Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

228results about "Liquid/gas/vapor removal by scraping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

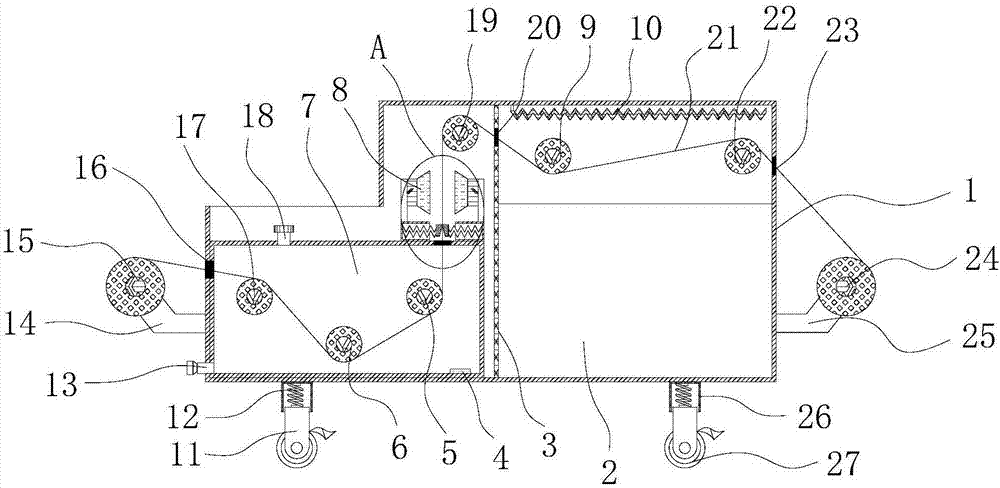

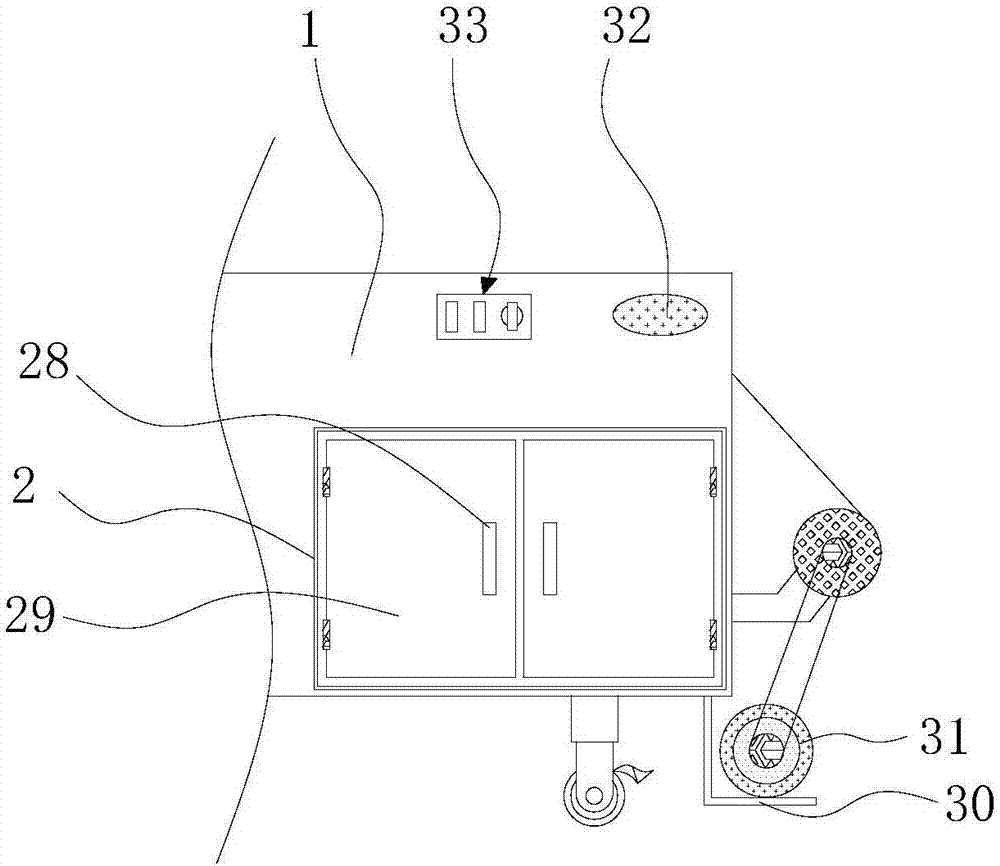

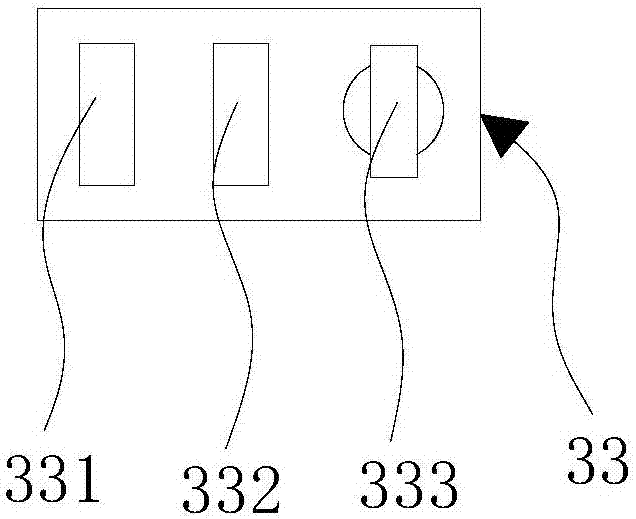

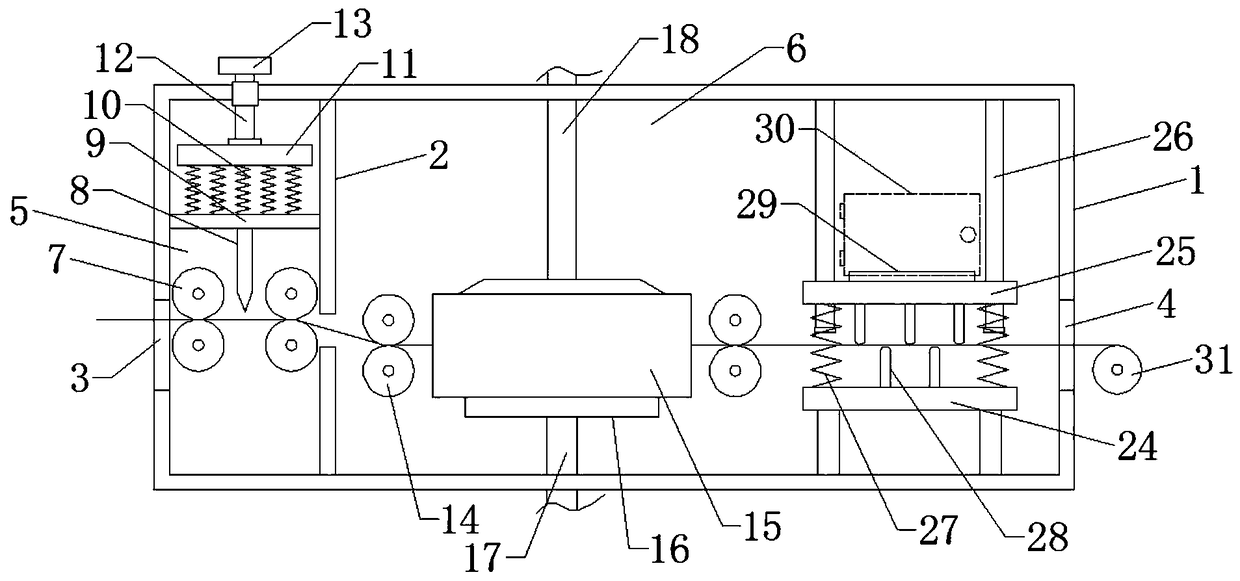

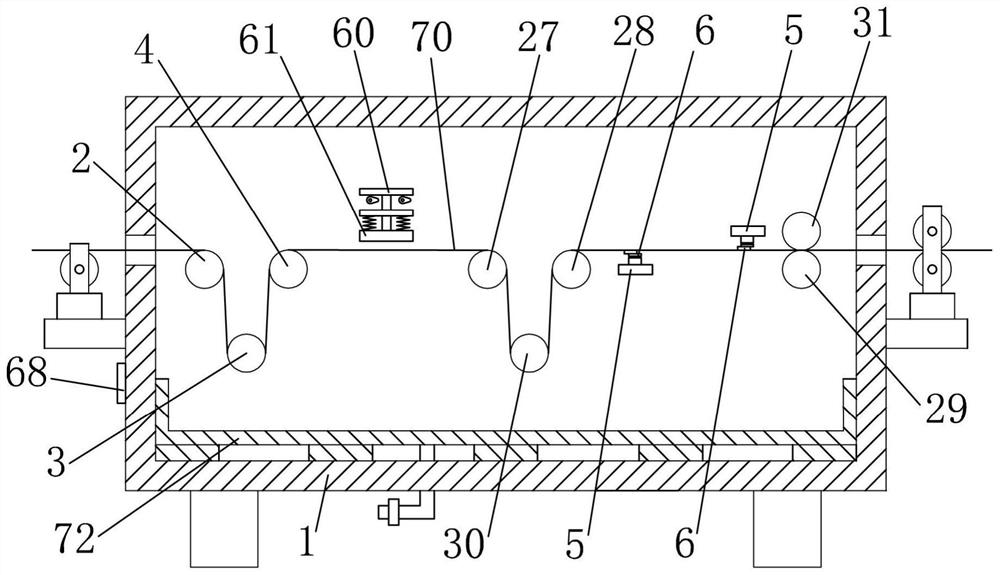

Textile dyeing device

InactiveCN106968069AExtended drying timeGuarantee normal dyeing workTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringDrying time

The invention discloses a textile dyeing device, comprising a box body, a dye box is fixedly installed at the left end of the bottom of the inner cavity of the box, and a first drive roller is movably installed at the upper left end of the inner cavity of the dye box. The lower end of the cavity is movably installed with a second transmission roller, the upper right end of the inner cavity of the dye box is movably installed with a third transmission roller, the right end of the upper surface of the dye box is provided with a second through hole, and the right end of the bottom of the inner cavity of the dye box is provided with a second through hole. A pressure sensor is fixedly installed. In the invention, the scraper is movably connected to the inner cavity of the second sleeve through the second spring, which can scrape off the dye adhering to the surface of the dyed fabric after dyeing. The fabric is air-dried, which solves the problem that a large amount of dye will adhere to the surface of the fabric during the dyeing process of the existing fabric dyeing machine, which not only prolongs the drying time of the fabric after dyeing, but also causes the waste of dye.

