Equipment for producing inorganic matter fine particle-coated plastic particles

A technology of plastic particles and inorganic substances, which is applied in the field of equipment for producing inorganic particles to coat plastic particles, can solve problems such as inability to meet the requirements, and achieve the effects of convenient operation, simple structure and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

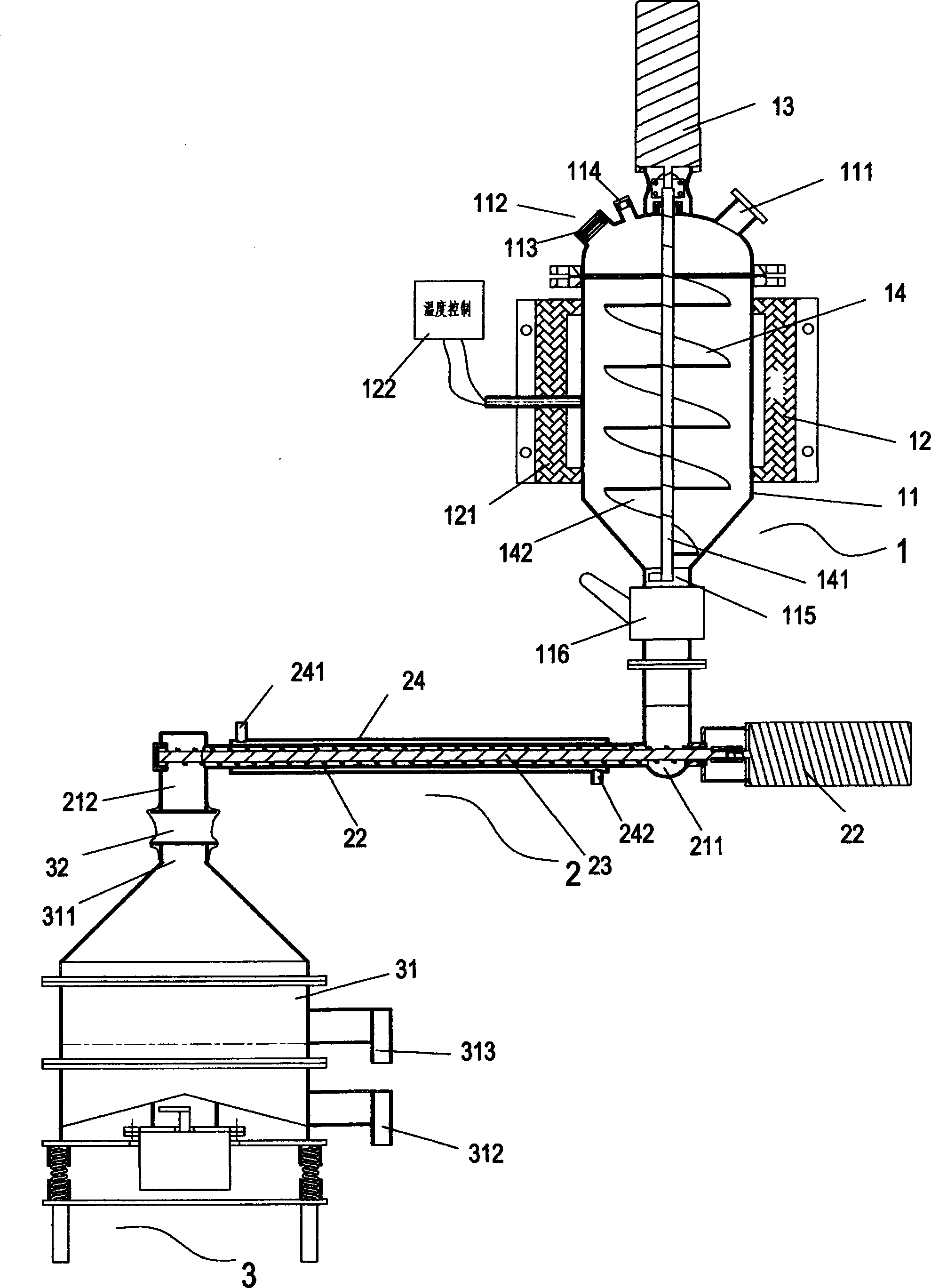

[0029] Such as figure 1 As shown, a device for producing plastic particles coated with inorganic particles, the device includes a reaction device 1 for wrapping inorganic particles outside plastic particles, cooling inorganic particles and plastic particles coated with inorganic particles The cooling device 2 and the screening device 3 for screening inorganic particles and plastic particles coated with inorganic particles.

[0030] Described reaction device 1 comprises a cylindrical material cylinder 11 that is placed upright, the infrared heater 12 that is positioned at material cylinder and is driven by a motor 13 that is arranged on the outside material cylinder and is positioned at the stirrer 14 in material cylinder; The upper part is provided with the first feed port 111 for adding inorganic particles and the second feed port 112 for adding plastic particles, and the second feed port adopts the explosion-proof film of glass material after adding the plastic particles 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com