Matched structure of synchronous ring and joint gear ring of automobile manual transmission

A technology for manual transmissions and ring gears, applied to components with teeth, mechanically driven clutches, clutches, etc., can solve problems such as increasing transmission failure frequency, synchronous ring fracture failure, and increasing ring release force, so as to avoid fracture failure , increase the comfort of use, reduce the effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

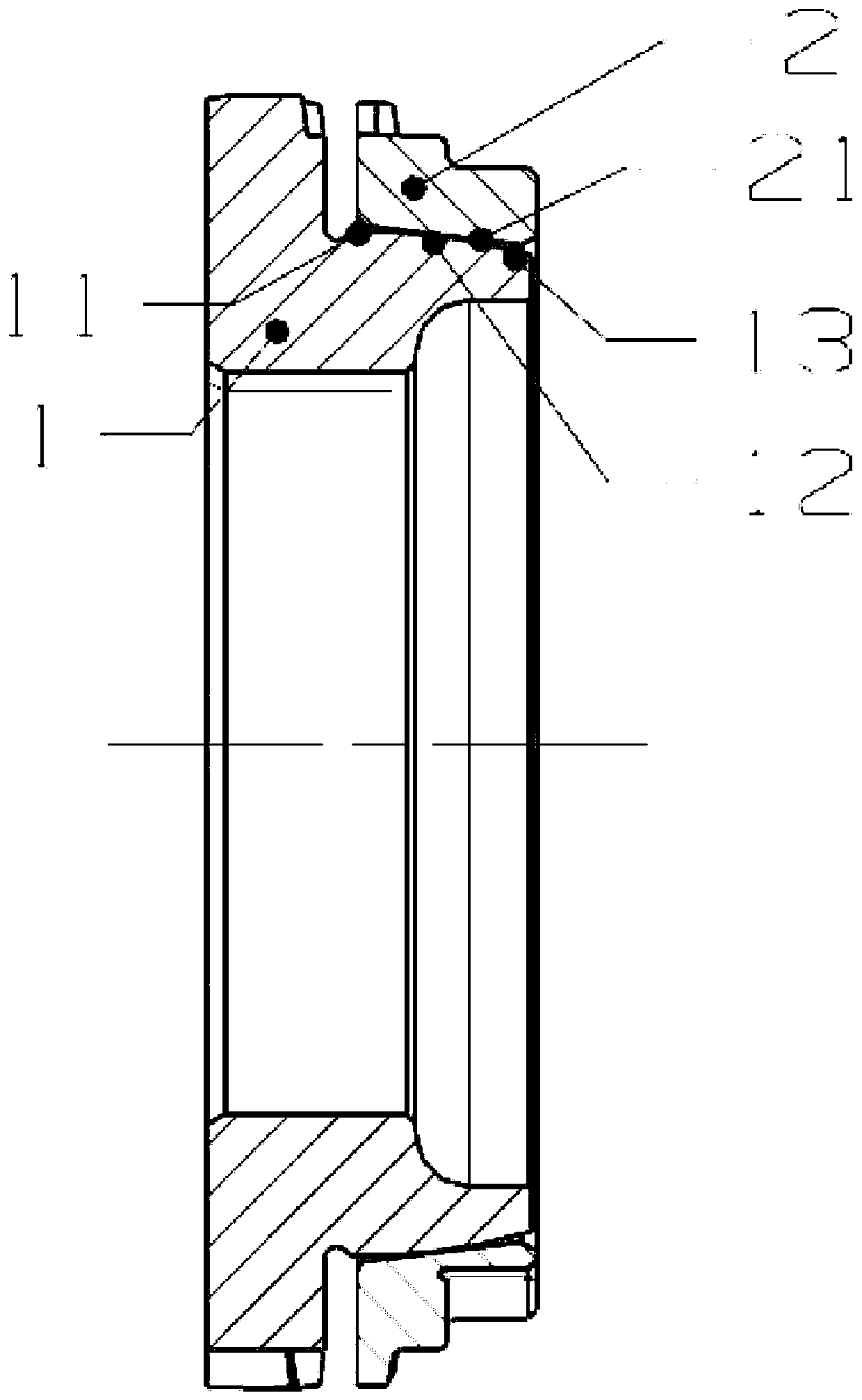