Owner:湖州梦源环保科技有限公司

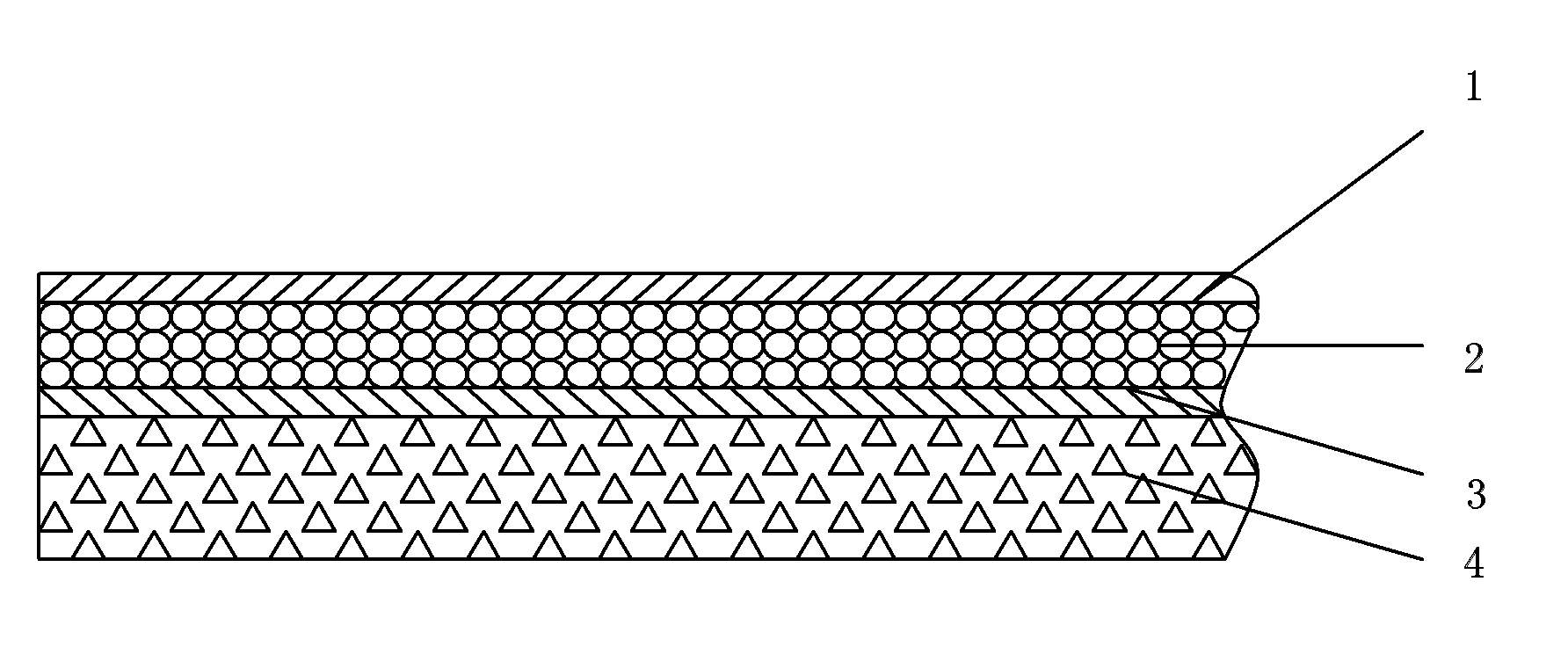

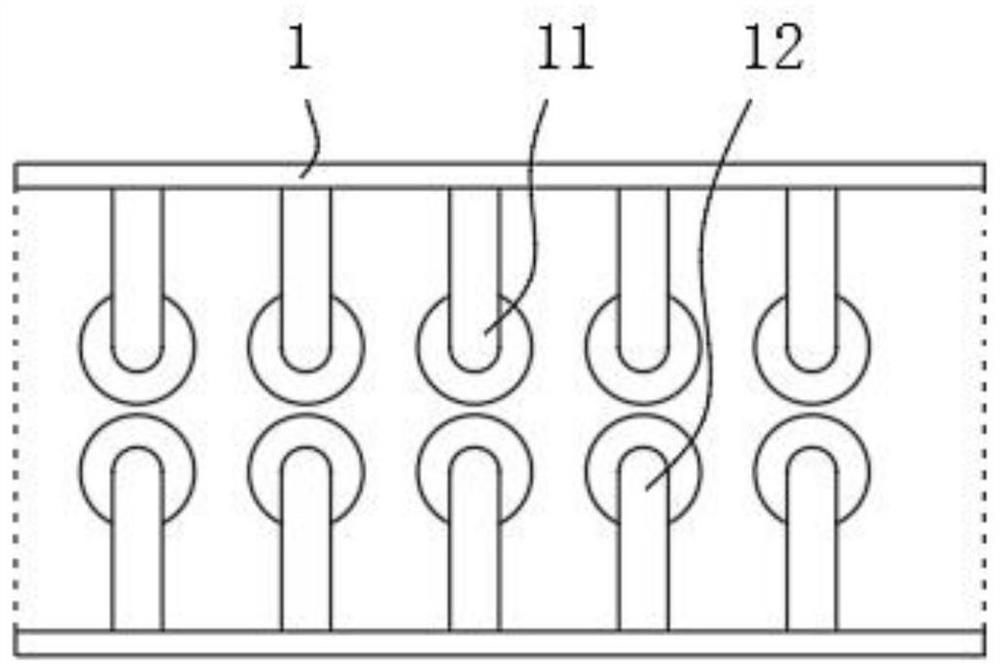

Coating fabric with high water pressure resistance and high moisture penetrability and preparation process thereof

InactiveCN101929081AReduced drainage resistanceImprove wear resistanceSynthetic resin layered productsLiquid/gas/vapor removal by scrapingWear resistantPolyurethane coating

The invention discloses a coating fabric with high water pressure resistance and high moisture penetrability, which comprises a bearing layer, a waterproof layer coated on the bearing layer, a micropore layer coated on the waterproof layer and a protective layer coated on the micropore layer, wherein the protective layer is a wear-resistant coating with a micropore structure and is a hydrophilic waterproof and penetrable polyurethane coating with a hydrophilic function; the micropore layer in the middle is a micropore waterproof and penetrable polyurethane coating with a micropore structure; and the bottom layer of the fabric coating is a waterproof layer which has favorable film formation property and can provide a hydrophilic waterproof and penetrable polyurethane coating with high water pressure resistance. The fabric provided by the invention has the characteristics of higher water pressure resistance, high penetrability and wearing comfortability.

Owner:CHINESE TEXTILE ACAD +1

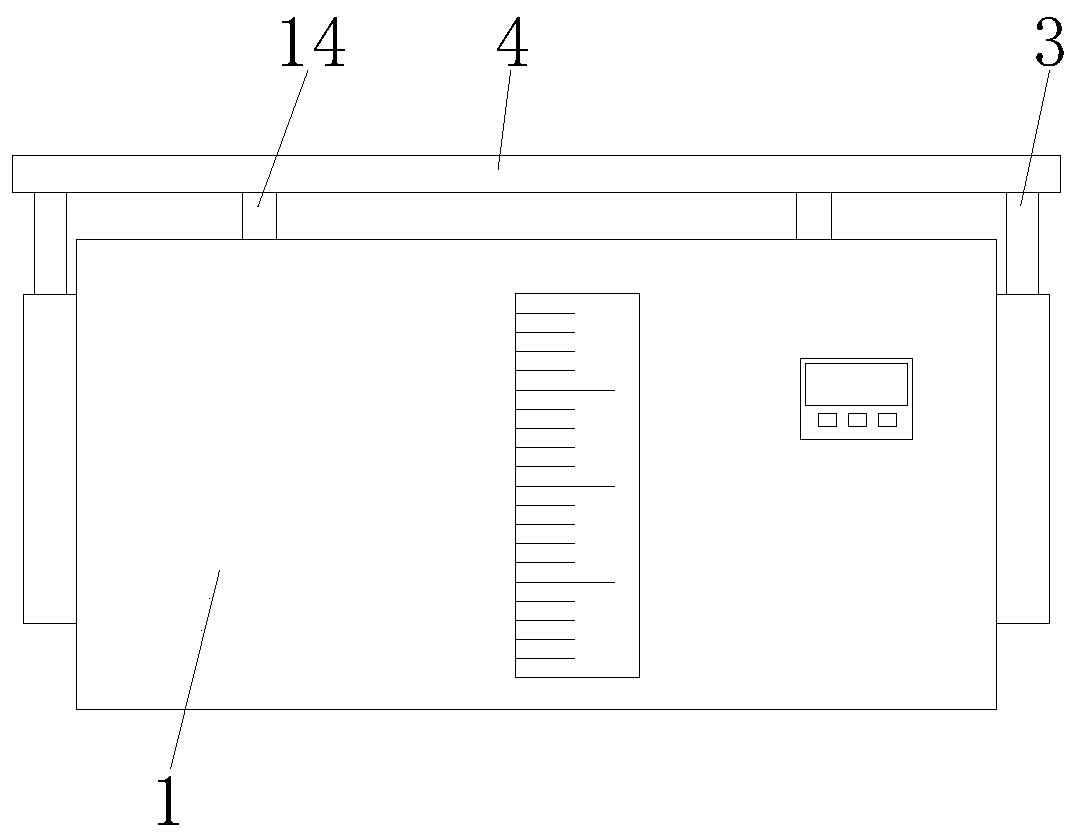

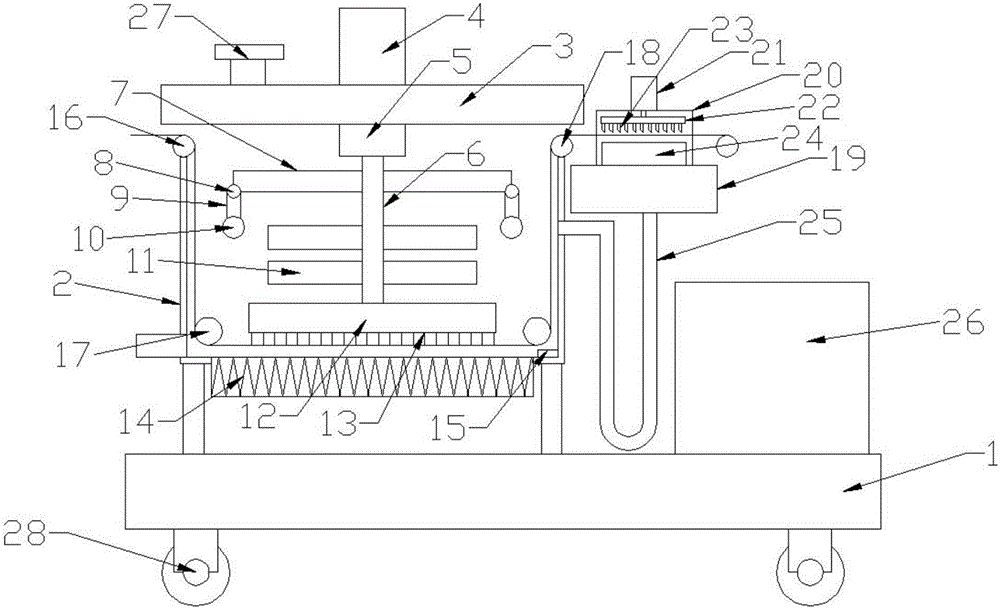

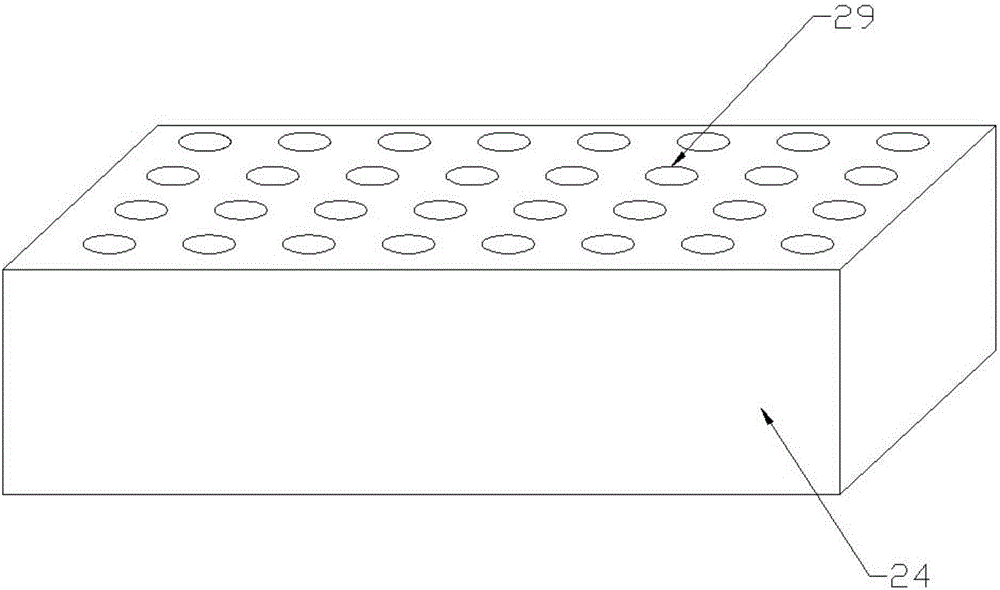

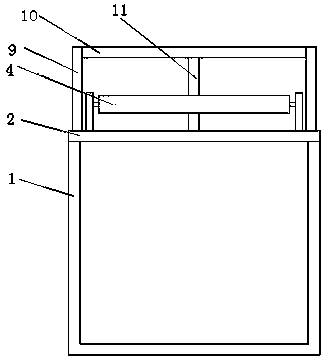

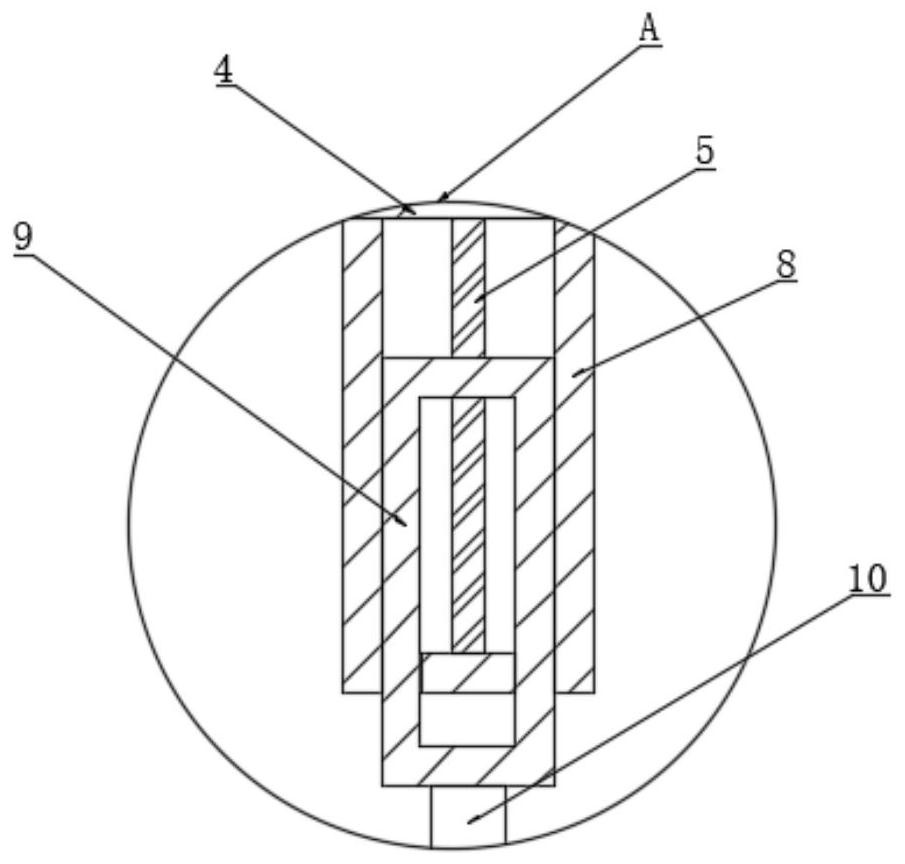

Textile fabric printing and dyeing equipment and printing and dyeing principle

InactiveCN110924015AImprove printing and dyeing qualityEasy to moveMechanical cleaningPressure cleaningPolymer scienceEngineering

The invention discloses textile fabric printing and dyeing equipment and a printing and dyeing principle. The textile fabric printing and dyeing equipment comprises a box body, wherein an inner cavityof the box body is movably connected with a supporting shaft through a rotating shaft; an electric telescopic rod is fixedly connected to each of the front face and the back face of the box body separately; a flat plate is fixedly connected to the tops of the electric telescopic rods; a first spring is fixedly connected to the center of the bottom of the flat plate; the bottom of the first springextends to the inner cavity of the box body and is fixedly connected with a pressing plate; a vertical plate is fixedly connected to each of the front side and the rear side of the bottom of the pressing plate separately; and an extrusion shaft is movably connected to opposite sides of the vertical plates through a rotating shaft. The textile fabric printing and dyeing equipment has the advantages of carrying out pre-dedusting on cloth firstly and then rolling dye on the surface of the cloth, achieving high printing and dyeing quality and capability of scraping and collecting excess dye on the cloth, and solving the problems that the dye and the cloth are not tight in contact, the printing and dyeing quality is poor, scraping and collecting of excess dye on the cloth after printing and dyeing cannot be realized, the dye drips on the ground, and the waste of the dye is caused.

