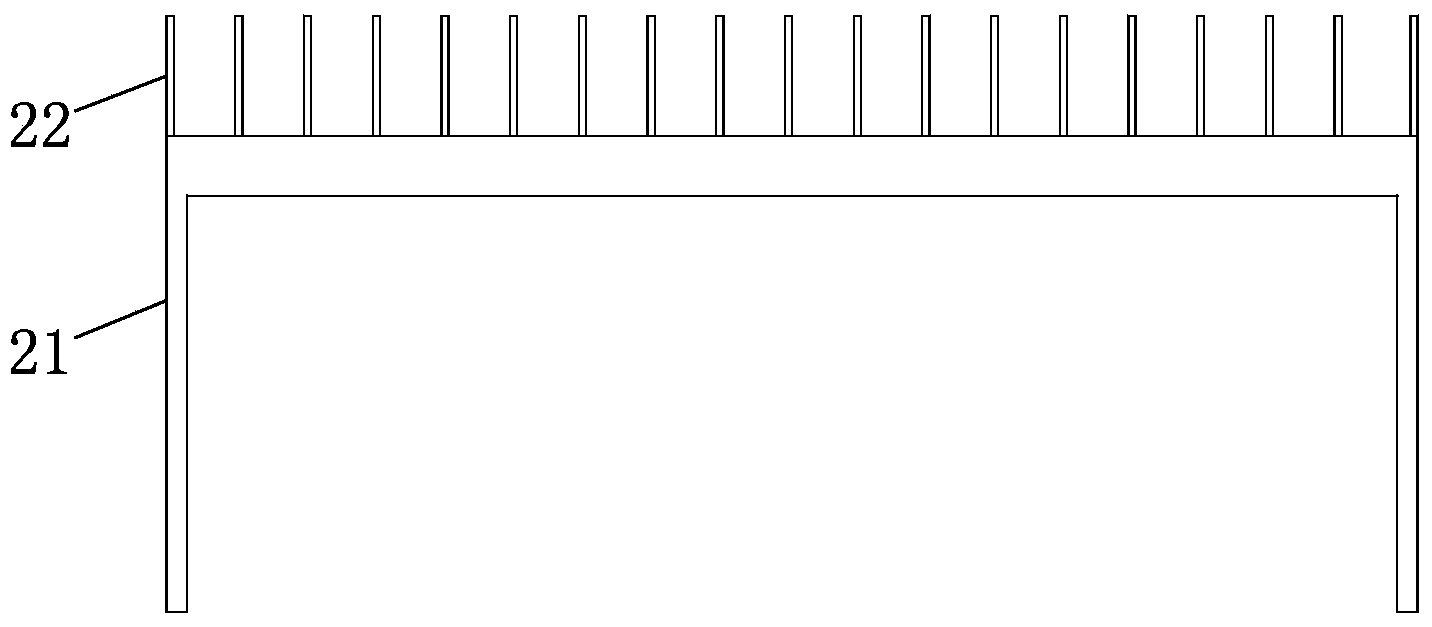

The invention relates to an external-heating energy-saving and environment friendly rotary carbonization furnace; a furnace body (5) consists of at least three independent material passages (21) that are connected with each other through reinforcing plates (22); the left feed end of the furnace body is sealed with a sealing flange (20), and the right feed end of the furnace body is sealed with a material passage expansion sealing device (8); the left and the right ends of a discharge warehouse are sealed with sealing flanges (16, 17); a feeding warehouse (3), the sealing passage (21), the discharge warehouse (9), a fugitive constituent pipeline (10), a combustion chamber (13), a high-temperature smoke gas pipe (12), a space between the inner part of a furnace housing (6) and the outer part of the material passage (21) and a tail gas exhaust pipe (1) are communicated with each other in sequence; and the temperature of the high-temperature smoke gas of heated material is adjusted through an air distributing pipe (15). In the invention, the temperature and heating rate are easy to control when the material is carbonized, and the material is capable of uniformly and sufficiently absorbing heat with low material ablation, high yield and few energy consumption; and the produced carbonized material has good quality.

Owner:淮北市协力重型机器有限责任公司 +1

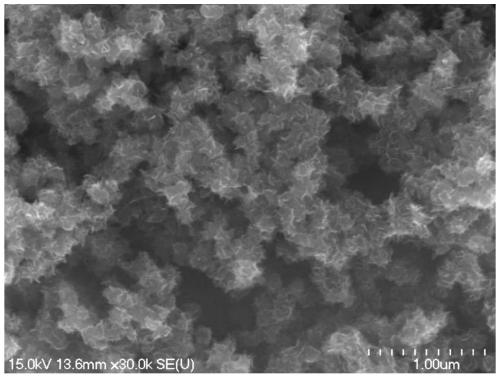

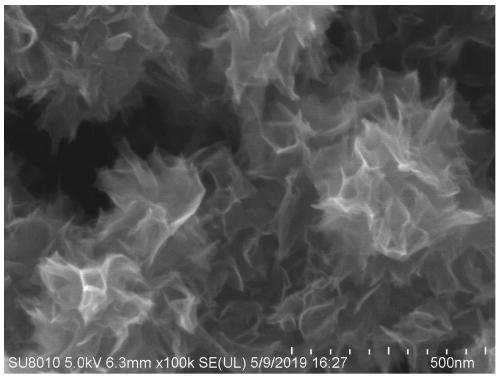

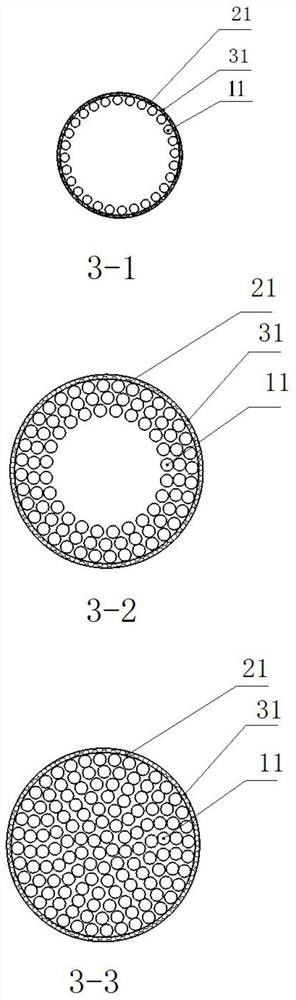

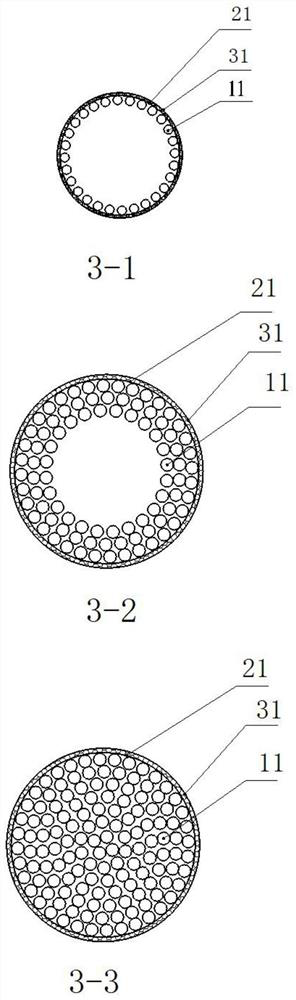

Carbon-coated current collector coated with three-dimensional graphene powder and preparation method of carbon-coated current collector

InactiveCN111180741AGood dispersionAvoid sticking togetherElectrode carriers/collectorsCopper foilCarbon black

The invention discloses a carbon-coated current collector coated with three-dimensional graphene powder and a preparation method of the carbon-coated current collector, and the preparation method comprises the following steps: mixing the three-dimensional graphene powder, an adhesive and a dispersing agent in a proper solvent, and preparing three-dimensional graphene powder slurry through procedures of sanding, sieving and the like; and then uniformly coating a substrate such as an aluminum foil, a copper foil and the like with the three-dimensional graphene powder slurry to prepare the carbon-coated current collector. Compared with carbon black, the three-dimensional graphene powder coated current collector is higher in conductivity, coating strength and bonding strength, and can be madethinner. Compared with conventional flake graphene powder, the three-dimensional graphene powder coated current collector is higher in bonding strength, isotropic in coating performance, simpler in preparation process and higher in surface roughness, thereby being better combined with an active material. The specific capacity, the rate capability and the cycling stability of the lithium ion battery prepared by taking the aluminum foil coated with the three-dimensional graphene powder as the positive current collector are greatly superior to those of a current collector coated with carbon black.

Owner:SONGSHAN LAKE MATERIALS LAB

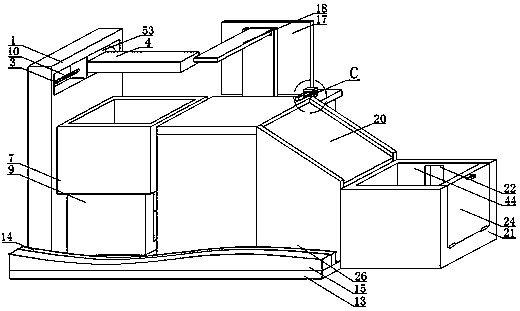

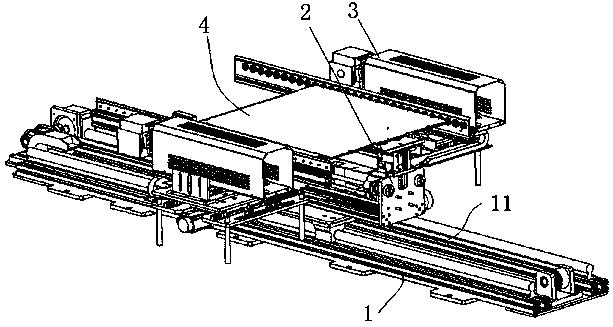

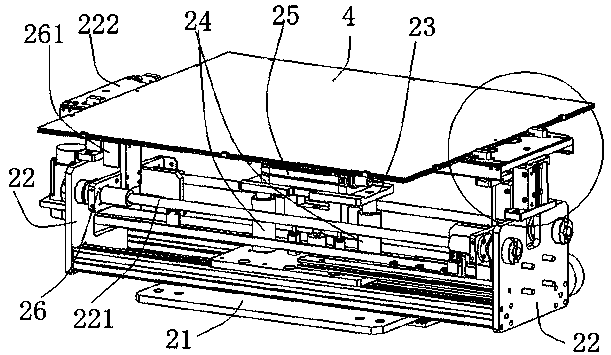

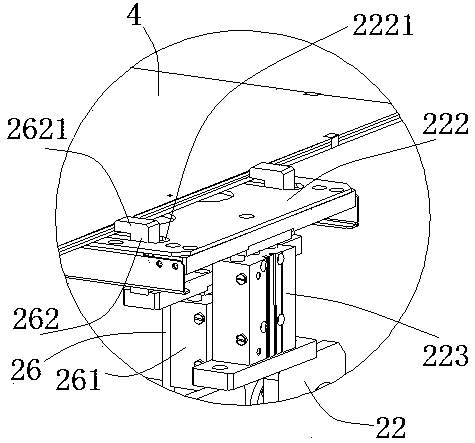

Laser cutting-based plate cutting equipment

InactiveCN113751899AAvoid sticking togetherAvoid bondingLaser beam welding apparatusLaser cuttingMolten slag

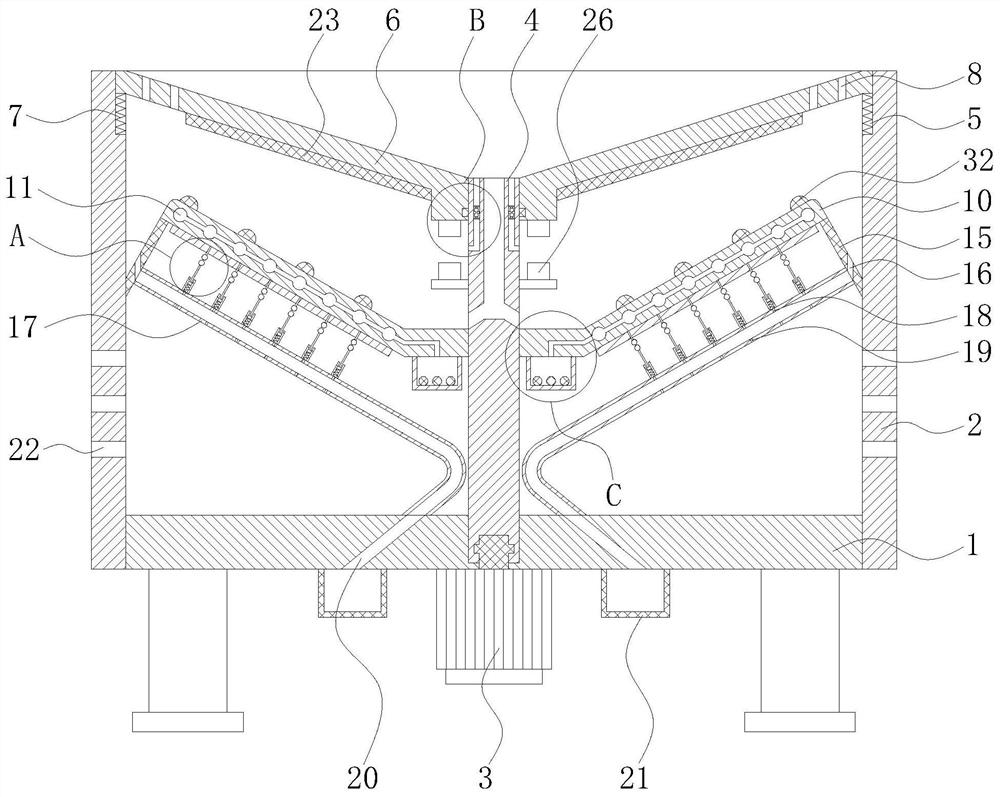

The invention relates to the field of laser cutting, in particular to laser cutting-based plate cutting equipment. The technical problems that a metal plate is molten through laser, molten metal can form molten slag, the molten slag can be attached to the edge of a metal cutting material and a bearing object of the metal plate and is difficult to remove, the high temperature of the metal cutting material is difficult to decrease rapidly, and the metal slag can bond the cut metal together again are solved. According to the technical scheme, the laser cutting-based plate cutting equipment comprises a bottom frame, a laser cutting unit and the like, wherein the upper surface of the bottom frame is connected with the laser cutting unit used for conducting laser cutting on the metal plate. According to the laser cutting-based plate cutting equipment, multiple layers of metal plates can be cut at the same time, and meanwhile, the situation that metal cutting materials of all layers are bonded together through slag generated after cutting can be effectively avoided.

Owner:张家港市棋瑞德机械制造有限公司

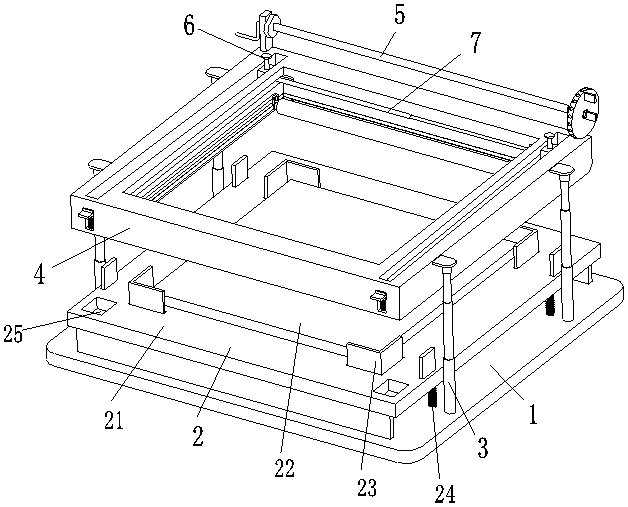

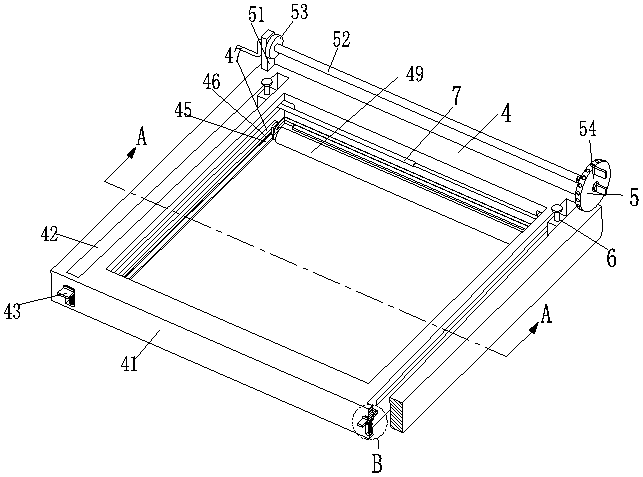

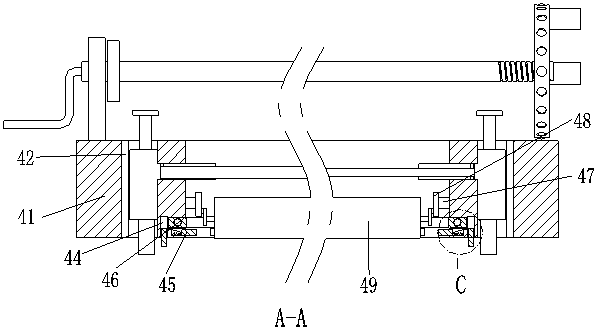

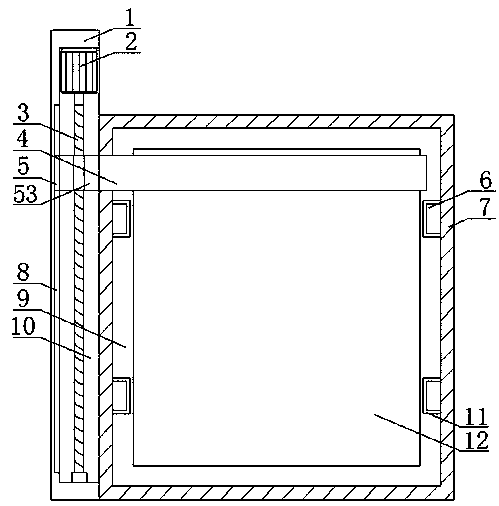

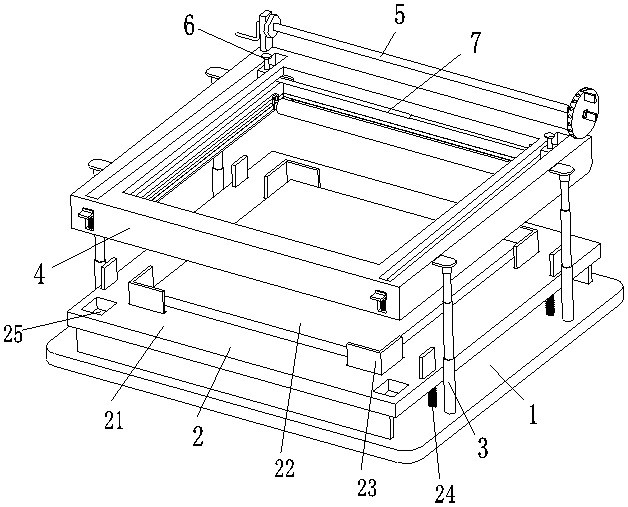

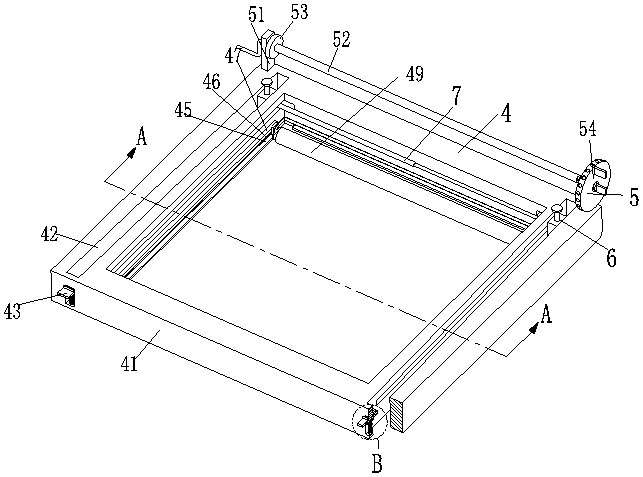

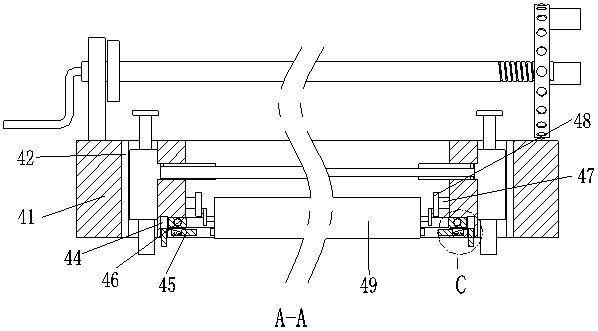

Surface film coating treatment device and film coating method after ceramic tile forming

The invention relates to a surface film coating treatment device after ceramic tile forming. The device comprises a bottom plate, a placing base, an air cylinder, a film coating frame group, a windingdevice, two clamping devices and a telescopic rod. The placing base is installed in the middle of the bottom plate, an air cylinder is connected between the bottom plate and the film coating frame group, the winding device is installed at a rear end of the film coating frame group, the two clamping devices are arranged at a left end and a right end of the film coating frame group, and the telescopic rod is connected between the two clamping devices. In the invention, conditions that a protective film is thin, an area of a single ceramic tile is large, during manual film coating, a film is difficult to tighten by two hands and the untightened protective film is easily stuck together so that bubbles are easy to generate due to the uneven coating film are solved; and problems that the area of the protective film covering the surface of the ceramic tile is larger than that of the ceramic tile so that an edge part of the protective film is exposed out of the ceramic tile, personnel need tocut or wrap the protective film on the edge of the ceramic tile, and overall working efficiency is low due to excessive dependence on manual work are solved too.

