Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Uniform printing and dyeing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

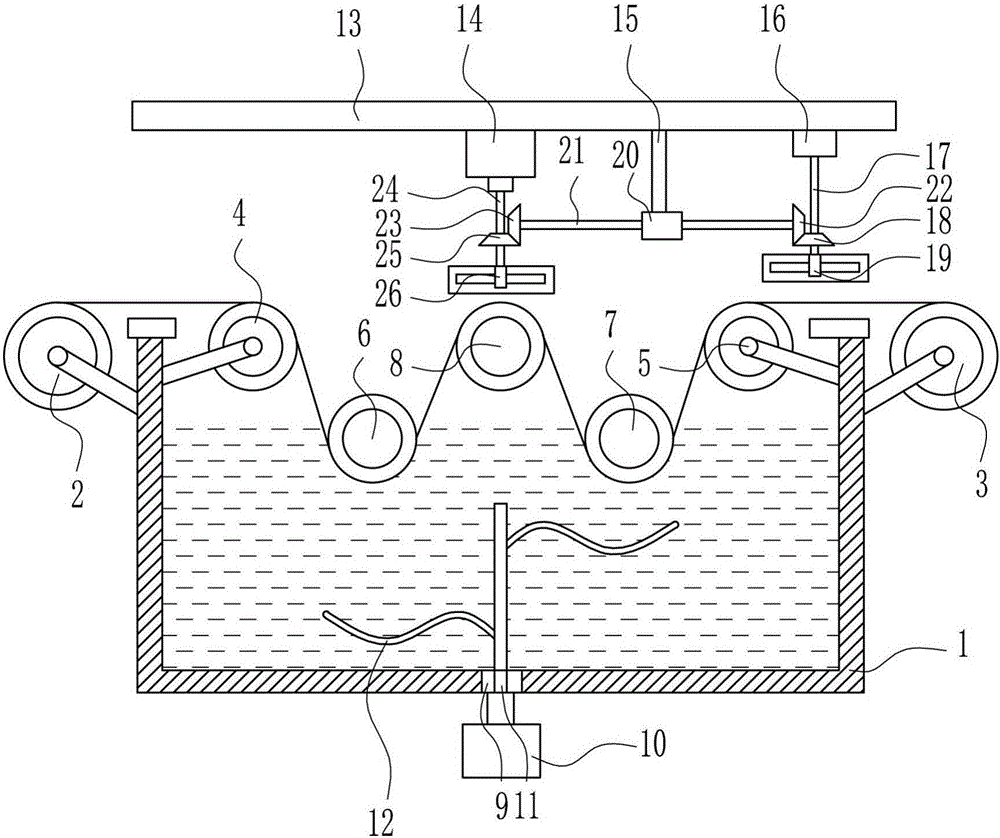