Owner:陈美和

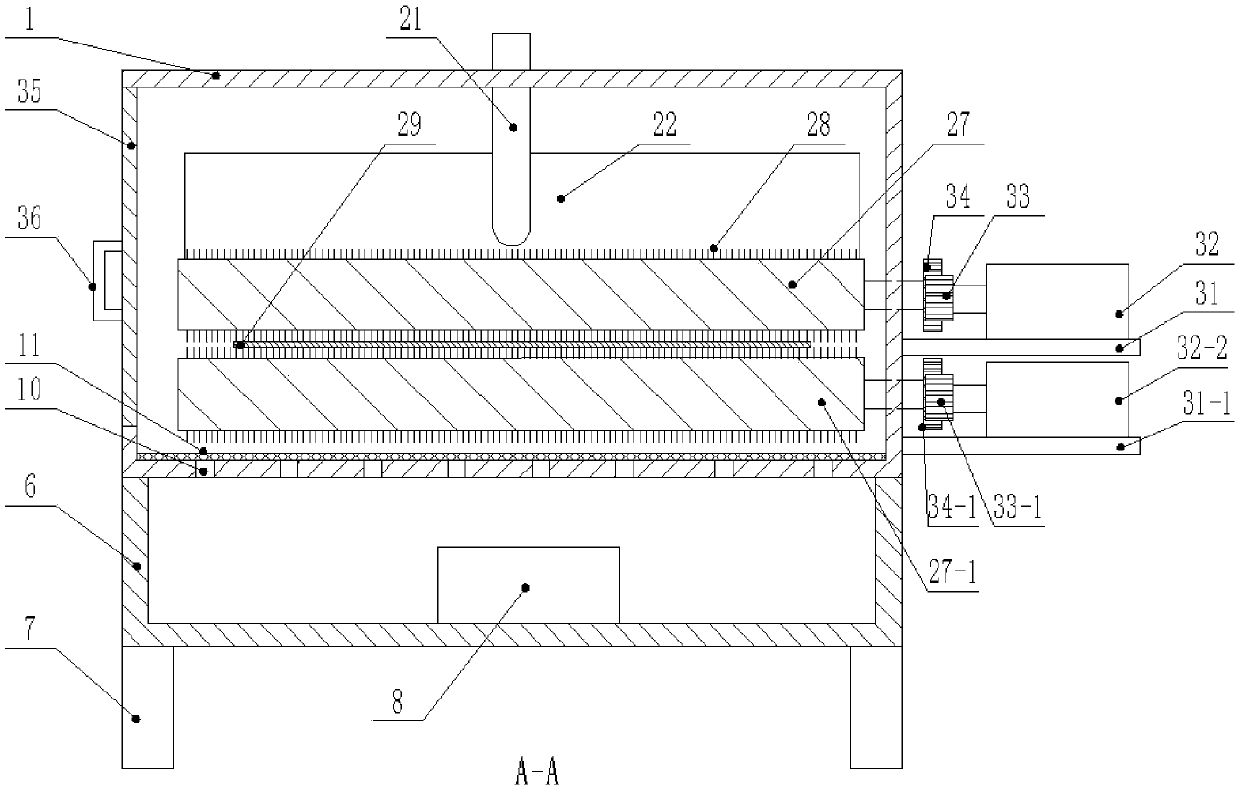

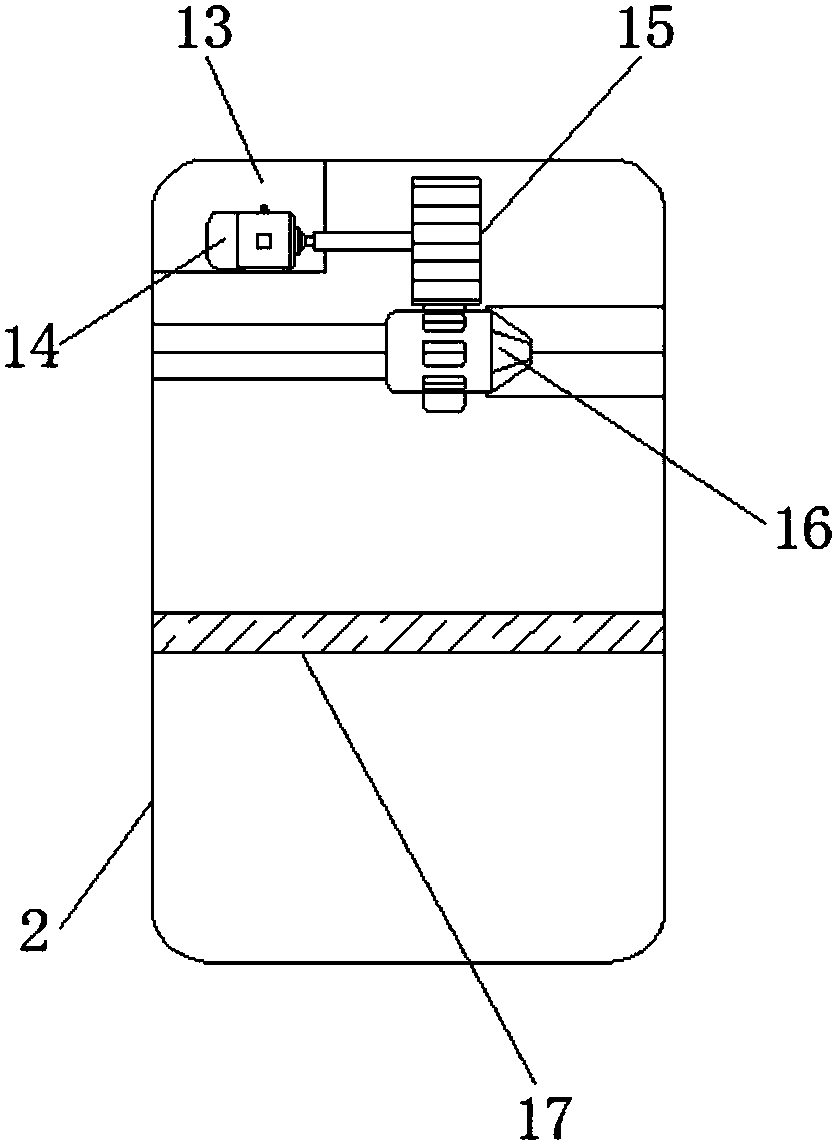

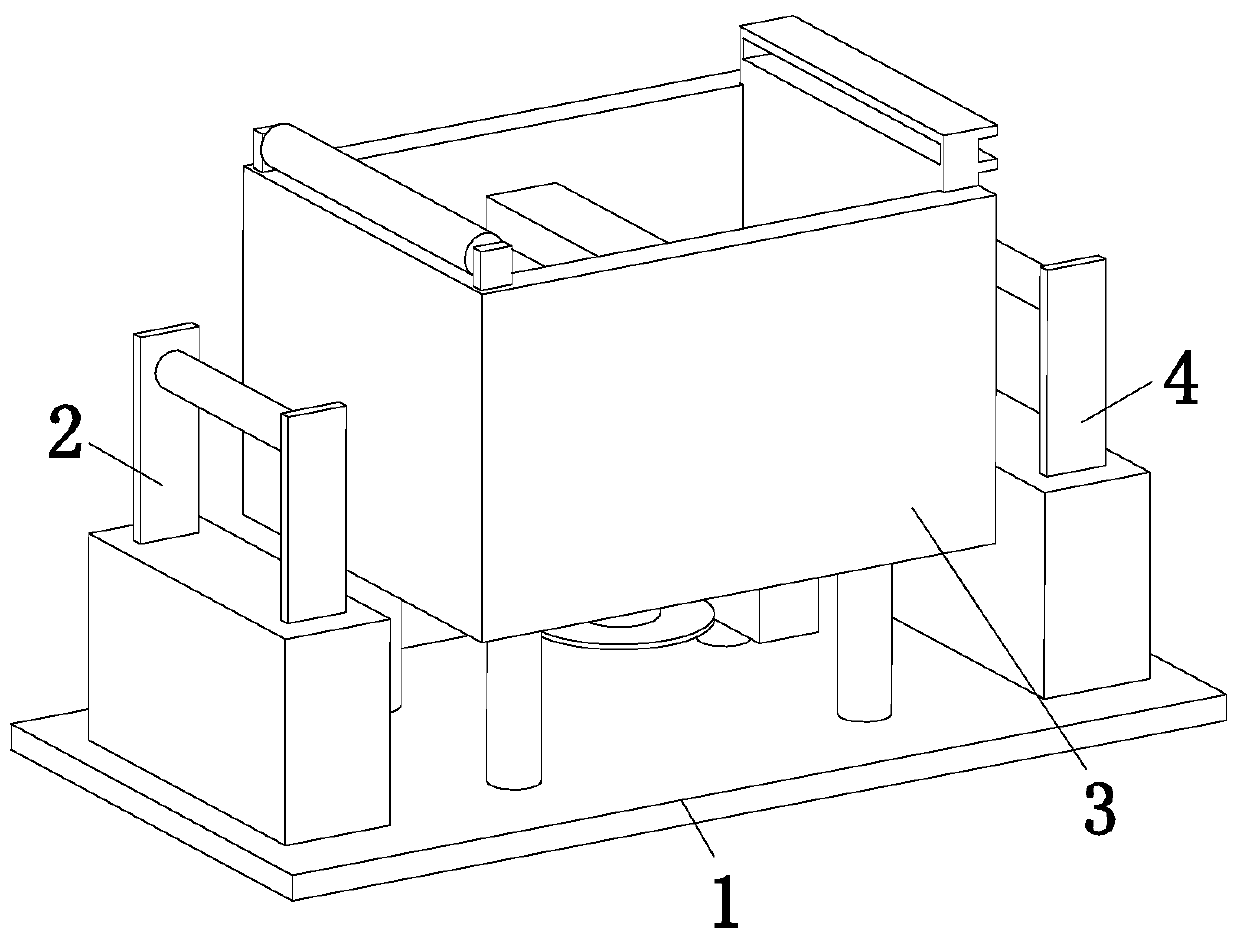

Sizing device of textile fabric

InactiveCN108265428ASimple structureReduce labor intensityTextile treatment containersTextile treatment machine arrangementsSlurry coatingEngineering

The invention provides a sizing device of a textile fabric. The sizing device comprises a feeding mechanism, a slurry coating mechanism and a drying and discharging mechanism, wherein the slurry coating mechanism is located between the feeding mechanism and the drying and discharging mechanism; the slurry coating mechanism comprises a slurry box, a slurry coating assembly, a slurry scraping assembly and a first material guide assembly; the drying and discharging mechanism comprises a drying assembly and a discharging assembly; the slurry scraping assembly comprises a material guide box and twoL-shaped mounting plates; the material guide box is located between the two L-shaped mounting plates; the material guide box and each L-shaped mounting plate are connected through a rotary rod; a slurry scraping plate is arranged at one end, close to the slurry coating assembly, of the material guide box. The sizing device provided by the invention has the beneficial effects that the slurry coating mechanism is simple in structure and can be used for automatically carrying out slurry coating work on the fabric, so that a lot of labor intensity of workers is reduced; the slurry scraping assembly can be used for scraping off slurry dreg on the fabric and preventing the slurry dreg from falling off in a fabric conveying process; the drying assembly can be used for carrying out drying work onthe fabric so that the fabric can be rapidly shaped.

Owner:安聪聪

Cloth washing device

InactiveCN109554857AGuaranteed to be free from cleaning stainsEffective squeezeMechanical cleaningPressure cleaningRinse waterSpray nozzle

The invention discloses a cloth washing device which comprises a tank. A water tank is fixed to the bottom of the tank. The cloth washing device has the advantages that rinsing work can be carried outon two surfaces of cloth by spray nozzles on a spray tank and a first spray tank at first, and accordingly floating color objects on the surfaces of the cloth can be approximately rinsed away; the two surfaces of the cloth can be simultaneously finely scrubbed by soft brushes on scrubbing rollers and first scrubbing rotary drums, and accordingly the purpose of finely cleaning the cloth can be effectively achieved; the cloth can be rinsed again by first spray nozzles on a second spray tank and a third spray tank, accordingly, dirty marks, which are brushed by the soft brushes, on the cloth canbe effectively rinsed away, and the surfaces of the cloth can be effectively guaranteed against being contaminated by cleaning dirty marks; rinse water attached onto the two surfaces of the cloth canbe squeezed and scraped by rubber strips on a scraping plate and a first scraping plate, accordingly, most cleaning water on the surfaces of the cloth can be effectively squeezed, and water resourcesfurther can be effectively prevented from being wasted.

