Needle shield remover

A needle shield and shield technology, which is applied in the field of needle shield removers, can solve the problems of difficult grip, complicated manufacturing and assembly, change in grip ability, etc., and achieve the effect of good friction fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

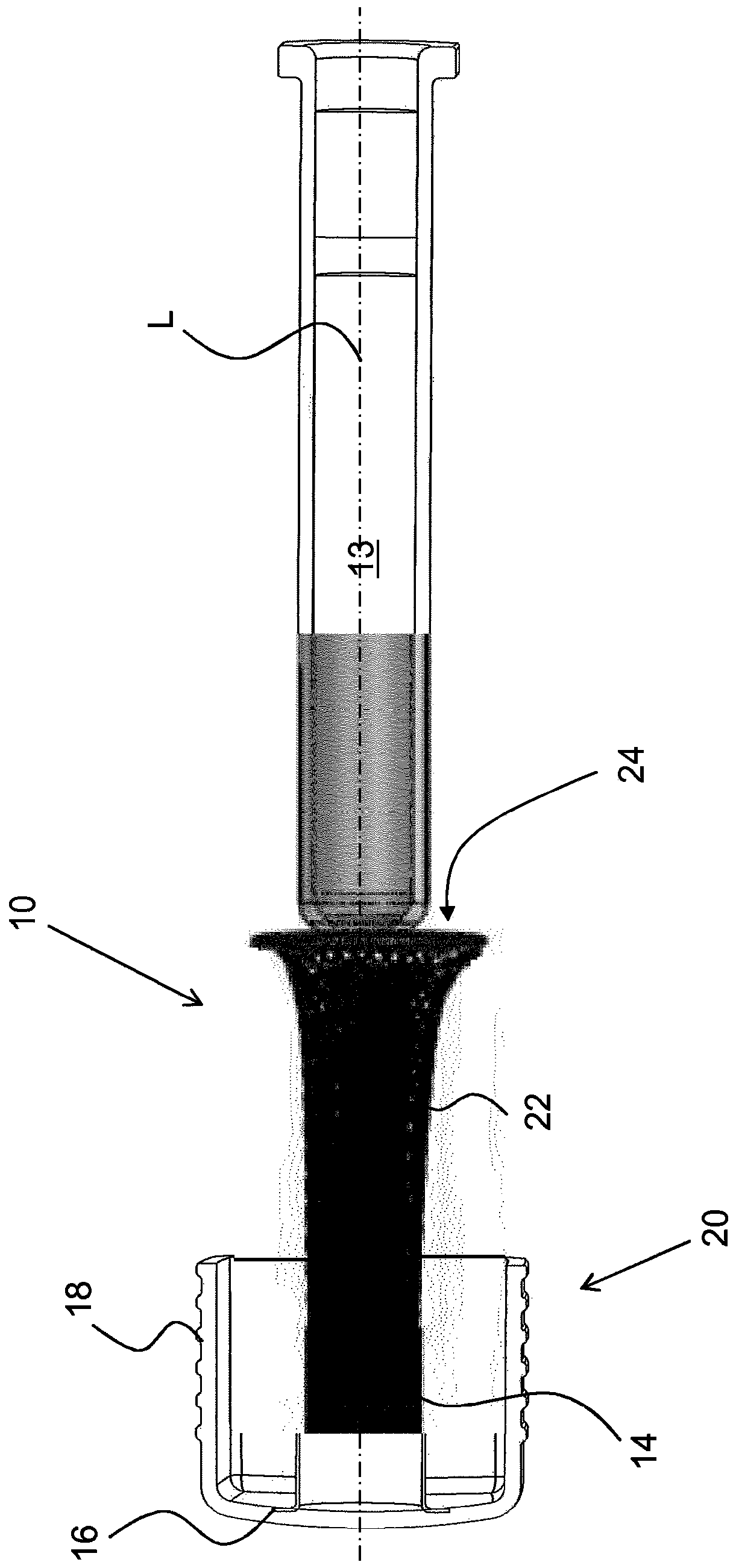

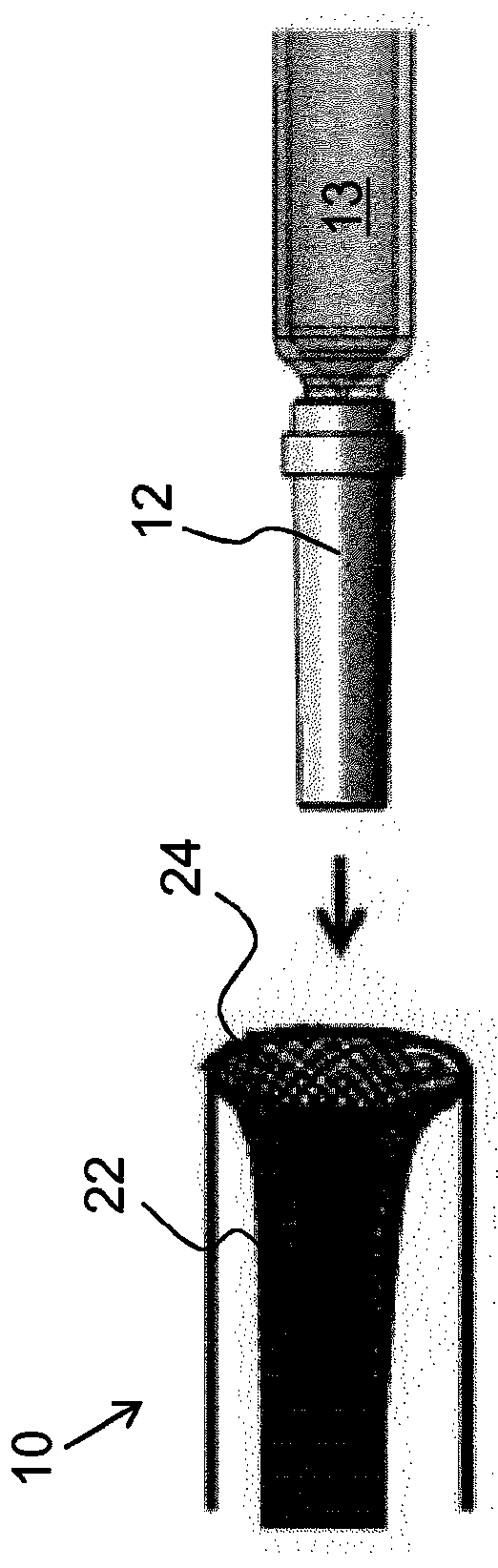

[0014] The present disclosure relates to a needle shield remover 10 for use, for example, in conjunction with a medicament delivery device. Before using the medicament delivery device, the injection needle 11 of the medicament container 13 ( figure 1 and FIG. 2 ) are protected by a needle shield 12, usually a so-called flexible needle shield (or FNS) or a rigid shield remover (or RNS). In this regard, the FNS is made of a soft elastic material, such as rubber, and the RNS is provided with a shell or housing made of a rigid material. In order to inject, the needle shield must be removed. In this regard, the medicament delivery device is provided with a needle shield remover 10 ( figure 1 ).

[0015] In the embodiment shown in the figures, the needle shield remover 10 includes a generally tubular body 14 extending in a longitudinal direction L ( figure 1 ). At the distal end of the main body 14 there may be provided an attachment element 16 which may be designed to cooperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com