Owner:戴志刚

External-heating energy-saving and environment friendly rotary carbonization furnace

InactiveCN102092706BImprove qualityHigh mechanical strengthChemical industryCombustion chamberCarbonization

The invention relates to an external-heating energy-saving and environment friendly rotary carbonization furnace; a furnace body (5) consists of at least three independent material passages (21) that are connected with each other through reinforcing plates (22); the left feed end of the furnace body is sealed with a sealing flange (20), and the right feed end of the furnace body is sealed with a material passage expansion sealing device (8); the left and the right ends of a discharge warehouse are sealed with sealing flanges (16, 17); a feeding warehouse (3), the sealing passage (21), the discharge warehouse (9), a fugitive constituent pipeline (10), a combustion chamber (13), a high-temperature smoke gas pipe (12), a space between the inner part of a furnace housing (6) and the outer part of the material passage (21) and a tail gas exhaust pipe (1) are communicated with each other in sequence; and the temperature of the high-temperature smoke gas of heated material is adjusted through an air distributing pipe (15). In the invention, the temperature and heating rate are easy to control when the material is carbonized, and the material is capable of uniformly and sufficiently absorbing heat with low material ablation, high yield and few energy consumption; and the produced carbonized material has good quality.

Owner:淮北市协力重型机器有限责任公司 +1

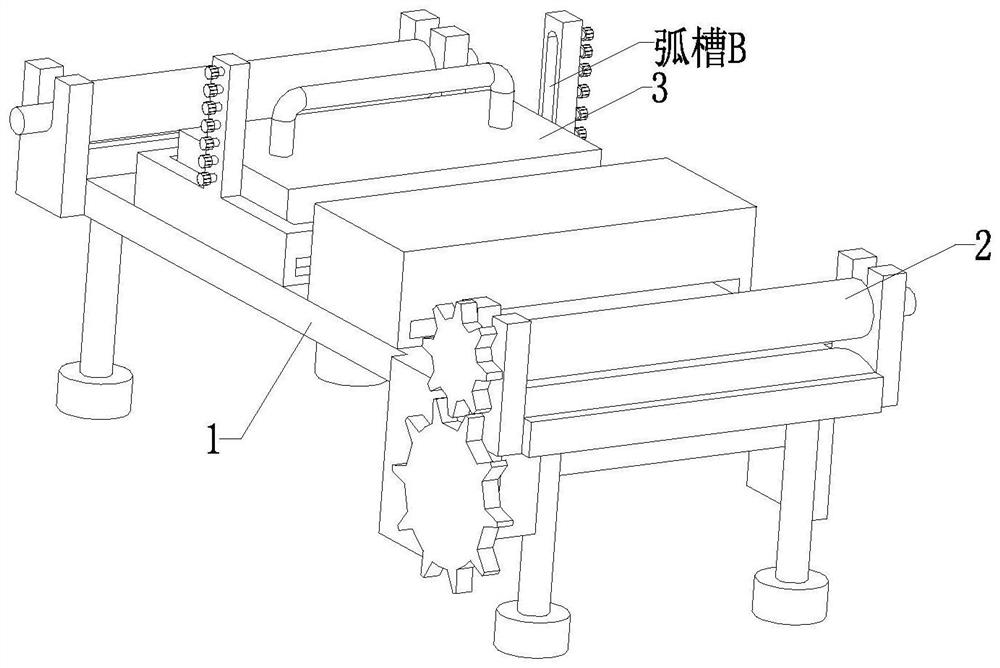

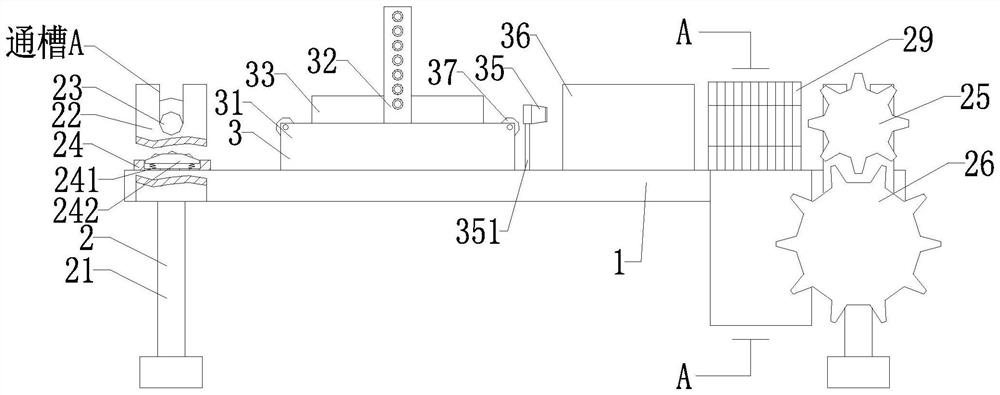

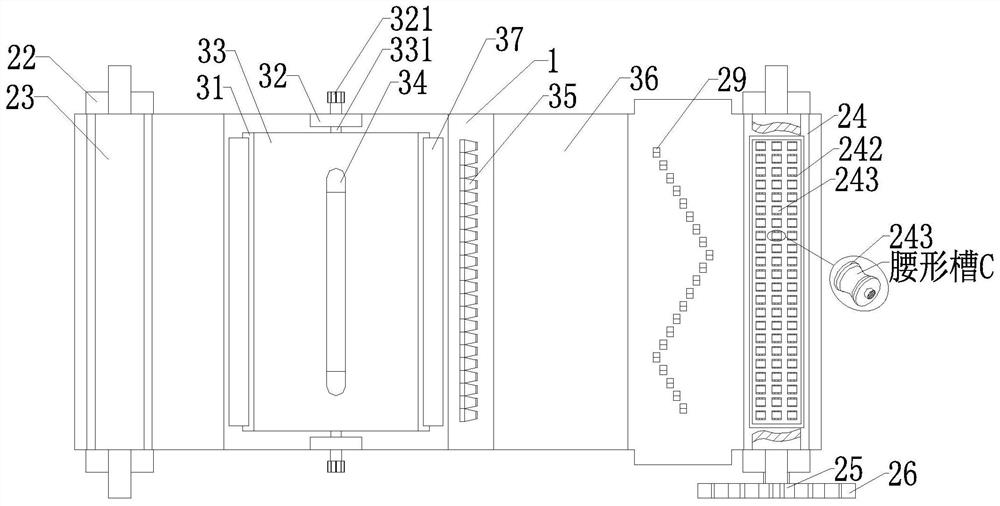

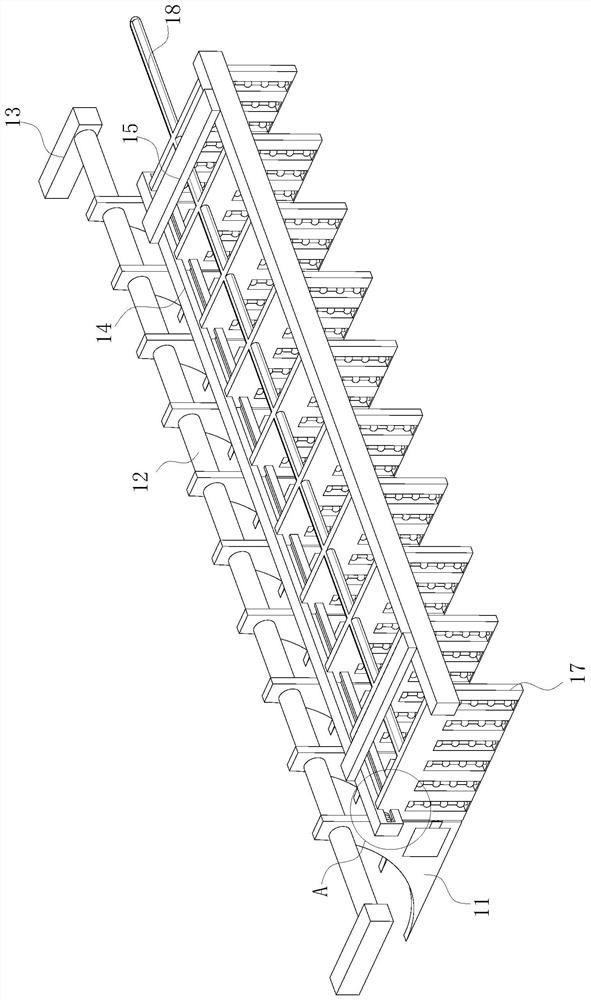

Double-core yarn production device and production method

InactiveCN113026253AIncrease workloadImprove sizing effectLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsYarnIndustrial engineering

The invention relates to a double-core yarn production device and production method. The double-core yarn production device comprises a mounting base plate, a conveying suite and a sizing suite, wherein the conveying suite and the sizing suite are sequentially arranged on the mounting base plate from left to right. The device and the method can solve the following problems during sizing treatment of existing double-core yarns: a, when the existing double-core yarns are subjected to sizing treatment, the double-core yarns often penetrate through size, the surfaces of the double-core yarns are wrapped with a layer of size, and when the double-core yarns are relatively thick, the situation of insufficient sizing and soaking often occurs, so that the sizing effect of the double-core yarns is influenced, and the quality of the double-core yarns is reduced; and b, when the existing double-core yarns are subjected to size adhesion treatment, a large amount of size is often adhered to the surfaces of the double-core yarns, so that the adjacent double-core yarns are easily adhered together during subsequent drying treatment, the adhered yarns need to be separated manually during subsequent operation, the workload of a staff is greatly increased, and manpower is wasted.

Owner:徐州时代纺织有限公司

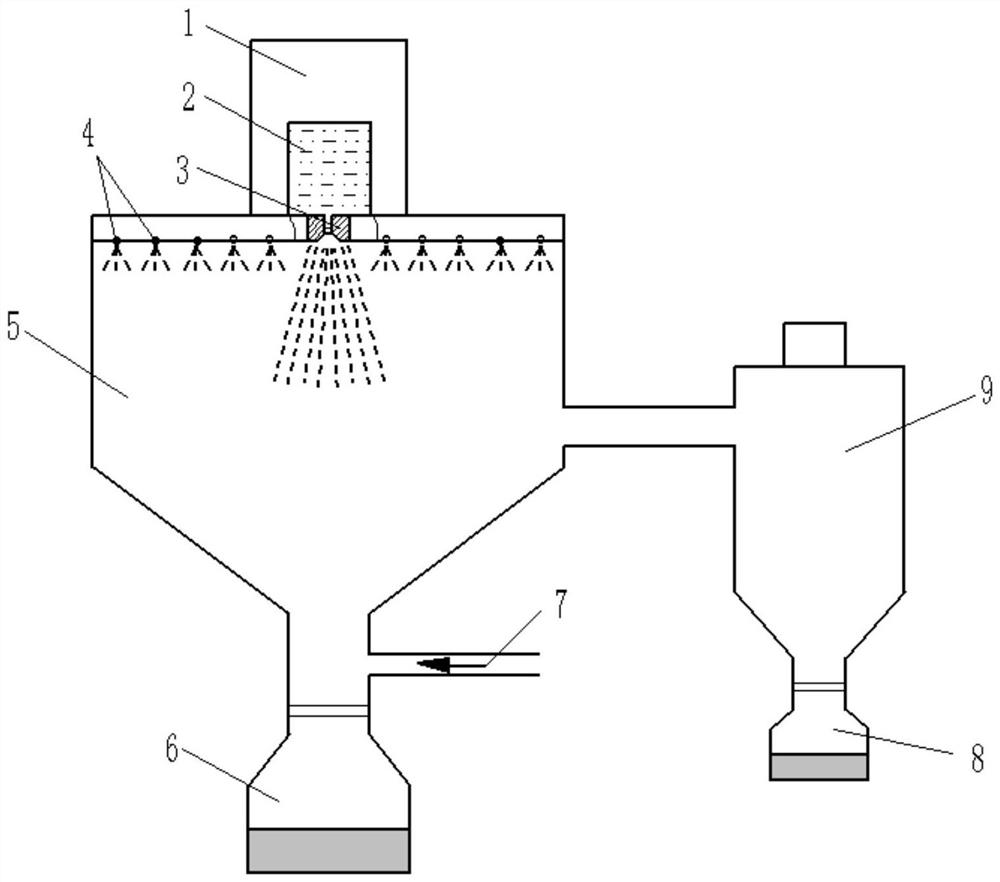

Gas atomization pulverizing device capable of reducing satellite powder

The invention provides a gas atomization pulverizing device capable of reducing satellite powder, and belongs to the technical field of metal powder preparation devices. The problems that in an existing vacuum gas atomization pulverizing technology, the yield of fine powder is low, powder adheres and agglomerates, and the number of satellite ball powder is large are solved. A second nozzle is additionally arranged at the bottom of an atomizing chamber, bottom airflow is introduced, the temperature of the atomizing chamber is reduced, and meanwhile the moving track of backflow airflow is improved. Annular auxiliary gas of an annular gas spraying device promotes atomized liquid drops to be cooled, reverse argon spraying is carried out at the bottom of an atomization cabin, cooling is accelerated, meanwhile, the collision and bonding probability between metal molten drops in the powder atomization process is reduced, powder adhesion and agglomeration are avoided, the powder fluidity is improved, and the gas atomization powder satellite powder content is reduced. The high-standard requirement of industrial production for high-quality spherical metal powder is met, and meanwhile the working efficiency of vacuum induction melting gas atomization powder manufacturing equipment of a cold-wall crucible is improved.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