Owner:张醒雄

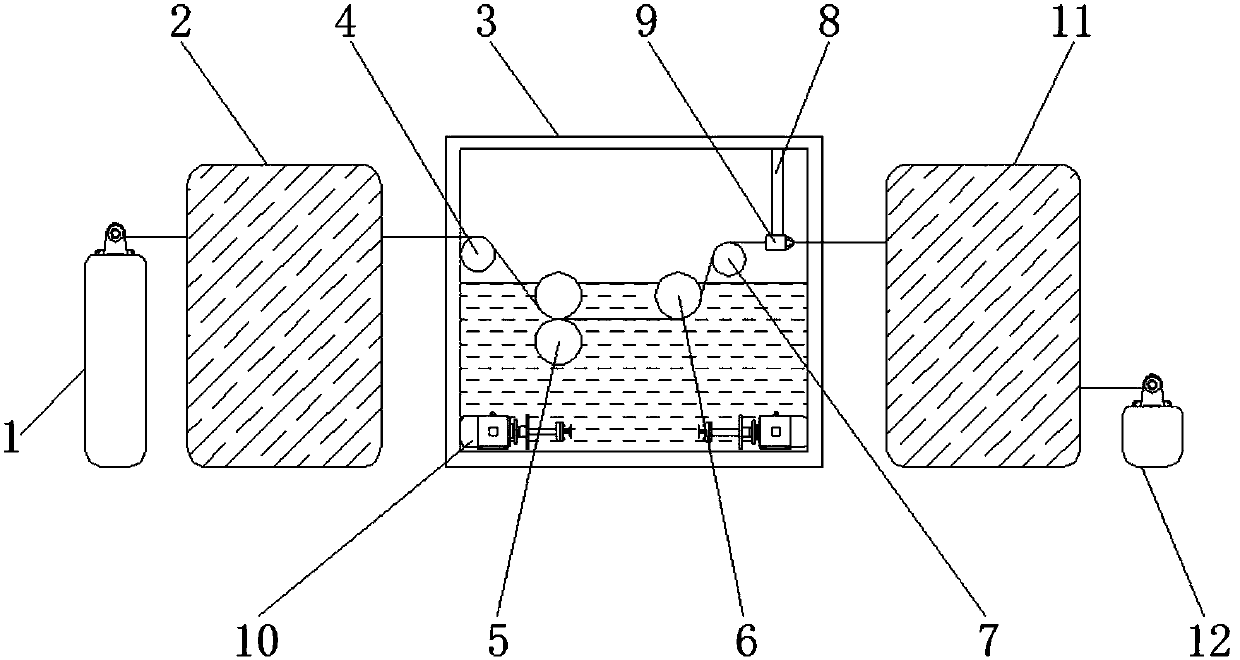

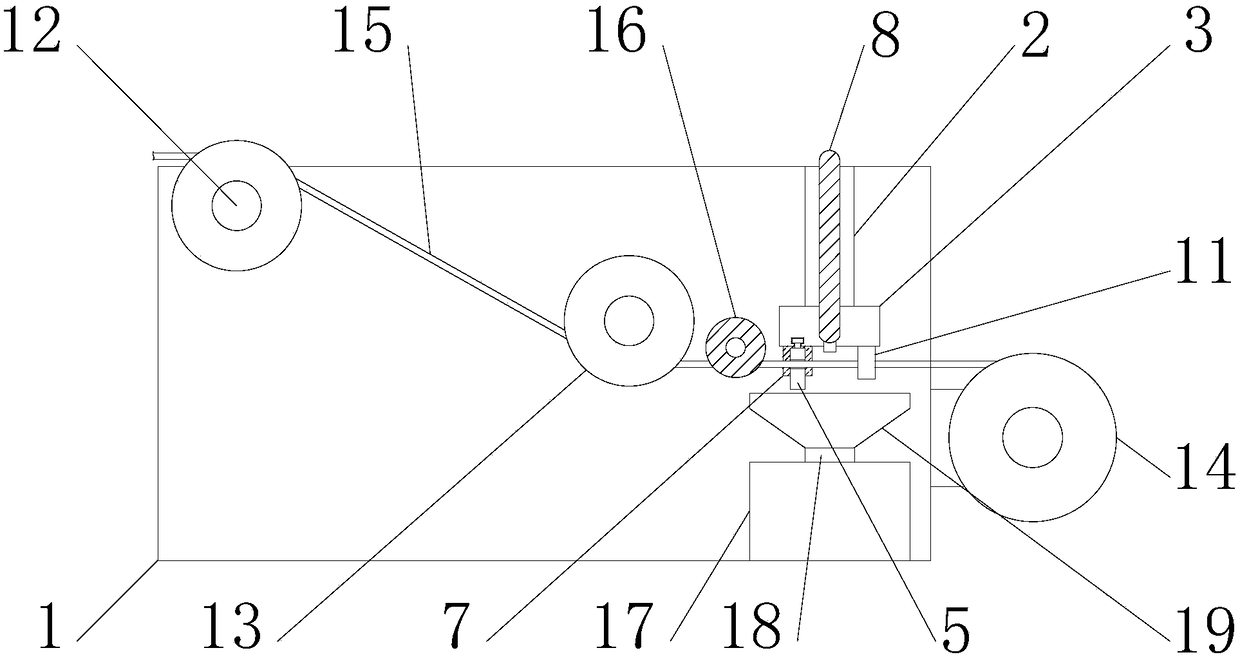

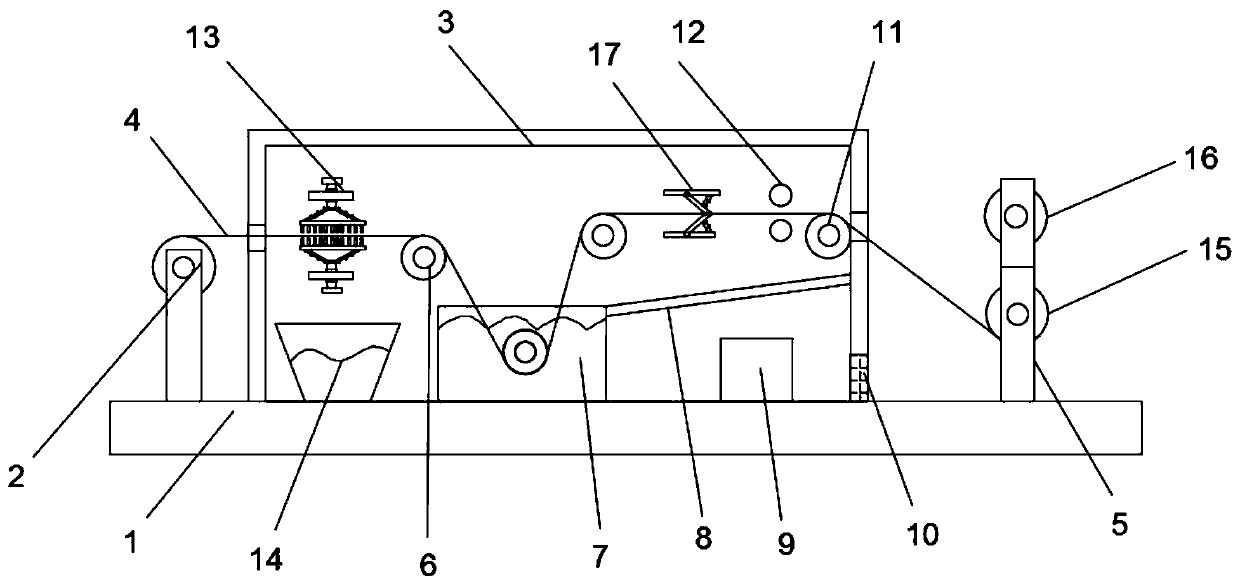

Plate membrane coating machine

InactiveCN102011282ARealize streamlined productionReasonable structureSemi-permeable membranesLiquid/gas/vapor removal by scrapingBiochemical engineeringAssembly line

The invention discloses production equipment for plate membranes, in particular a plate membrane coating machine. The plate membrane coating machine is characterized by comprising an uncoiling feeding unit, a coating unit, a conveying unit, a washing unit and a coiling folding unit, wherein the uncoiling feeding unit, the coating unit, the washing unit and the coiling folding unit are arranged in turn according to an assembly line; and the conveying unit is arranged on the functional units and mainly comprises a conveying rail consisting of a plurality of groups of cloth guide rollers, so that base fabrics can be treated by each functional unit through the conveying rail uninterruptedly. The plate membrane coating machine is reasonable in structure and high in production efficiency, realizes streamlined production of non-woven plate membranes and is suitable for large-scale industrial popularization.

Owner:ZHEJIANG SHENGSHI MECHANICS

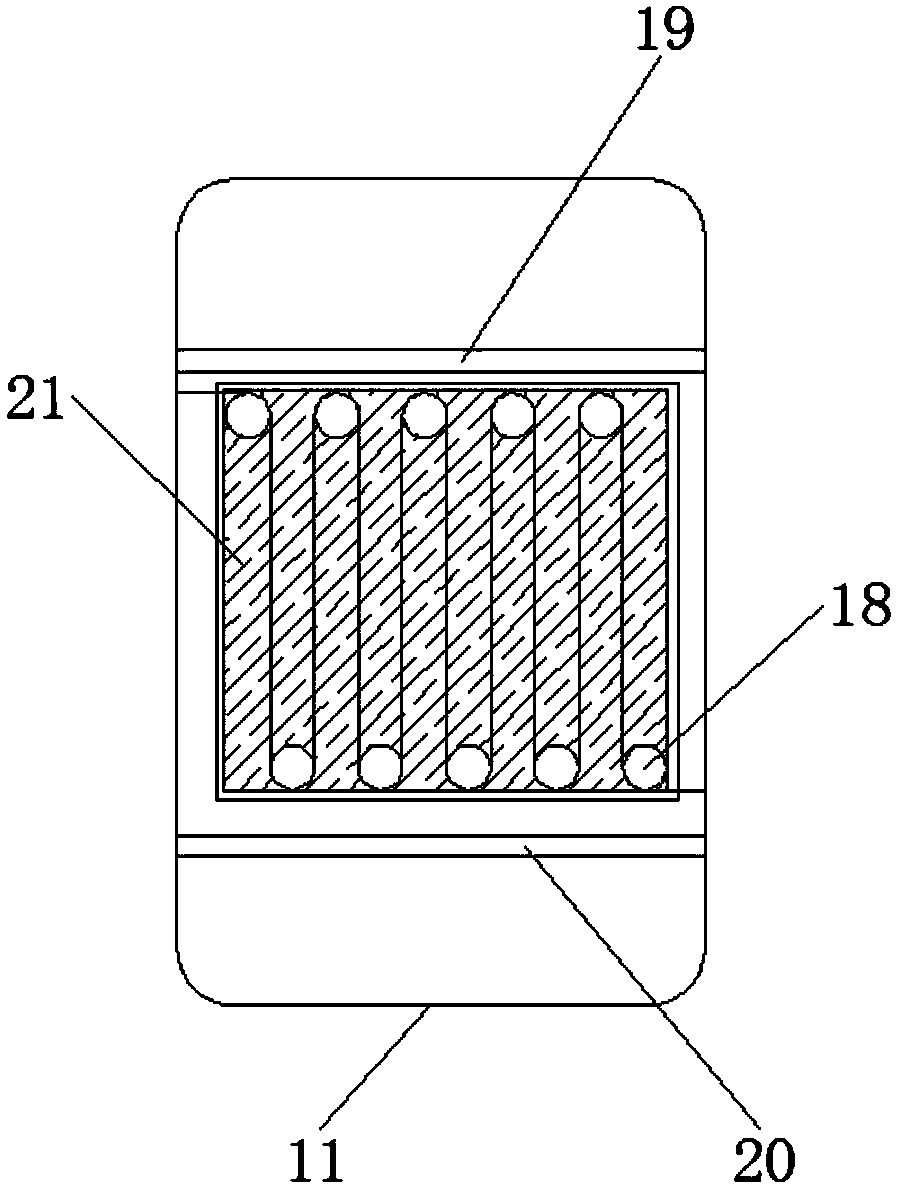

Yarn sizing machine capable of uniformly conducting sizing

InactiveCN107675388AExtended drying timeFully dryFibre cleaning/openingTextile treatment machine arrangementsPulp and paper industry

The invention discloses a yarn sizing machine capable of uniformly conducting sizing. The yarn sizing machine comprises a yarn putting device, a cleaning device shell is arranged at the right of the yarn putting device, a driving bin is arranged inside the cleaning device shell, a driving motor is installed inside the driving bin, the front end of the driving motor is connected with a dust tightening device through a gear, a static electricity dust remover is installed inside the cleaning device shell, a size tank is arranged at the right of the cleaning device shell, a first yarn guide rolleris arranged inside the size tank, a yarn extruding roller is arranged at the right of the first yarn guide roller, a sizing roller is installed at the right of the yarn extruding roller, and a secondyarn guide roller is arranged at the upper right portion of the sizing roller. According to the yarn sizing machine capable of uniformly conducting sizing, design of the dust tightening device, the gear, the static electricity dust remover, the yarn extruding roller, an air draft device and an air suction device is adopted, the speed for yarn to absorb sizing agent can be increased, and thereforethe work efficiency of the sizing machine is improved so that the yarn can be more fully dried.

