A method for manufacturing non-combustible cigarettes based on flocking technology

A non-combustible, flocking technology, applied in the manufacture of cigarettes, tobacco, applications, etc., can solve the problems of insufficient heating, weak tobacco taste, and high hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for manufacturing non-combustible cigarettes based on flocking technology, the method includes a flocking process and a cigarette rolling process; wherein, the flocking process sequentially includes a cloth rolling step, a gluing step 8, and a flocking step , drying step 9, washing step 10. The flocking step adopts an electrostatic flocking method.

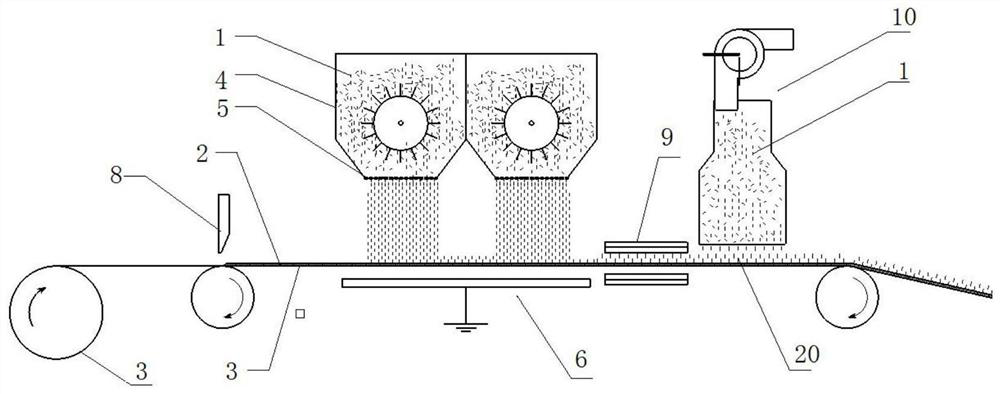

[0049] Such as figure 1 As shown, the specific operations of each step of the flocking process are as follows:

[0050] The cloth rolling step: place 3 rolls of cigarette paper in the paper feeding system;

[0051] The gluing step 8: spraying the adhesive 2 on the inner surface of the cigarette paper 3;

[0052] The flocking step: embedding and fixing the tobacco filler 1 in the adhesive 2 coated on the inner wall of the cigarette paper 3 of the cigarette;

[0053] The drying step 9: drying and curing the adhesive 2 on the surface of the cigarette paper 3 flocked with the tobacco filler 1 at a certain temperatu...

Embodiment 2

[0064] A method for manufacturing non-combustible cigarettes based on flocking technology, the only difference from Example 1 is that the flocking step adopts mechanical flocking.

[0065] The equipment used in the mechanical flocking step can use existing suitable mechanical flocking equipment, and only adjust the mechanical and electrical parameters of the equipment according to the characteristics of the cigarette paper and tobacco filler.

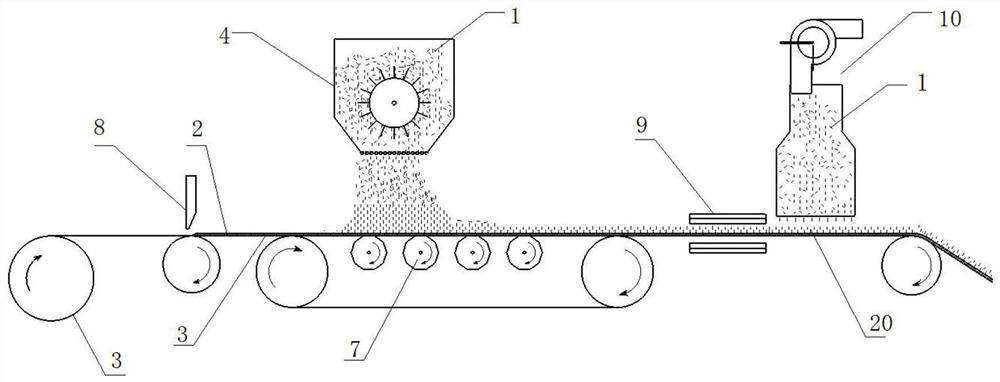

[0066] The specific operation is as follows:

[0067] The cigarette paper 3 coated with the adhesive 2 is passed over a set of polygonal rollers 7 which rotate rapidly to vibrate the cigarette paper 3 and drive the tobacco filler 1 into the adhesive 2 . The tobacco filler 1 is applied to the cigarette paper 3 from a hopper 4 by gravity. The tobacco filler 1 is adhered to the surface of the cigarette paper 3 to form a densely packed flocking layer 20 .

[0068] figure 2 It is a process flow diagram of the flocking process in a method...

Embodiment 3

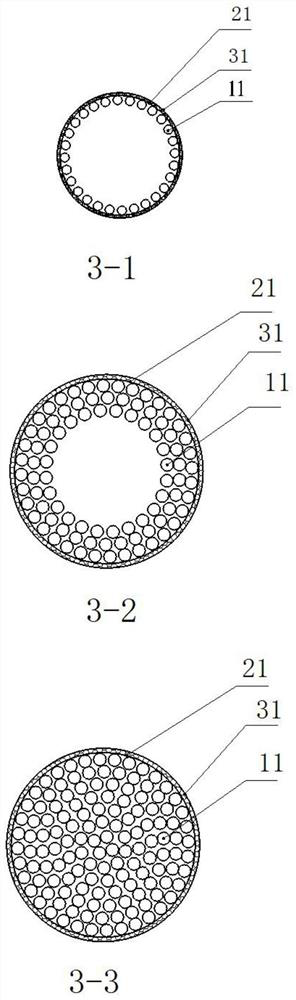

[0070] Such as image 3 3-1 is a radial cross-sectional view of a tobacco segment of a non-burning cigarette manufactured using the manufacturing method of Example 2 of the present invention. The cigarette rod comprises a tobacco segment including the cigarette paper layer 31 wrapped in the outermost periphery. The cigarette paper layer 31 is a hollow cylindrical structure, and the inner wall of the cigarette paper layer 31 is provided with an adhesive layer 21 , and the tobacco filler particles 11 are fixedly bonded to the adhesive layer 21 . The tobacco filler particles 11 are circumferentially arranged along the inner wall of the cigarette paper layer 31 to form a tobacco filler particle layer, the number of the tobacco filler particle layer is one layer, and the number of the binder layer is one layer . The inside of the cigarette paper layer 31 is filled with the tobacco filler particles 11 to be hollow. The adhesive layer 21 is formed by coating the adhesive 2 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com