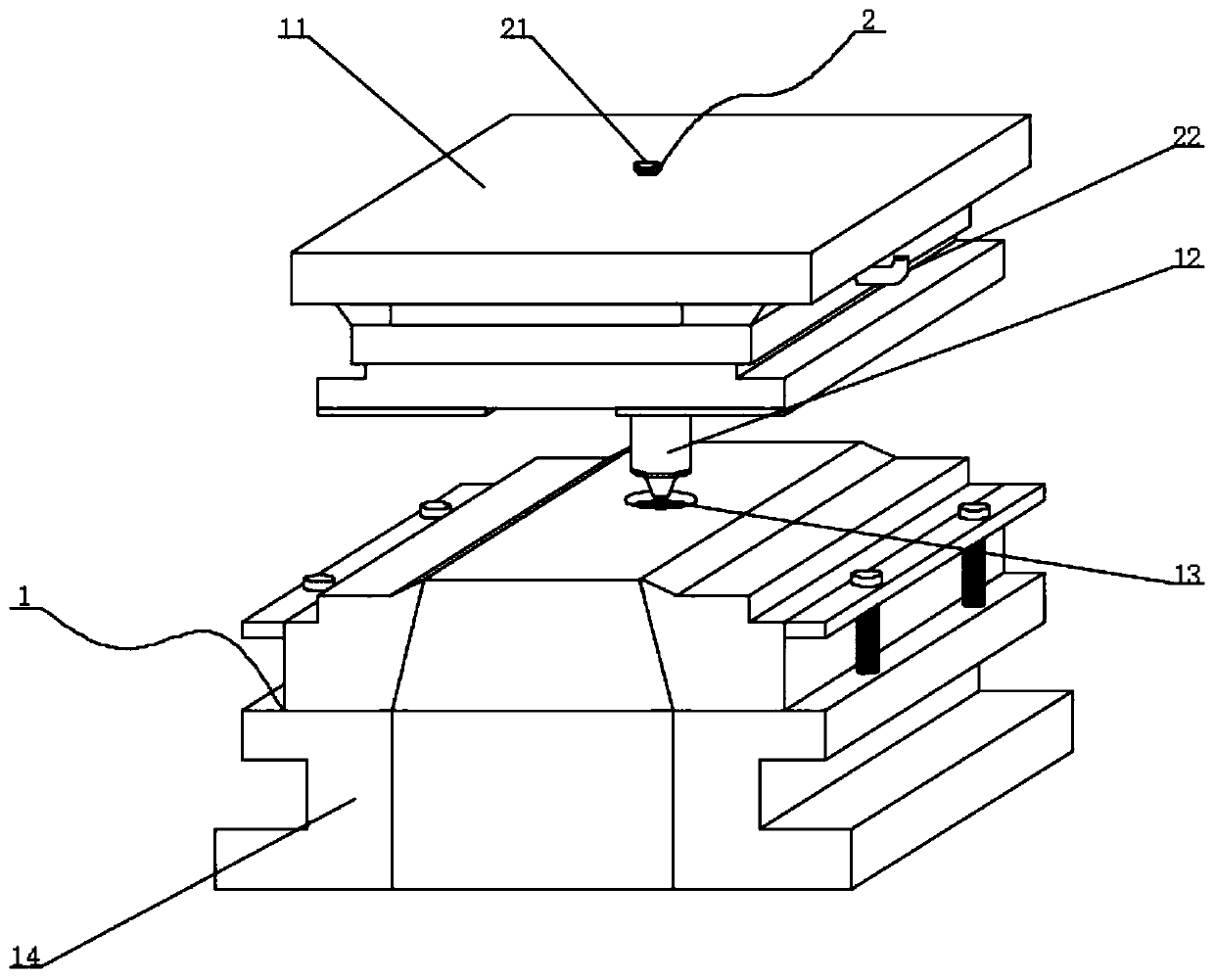

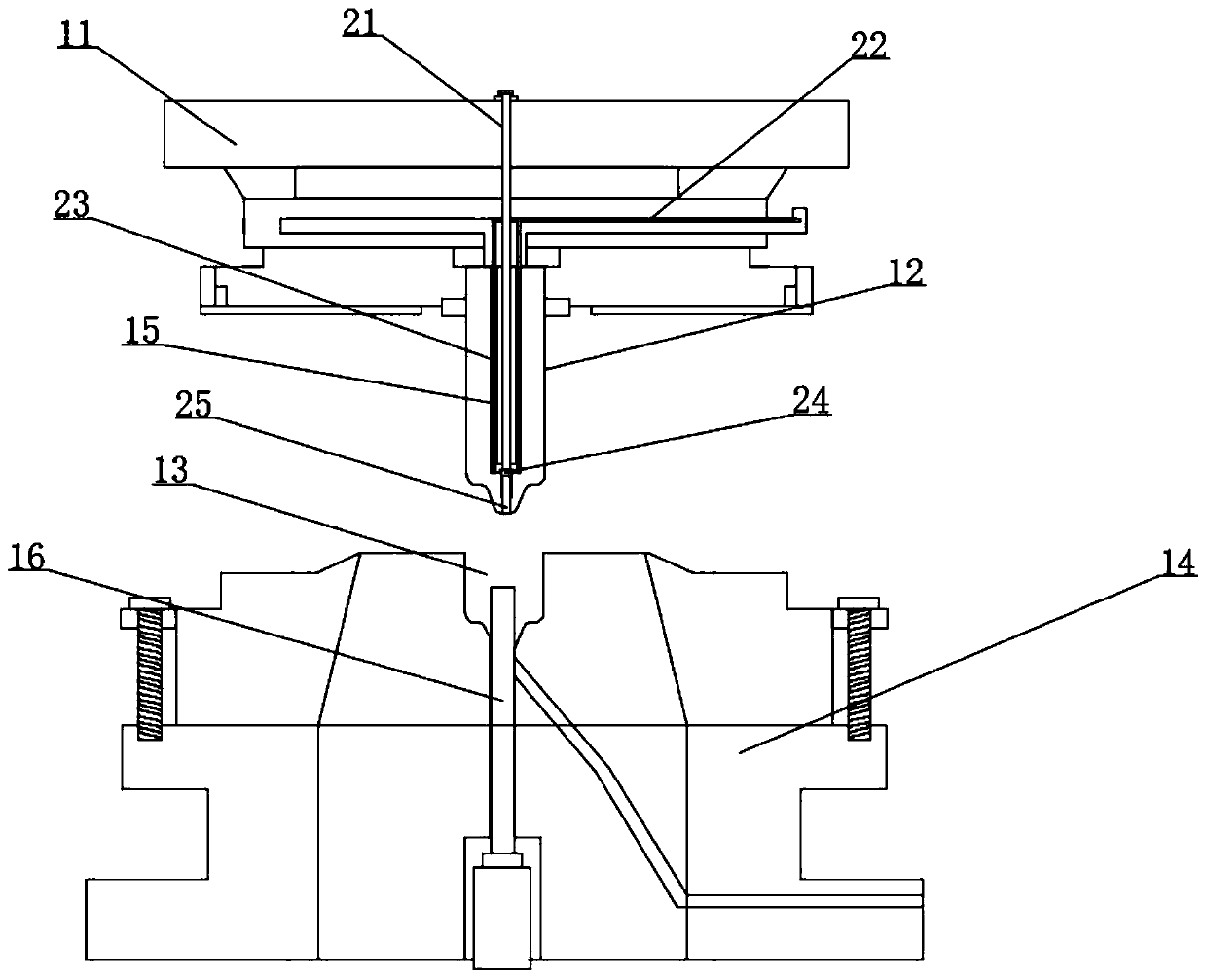

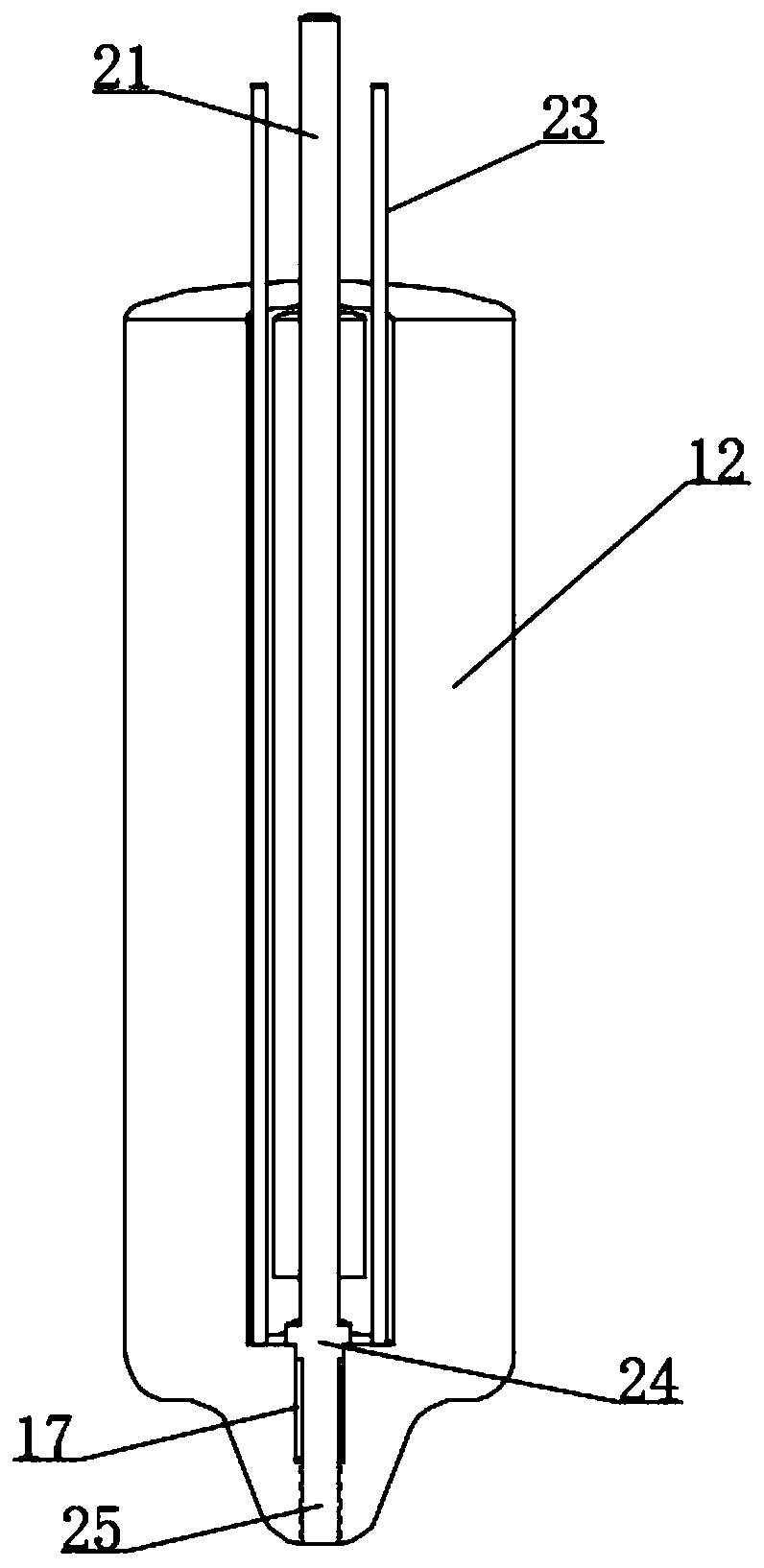

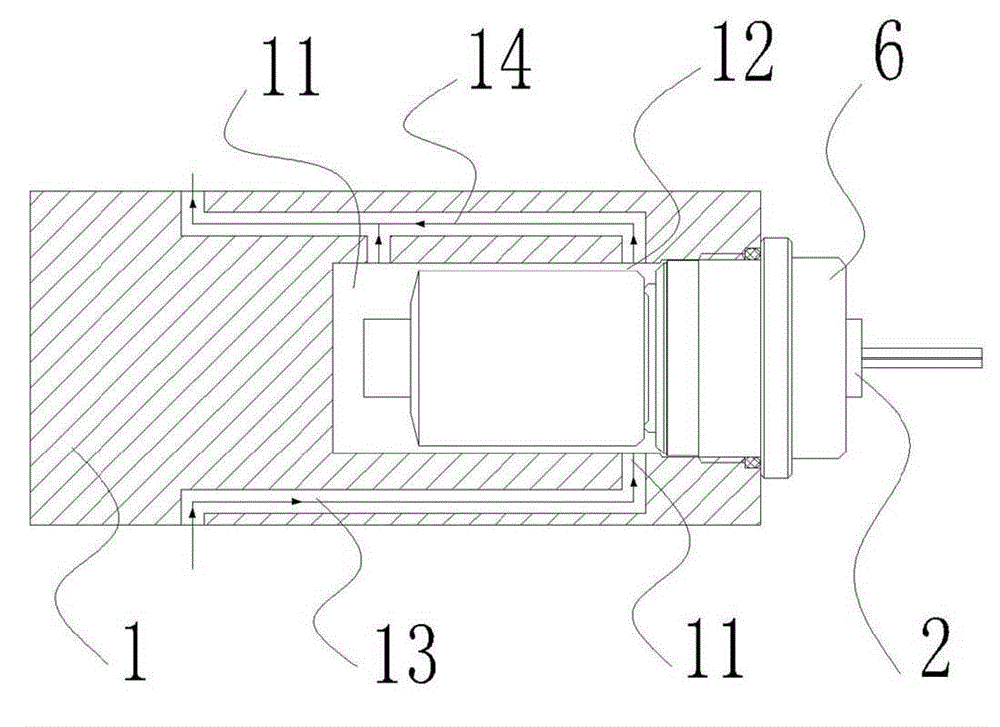

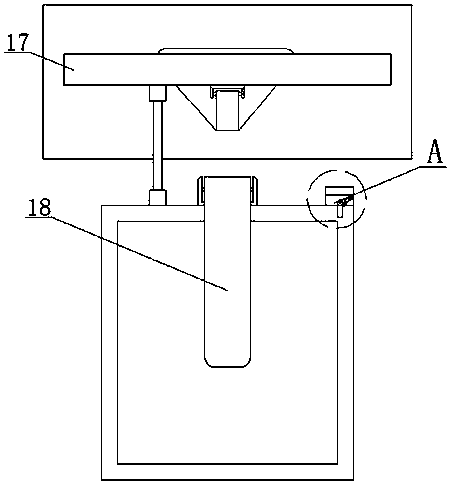

Upper die of hot-forging die with internal cooling function and cooling method thereof

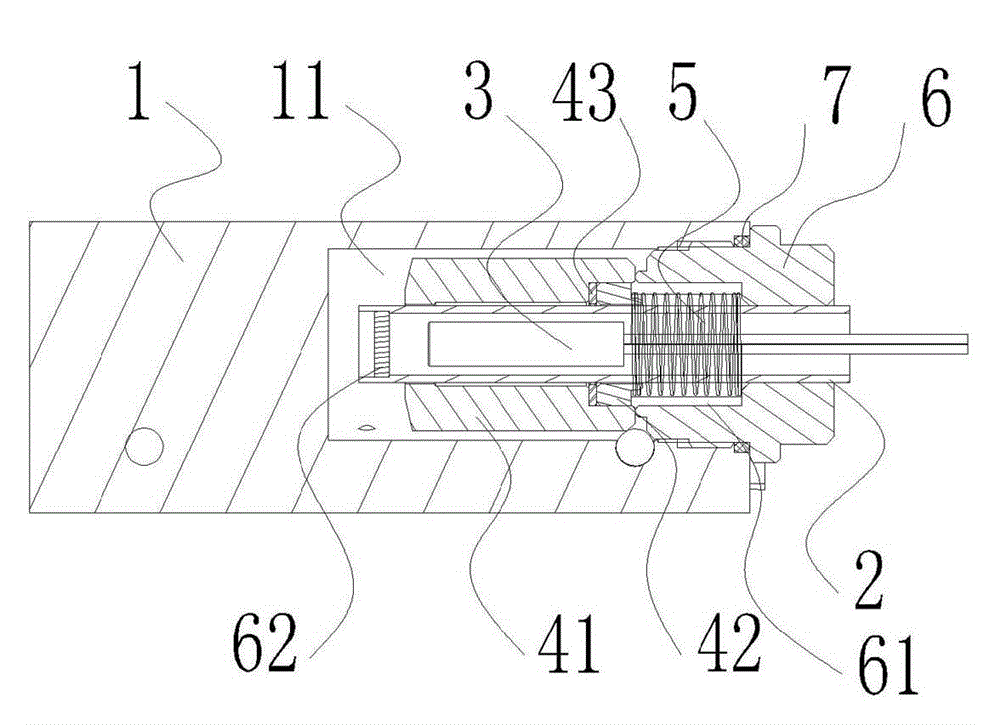

InactiveCN111112533AAvoid sticking togetherWith internal cooling functionForging/hammering/pressing machinesHeating/cooling devicesPhysicsEngineering

The invention belongs to the technical field of dies and provides an upper die of a hot-forging die with an internal cooling function and a cooling method thereof. The upper die comprises a forging assembly. The forging assembly comprises an upper die, a punch and a lower die matched with the upper die. The punch is fixedly connected to the upper die. The upper die also comprises a cooling assembly. The cooling assembly comprises an adjusting part and a punch. As a cooling pipe communicates to the inner side of the punch, a cooling liquid in the cooling pipe will flow into the punch, and the punch is cooled by the cooling liquid contained in the punch to achieve an internal cooling purpose. Secondly, when the adjusting part rotates, the bottom of the adjusting part shrinks and is separatedfrom the bottom of the punch to further open an opening in the bottom of the punch, so that the internal cooling liquid flows out to a position where the punch is in contact with a hot forging part to cool the connection of the punch and the hot forging part, and therefore, a condition that the punch and the hot forging part are bonded together for a long time is avoided.

Owner:安徽省巢湖市冠来模具有限责任公司

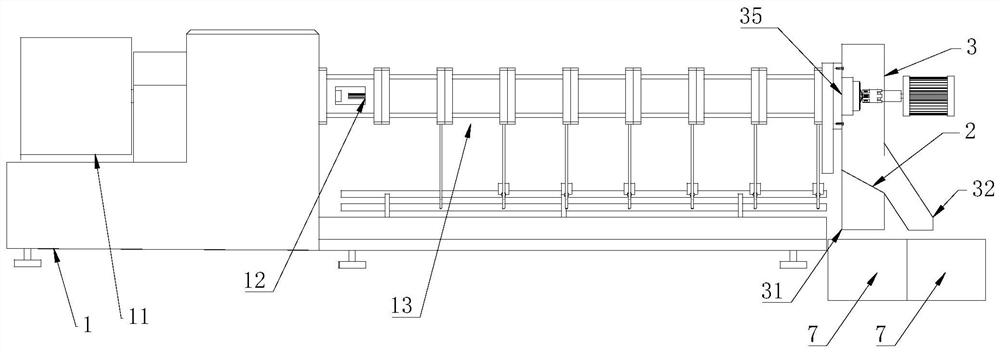

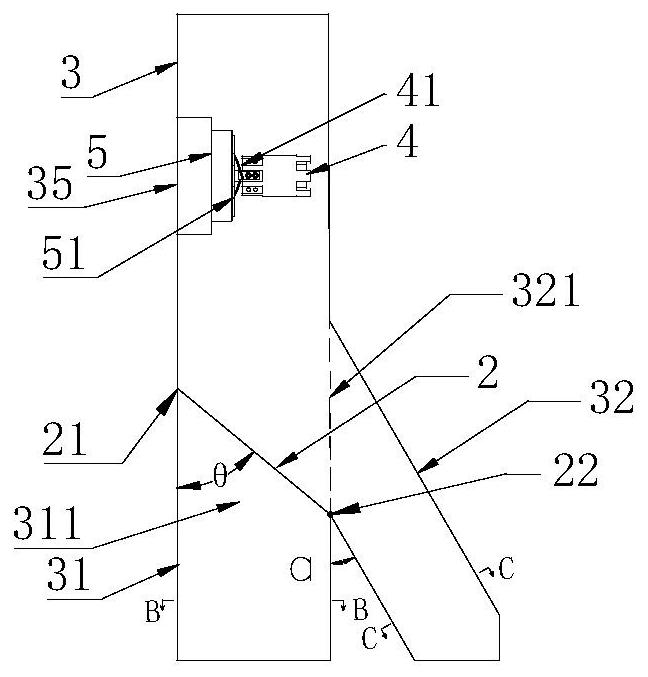

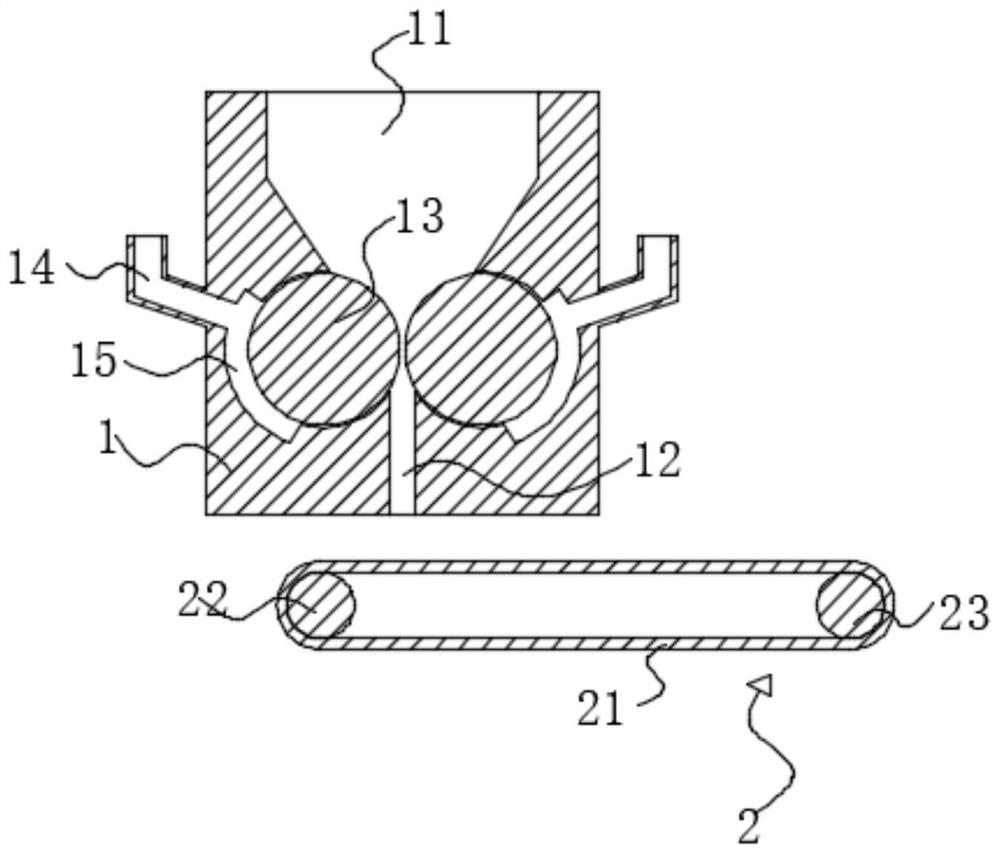

Extruder for making self-heating rice

PendingCN112772841AEasy control opening and closingDischarge will not affectFood shapingElectric machineryEngineering

The invention provides an extruder for making self-heating rice. The extruder comprises a base, a motor arranged in the base, a screw in power connection with the motor and an extrusion cavity sleeving the screw, wherein an extrusion die head communicated with the extrusion cavity is arranged at the tail end of the extrusion cavity; the extrusion screw is matched with the extrusion die head to extrude powdery rice grains into rice blanks; a shearing mechanism for shearing the rice blanks into grains is arranged at the extrusion die head; a protective cover is also arranged at the extrusion die head; the protective cover covers the extrusion die head and the shearing mechanism; at least two discharge channels are formed in the lower part of the protective cover; the discharge channels are formed below an extrusion opening of the extrusion die head; a baffle for opening and closing upper openings of the discharge channels is arranged in the protective cover; the baffle rotates in a vertical plane; and lower openings of the discharge channels are open. The rice grains extruded by the extruder are smoothly discharged and are difficult to adhere, good rice and bad rice can be timely distinguished and discharged without disorder, and the discharged rice grains are compact, complete and full.

Owner:日照尚健食品有限公司

Labeling equipment for transmitting cosmetic bottles by utilizing gravity principle

InactiveCN112896691AAvoid sticking togetherTightly bondedLabelling machinesMechanical engineeringCosmetics

The invention relates to the related technical field of cosmetics, and discloses labeling equipment for transmitting cosmetic bottles by utilizing the gravity principle. The labeling equipment comprises a lower bin, and a supporting plate is fixedly connected to the upper portion of the lower bin. Conical wheels rotate to enable labels to be laid step by step, a labeling device extrudes the laid labels, the labels are prevented from being bonded together, the labels can be tightly attached to the cosmetic bottles, a second moving rod moves upwards to push the cosmetic bottles out of a device table, manual transfer is avoided, and the working efficiency is improved. The containing table moves downwards to cause rightward movement of a first moving rod to hinder rotation of a stop rod and pause rotation of a third connecting rod, so that the situation that a push block pushes the cosmetic bottles out of the containing table in the labeling process of the labeling device is avoided, smooth labeling work is guaranteed, the motion state of the first connecting rod is not affected by a second connecting rod all the time, the second connecting rod can rotate along with the first connecting rod and can also keep static, the relevance between the structures is increased, the two hands are liberated, and the operation is more convenient.

