Sewage pipe forming and manufacturing method

A manufacturing method and technology of sewage pipes, which are applied to ceramic molding machines and manufacturing tools, etc., can solve problems such as affecting production efficiency, difficulty in demoulding, and slow shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

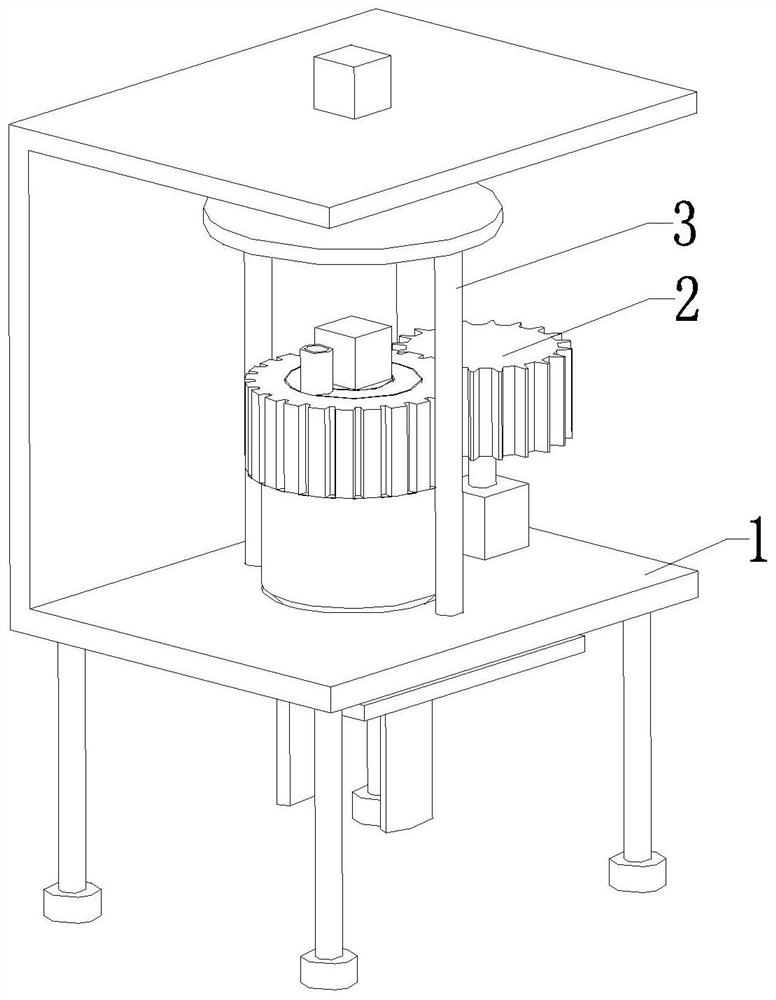

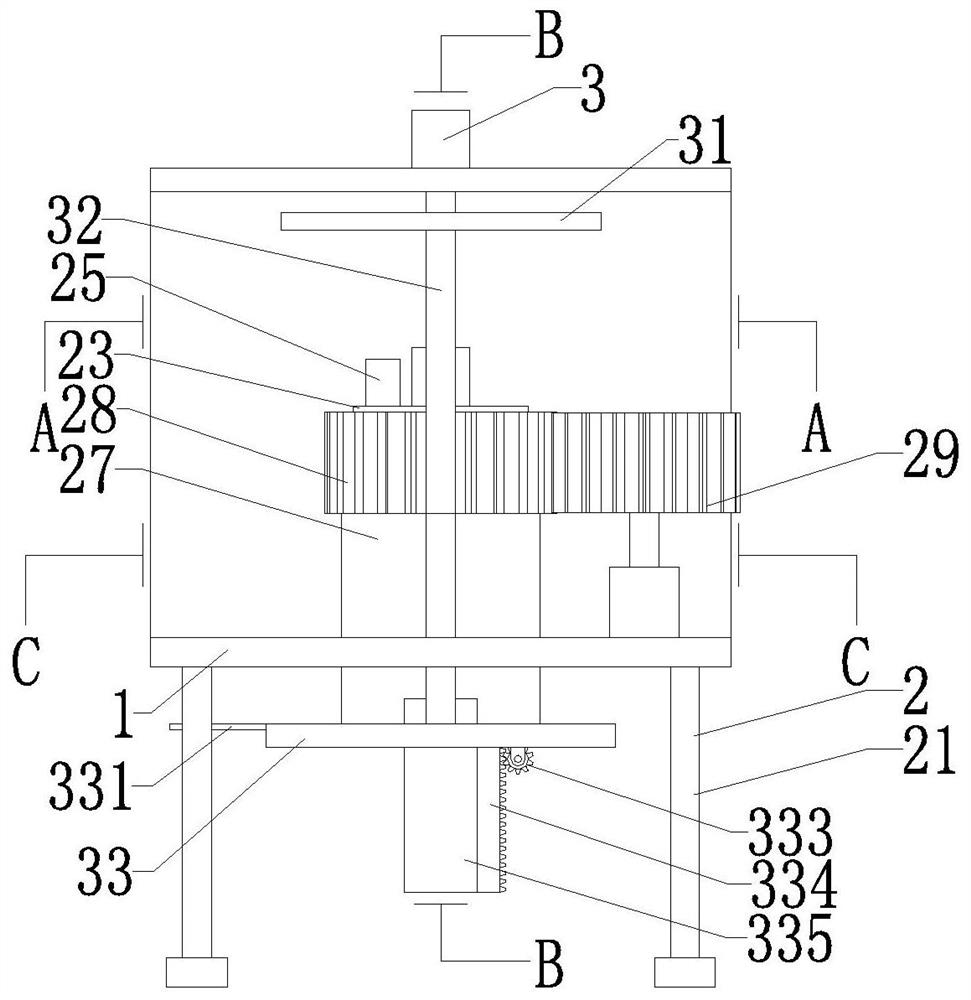

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

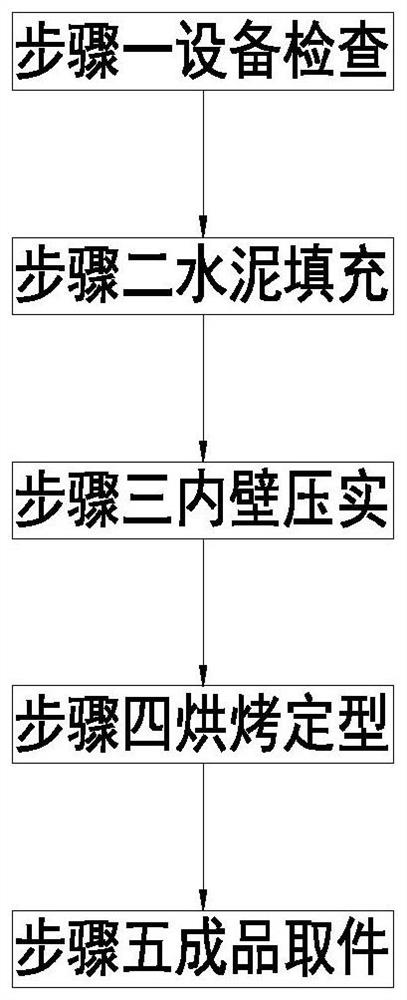

[0030] like Figure 1 to Figure 6 As shown, a manufacturing method for forming a sewage pipe mainly includes the following steps:

[0031] Step 1: Equipment inspection: before using the sewage pipe manufacturing equipment to prepare sewage pipes, check the operation of the equipment;

[0032] Step 2: Cement filling: Manually inject cement between the rotating outer cylinder 22 and the inner wall cylinder 26 through the feeding pipe 25, so as to complete the purpose of cement filling;

[0033] Step 3: Compaction of the inner wall: After completing the cement filling operation in step 2, the No. 1 motor works to drive the inner wall cylinder 26 to work, and rolls the inner wall of the cement to make the inner wall of the cement smooth, and through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com