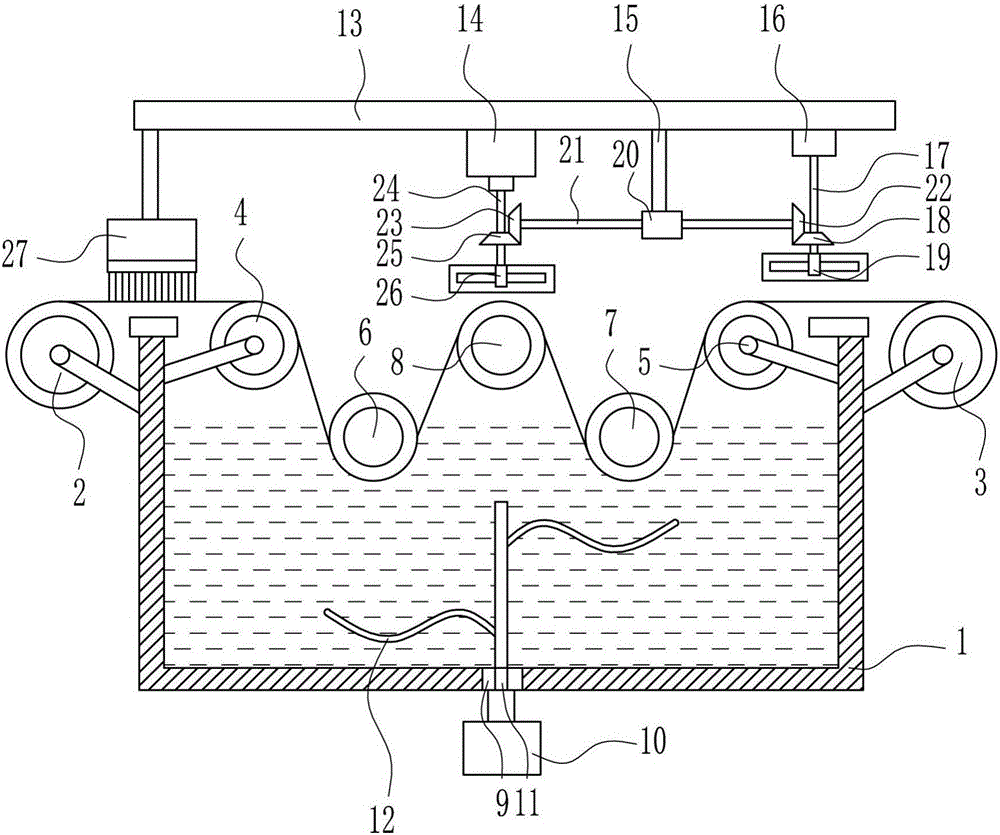

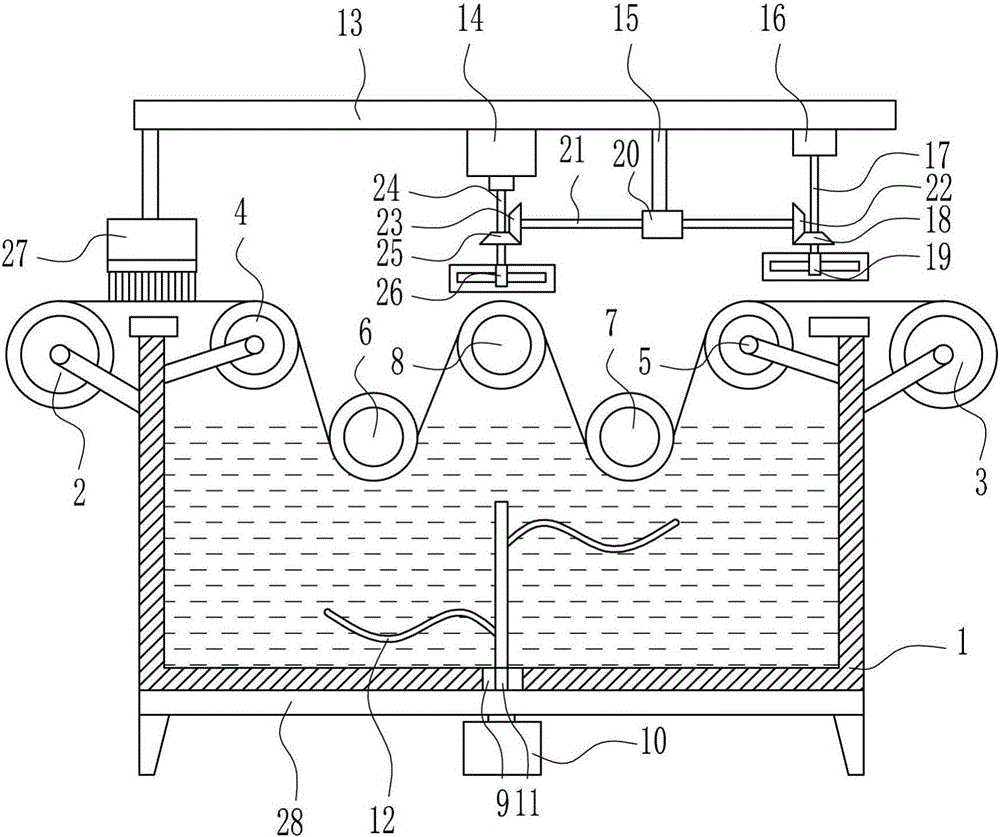

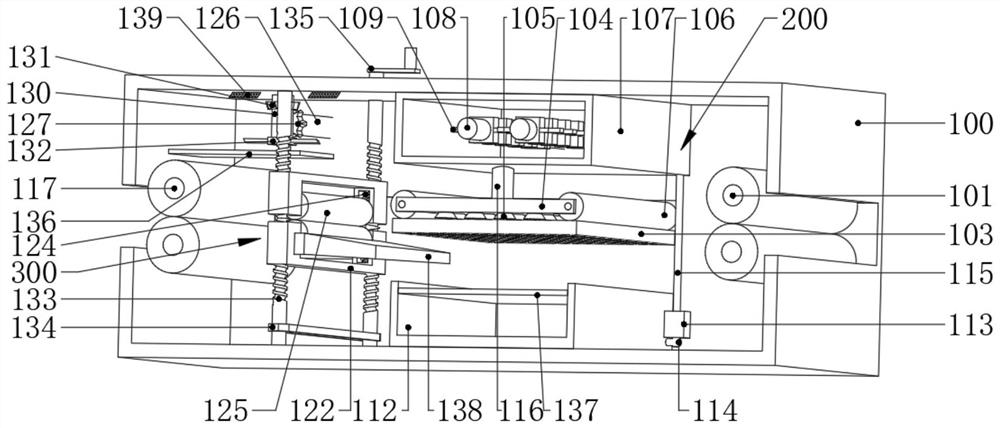

Efficient printing and dyeing device for cloth material

InactiveCN106436098AImprove affordabilityExtend the service lifeTextile treatment containersLiquid/gas/vapor removalElectric machineryDyeing