Owner:杭州依翰丝绸文化创意有限公司

Textile processing equipment

ActiveCN108517639AReduce speedHigh degree of automationLiquid/gas/vapor removal by suctionTextile treatment machine arrangementsMotor driveElectric machinery

The invention relates to the field of textile processing, and particularly discloses textile processing equipment. The textile processing equipment comprises a rack, and further comprises a water wiping mechanism, a water absorbing roller, an ironing mechanism, a drying roller, a material collecting roller, a first motor and a second motor, wherein the water wiping mechanism, the water absorbing roller, the ironing mechanism, the drying roller, the material collecting roller, the first motor and the second motor are arranged on the rack in the horizontal direction in sequence, the first motordrives the water absorbing roller, and the second motor drives the material collecting roller; the water wiping mechanism is arranged at the discharging end of a textile, the material collecting roller is arranged at the material collecting end of the textile, the water wiping mechanism comprises several water wiping rollers facing the water absorbing roller, the water wiping rollers are divided into a first water wiping set and a second water wiping set, the first water wiping set and the second water wiping set are opposite, the first water wiping set is rotatably connected with the rack, and a water wiping plate is fixedly connected to the second water wiping set. The textile is processed through the four motions of water wiping, water absorbing, ironing and drying in sequence, and thenthe textile is also reeled after being processed; the automated degree is high, and the processing efficiency is high; moreover, when processed by multiple processing steps, the textile does not needto be carried and can be processed at a time, and the time and labor are saved.

Owner:NINGBO WENZE TEXTILE CO LTD

Cloth drying equipment with leveling function used for textile processing

InactiveCN109137334AHeating fastReduce absorptionTextile treatment machine arrangementsFabric finishing guides/expandersEngineeringMechanical engineering

The invention discloses cloth drying equipment with a leveling function used for textile processing. The equipment comprises a box body, a separation plate, a feed inlet, a discharge port, conveyor roller groups, material guide roller groups and a rolling roller. The outer side of the discharge port is correspondingly provided with the rolling roller with driving clicking. Two conveyor roller groups are installed in a drying chamber. A vertical and adjustable scrape plate is arranged between the two conveyor roller groups. The two sides of a drying box are provided with the material guide roller groups. Clothes are sent to the drying box through the material guide roller groups. The right side of the drying box is provided with a leveling device. In the invention, the water of the sent clothes can be scraped under the effect of the scrape plate in the drying chamber, the scrape plate can adjust pressure according to the different materials of the clothes and the like, the water in theclothes can be scraped safely, the water absorbed in the clothes is reduced and a drying effect is increased. A contact roller in the drying box is fully contacted with the clothes, and high temperature air blown into from a lower portion can directly heat the contact roller so that the clothes can be heated rapidly.

Owner:陈璐

Yarn plush removal device for spinning

InactiveCN108547028AImprove removal efficiencyGood removal effectTextile treatment machine arrangementsTextile treatment by spraying/projectingYarnEngineering

The invention discloses a yarn plush removal device for spinning. The device comprises a box, a connecting plate, a fixing rod, a sliding block, a clamping plate, a spring, a fixing plate, a water pipe, a nozzle, a water pump, a scraper plate, a conveying roller, a pressing roller, a winding reel, yarn, a rotating shaft, a water tank, a filter net and a dust hopper. The yarn plush removal device for spinning is simple in structure and convenient to operate, the yarn is clamped by the clamping plate, when the yarn is fed, plush on the surface is removed, due to the design of the rotating shaft,the yarn swings left and right during feeding, friction force between the yarn and the clamping plate is enlarged, the yarn flush removal efficiency is improved, and plush removal is facilitated; according to the yarn plush removal device for spinning, the yarn is cleaned through the nozzle, the yarn cleanness is ensured, the quality of finished products is improved, the yarn is wetted through water, static electricity generated on the yarn by friction is effectively reduced, and accidents are avoided.

Owner:苏州秦汉纺织有限公司

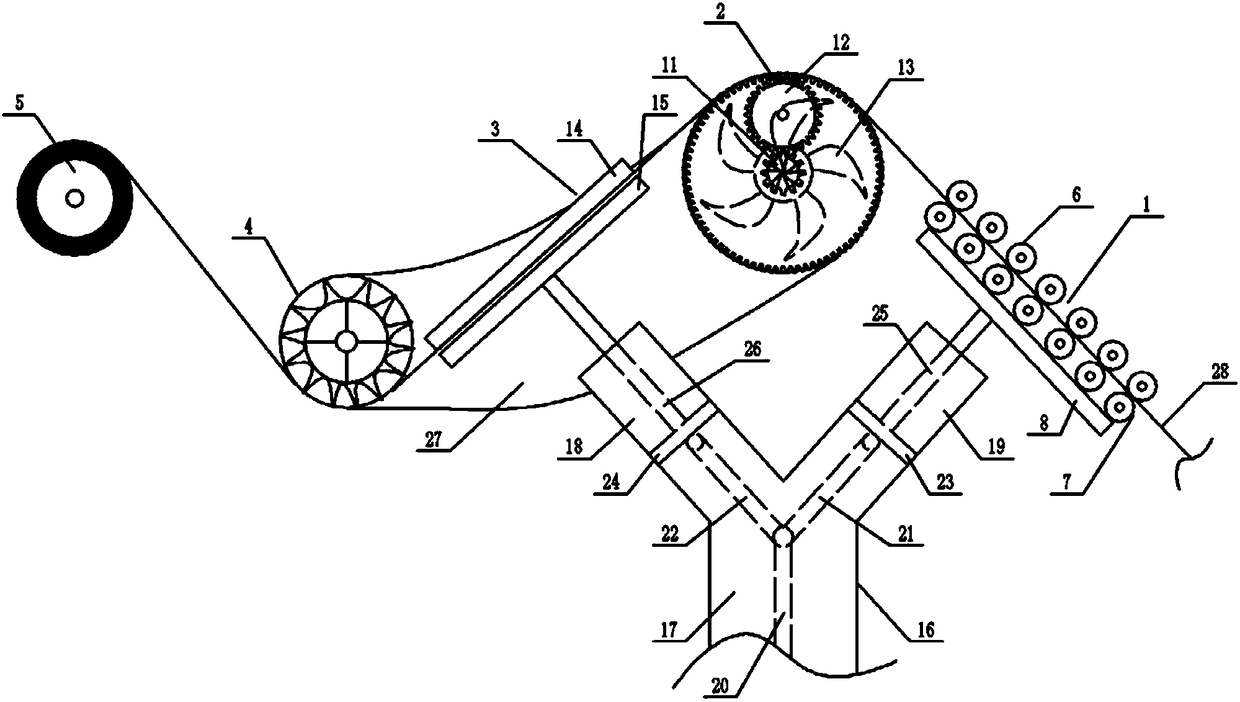

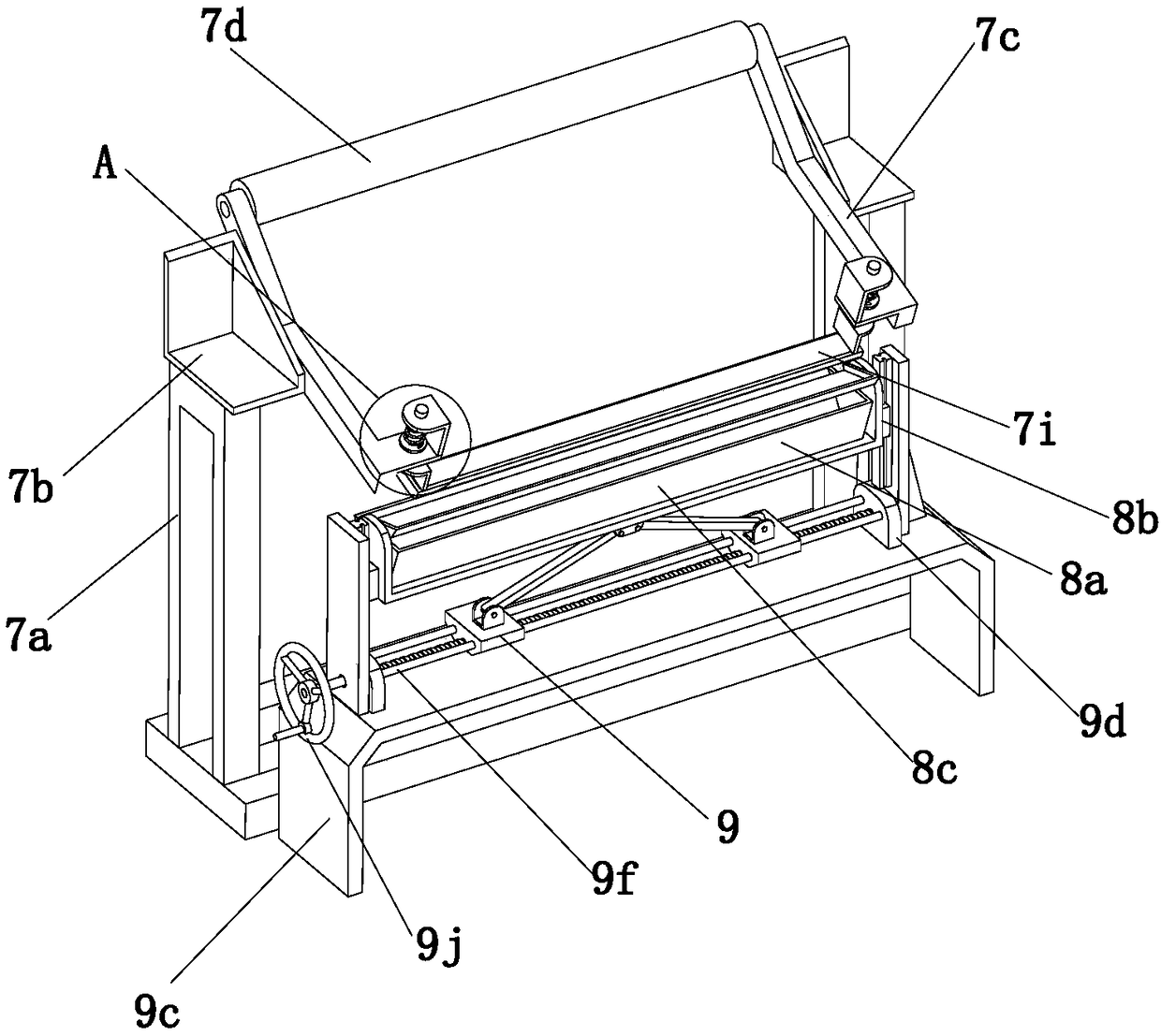

Textile cloth dip-dyeing process

InactiveCN111270447AReduce dyeing efficiencyImprove the efficiency of dippingLiquid/gas/vapor treatment of indefinite length materialsLiquid/gas/vapor removal by scrapingPolymer scienceEngineering

The invention relates to a textile cloth dip-dyeing process. A base plate, a bearing frame, a dyeing device and a winding device are included; and the bearing frame is installed at the upper end of the base plate through a base, the dyeing device is arranged on the right side of the bearing frame, the dyeing device is installed on the base plate through a support column, the winding device is arranged on the right side of the dyeing device, and the winding device is installed on the base plate through the base. The textile cloth dip-dyeing process in the invention is capable of solving the problems that the existing equipment is incapable of layering the multi-layer textile cloth during dyeing, such that the middle part of the textile cloth is unable to completely contact with dye, causingthe fact that the middle part cannot be completely dyed, and the dyeing efficiency is reduced; and simultaneously, the redundant dye on the surface of the textile cloth cannot be scraped after the textile cloth is dyed, such that the textile cloth has different surface colors, and the dyeing effect is reduced.

