Frying bleaching device and frying bleaching method for jeans

A technology of frying and bleaching jeans, which is applied in the field of jeans production, can solve problems such as shrinkage, wrinkles in jeans, uneven background color, etc., and achieve the effects of reducing pollution, strong three-dimensional effect, and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

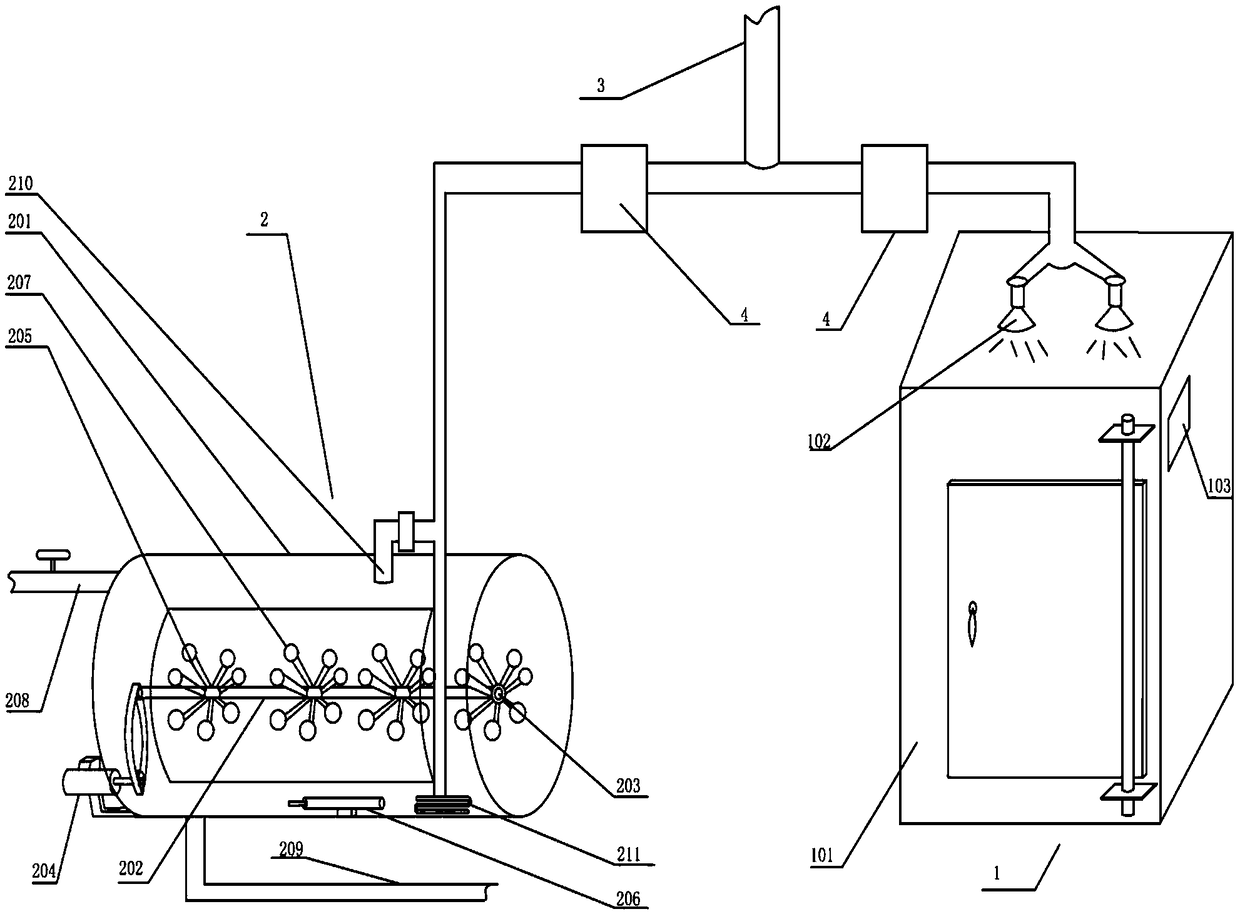

[0034] refer to figure 1 , a jeans frying and bleaching device, comprising a distillation device 1 and a tumbling device 2, the distillation device 1 includes a distillation cylinder 101 connected to a steam pipe 3, the top surface of the distillation cylinder 101 is provided with a steam nozzle 102, and the steam nozzle is opposite to the distillation cylinder 101 The jeans inside are heated in advance to allow it to shrink in advance, so as to prevent wrinkles from being heated in the tumbling device 2 and affect the quality of beating and running-in. The distillation cylinder 101 is provided with a multi-layer stand, which is used to hold jeans; the tumbling device 2 includes a tumbling cylinder 201, a tumbling shaft 202 in the middle of the tumbling cylinder 201, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com