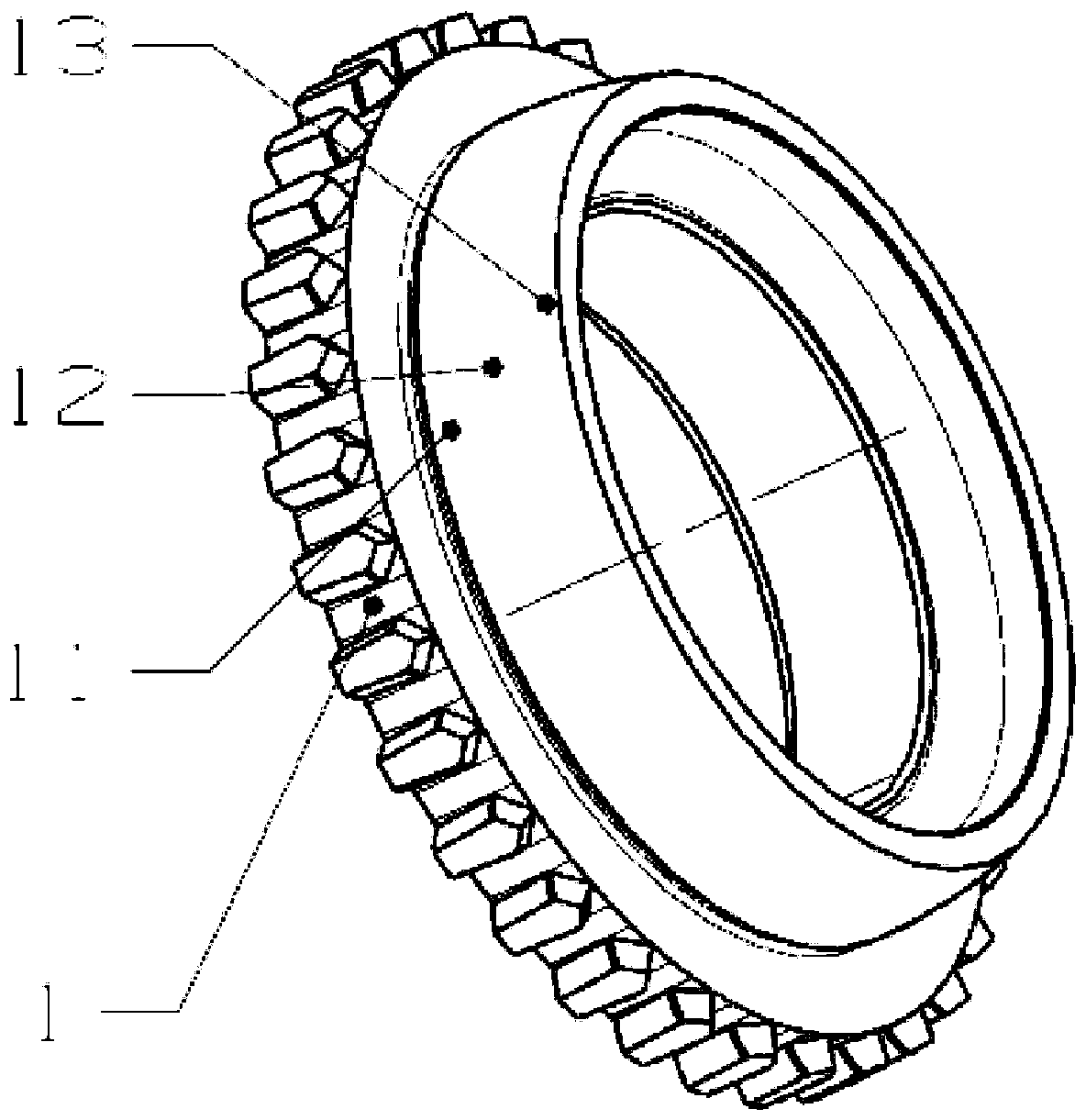

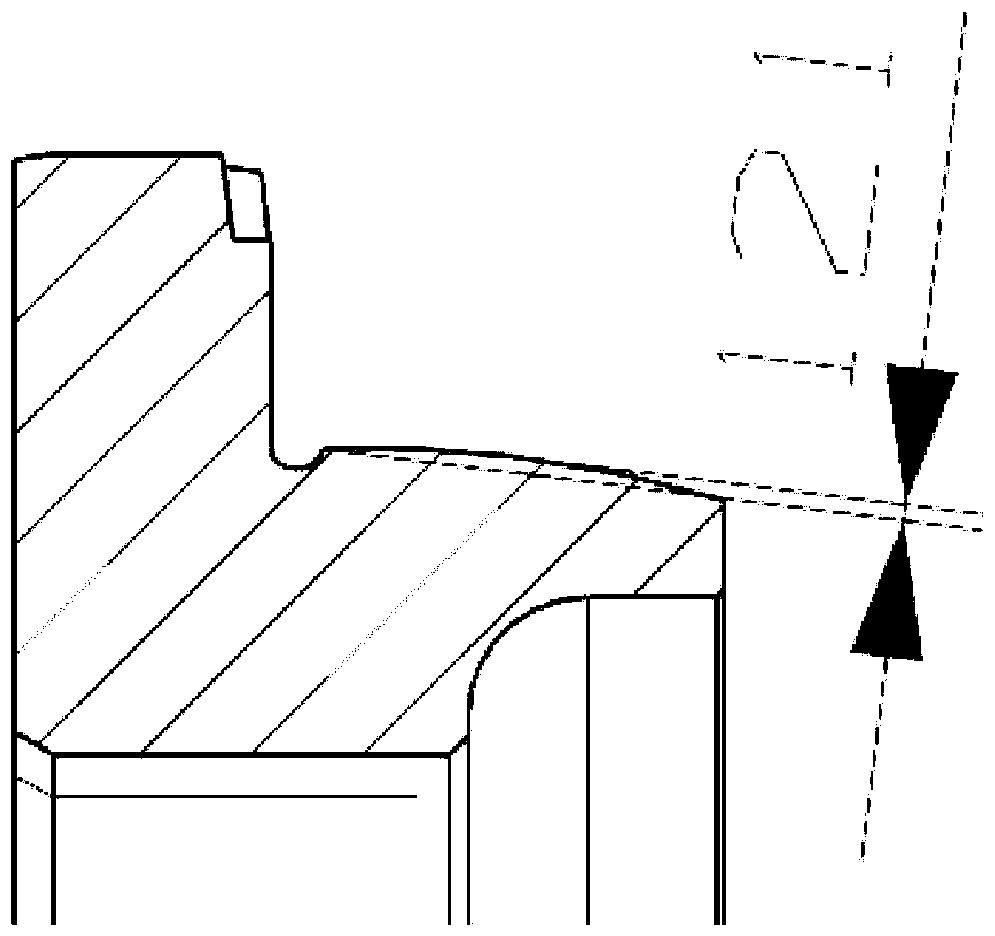

[0014] see Figure 1 to Figure 3 , a matching structure of a synchronous ring and an engaging ring gear of an automobile manual transmission, comprising an engaging ring gear 1 and a synchronizing ring 2, the engaging ring gear 1 has an axially extending outer cone friction part, and a small end 13 of the outer cone friction part for the extension. The synchronous ring 2 has an inner cone friction surface 21 , and the inner cone friction surface 21 is frictionally engaged or separated from the outer cone friction part of the engaging ring gear 1 by moving the synchronous ring 2 axially. The taper of the inner cone friction surface 21 of the synchronous ring 2 is the same as the taper of the outer cone friction part of the engaging ring gear 1 . The same taper will make the synchronous ring 2 and the engaging ring gear 1 have a better friction fit. The large end 11 to the small end 13 of the axial section of the outer tapered friction part of the engagement ring gear 1 is cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com