Owner:刘金红

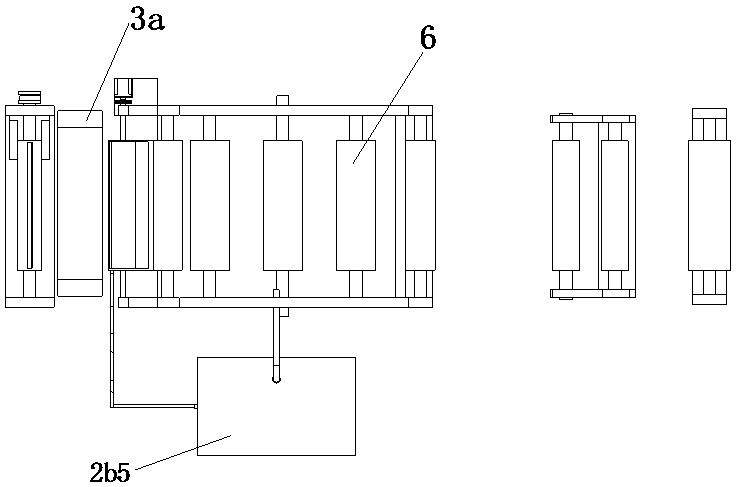

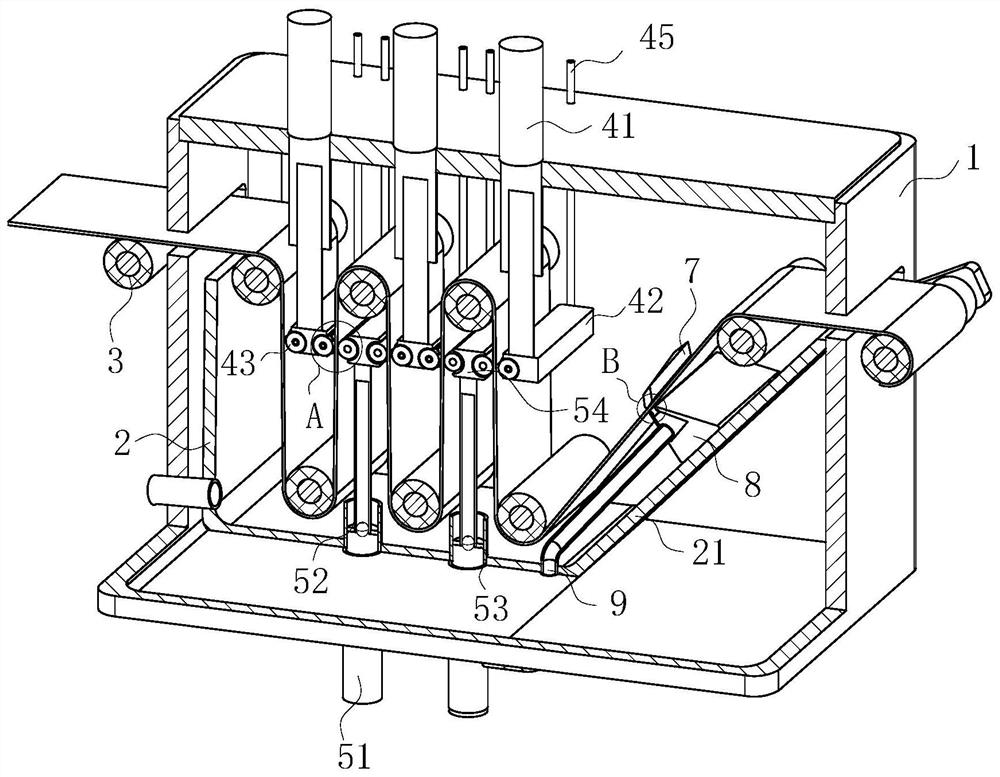

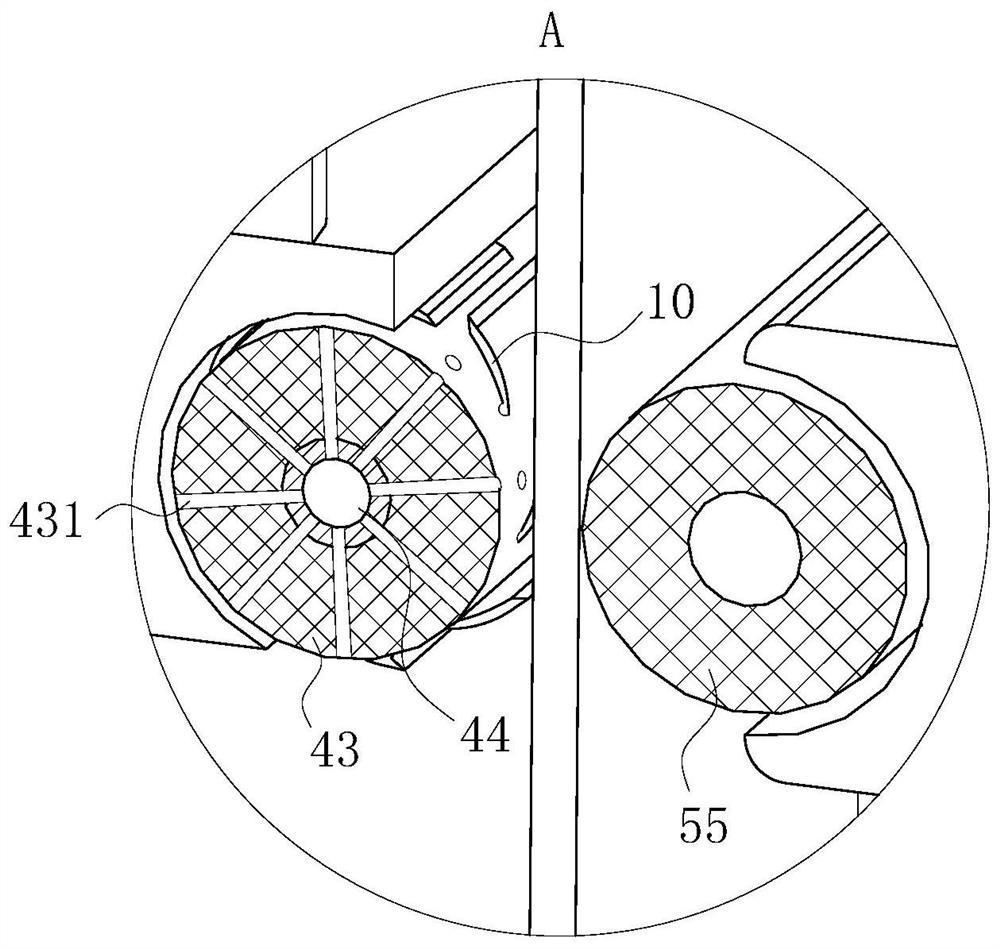

Yarn sizing device for textile

ActiveCN109267267AAutomatic sizingAutomatic dischargeTextile treatment machine arrangementsLiquid/gas/vapor removal by scrapingYarnEngineering

The invention discloses a yarn sizing device for textile, and belongs to the technical field of textile equipment. The device comprises a sizing mechanism, a receiving mechanism, a discharging mechanism and a scraping mechanism, wherein the discharging mechanism comprises a discharging assembly and a yarn limiting assembly, the yarn limiting assembly is arranged at the right end of the dischargingassembly, the scraping mechanism comprises a top-surface scraping assembly and a bottom-surface scraping assembly, the top-surface scraping assembly is arranged above the bottom-surface scraping assembly, the bottom-surface scraping assembly comprises a scraping assembly and a lifting assembly used for driving the scraping assembly to rise and fall, and the scraping assembly is arranged at the top of the lifting assembly. The yarn sizing device for textile has the advantages that scraping can be automatically performed on yarn through the scraping mechanism, thereby ensuring the surface thickness of warp yarn; the tension of the yarn can be automatically adjusted through the yarn limiting assembly, thereby avoiding the phenomena of breakage, abrasion and the like of the yarn during transport.

Owner:江苏富尔达电子科技有限公司

High quality fabric printing, dyeing and drying integrated machine

InactiveCN109629152AUniform printing and dyeingImprove processing qualityTextile treatment containersTextile treatment machine arrangementsState of artEngineering

The invention discloses a high quality fabric printing, dyeing and drying integrated machine. The machine comprises a dye box, the right side of the dye box is fixedly connected with a drying box, aninner cavity of the dye box is movably connected with a lower extrusion stick through a rotating shaft, the front and back sides of the dye box are fixedly connected with electric telescopic rods, thetops of the electric telescopic rods are fixedly connected with first transverse plates, vertical pipes are fixedly connected with the front and back sides of the bottoms of the first transverse plates, and the bottoms of the vertical pipes extend to the inner cavity of the dye box. The machine integrates the printing, dyeing and drying of a fabric, can immediately dry the fabric after the printing and dyeing, can guarantee the evenness of the printing and dyeing of the fabric, improves the quality of fabric processing, and solves the problems in the prior art that the separation performing of the fabric printing, dyeing and drying not only has a low efficiency, but also increases the labor intensity, the quality of the printing and dyeing is poor, the phenomenon of the uneven fabric printing and dyeing easily occurs, and the qualities of finished products are low.

Owner:管洪化

Cloth dip dyeing device for garment production

PendingCN112080876AImprove dyeing qualityAuto shut offTextile treatment machine arrangementsLiquid/gas/vapor removal by scrapingPolymer scienceEngineering

The invention relates to a dip dyeing device, in particular to a cloth dip dyeing device for garment production. According to the cloth dip dyeing device for garment production, dip dyeing color is uniform, and it can be ensured that cloth does not wrinkle in the dyeing process. The cloth dip dyeing device for garment production comprises a base, a vertical shaking mechanism and a horizontal shaking mechanism, and a dip dyeing pool is arranged at the top of the base; the vertical shaking mechanism is arranged between the two side walls of the dip dyeing pool; and the horizontal shaking mechanism is arranged on the dip dyeing pool. Under high-speed rotation of a motor, a first cam rotates to drive a bolt and the concave side of a second fixing block to clamp four corners of the cloth to reciprocate up and down to finish cloth dip dyeing.

Owner:王碧丹

Soaking device used in fabric wet transfer printing process

ActiveCN101643984ASimple structureImprove practicalityLiquid/gas/vapor removal by scrapingLiquid/gas/vapor textile treatmentQuality controlPulp and paper industry

The invention discloses a soaking device used in a fabric wet transfer printing process, which comprises an anilox roller and a rubber roller which are horizontally opposite up and down, wherein the anilox roller is arranged above the rubber roller and is in contact with a scraper; both ends of a center shaft of one roller in the anilox roller and the rubber roller are fixedly connected to a frameby bearings, and one shaft end is connected with a transmission mechanism; both ends of a center shaft of the other roller are connected with a pressurizing device by bearings; and the scraper is connected with a position adjusting device which can adjust the compressing degree between the scraper and the anilox roller. The soaking device used in the fabric wet transfer printing process has simple structure and favorable utility effect, can arbitrarily control the moisture content of wet transfer printing fabric, solves the problems of vague flower pattern and difficult quality control causedby the difficult control of the moisture content in wet transfer printing and leads a wet transfer printing product to reach the quality which is the same with a thermal transfer printing product.

Owner:王勇

Crease-removing environment-friendly chemical-resistant fiber textile printing and dyeing machine

InactiveCN110846836AEasy to useQuick location replacementSucessive textile treatmentsTextile treatment containersTextile printerFiber

The invention discloses a crease-removing environment-friendly chemical-resistant fiber textile printing and dyeing machine which comprises a worktable and a frame. An adjusting component is mounted on one side of the top end of the worktable, mounting racks are symmetrically welded in the middle of the top end of the worktable, a downward pressure shaft is welded at one end of two linkage side plates on the same side, a dyeing bath component corresponding to the mounting racks is mounted in the middle of the top end of the worktable, dyeing boxes are symmetrically mounted at the top end of asliding plate, and a plurality of flap pieces are equidistantly welded on the outer surface of a mounting column. The adjusting component is combined with the dyeing bath component, the sliding platedrives the dyeing boxes to move, the positions of the dyeing boxes are rapidly replaced, the linkage side plates drive the downward pressure shaft to swing, rapid replacement of the dyeing boxes cannot be interfered, and the printing and dyeing machine solves the problems that when existing dyeing liquid is replaced, dyeing needs to be replaced to replace the dyeing liquid, consequently, fabric dyeing efficiency is reduced, and large-batch fabric dyeing cannot be facilitated.

Owner:嘉兴运通印染有限公司

Cloth cleaning device for textile processing

ActiveCN113584769AAvoid deformationAvoid breakingTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsMechanical engineeringIndustrial engineering

The invention discloses a cloth cleaning device for textile processing. The device comprises a box body, a flexible cleaning device and a water removal device; the flexible cleaning device is arranged in the center of the interior of the box body and close to the bottom; the water removal device is arranged in the box body and located above the flexible cleaning device; a driving roller is rotationally connected between the two corresponding sides of the inner wall of the box body; a cam is arranged at one end of the driving roller; a brush cleaning device is arranged in the driving roller and located at the surface position; and the brush cleaning device is connected with the driving roller in a matched mode. The invention relates to the technical field of textile processing equipment. According to the cloth cleaning device for textile processing, the effects of flexible cleaning and moisture removal are achieved; the cloth can be flexibly cleaned, so that rigid contact is avoided, the cloth is not prone to deformation or damage, and the cleaning efficiency is high; moisture attached to the cloth is removed in time, so that subsequent rapid drying is facilitated; and the safety and reliability are achieved, and the use performance is improved.

Owner:南通刚正纺织品有限公司

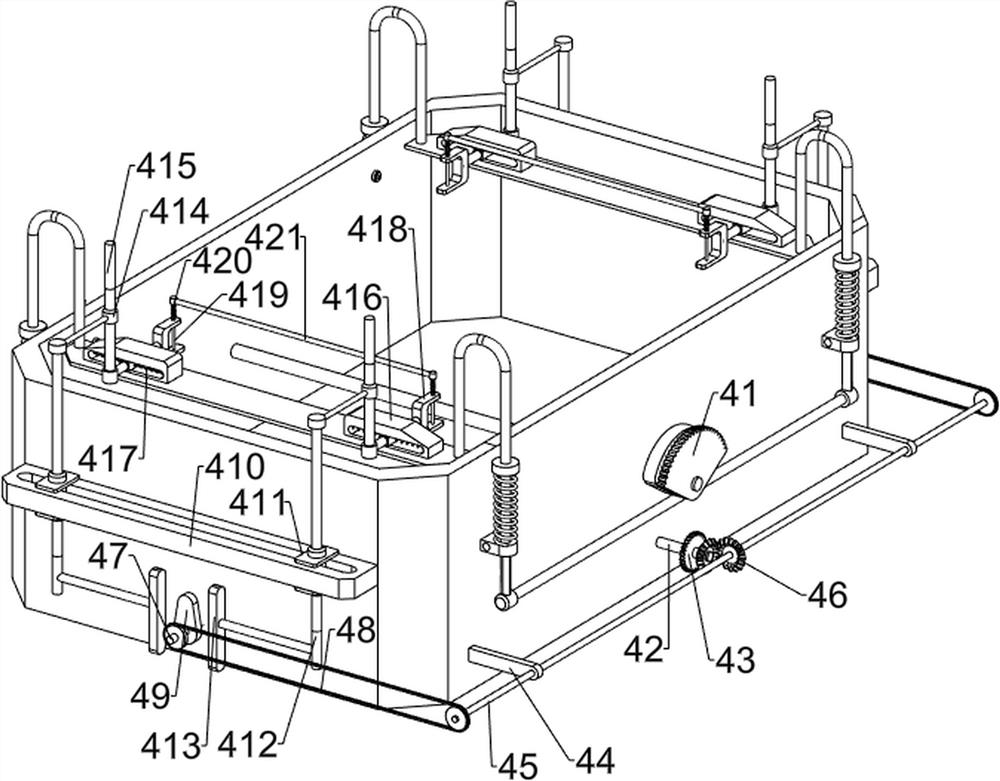

Working method of yarn sizing device for textiles

ActiveCN109338625AAutomatic sizingAutomatic dischargeTextile treatment machine arrangementsLiquid/gas/vapor removal by scrapingYarnPulp and paper industry

The invention discloses a yarn sizing device for textiles and belongs to the technical field of textile equipment. The yarn sizing device comprises a sizing mechanism, a material receiving mechanism,a material discharging mechanism and a material scraping mechanism; the material discharging mechanism comprises a material discharging assembly and a yarn limiting assembly, the yarn limiting assembly is disposed at the right end of the material discharging assembly, the material scraping mechanism includes a top face pulp scraping assembly and a bottom face pulp scraping assembly, and the top face pulp scraping assembly is disposed above the bottom face pulp scraping assembly; the bottom face pulp scraping assembly includes a pulp scraping component and a lifting assembly used for driving the pulp scraping component to ascend and descend, and the pulp scraping component is disposed on the top of the lifting assembly. Through the material scraping mechanism, automatic pulp scraping work can be conducted on yarn, so that the surface thickness of the warp yarn is ensured; moreover, through the yarn limiting assembly, the tension of the yarn can be automatically adjusted, so that the phenomena of breakage, wearing and the like of the yarn during transport are avoided.

