Double-core yarn production device and production method

A production device and core yarn technology, applied in the field of double-core yarn production devices, can solve the problems of wasting manpower, increasing the workload of employees, reducing the quality of double-core yarns, etc., to avoid insufficient penetration, improve sizing effect, increase The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

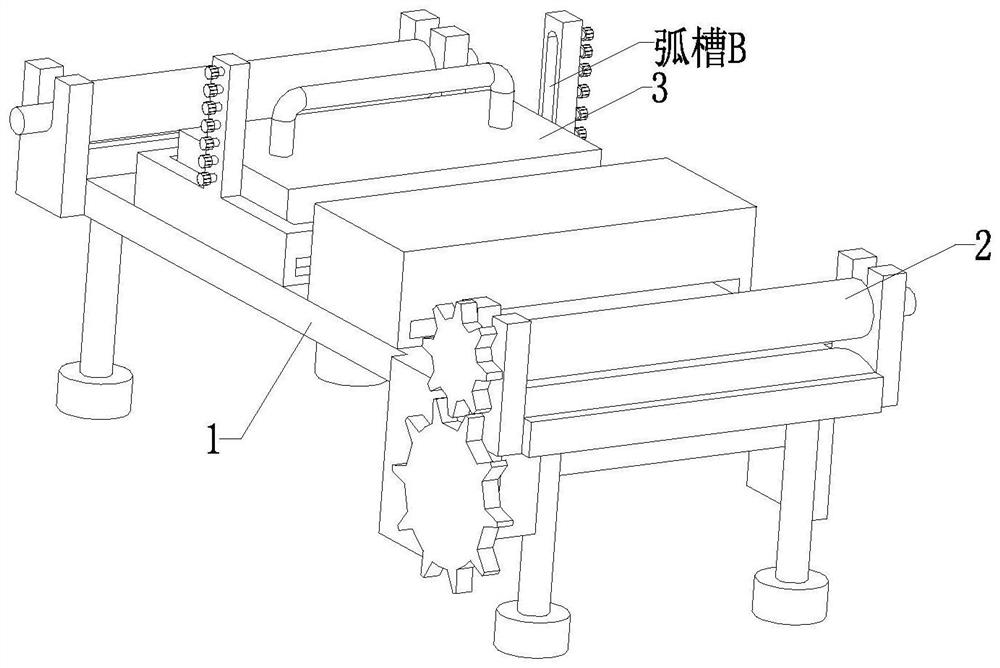

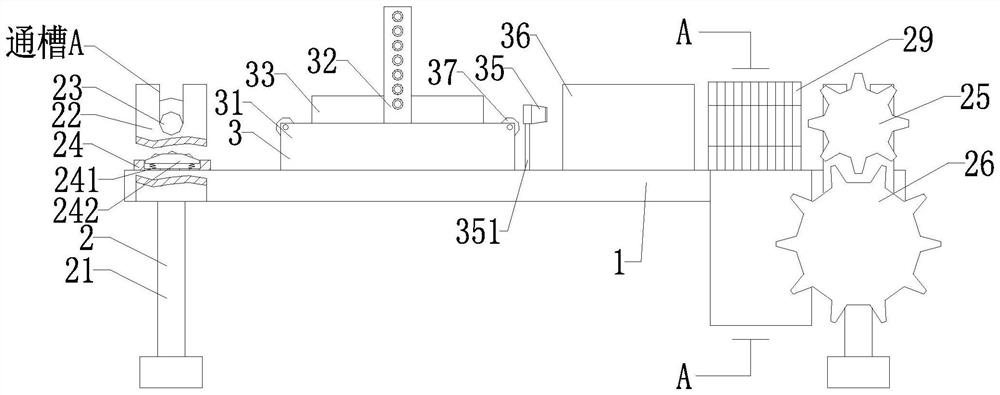

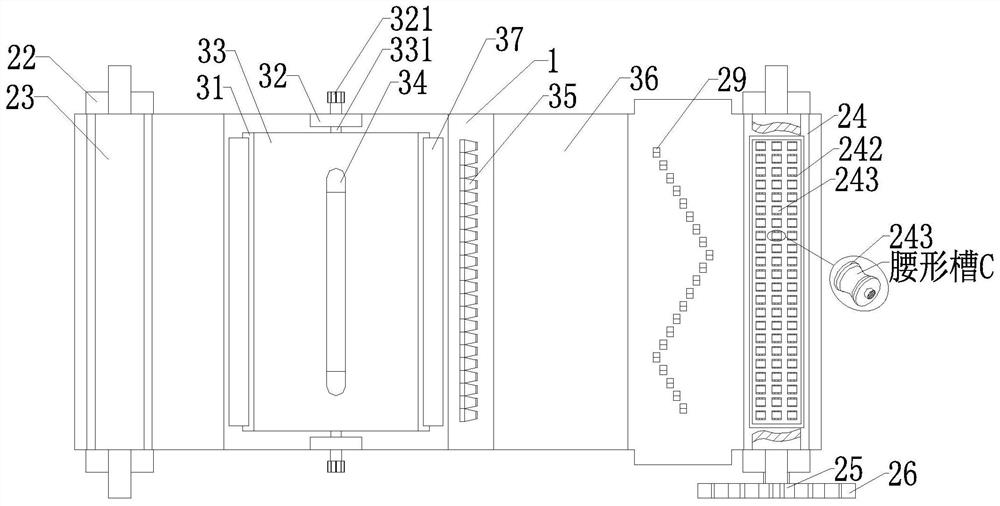

[0031] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0032] A production device for double-core yarn, including an installation base 1, a conveying set 2, and a sizing set 3, and the conveying set 2 and the sizing set 3 are sequentially arranged on the installation base 1 from left to right, wherein:

[0033]The conveying set 2 includes a support rod 21, a placement frame 22, a winding roller 23, a lifting pad 24, a driven toothed plate 25, a driving toothed plate 26, a No. 1 motor, a transmission belt 27, a jacking roller 28 and a distribution wheel. Line 29, the support rod 21 is evenly installed on the lower end surface of the installation substrate 1 by welding, the installation substrate 1 is uniformly installed with a placement frame 22 by welding, the placement frame 22 is provided with a throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com