Owner:HUNAN UNIV OF TECH

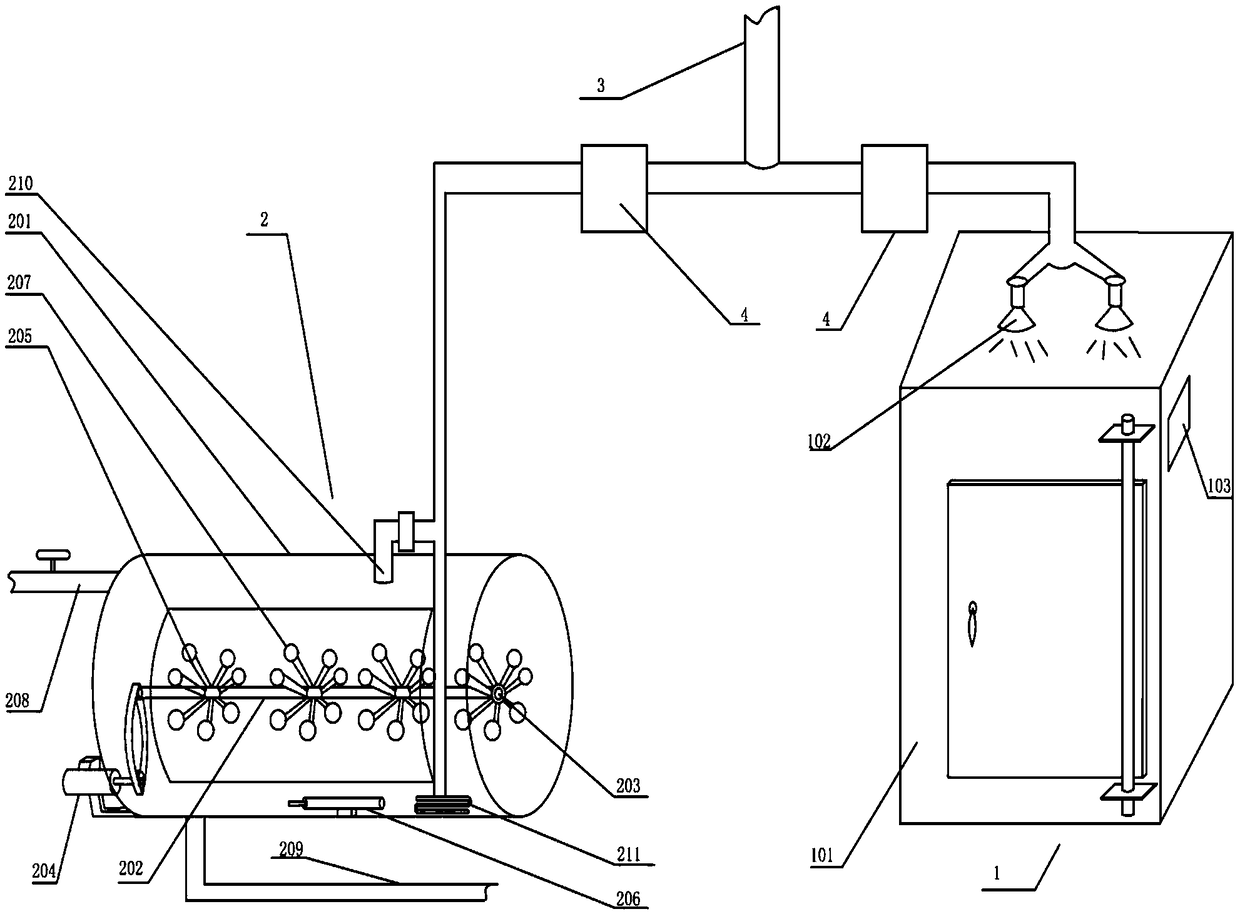

Frying bleaching device and frying bleaching method for jeans

ActiveCN108642748AAvoid sticking togetherGuaranteed to hitTextile treatment machine arrangementsTextile treatment by spraying/projectingMotor driveDistillation

The invention discloses a frying bleaching device and frying bleaching method for jeans. The device comprises a distillation device and a rolling device, wherein the distillation device comprises a distillation cylinder connected to a steam tube, the top face of the distillation cylinder is provided with a steam nozzle, the distillation cylinder is internally provided with a multi-layer placing frame; the rolling device comprises a rolling cylinder and a rolling shaft in the middle of the rolling cylinder, the two ends of the rolling cylinder are provided with rotating bearings of the rollingshaft, one of the ends is provided with a motor driving the rolling shaft, the rolling cylinder is provided with a plurality of sets of beating rods, the beating rods are distributed around the circumference of the rolling shaft and have certain inclined angles with the rolling shaft, and the inner surface of the rolling cylinder is provided with a heating rod. According to the frying bleaching method for the jeans, the jeans are pre-distilled for pre-shrinkage, folds are prevented from being generated during the frying bleaching, the beating rods can promote the rolling effect, each face of the jeans can be beaten in place, the heating rod can maintain the temperature during the frying bleaching, the frying bleaching effect is promoted, the treated jeans have uniform multicolored positions and bottom color, and the stereoscopic impression is higher.

Owner:广州市创兴服装集团有限公司

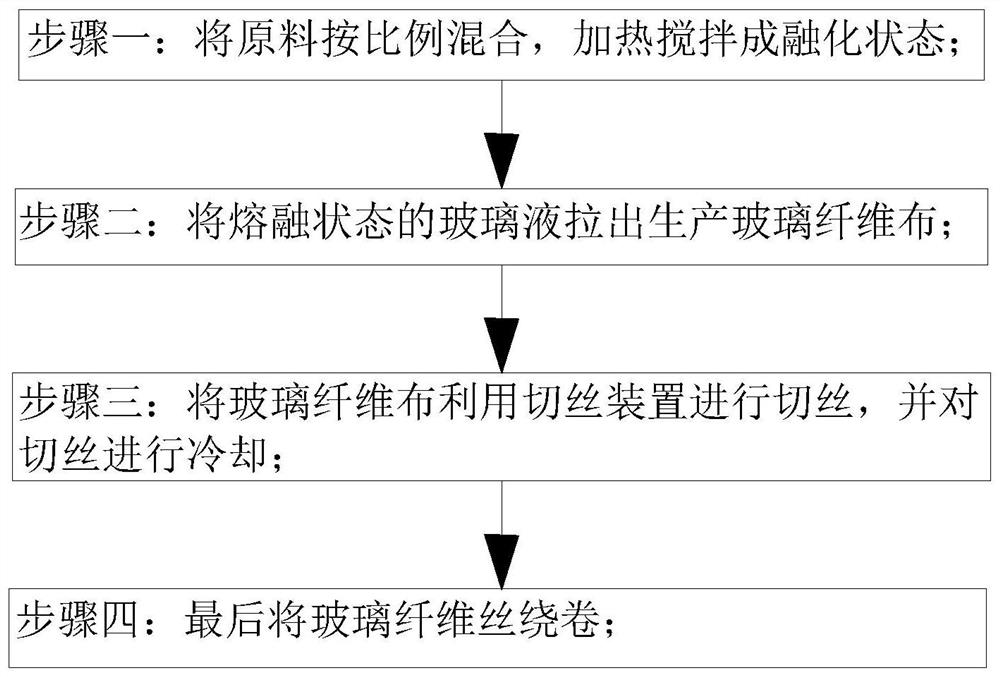

Glass fiber reinforced plastic material manufacturing process

PendingCN112679084AGuaranteed StrengthAvoid continuous large area contactGlass making apparatusPlastic recyclingMolten glassPlastic materials

The invention discloses a production and manufacturing process of a glass fiber reinforced plastic material in the technical field of production of glass fiber reinforced plastic materials. The method comprises the following specific steps: 1, mixing raw materials in proportion, and performing heating and stirring to a molten state; 2, pulling out the molten glass to produce glass fiber cloth; 3, shredding the glass fiber cloth by using a shredding device, and cooling the shredded glass fiber cloth; 4, finally, winding the glass fiber filaments. When glass fiber cloth is shredded, the arc-shaped partition plate is used for isolating cut glass fiber filaments in time, the cut glass fiber filaments are prevented from making contact again, then the vibration partition plate is used for vibrating, the fan blades are matched to rapidly cool and form the glass fiber filaments, and the phenomenon that the glass fiber filaments are adhered together when the glass fiber filaments are wound for a long distance is avoided; moreover, the conveying belt is matched with the winding drum to convey the glass fiber filaments, so the glass fiber filaments are prevented from being pulled strongly, and the quality and the strength of the glass fiber filaments are guaranteed.

Owner:广州鸿科金属材料有限公司

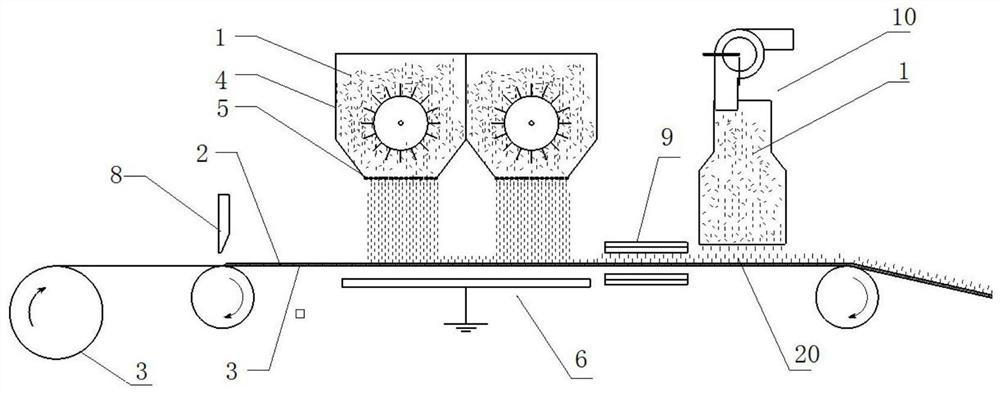

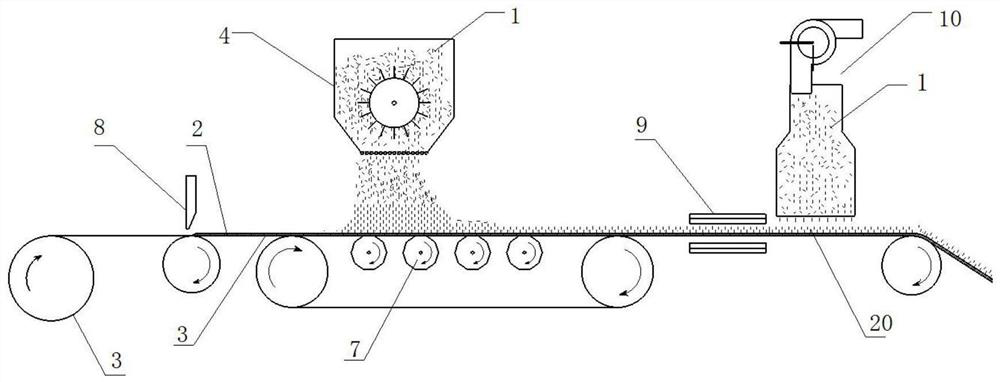

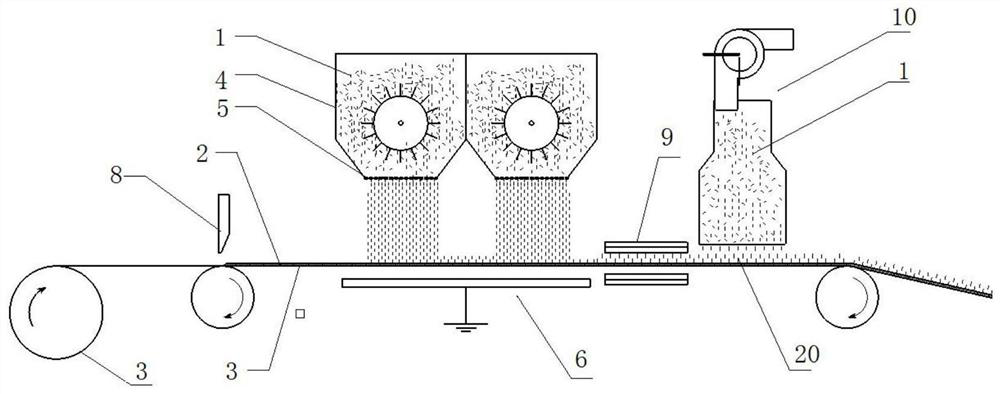

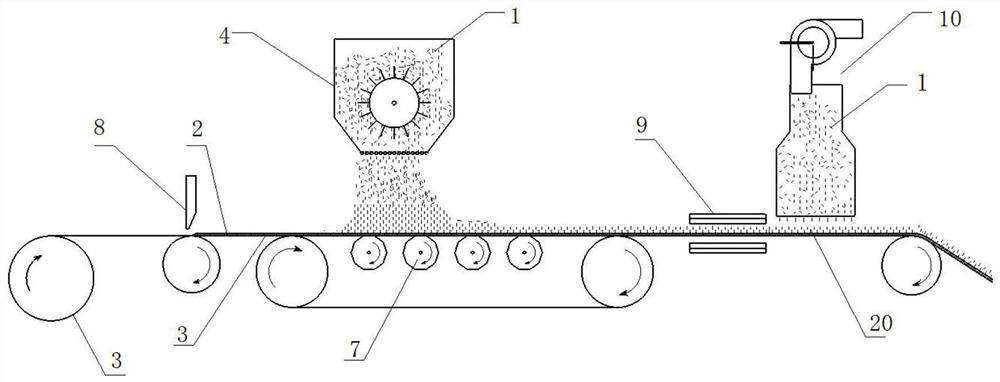

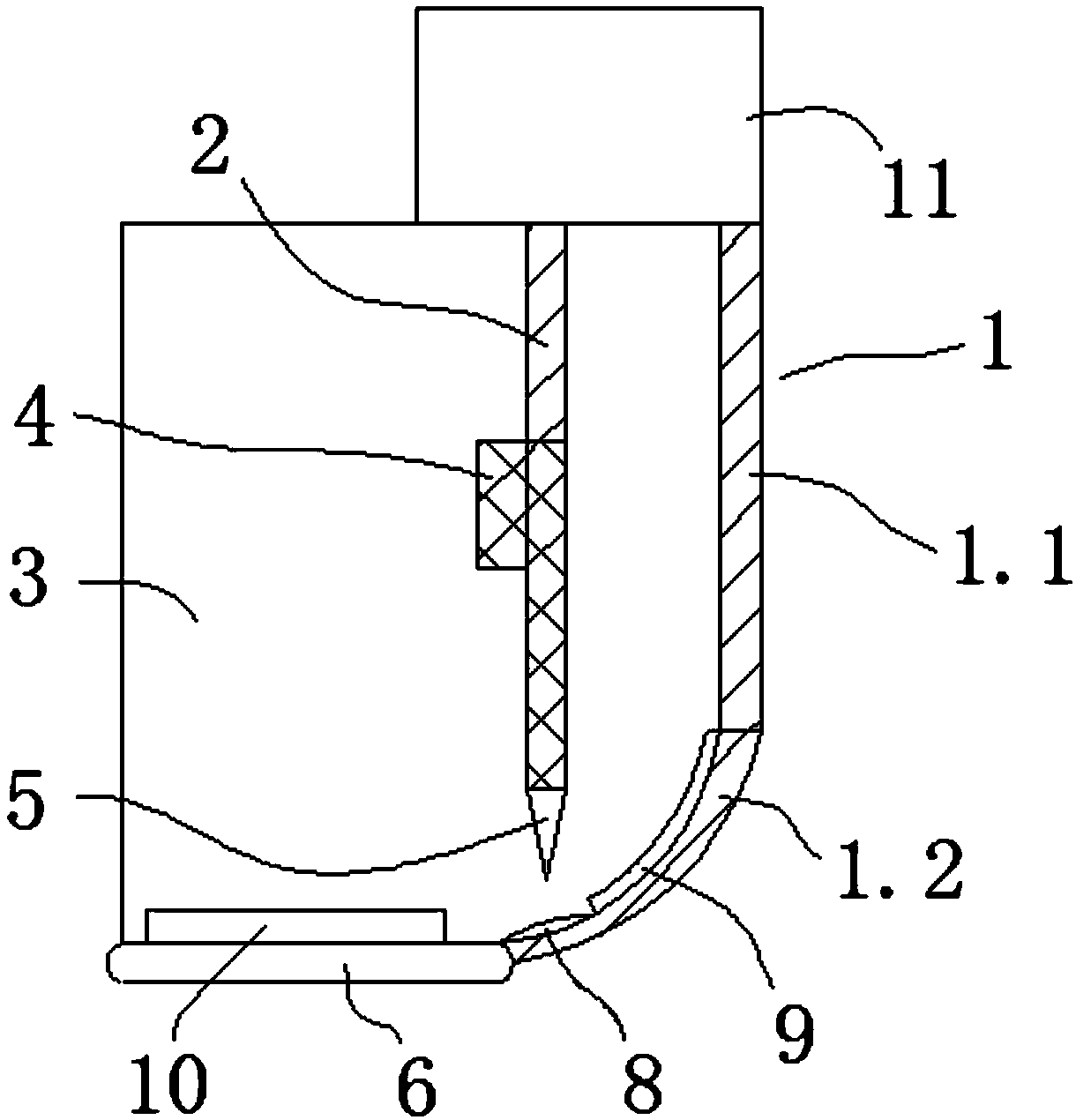

Method for manufacturing non-combustion type cigarette based on flocking technology

ActiveCN111642790AWon't fallReduce processing complexityCigarette manufactureProcess engineeringMechanical engineering

The invention belongs to the technical field of heating cigarette manufacturing, and particularly relates to a method for manufacturing a non-combustion type cigarette based on a flocking technology.The method comprises a flocking procedure and a cigarette rolling and connecting procedure. The flocking procedure comprises a flocking step, and the flocking step is to flock the tobacco filler (1) on the cigarette paper. The method for manufacturing the non-combustion type cigarette based on the flocking technology is provided for the first time, the flocking technology is adopted for automatically flocking filamentous or fibrous or granular tobacco to the surface of cigarette paper, then the cigarette rolling and connecting procedure is connected, and the non-combustion type cigarette can be obtained. When the cigarette is filled with tobacco filler particles, the complex process of adopting a plugging device at the opening end of the cigarette is omitted. When the cigarette is filled with tobacco filler filaments or fibers, the heat resistance of heat spreading in the radial direction of the cigarette is greatly reduced, and the defects that an existing cigarette is large in heat resistance, low in heat transfer rate and uneven in heating are overcome.

Owner:CHINA TOBACCO YUNNAN IND

Multi-piece-paper scanning device for character emotion recognition of film and television script

ActiveCN109151248AImprove adsorption capacityEasy to movePictoral communicationEngineeringCharacter recognition

The invention discloses a multi-piece-paper scanning device for character emotion recognition of a film and television script. The scanning device comprises a first placing block; a first groove is formed in the upper end of the first placing block; a first electric expansion rod is fixed at the bottom in the first groove; a first pressing plate is fixed to the upper end of the first electric expansion rod; and the first pressing plate is arranged in the first groove. Two first moving slots are formed in each of two sides of the first placing block; and second electric expansion rods are fixedat the bottoms in the first moving slots. According to the invention, the static electricity on the script paper can be eliminated effectively, so that a phenomenon of multi-piece-paper electrostaticbonding is avoided; the multi-piece-paper script can be absorbed and transferred continuously, so that script scanning and inputting speed is increased; an emotion recognition unit program in a computer can carry out classification processing and identification on the inputted information conveniently and the character emotion in the script can be identified accurately, so that the emotion recognition quality is improved; and emotion collection is carried out conveniently.