Owner:江苏富尔达电子科技有限公司

Textile fabric dewatering device

InactiveCN112981812AImprove the opening effectEasy to cleanMechanical cleaningPressure cleaningStructural engineeringMechanical engineering

The invention discloses a textile fabric dewatering device and belongs to the technical field of textile equipment. The textile fabric dewatering device comprises a box body, a first conveying roller, a first tensioning roller, a second conveying roller, a third conveying roller, a second tensioning roller, a fourth conveying roller and a fifth conveying roller are arranged in the box body, a supporting plate is arranged between the second conveying roller and the third conveying roller, a moving rod is arranged at the center of the supporting plate in a penetrating mode, one end of the moving rod is connected with a moving plate, the other end of the moving rod is connected with a beating plate, the bottom end of the supporting plate is connected with a spring, the other end of the spring is connected with the top end of the beating plate, a first rotating shaft and a second rotating shaft are arranged between the moving plate and the supporting plate, a first cam is installed on the first rotating shaft, and a second cam is installed on the second rotating shaft. Through mutual cooperation of the first cam, the second cam, the moving plate, the moving rod, the supporting plate, the spring and the beating plate, the surface of fabric can be beaten, beating dewatering treatment is conducted on the fabric, and the beating plate can beat the fabric once every time the fabric is rotated by 180 degrees.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

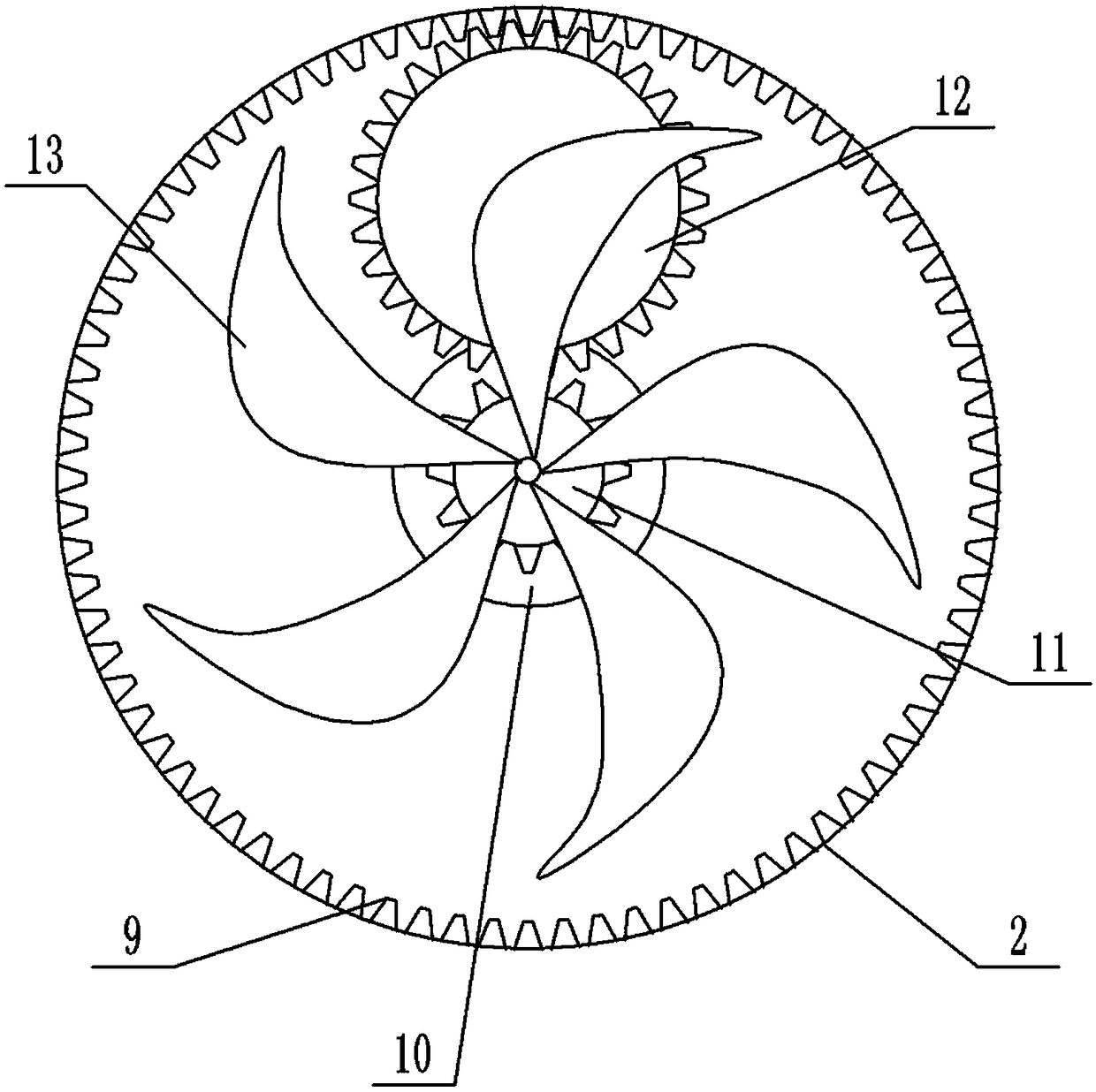

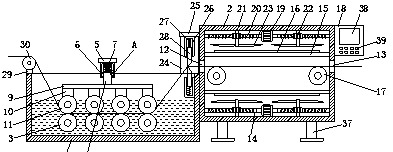

High-efficient dewatering dyeing machine

InactiveCN106521845AUniform dyeingImprove diffusion efficiencyTextile treatment machine arrangementsLiquid/gas/vapor removal by scrapingMotor driveEngineering

The invention discloses a high-efficient dewatering dyeing machine, comprising a base, a dye vat, an upper cover and a motor; the output shaft of the motor is connected with a reducer, and the middle lower output end of the reducer is fixedly connected with a vertical rotary shaft; the lower end of the rotary shaft is fixed with a horizontal brush disk, and the lower surface of the brush disk is provided with several brushes; stirring blades are fixed on the rotary shaft, and both sides of the rotary shaft are further provided with horizontal hammering rods, hinges are installed on both ends of the hammering rods; link rods are installed on the hinges, and hammers are fixed on the tail end of the link rods; a U-shaped pipe is connected to the side wall of the dye vat, and interconnected with a collecting tank. Through a guide roller, cloth is conveyed from the dye vet internally, and the motor drives the hammer to rotate and strikes on the cloth, thus the cloth is continuously vibrated so that the dye is contacted with the cloth; the cloth is dyed evenly by cooperating with the lower part; fluid on the conveyed cloth is scrapped through a scraper plate, and then delivered to the dye vat again, thus the loss of dye fluid is reduced.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

Uniform-coloring dyeing device for garment fabric production

InactiveCN109097936AQuick installationUniform dyeingLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsDrive shaftEngineering

The invention provides a uniform-coloring dyeing device for garment fabric production. The uniform-coloring dyeing device comprises tension springs, a transmission shaft, a hand-cranking part, mounting plates and clamping rods. Bottom ends of supporting rods are mounted on two upper sides of a body by welding; the hand-cranking part is mounted on the outer lateral side of the transmission shaft bywelding, and the middle of the transmission shaft is mounted in the middle of the front end of a dyeing chamber through a connector; the outer middle of the mounting plate in the rear side of the dyeing chamber is connected with the inner middle of the dyeing chamber through a rotating shaft, and clamping parts drive guide parts to move, so that clamping of the two guide parts is realized, a dyedfabric is extruded to remove excessive dyes from the fabric, and the dyes infiltrate the fabric to improve uniformity in fabric dyeing. The tension springs at the bottoms of the clamping parts pull the clamping parts to enable the guide parts above to move downwards.

Owner:杨智超

Textile cloth dyeing device

InactiveCN107558073AUniform dyeingEasy to dryTextile treatment containersLiquid/gas/vapor removal by scrapingEngineeringMechanical engineering

The invention discloses a textile cloth dyeing device. The textile cloth dyeing device comprises a dyeing box, wherein the dyeing box has a rectangular cavity structure; an opening is formed in the top of the dyeing box; a first supporting plate is mounted on the top of a side wall of the dyeing box; a second supporting plate is mounted on the top of the side wall, which is away from the first supporting plate, of the dyeing box; a guide-in roll is mounted on the upper surface of the first supporting plate; a guide-out roll is mounted on the upper surface of the second supporting late; a driving device is mounted on the upper surface of the second supporting plate; conveying rolls are symmetrically mounted on opposite inner walls of the dyeing box; dyeing rolls are symmetrically mounted onopposite inner walls of the dyeing box; the dyeing rolls are positioned below the conveying rolls; and two supports are connected between the first supporting plate and the second supporting plate. By the device, cloth can be dyed uniformly, residual dyestuff on the surface of the cloth can be scraped out, the dyestuff is saved, water of cloth is squeezed, drying treatment on the cloth is facilitated, and the working efficiency is improved.

Owner:南陵百绿汇农业科技有限公司

Non-woven fabric dyeing device for production

InactiveCN111945328AUniform dyeingAvoid damageDispersed particle separationHeating/cooling textile fabricsHeater RodNonwoven fabric

The invention discloses a non-woven fabric dyeing device for production, belongs to the technical field of non-woven fabric production, and solves the problem that an existing non-woven fabric dyeingdevice is low in dyeing efficiency. The technical key point is as follows: the non-woven fabric dyeing device comprises a non-woven fabric, the non-woven fabric is arranged in a dyeing box in a penetrating manner under the conduction effect of a first rotating roller, and a first motor is started to drive a movable sleeve so as to drive the first rotating roller to move up and down, so that up-down adjustment of the non-woven fabric is achieved; a third motor is started, to drive stirring blades and heating rods to rotate, so that dyeing of the non-woven fabric is more uniform; through the arrangement of hairbrushes, sediments can be cleaned up; through the arrangement of a filter screen, the non-woven fabric can be prevented from being damaged; scraper blades remove redundant dyeing liquid, a dehydration block carries out dehydration, an air cooler is used for cooling, an activated carbon layer is used for purification and sterilization, enzyme water washing liquid in a cleaning box is used for cleaning, the non-woven fabric enters the drying box through conduction of the first rotating roller at an outer cover, and the air heater is started for drying. The dyeing device has the advantage of being high in dyeing efficiency.

