Heat pump drying device

A technology of heat pump drying and drying oven, which is applied in the direction of drying gas arrangement, drying solid materials, local agitation dryers, etc. It can solve the problems of temperature, humidity and wind speed requirements difference, increase energy consumption, reduce product quality and other problems, and achieve improvement Effect of drying quality, improving drying speed, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

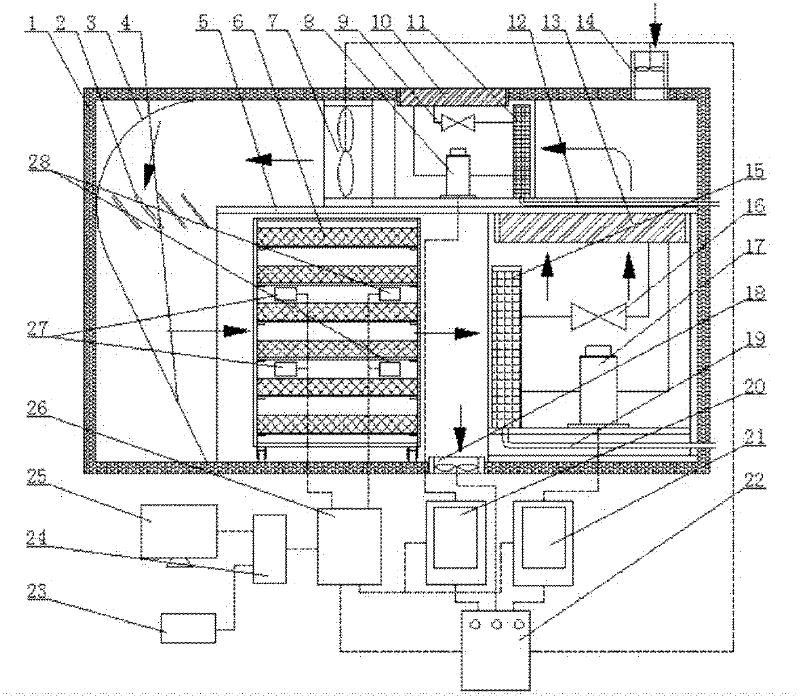

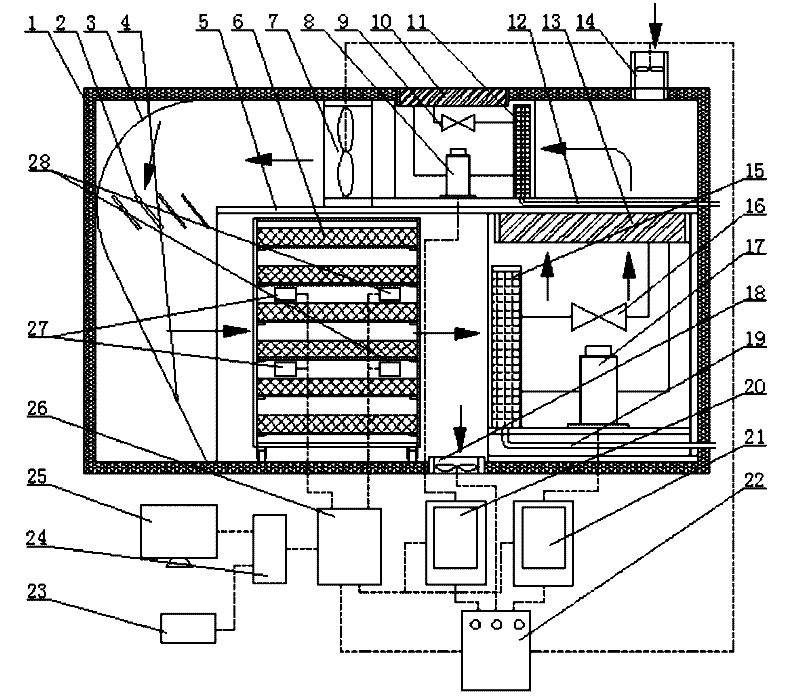

[0021] like figure 1 As shown, the heat pump drying device of the present invention includes a drying box and a control system. The drying box includes a housing 1 and an air inlet fan 14 disposed in the housing 1, a dehumidification heat pump, a main fan 7, a material rack 6, an exhaust air Air blower 18 and heating heat pump. Air inlet fan 14, dehumidification heat pump, main fan 7, air outlet fan 18, and heating heat pump are all connected with the control system. The top of the casing 1 is provided with an air inlet, and the air inlet fan 14 is located in the air inlet. The dehumidifying heat pump and the main fan 7 are arranged on the upper part of the housing 1, separated from the material rack 6 and the heating heat pump arranged on the lower part of the housing 1 by a partition 5. The upper part of the housing 1 is provided with an arc-shaped baffle 3 perpendicular to the front and rear surfaces of the housing in the direction facing the exhaust outlet of the main fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com