Owner:XIAN UNIV OF FINANCE & ECONOMICS

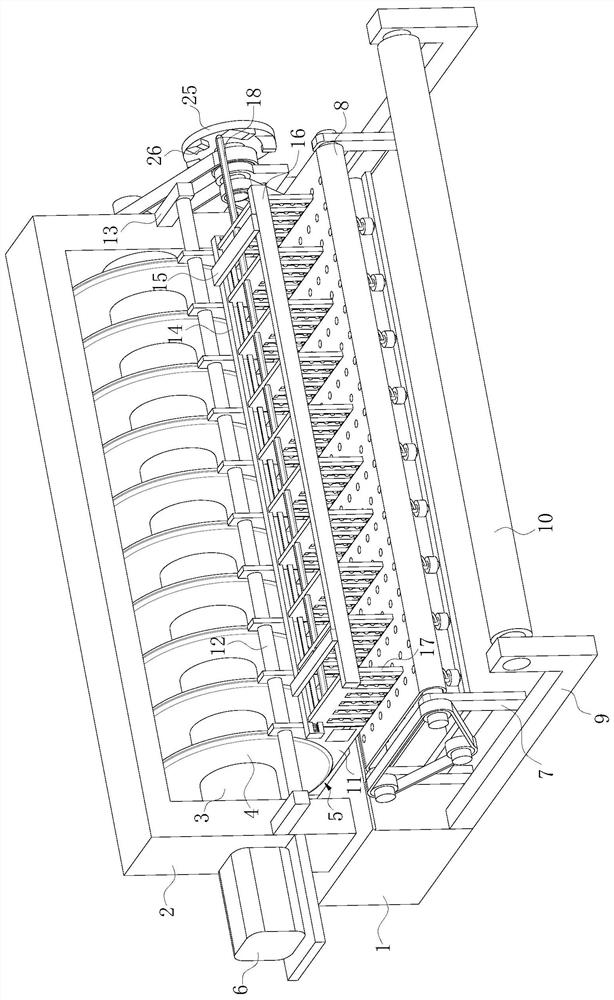

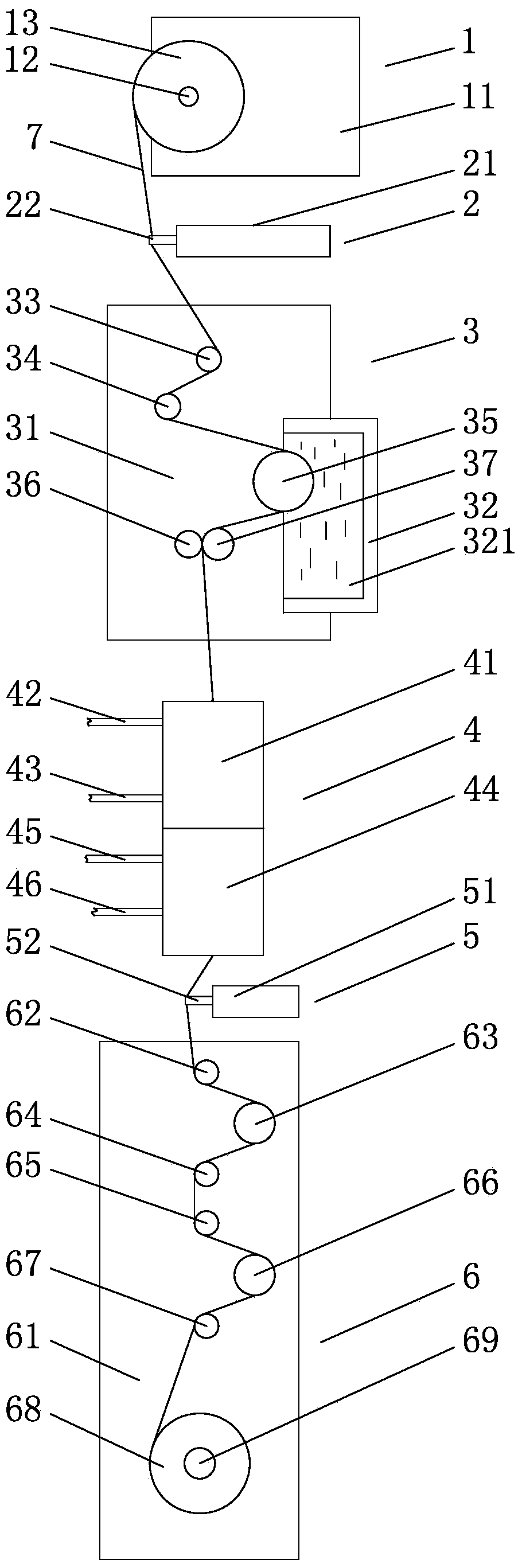

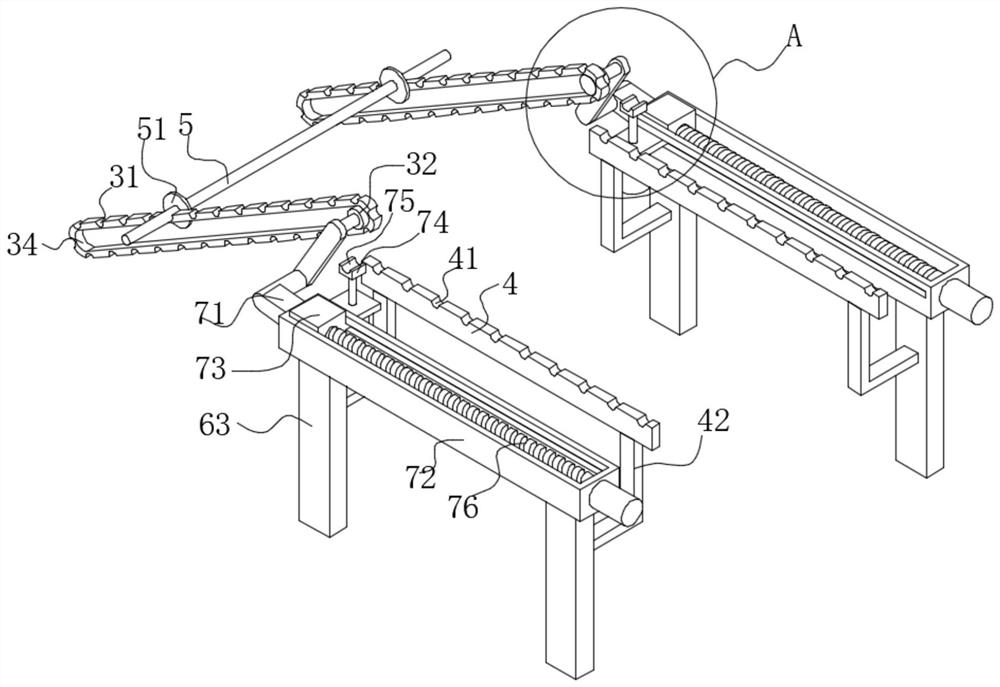

Yarn sizing device capable of separating yarns

InactiveCN104074007AAvoid stickingAvoid sticking togetherTextile treatment carriersTextile treatment guiding meansSizingYarn

The invention relates to a yarn sizing device capable of separating yarns, belongs to the field of textile equipment, and solves the problem of bonding of adjacent yarns after being sized because of the slurry effect. In order to solve the problem, the invention provides the following scheme: the yarn sizing device capable of separating the yarns comprises an emptying device, a sizing device, a drying device and a yarn collecting device arranged in sequence, wherein a first yarn separating device is arranged between the emptying device and the sizing device, and comprises a first yarn separating frame and first yarn separating rods; the first yarn separating rods are evenly arranged on the first yarn separating frame, and are upwards projected; a second yarn separating device is arranged between the drying device and the yarn collecting device, and comprises a second yarn separating frame and second yarn separating rods; and the second yarn separating rods are arranged on the upper end surface of the second yarn separating frame, and are upwards projected.

Owner:CHANGXING ZHIHENG CLOTHING MATERIAL

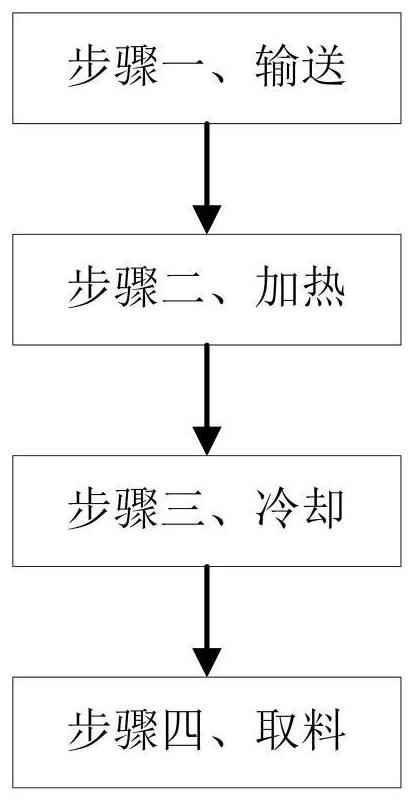

Drying technology for green organic compound fertilizer after granulation forming

PendingCN112815663AAvoid breakageIncrease the collision forceDrying chambers/containersDrying solid materialsThermodynamicsSoil science

The invention belongs to the technical field of fertilizer production, and particularly relates to a drying technology for a green organic compound fertilizer after granulation forming. The technology is completed by adopting a drying device for the green organic compound fertilizer after granulation forming in a cooperative mode, and comprises the following steps that S1, conveying is carried out, and specifically, fertilizer granules on the upper surface of a material containing disc slide to the upper surface of a heating disc from a first falling groove; S2, heating is carried out, wherein a main shaft and the heating disc are driven to rotate through a driving motor, the fertilizer particles on the heating disc slide towards the edge of the heating disc under the action of centrifugal force and absorb heat of the heating disc, and water in the fertilizer particles overflows from an air outlet groove after being evaporated; S3, cooling is carried out, wherein the fertilizer particles enter a material guide pipe through a second material falling groove, and air cools the fertilizer particles and takes away residual moisture on the surfaces of the fertilizer particles at the same time; and S4, material taking is carried out, the fertilizer particles fall into an annular material receiving box, the annular material receiving box is taken down, and the fertilizer particles are poured out. According to the drying technology, when the fertilizer particles are dried, the situation that the fertilizer particles are broken is avoided, and the situation that the fertilizer particles are bonded in the annular material receiving box is avoided.

Owner:张敏

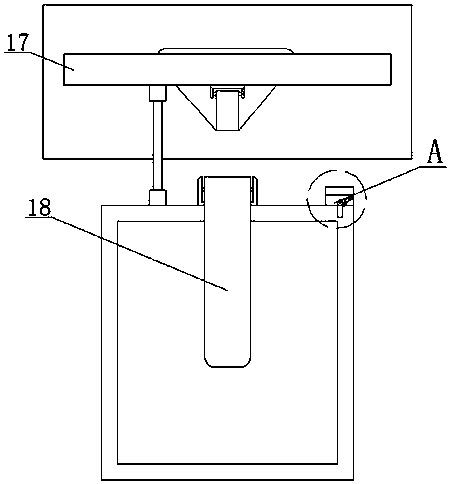

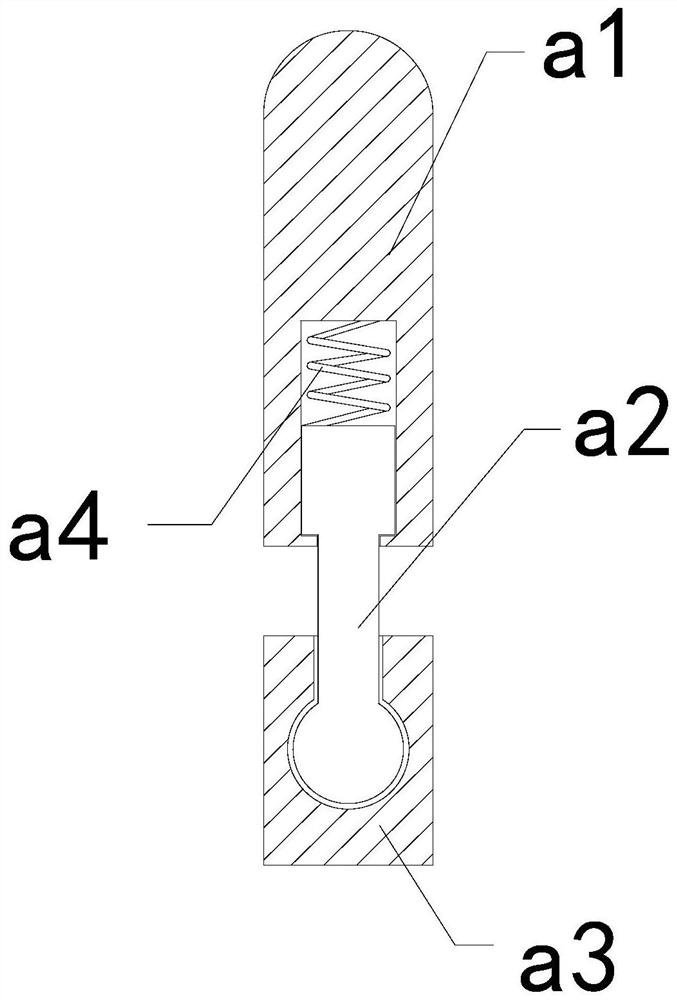

Vapor-liquid sensor

InactiveCN104949738AImprove use reliabilityReduce volumeLevel indicators by floatsVapor liquidEngineering

The invention discloses a sensor, and provides a vapor-liquid sensor which is high in detection sensitivity and stable and reliable in performance. The vapor-liquid sensor solves the technical problems that in the prior art, detection sensitivity is low, and as floating balls are easily attached to a guide rod, a vapor-liquid sensor fails. The vapor-liquid sensor comprises a valve body and a hollow guide rod with one end packaged in a containing cavity of the valve body, a magnetic switch is arranged at the portion, corresponding to the interior of the valve body, in the hollow guide rod, a floating ball set is connected to the portion, corresponding to the magnetic switch, outside the hollow guide rod in a sliding mode, an input port and an output port are formed in the portions, corresponding to the two ends of the floating ball set, in the containing cavity respectively, the floating ball set comprises a floating sleeve made of a PP material, an annular magnet and a close cover, the hollow guide rod is sequentially sleeved with the floating sleeve, the annular magnet and the close cover, the annular magnet is clamped between the floating sleeve and the close cover, and the portion, between the floating ball set and the valve body, of the hollow guide rod is sleeved with an auxiliary spring.

Owner:陆宇

A method for manufacturing non-combustible cigarettes based on flocking technology

ActiveCN111642790BWon't fallReduce processing complexityCigarette manufactureBurn cigaretteProcess engineering

The invention belongs to the technical field of heating cigarette manufacturing, in particular to a method for manufacturing non-combustible cigarettes based on flocking technology. The method includes a flocking process and a cigarette rolling process; wherein, the flocking process includes a flocking step, and the flocking step is to flock the tobacco filler (1) on the cigarette paper. The present invention proposes a method for manufacturing non-combustible cigarettes based on flocking technology for the first time. The flocking process is used to automatically flock filamentous, fibrous or granular tobacco to the surface of cigarette paper, and then connect the cigarette rolling process to obtain non-combustible cigarettes. Burning cigarettes. When the cigarette stick contains tobacco filler particles, the complicated process of using a plugging device at the opening end of the cigarette stick is omitted. When the cigarette is filled with filaments or fibers of tobacco filler, the thermal resistance of heat propagating in the radial direction of the cigarette is greatly reduced, and the defects of large thermal resistance, slow heat transfer rate and uneven heating of the existing cigarette are improved.