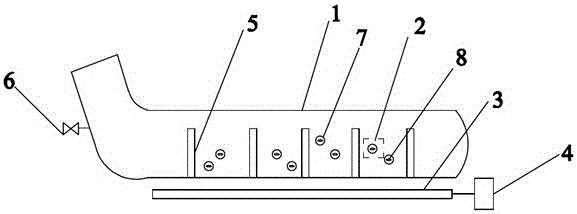

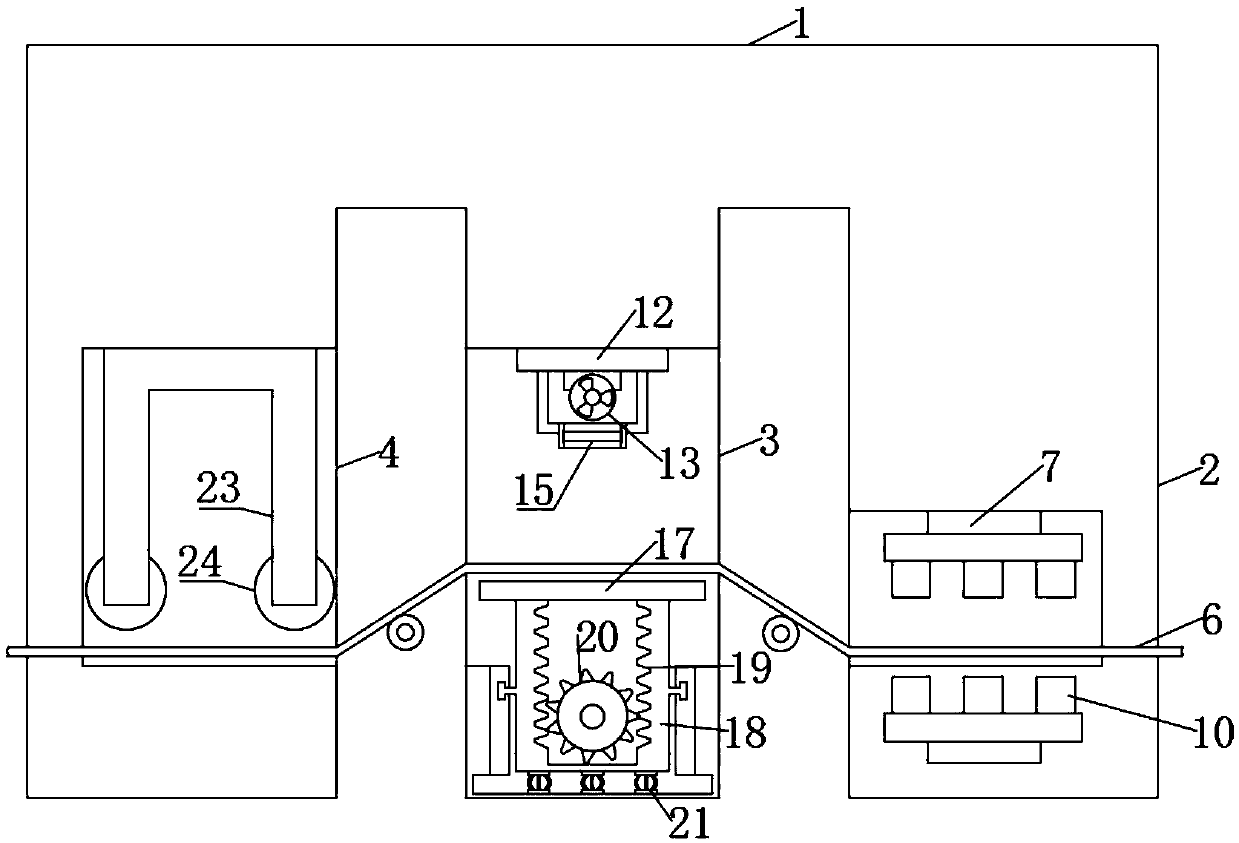

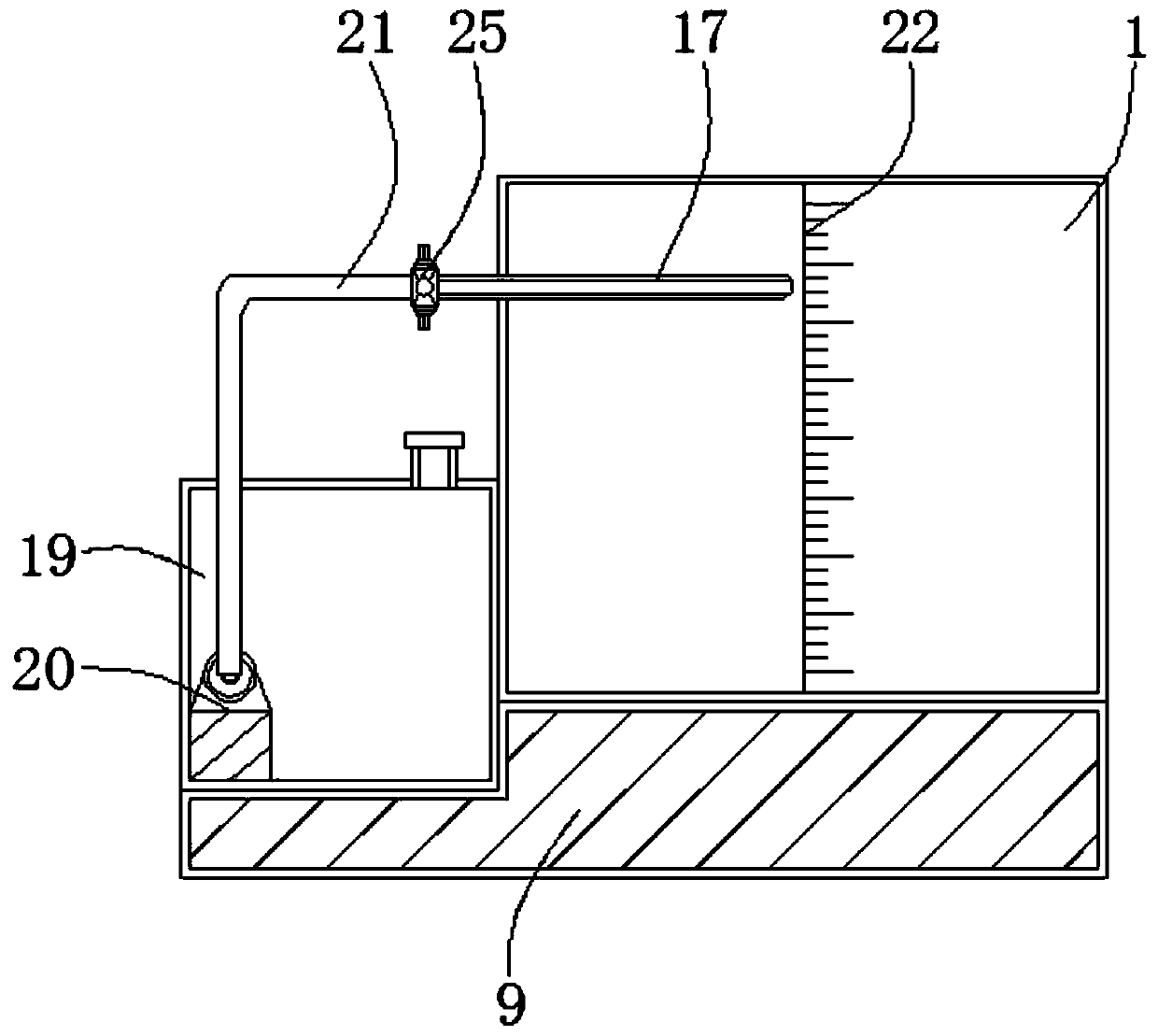

The invention relates to a printing and dyeing device for a cloth material, in particular to an efficient printing and dyeing device for the cloth material. The efficient printing and dyeing device for the cloth material achieves the technical purposes that printing and dyeing are uniform, air drying can be performed in the printing and dyeing process, and no printing and dyeing agent residue is contained. In order to achieve the technical purposes, the efficient printing and dyeing device for the cloth material comprises a printing and dyeing pond, a discharging roller, an electric receiving roller, a left guiding roller, a right guiding roller, a first guiding roller, a second guiding roller, an upper guiding roller, a first motor, a rotating rod and the like. The upper portions of the left and right sides of the printing and dyeing pond are provided with the discharging roller and the electric receiving roller respectively. The upper portions of the left and right sides inside the printing and dyeing pond are provided with the left guiding roller and the right guiding roller respectively. The first guiding roller and the second guiding roller are symmetrically arranged inside the printing and dyeing pond. The mode of two-time printing and dyeing is adopted, a fan is used for performing air drying on the cloth material obtained after two-time printing and dyeing, and a printing and dyeing agent is prevented from being stuck to the inner wall of the printing and dyeing pond through a stickiness removal structure.