Owner:刘鹏刚

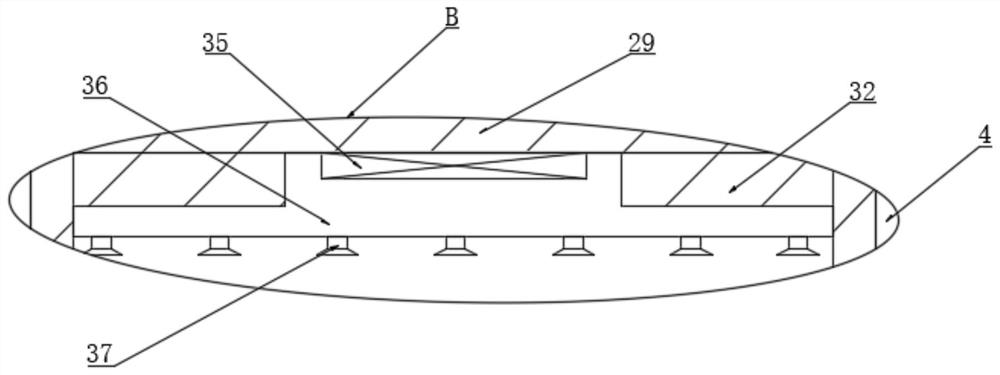

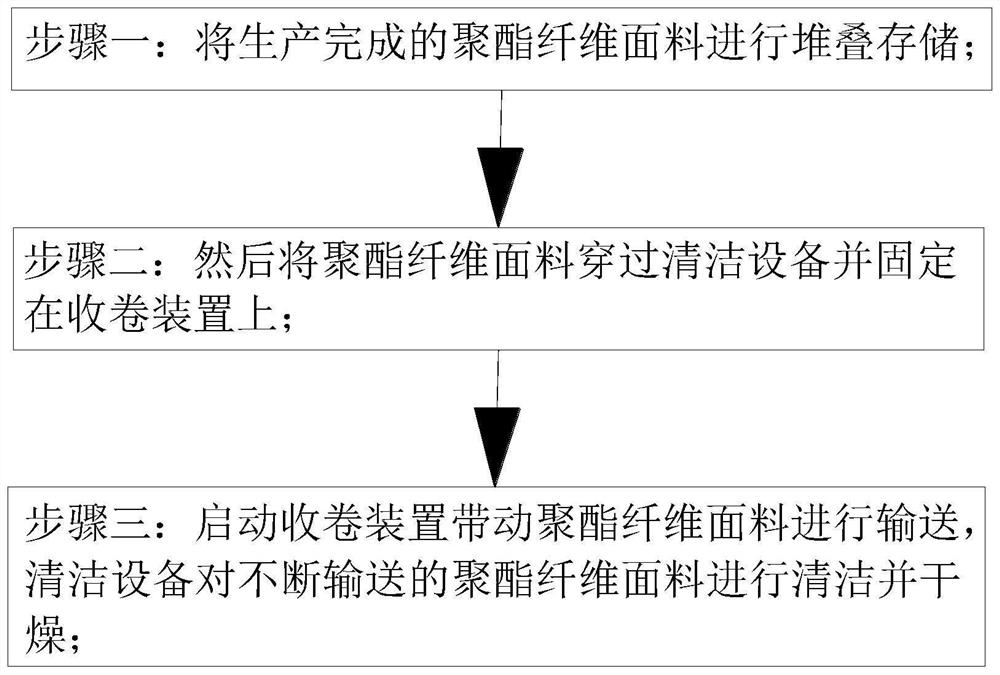

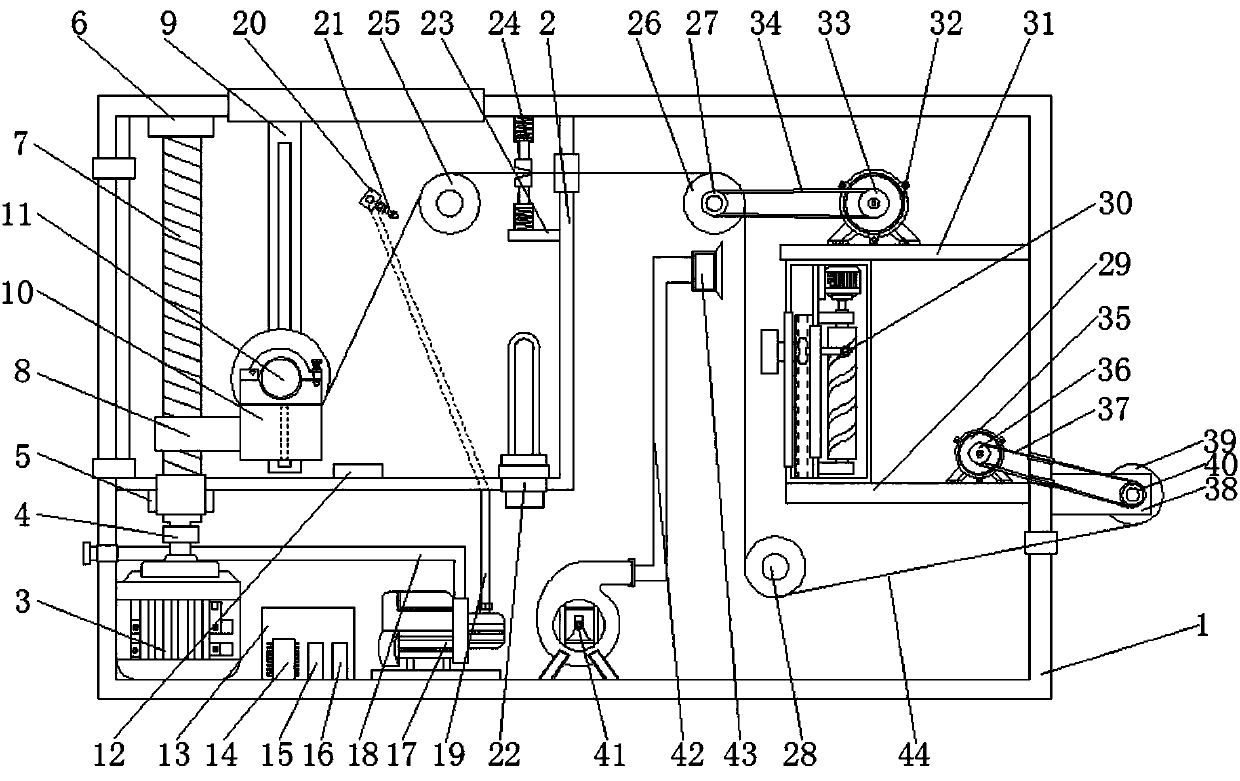

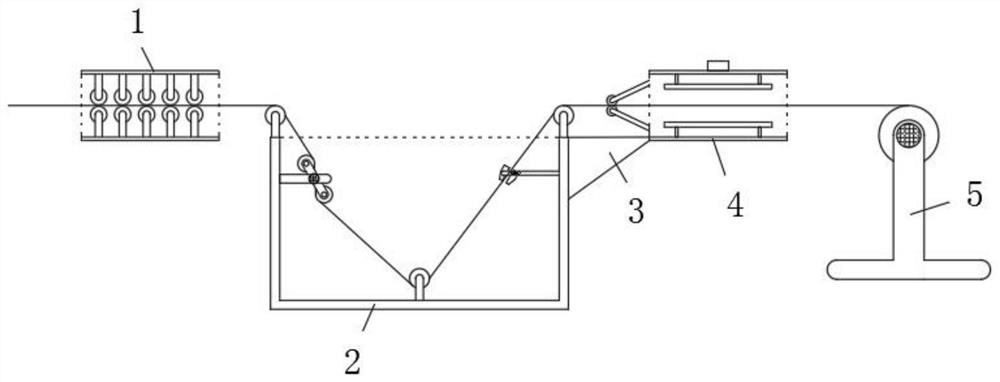

Polyester fiber fabric processing and preparing technology

ActiveCN113265786AClean and thoroughImprove cleaning efficiencyTextile treatment by spraying/projectingLiquid/gas/vapor removal by scrapingPolyesterFiber

The invention discloses a polyester fiber fabric processing and preparing technology in the technical field of polyester fiber fabric processing and preparing. The technology comprises the specific steps that 1, produced polyester fiber fabrics are stacked and stored; and 2, the polyester fiber fabrics penetrate through cleaning equipment and are fixed to a winding device. When the polyester fiber fabrics are cleaned every time, the fabrics are vertically conveyed first, and then a water spraying pipe is used for directly spraying water to clean the fabrics; two T-shaped scraping plates move up and down in a reciprocating mode, so that the fabrics are scraped for multiple times, and water stains and stains on the fabrics are cleaned and discharged together; when the T-shaped scraping plates move up and down, a vibrating mechanism vibrates continuously, a vibrating rotating rod is pushed to enable the fabrics to vibrate frontwards and backwards, and water stains left in the cleaned fabrics are shaken out; and the cleaned fabrics are thoroughly dried through a water scraping plate and a drying machine, so that the cleaning and drying efficiency is improved, and the fabrics are thoroughly cleaned.

Owner:浙江天源环保科技股份有限公司

Cleaning device of dyed textile

ActiveCN107641917AGuaranteed tidyNot looseTextile treatment machine arrangementsTextile treatment by spraying/projectingTemperature controlEngineering

The invention discloses a cleaning device of dyed textile. The device comprises a box body, a cleaning box is fixedly connected with one side of the inner wall of the box body, and a first motor, a water pump and a blower are fixedly connected with the bottom of the inner wall of the box body in sequence; a screw rod is fixedly connected with an output shaft of the first motor through a coupler, asupporting rack is fixedly connected with the surface of the screw rod through a sliding block, and a discharging roller is rotatably connected with the top of the supporting rack; a temperature sensor and a heater are fixedly connected with the bottom of the inner wall of the cleaning box, a temperature control box is fixedly connected with the bottom of the inner wall of the box body, a water wiping device is fixedly connected with one side of the inner wall of the cleaning box through a fixing plate, and a drying device is fixedly connected with one side of the inner wall of the box body through a second supporting plate. The invention relates to the technical field of textile processing. The cleaning device of dyed textile effectively controls the temperature of clear water, guarantees the cleaning quality, dries and collects the cleaned textile at the same time, improves the working efficiency and reduces the labor force.

Owner:徐州势甲信息科技有限公司

Non-woven fabric dyeing process and non-woven fabric dyeing production line

PendingCN112267235AImprove dyeing uniformityAvoid the phenomenon of inconsistent local dyeing thicknessLiquid/gas/vapor removal by scrapingTextile treatment carriersProcess engineeringWoven fabric

The invention discloses a non-woven fabric dyeing production line. The non-woven fabric dyeing production line comprises a dyeing pool and a winding frame; a winding motor is arranged on the winding frame; an output end of the winding motor is connected with a winding roller and drives non-woven fabric to be connected in a winding mode; a tensioning assembly for adjusting dyeing tension of the non-woven fabric is arranged on the inner wall of one side of the dyeing pool; the other side of the dyeing pool is provided with a cleaning and scraping assembly for cleaning and scraping excess dye onthe non-woven fabric; and a pair of drying bins for drying the dye on the non-woven fabric is arranged between the dyeing pool and the winding frame. According to the non-woven fabric dyeing production line, through the arranged tensioning assembly, it is ensured that the non-woven fabric enters or moves out of dye in the optimal tensioning state, the dyeing uniformity of the non-woven fabric is improved, and the redundant dye on the non-woven fabric can be removed in combination with the scraping effect of the cleaning and scraping assembly; and the dyeing uniformity of the dye on the non-woven fabric is further improved, and the phenomenon that the local dyeing thickness of the non-woven fabric is inconsistent is avoided.

Owner:邵阳东州无纺布有限公司

Clothing fabric dyeing and finishing process

ActiveCN113026386AHigh color fastnessImprove permeabilityLiquid/gas/vapor removal by gas jetsDyeing processColour fastnessProcess engineering

The invention belongs to the technical field of clothing dyeing and finishing processing, and particularly relates to a clothing fabric dyeing and finishing process which includes the following steps: S1, pre-treating gray fabric to be treated, and removing dust, impurities, fluff and an oil agent on the gray fabric; S2, on the basis of S1, dyeing the pretreated gray fabric to complete treatment of the gray fabric to obtain semi-finished fabric; and in a dyeing process, atomizing liquid dye on two sides of the gray fabric and then spraying to the gray fabric through spray guns, wherein the spray guns are symmetrically distributed on the two sides of the gray fabric; and S3, feeding the semi-finished fabric into a dryer on the basis of S2, and performing high-temperature drying on the semi-finished fabric to obtain a dried finished fabric. The process is simple and convenient to operate, and the prepared fabric is good in color fastness and color depth; and meanwhile, the fabric is sufficient in liquid absorption and good in shrinkage resistance.

Owner:浙江日升服装有限公司

Cloth cleaning equipment

InactiveCN108505240ARealize double-sided cleaningSo as not to damageTextile treatment machine arrangementsTextile treatment by spraying/projectingBiochemical engineeringWater pipe

The invention relates to the field of cloth processing equipment, and discloses a cloth cleaning equipment, which comprises a water pipe, wherein the water pipe is connected with a spray head, the spray head is slidably arranged above the cloth conveying direction, and a plurality of needle tubes are arranged on the spray head; the lower part of the needle tubes is provided with a reflecting mechanism for reverse sputtering of water, the reflecting mechanism comprises a water receiving tank, a plurality of reflecting plates are arranged in the water receiving tank, jumping balls are arranged in the plurality of reflecting plates, and a supporting spring is connected between the jumping ball and the reflecting plates. According to the invention, the double-side cleaning of the cloth can berealized, and the processing quality of the cloth can be improved.

Owner:重庆曹浩思瑗电子商务有限公司

Textile fabric desizing device

InactiveCN111962230AFast and efficient uniform desizing effectApply evenlyTextile treatment machine arrangementsLiquid/gas/vapor removal by vibrationEngineeringMechanical engineering

The invention belongs to the technical field of fabric desizing equipment, and particularly relates to a textile fabric desizing device. The textile fabric desizing device comprises a desizing pond. Asoaking trough is arranged in the desizing pond. Multiple guide rollers are rotationally arranged on the desizing pond, and the guide rollers are used for carrying out guiding and conveying on a fabric body. Multiple electric telescopic rods are fixed to a sealing plate movably arranged on the upper portion of the desizing pond, and a fixed guide strip is fixed to the telescopic end of each electric telescopic rod. The multiple fixed guide strips are located between the adjacent guide rollers, and rotating cavities are formed in the two sides of each fixed guide strip. Rotating brush rollersare rotationally arranged in the rotating cavities through cavity columns, and multiple liquid spray holes are evenly formed in the outer wall of each rotating brush roller. The end of each cavity column communicates with multiple liquid guide hose through multiple rotating sleeves. The side walls of the cavity columns communicate with the liquid spray holes through guide holes. The outer walls ofthe rotating brush rollers are in rotating contact with the outer wall of the fabric body. The rapid, efficient and even desizing effect of desizing liquid to the fabric body is improved.

Owner:宿州市悦然纺织有限公司

Breathable and antistatic men's suit fabric and processing technology thereof

InactiveCN110373791AImprove antibacterial propertiesImprove breathabilityMechanical cleaningPressure cleaningAntistatic agentEngineering

The invention discloses a breathable and antistatic men's suit fabric and a processing technology thereof. The suit fabric comprises a base layer, wherein an antistatic layeris bonded on the surface of the base layer, and a breathable layeris bonded on the surface of the antistatic layer; the base layer is woven by warp yarn and weft yarn by interweaving, the anti-static layer is anti-static gridgrey cloth, and the breathable layer is aramid fiber finished by asoft finishing liquid. The warp yarn formed by high-shading fiber yarn andflax fiber containing adeinsectization solventis woven withthe weft yarn formed by bamboo charcoal fiber and cotton fiber to formthe base cloth layer, and the flax fiber, the high-shading fiber yarn, the bamboo charcoal fiber and the cotton fiber all have good antibacterial performance, so that tent cloth can effectively remove bacteria and repel mosquitoes, and green production is realized as the used materials are relatively environmentally friendly.

Owner:安徽弋尚纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com