Owner:CHINA TOBACCO YUNNAN IND

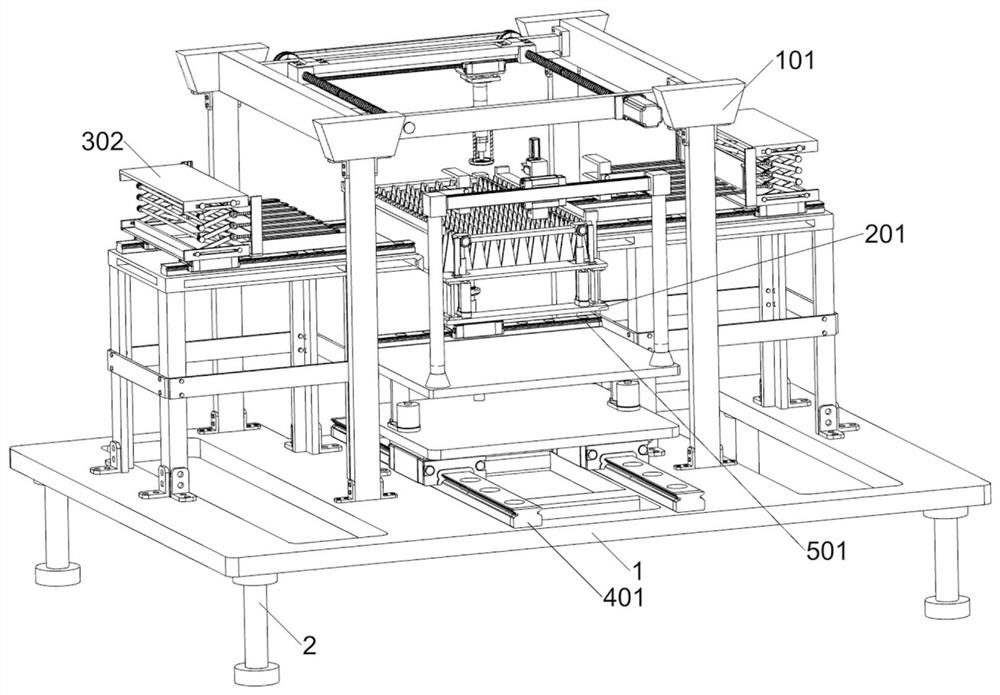

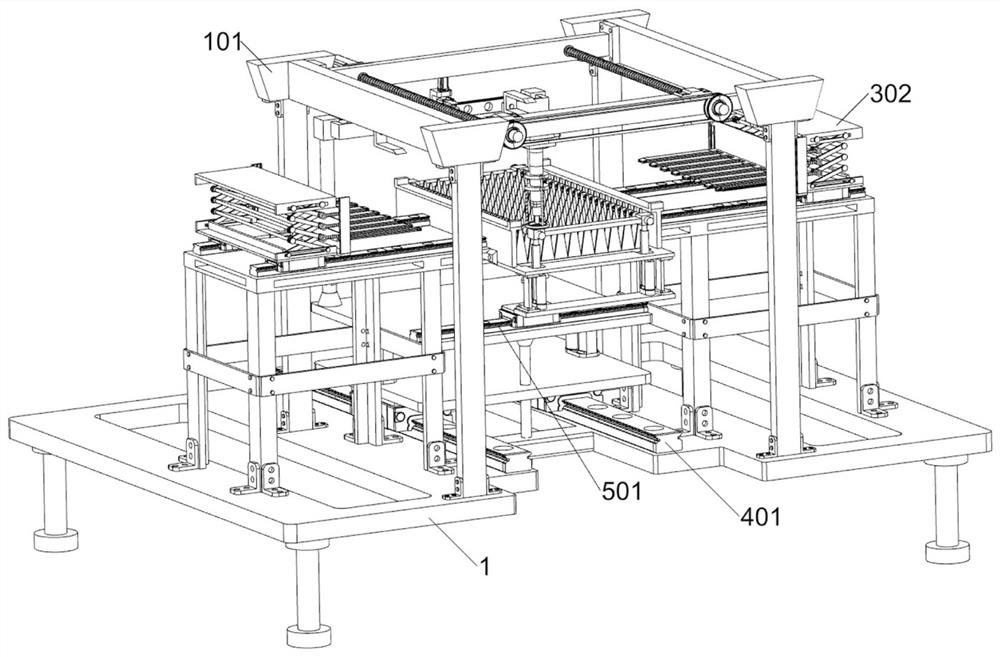

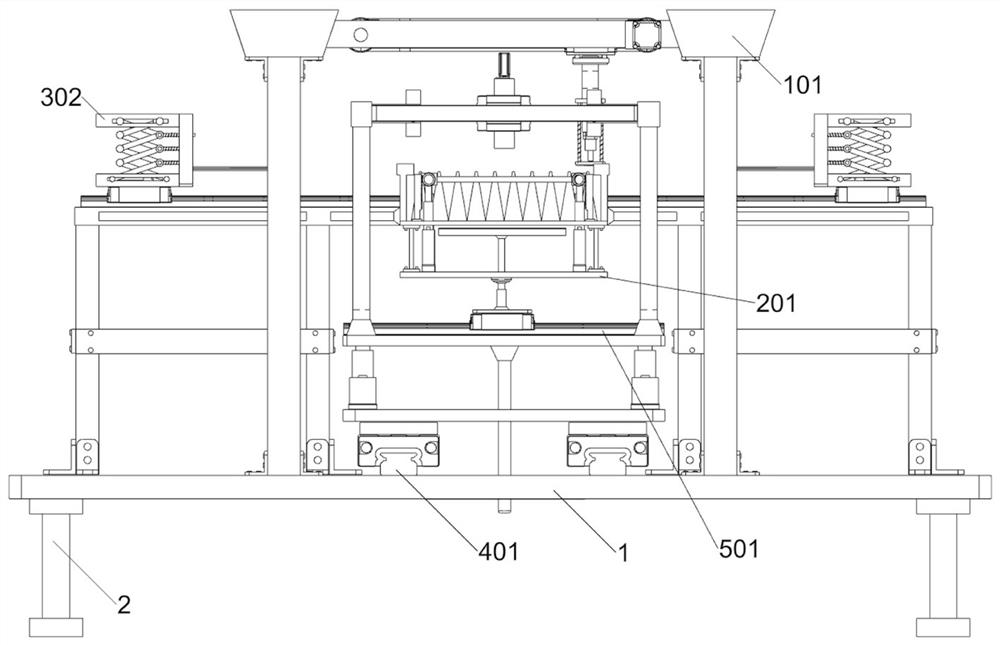

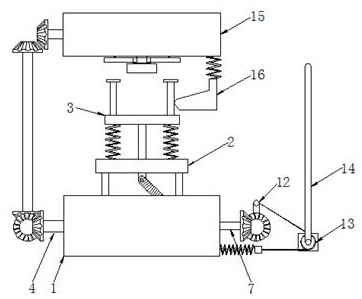

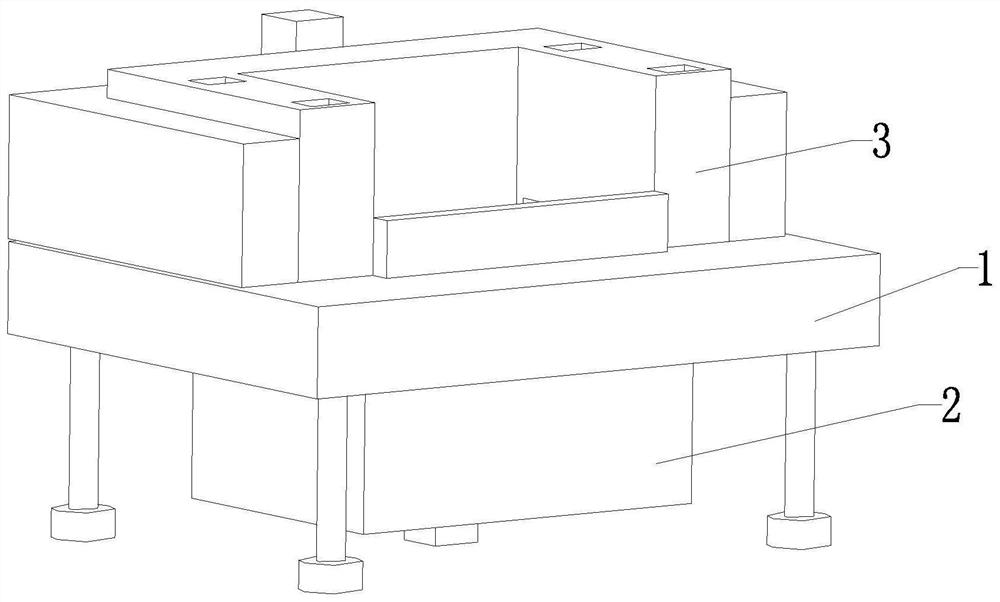

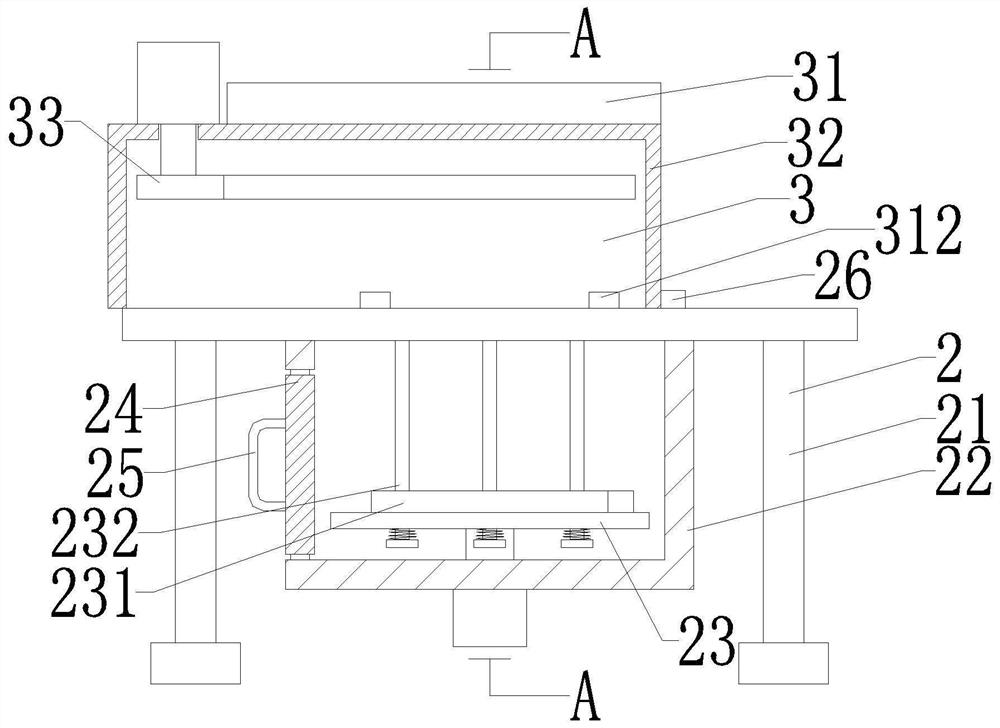

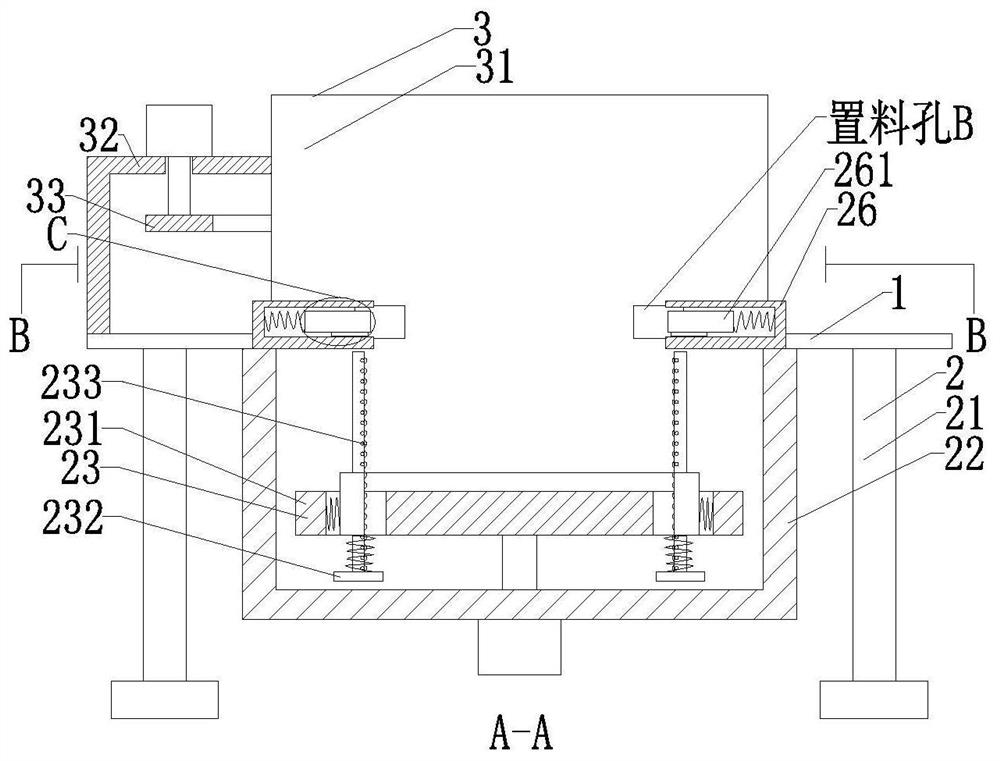

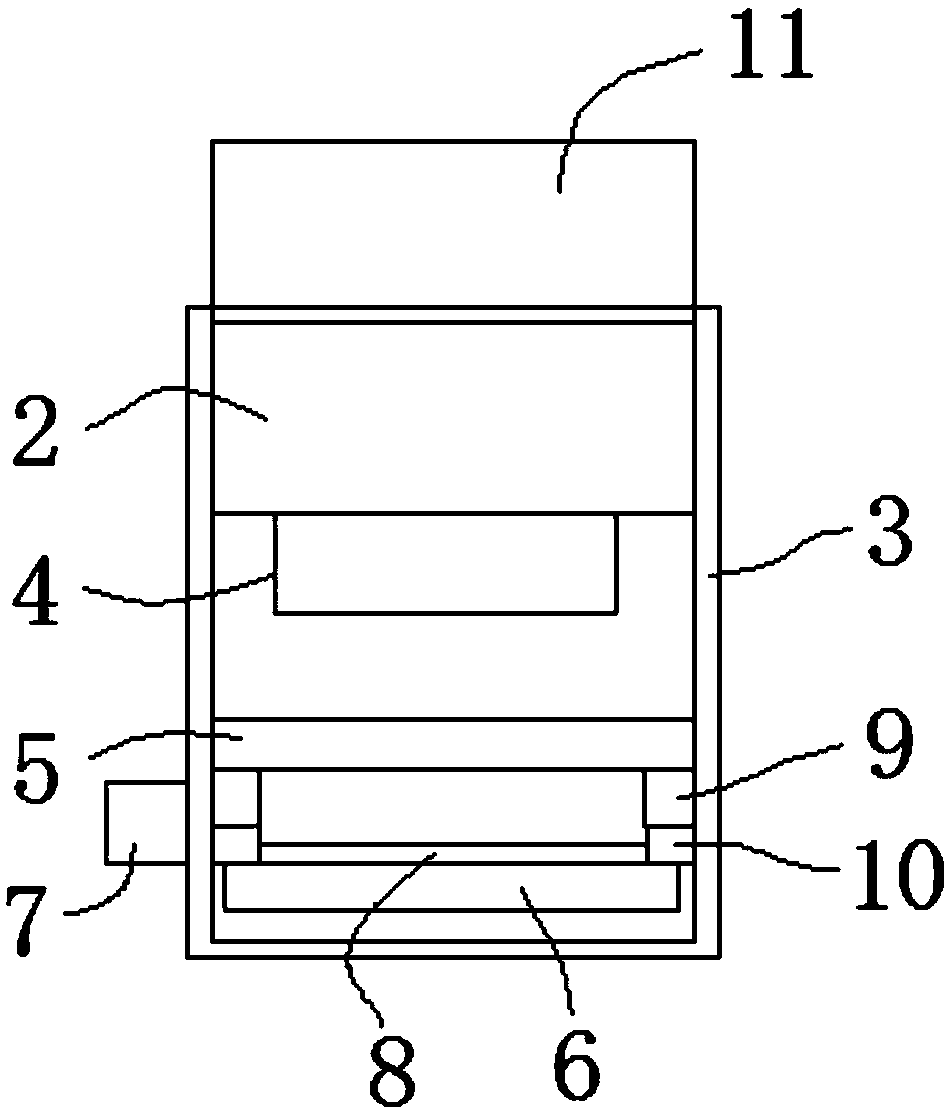

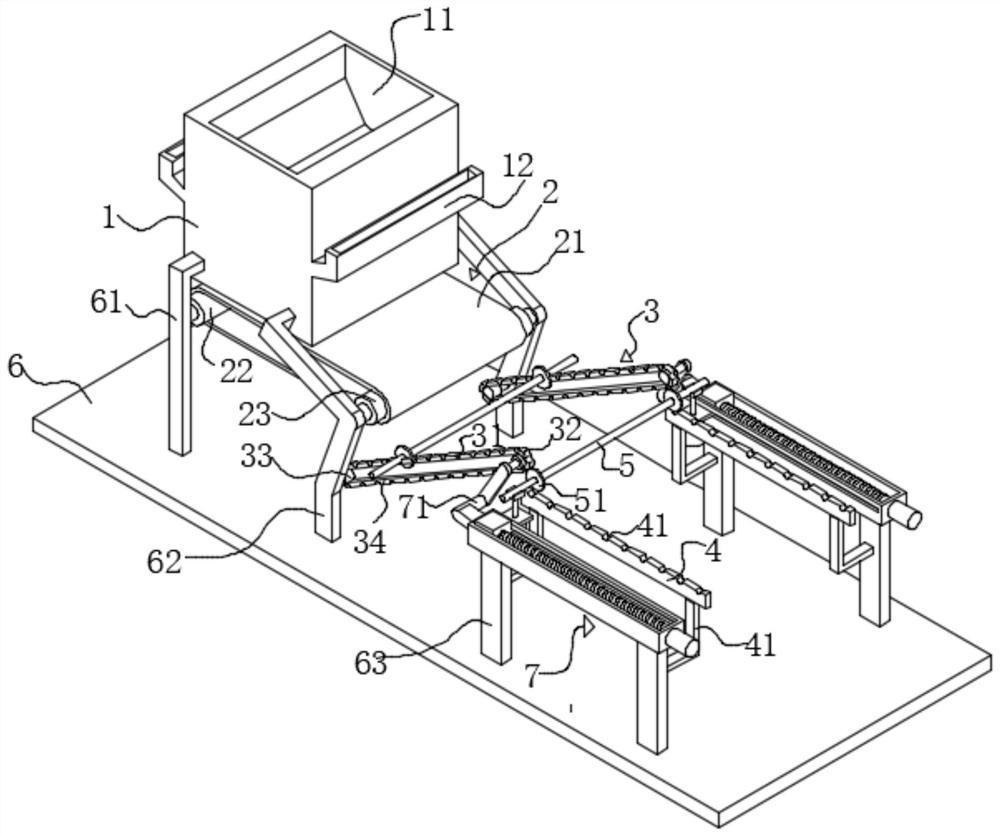

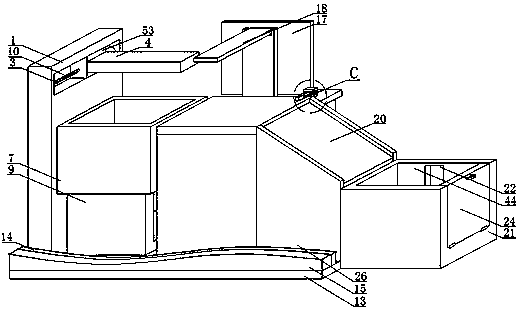

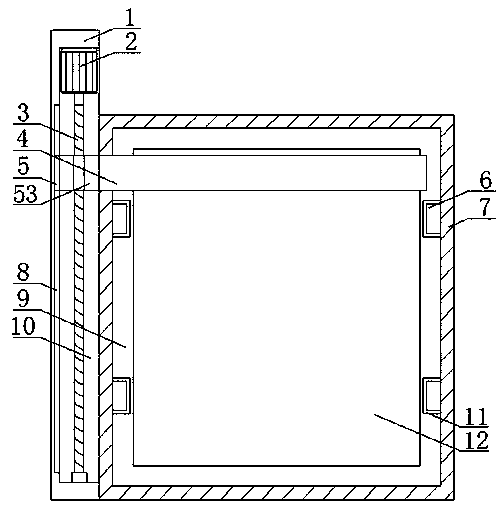

Refrigerator partition plate assembling machining device

InactiveCN112847238ASlow down productivityAvoid sticking togetherLighting and heating apparatusMetal-working hand toolsStructural engineeringMechanical engineering

The invention relates to a refrigerator partition plate assembling machining device. The refrigerator partition plate assembling machining device comprises a mounting frame, a fixing suite and a combining suite, wherein the fixing suite is mounted on the mounting frame, and the combining suite is arranged at the upper end of the fixing suite. The refrigerator partition plate assembling machining device can solve the problems, existing in the existing refrigerator partition plate assembling process, that a, when an existing refrigerator partition plate is assembled, the situation that combination base plates adhere frequently occurs, so that combination fails frequently during combination, and then the production efficiency is greatly lowered; and b, in the assembling process of the existing refrigerator partition plate, the situation that direct combination of the combination base plate and a combination sleeve is insufficient often occurs, then secondary combination is needed, and therefore the production efficiency is greatly lowered.

Owner:伍晓明

Noodle cutting machine

ActiveCN109221318AEasy to separateQuick cutDough shaping and cutting apparatusDough processingEngineeringSlide plate

The invention relates to a noodle cutting machine, comprising a noodle sliding plate, a partition plate and two side plates, wherein the two side plates are respectively placed on two sides of the noodle sliding plate; the noodle sliding plate comprises a plumb plate and a curved plate, and the vertical plate is connected with the curved plate; the partition plate is placed between the two side plates; the partition plate is parallel with the plumb plate and constitutes a noodle channel; the lower end of the partition plate is fixedly connected with an electric push rod; a telescopic end of the electric push rod is detachably connected with a cutting knife; a horizontally arranged conveyor belt is arranged at the lower end part of the curved plate, and the conveyor belt is conveyed along one end away from the curved plate; an ultrasonic generating device is arranged on one side plate and corresponding to the lower end part of the curved plate, and the ultrasonic generating device emitsthe ultrasonic waves to the lower end part of the curved plate. Compared with the prior art, the noodle cutting machine cuts off noodles quickly, the cutting accuracy is high, the length of the cut noodles is uniform, the workload of staff is reduced, and the working efficiency is improved; and the noodles can be quickly cut and separated to avoid the situation that the tails of the noodles are stuck together, and to avoid waste and loss.

Owner:HUNAN JINLIN FOOD TECH

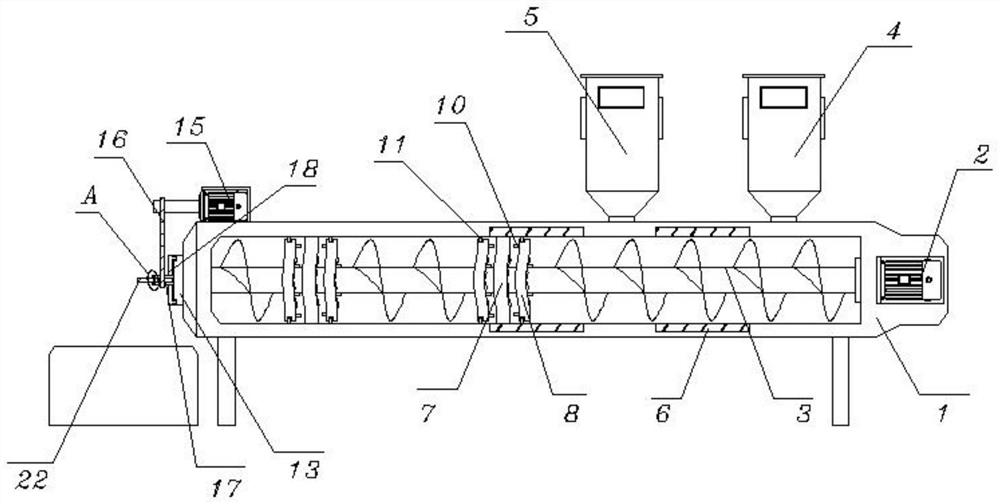

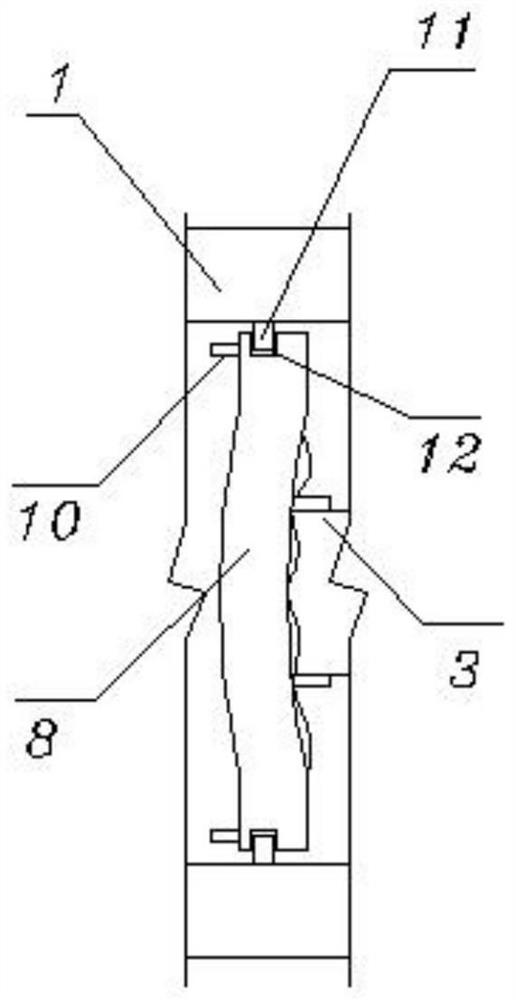

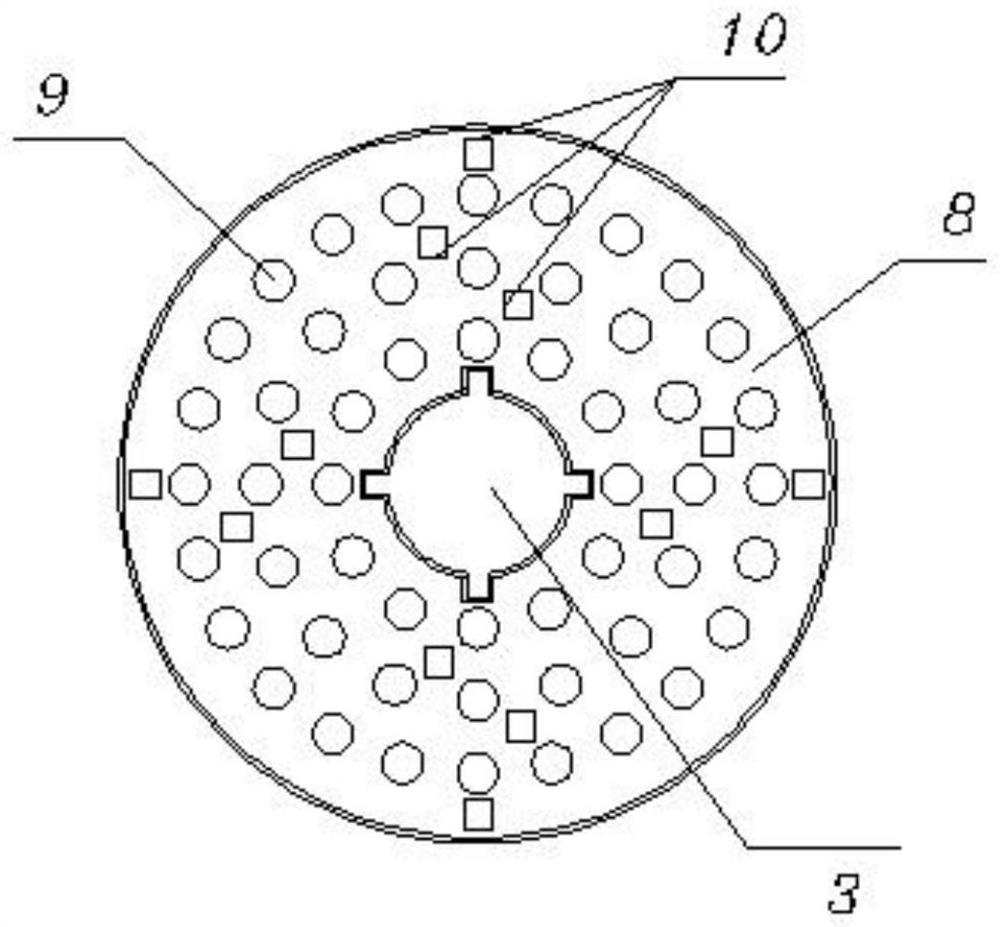

Extruder for manufacturing composite particles for efficiently shielding neutron gamma radiation

The invention discloses an extruder for manufacturing composite particles capable of efficiently shielding neutron gamma radiation, which comprises a rack, a first motor is mounted at one end of the rack in an embedded manner, and a first feed hopper and a second feed hopper are fixed at the top of the rack in a penetrating manner; the fixed material guide disc is fixed on the inner wall of the rack, uniform mixing holes are correspondingly formed in the fixed material guide disc and the movable material guide disc at equal angles, and a positioning rod is fixed on the inner wall of the rack; the extrusion disc is installed at the other end of the rack, a movable shaft is installed on a bearing on the outer side of the extrusion disc, a material cutting cover is fixed to the movable shaft, an inlet groove is formed in the side of the material cutting cover, and an airflow conveying pipe is installed at the side end of the movable shaft in a penetrating mode. According to the extruder for manufacturing the composite particles for efficiently shielding neutron gamma radiation, uniform mixing of materials is achieved, the forming effect is improved, meanwhile, single formed particles are rapidly cooled, and adhesion is avoided.

Owner:禾材高科(苏州)有限公司

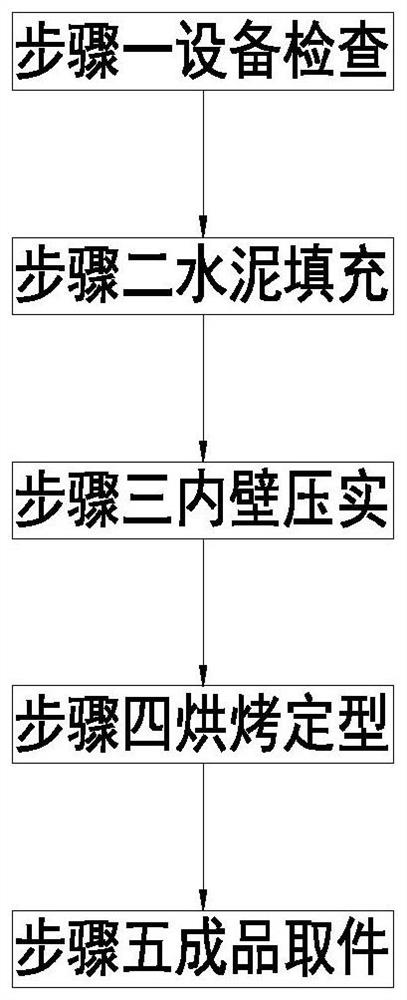

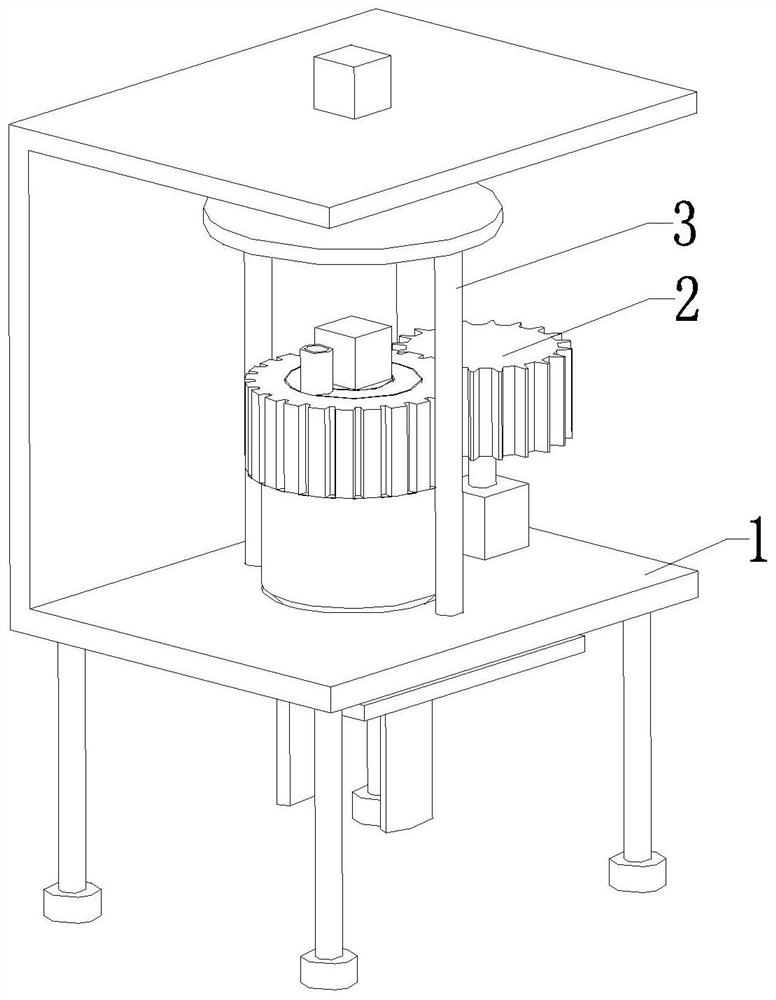

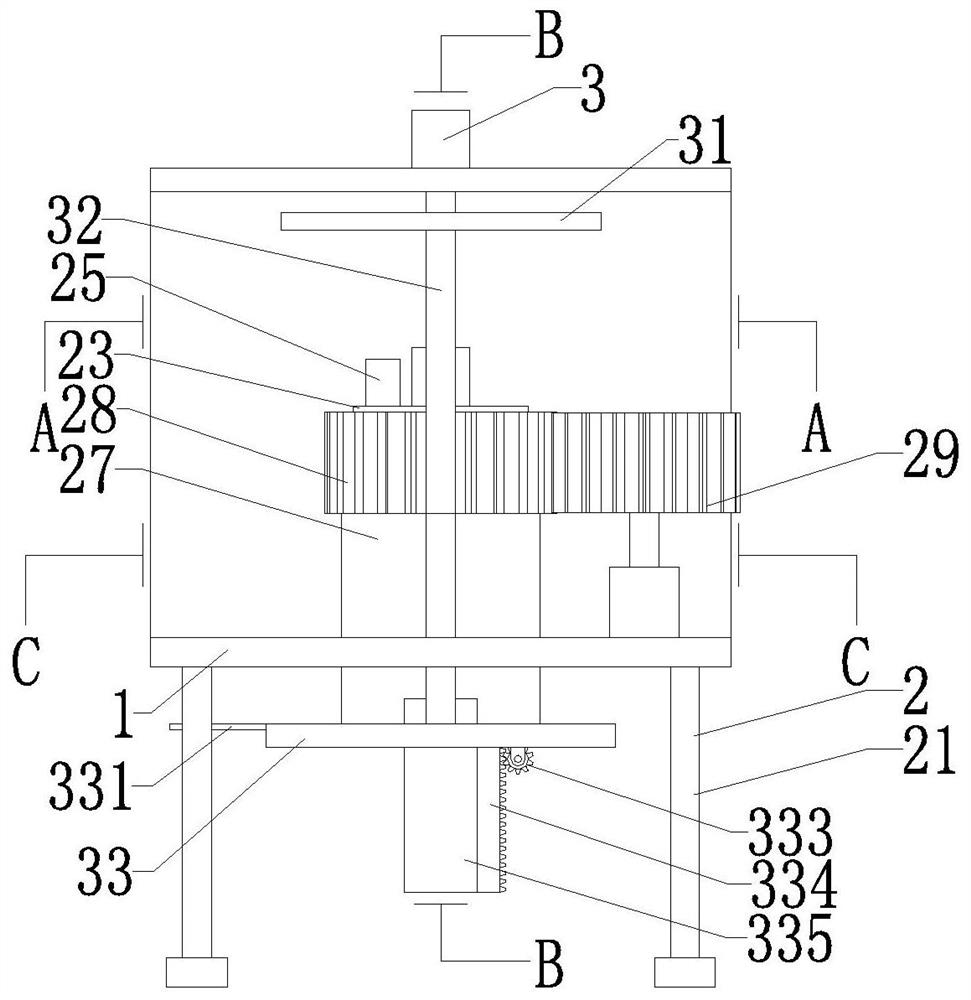

Sewage pipe forming and manufacturing method

InactiveCN112776164AIncrease drying speedImprove qualityCeramic shaping apparatusProcess engineeringSewage

The invention relates to a sewage pipe forming and manufacturing method. The sewage pipe forming and manufacturing method mainly comprises the following steps of equipment inspection, cement filling, inner wall compaction, baking shaping and finished product taking. Sewage pipe manufacturing equipment comprises a mounting frame, a forming suite and a discharging suite, wherein the forming suite is arranged on the mounting frame, the discharging suite is arranged at the upper end of the forming suite, and the discharging suite is arranged on the mounting frame. The sewage pipe forming manufacturing method can solve the following problems that when an existing sewage pipe is produced and prepared: a, when the existing sewage pipe is produced, shaping needs to be carried out through baking, but the circumstance that shaping is slow due to the fact that cement contains a large amount of water often occurs, and the production efficiency is influenced; and b, when the existing sewage pipe is produced by using the cement, the circumstance that the sewage pipe and a forming mold are adhered to each other often occurs, then demolding is difficult, and the production efficiency is influenced.

Owner:张凌云

Surface film coating treatment device and film coating method after ceramic tiles are formed

ActiveCN111003255BAvoid sticking togetherImprove efficiencyPackagingEngineeringMechanical engineering

Owner:戴志刚

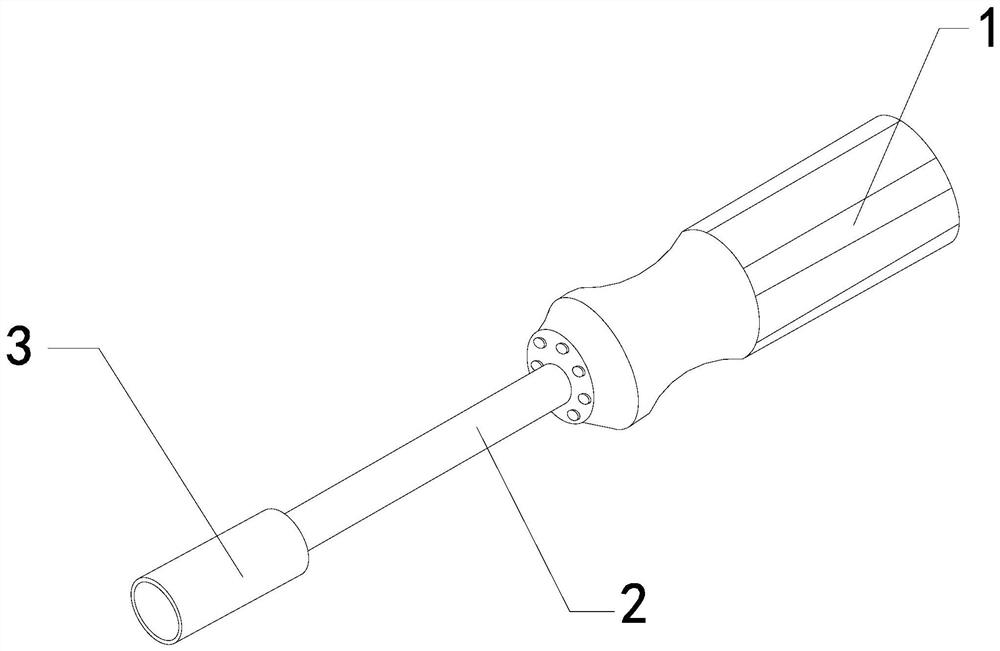

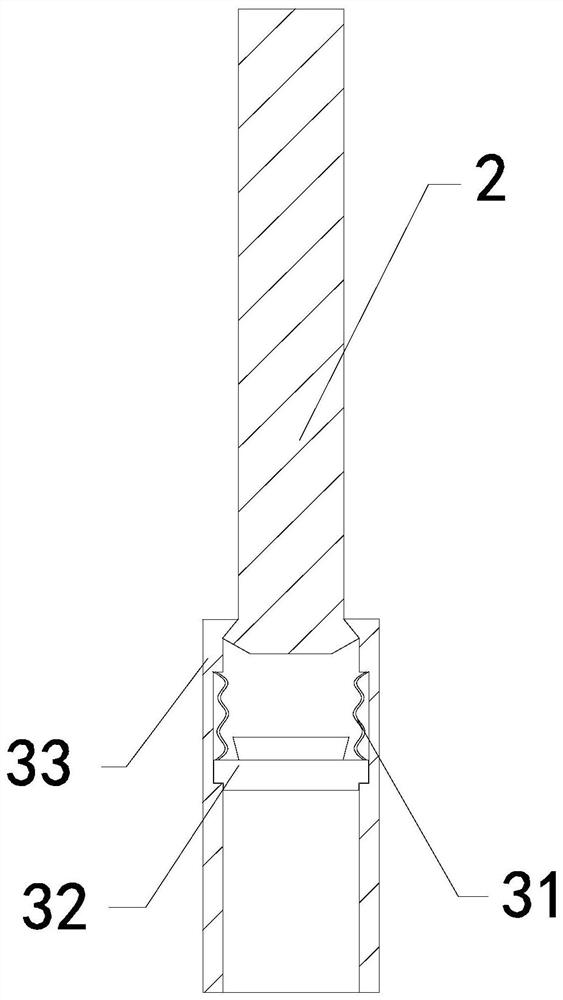

Rod-shaped piezoelectric material mounting equipment

InactiveCN112775896AAvoid sticking togetherAvoid situations where it is difficult to slide down to resetMetal-working hand toolsEngineeringSlide plate

The invention discloses rod-shaped piezoelectric material mounting equipment which structurally comprises a handle, a linkage rod and a press-in head. The linkage rod is embedded in the handle, the press-in head is welded to the bottom of the linkage rod, and when a pressed plate is attracted by voltage generated by the top of a rod-shaped piezoelectric material, the rod-shaped piezoelectric material pulls a downward extending plate, so that the downward extending plate extends out downwards along a bearing plate under the cooperation of an elastic sheet; electric charges between the rod-shaped piezoelectric material and the downward extending plate can be guided into an electric lead wire through a conductive block and then are guided out through the electric lead wire to be eliminated; and the electric charges on the pressed plate can be guided out to the two sides through a power connection strip by means of the cooperation of a lower push block and a sliding rod, and the top of the pressed plate can generate reverse thrust between two side sliding plates through the pressure generated by the weight of the lower push block on the top of the pressed plate, so that the side sliding plates can push the pressed plate away downwards.

Owner:谢美芬

Laser tape cutting machine for PCB tape cutting

PendingCN110919201AAvoid sticking togetherImprove cutting efficiencyLaser beam welding apparatusAdhesive beltReciprocating motion

The invention relates to a laser tape cutting machine for PCB tape cutting and belongs to the field of PCBs. The laser tape cutting machine comprises a rack. A first guide rail is arranged on the rack, and a moving mechanism is movably arranged on the first guide rail. The moving mechanism comprises a bottom plate movably arranged on the first guide rail. The bottom plate is in driving connectionwith a first driving mechanism arranged on the rack, and the first driving mechanism is used for driving the bottom plate to move along the first guide rail in a reciprocating manner. Supports are correspondingly arranged at the front end and the rear end of the bottom plate. A support plate used for containing the PCBs is arranged on each support. A rotating lifting mechanism is arranged on the rack. Laser cutters are arranged on the rack, and the laser cutters are located on the left side and the right side of the first guide rail. According to the laser tape cutting machine for PCB tape cutting, the laser is adopted to cut the adhesive tape on the PCBs, and compared with a mode of using a cutting blade for cutting the adhesive tape, by the adoption of the laser tape cutting machine, a blade does not need to be replaced, the cutting efficiency is improved, the situation that the adhesive tape cannot be cut off is avoided, and the cutting quality and the cutting efficiency can be improved effectively.

Owner:HUIZHOU CHENGTAI AUTOMATION TECH CO LTD

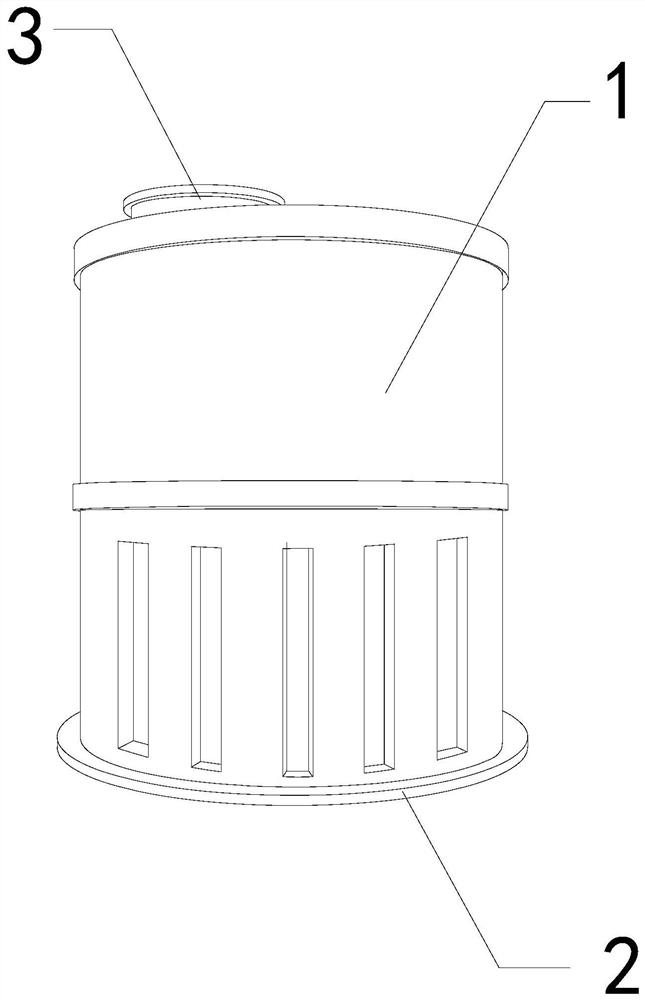

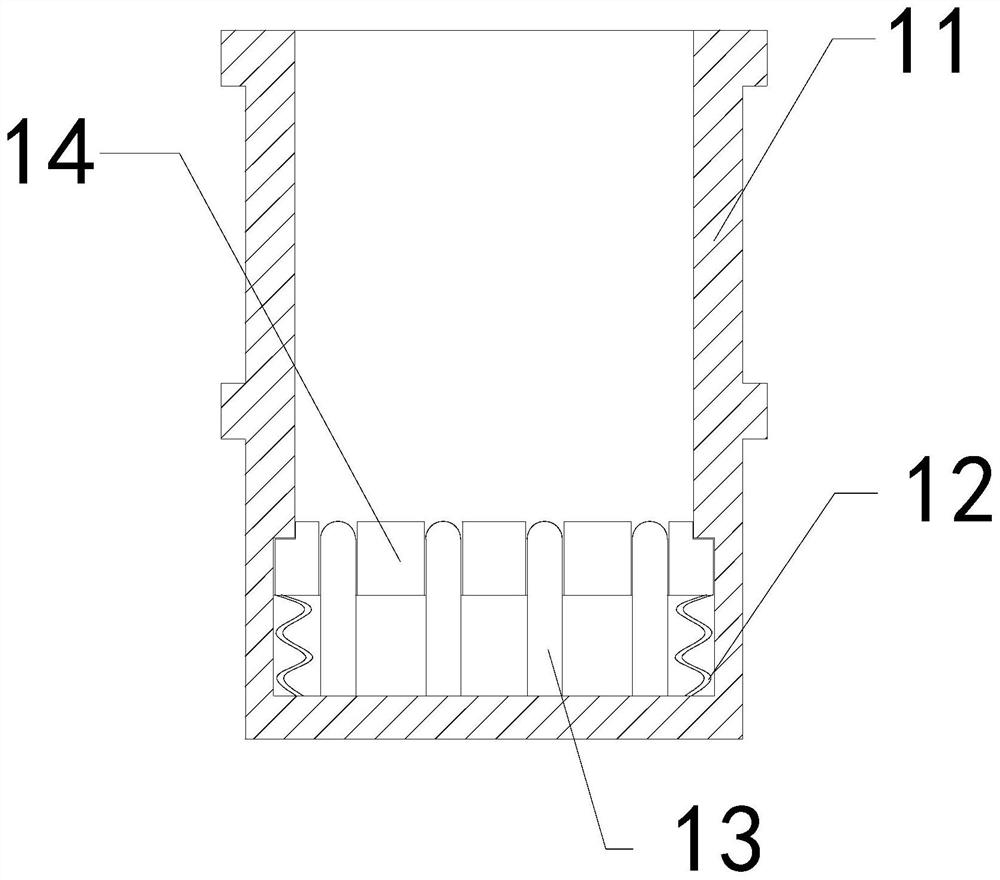

Storage equipment for polypropylene

InactiveCN112373896AAvoid sticking togetherSpeed up heat dissipationExternal fittingsInternal fittingsThermodynamicsEngineering

The invention discloses a storage device for polypropylene. The storage device for the polypropylene structurally comprises a storage barrel, a base and a feeding port, wherein the feeding port is fixedly embedded in the upper end of the storage barrel; and the storage barrel is welded to the base. A middle fixing rod drives a contact plate to rotate to generate throwing force, separation blocks can scatter polypropylene particles adhered to a bottom layer in the storage barrel along with the rotation of the middle fixing rod, so that the situation that the polypropylene particles at the bottom layer in the storage barrel are adhered together due to heat which cannot be dissipated in time is effectively avoided; and through the thrust of the inner wall of a frame against a flow increasingplate, the flow increasing plate can contract inwards along a built-in ring under the cooperation of a transition rod, and then the flow increasing plate can stretch out and draw back repeatedly through the cooperation of elastic pieces, so that the heat dissipation speed of heat on a bearing plate can be increased through airflow generated by the flow increasing plate, and the situation that thepolypropylene particles are adhered together again due to the heat of the polypropylene particles is effectively avoided.

Owner:钱立超

Fine dried noodle tabletting equipment

InactiveCN113575631AAchieve extrusionRealize integrated automatic operationDough-sheeters/rolling-machines/rolling-pinsDough processingStructural engineeringTransfer mechanism

The invention aims to provide fine dried noodle tabletting equipment, which comprises a rack, a tabletting box, a conveying mechanism, a transferring mechanism, a hanging rod frame and a plurality of hanging rods. A material groove and a discharging channel located below the material groove are formed in the tabletting box, and the material groove is communicated with the discharging channel; two opposite tabletting rollers are rotationally mounted at the joint of the material groove and the discharging channel, and a gap for extruding dough sheets is formed between the two tabletting rollers; the conveying mechanism is arranged below the tabletting box, the transferring mechanism is arranged between the discharging side of the conveying mechanism and the hanging rod frame and used for conveying the hanging rods in an inclined mode from bottom to top, a powder storage cavity surrounding the circumferential side of the tabletting rollers is further formed in the tabletting box, and a powder feeding groove communicated with the powder storage cavity is fixedly formed in the outer side of the tabletting box; the conveying mechanism comprises a conveying belt and two conveying rollers, the two conveying rollers are rotationally arranged on the rack, and the conveying belt is horizontally arranged and wound between the two conveying rollers.

Owner:安徽省蒙城县恒瑞面粉有限公司

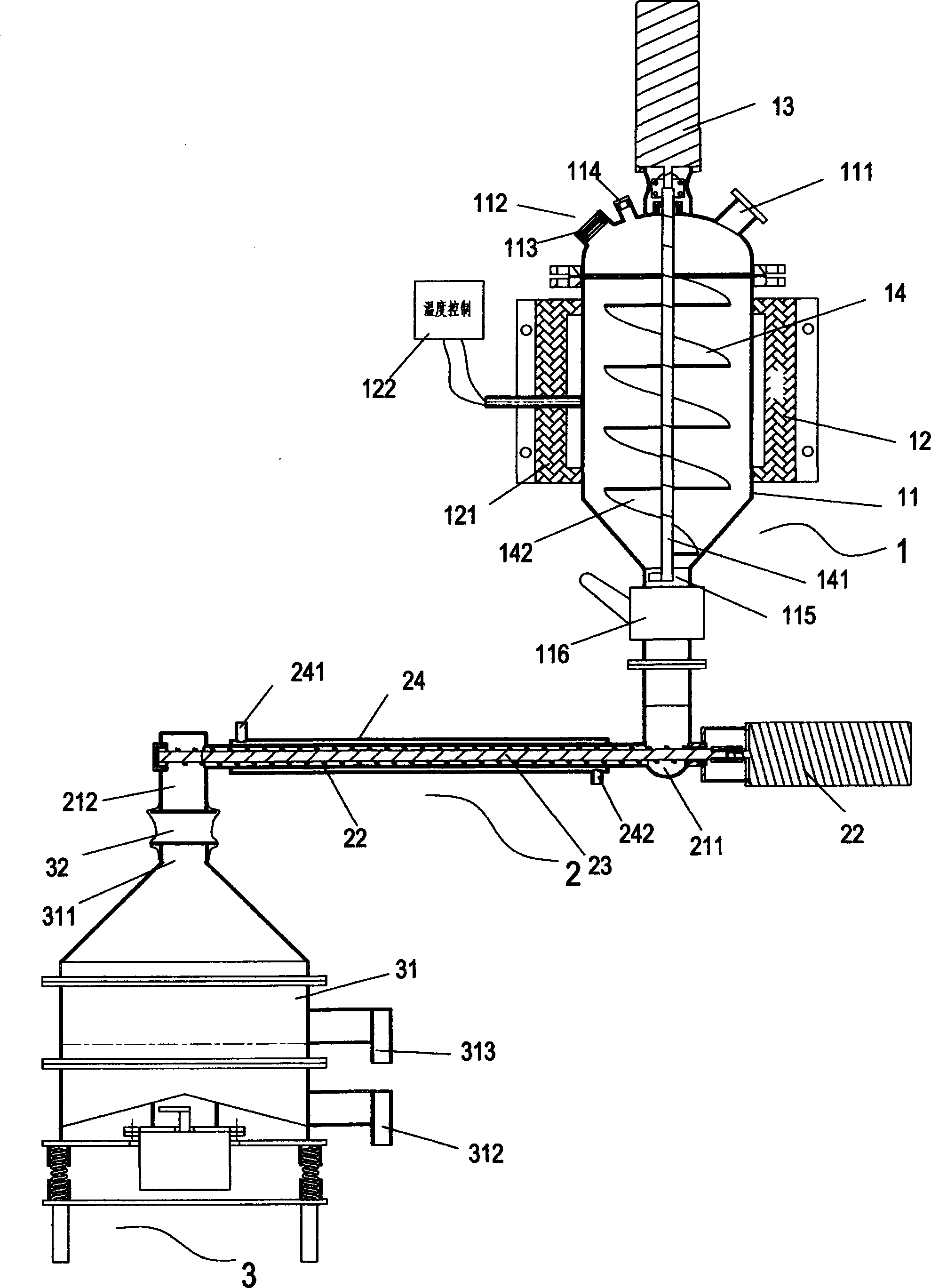

Equipment for producing inorganic matter fine particle-coated plastic particles

The invention relates to plastic modification production equipment, in particular to equipment for producing inorganic matter fine particle-coated plastic particles. The equipment comprises a reaction device for coating inorganic matter fine particles outside plastic particles, a cooling device for cooling inorganic matter fine particles and the inorganic matter fine particle-coated plastic particles, and a screening device for screening the inorganic matter fine particles and the inorganic matter fine particle-coated plastic particles, wherein the discharging hole of the reaction device is connected with the inlet of the cooling device; and the outlet of the cooling device is connected with the feeding hole of the screening device. By cooling the inorganic matter fine particles and the inorganic matter fine particle-coated plastic particles and screening the inorganic matter fine particles and the inorganic matter fine particle-coated plastic particles, hot inorganic matter fine particle-coated plastic particles are prevented from being attached to a screen mesh of a vibration screen, and the screened inorganic matter fine particle-coated plastic particles are prevented from being bonded together simultaneously.

Owner:SHENZHEN HALCYON NEW MATERIALS +1

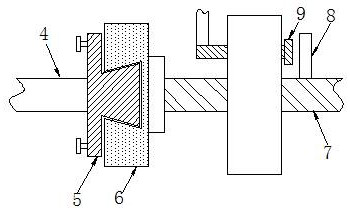

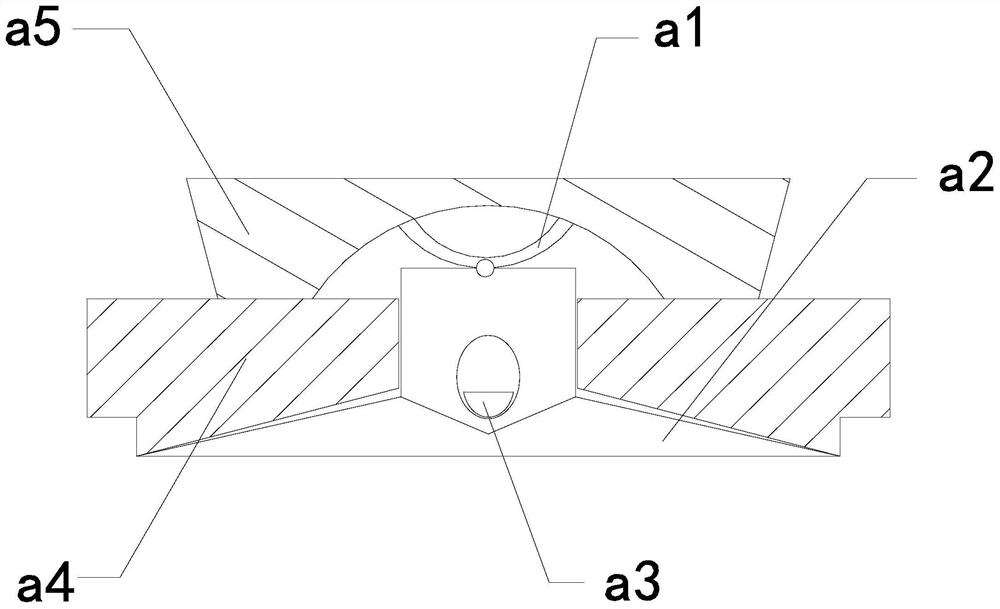

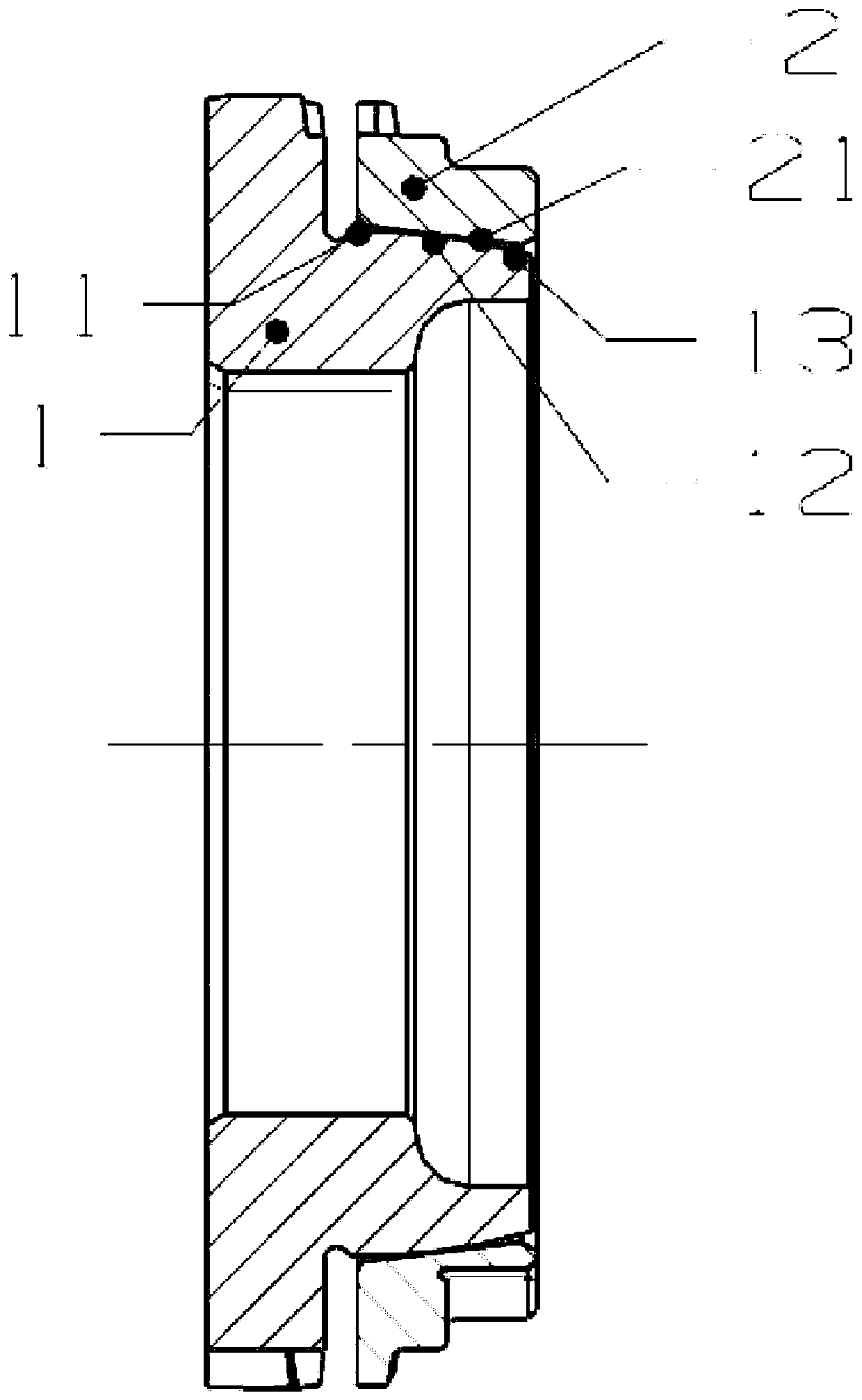

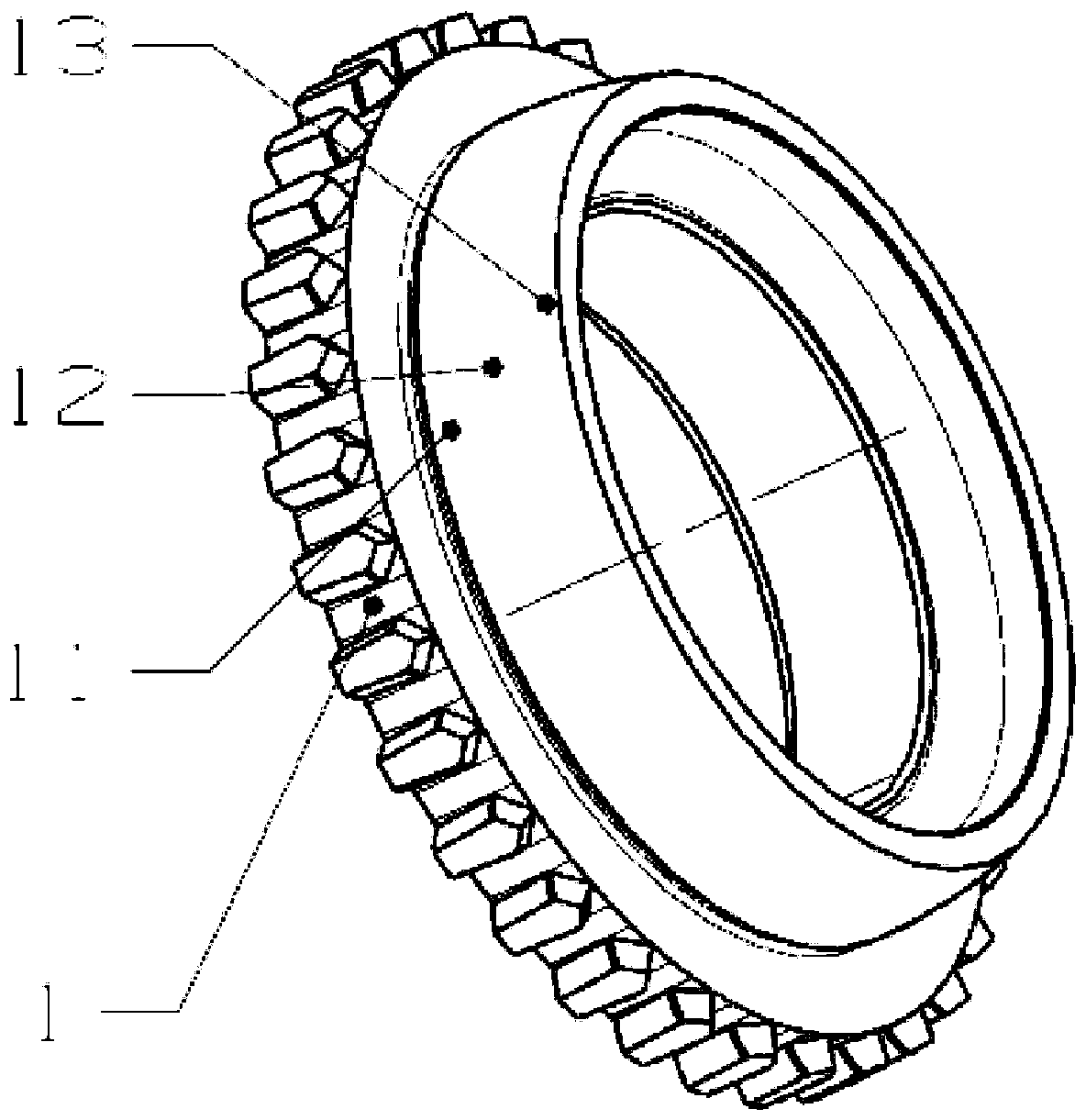

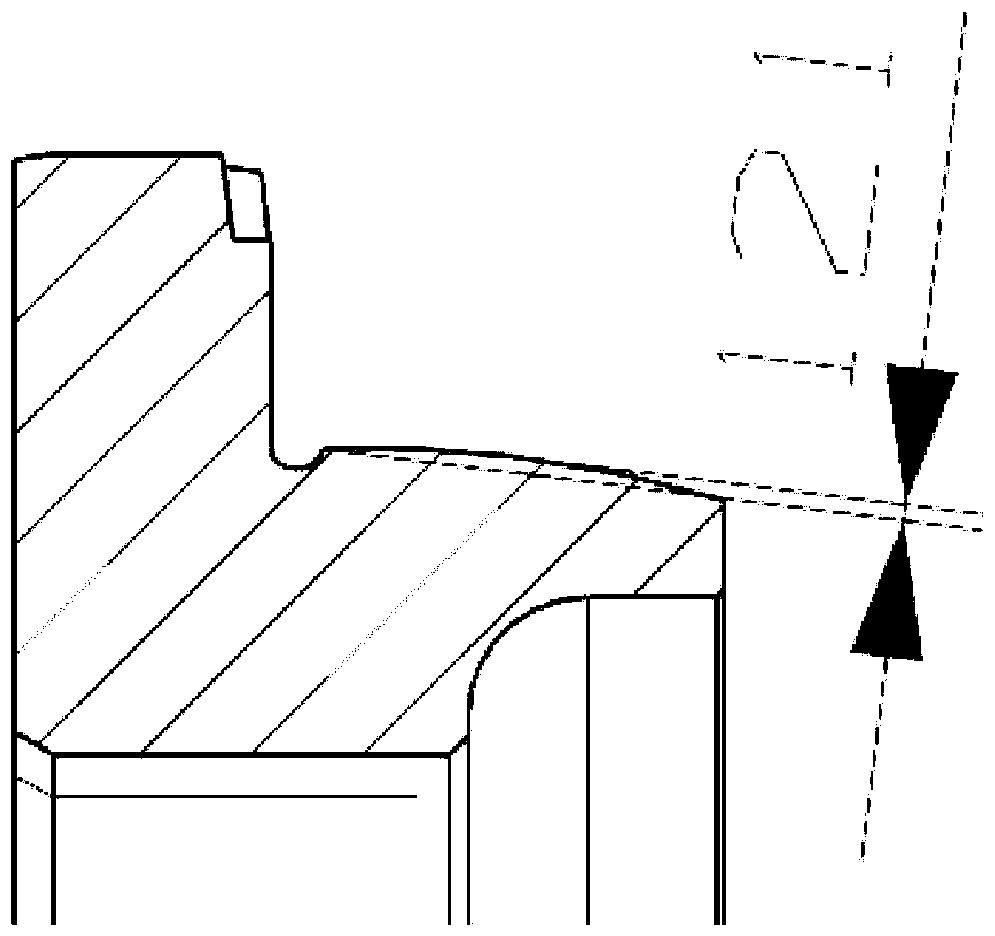

Matched structure of synchronous ring and joint gear ring of automobile manual transmission

PendingCN109780170AGood friction fitSimple structureMechanical actuated clutchesPortable liftingEngineeringMechanical engineering

The invention relates to a matched structure of a synchronous ring and a joint gear ring of an automobile manual transmission. The matched structure comprises the joint gear ring and the synchronous ring; the joint gear ring comprises an axially-extending outer conical friction part; the synchronous ring comprises an inner conical friction surface; the synchronous ring moves axially to enable theinner conical friction surface and the outer conical friction part of the joint gear ring to be in friction jointing or separated; the matched structure is characterized in that the part between the large end and the small end of the axial section of the outer conical friction part of the joint gear ring is bent in an arc shape, a drum-shaped friction surface is formed, and the height of connecting lines between the arc top of the drum-shaped friction surface and the large end and between the arc top and the small end ranges from 0.03 mm to 0.05 mm. The friction jointing of the synchronous ring and the joint gear ring is stable and smooth, the synchronous ring and the joint gear ring are easy to separate and unlink, noises are reduced, and the use comfort level is increased.

Owner:CHONGQING TSINGSHAN IND

A multi-paper scanning device for emotional recognition of characters in film and television scripts

ActiveCN109151248BEliminate static electricityImprove entry qualityPictoral communicationEngineeringEmotion identification

Owner:XIAN UNIV OF FINANCE & ECONOMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com