Owner:绍兴明业印染有限公司

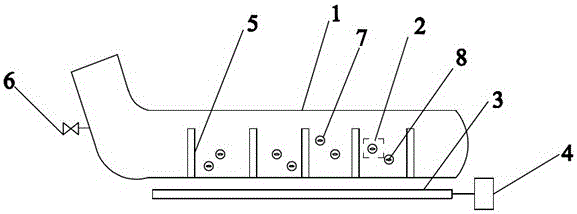

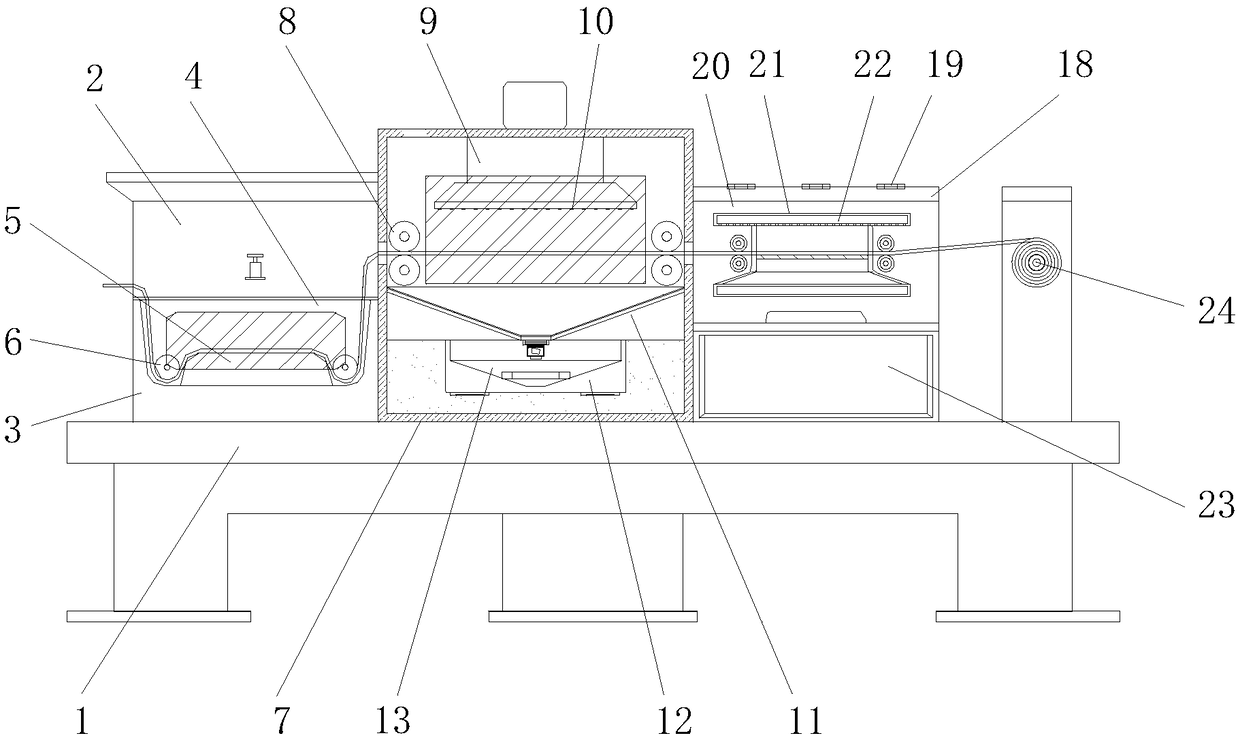

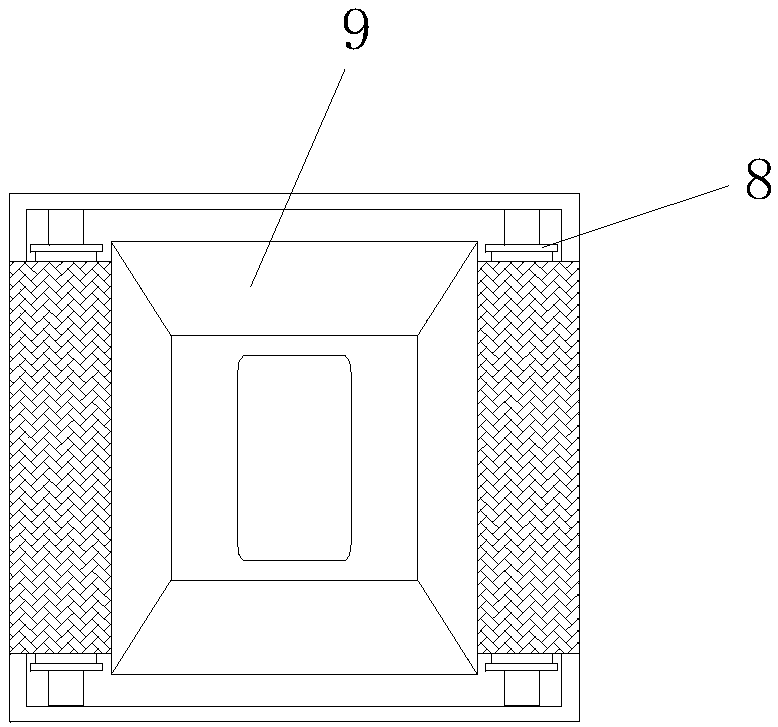

Dyeing equipment for textile fabric production

InactiveCN112430942AEfficient mixingThoroughly tumble up and down to mixTextile treatment containersTextile treatment machine arrangementsAir cleaningElectric machinery

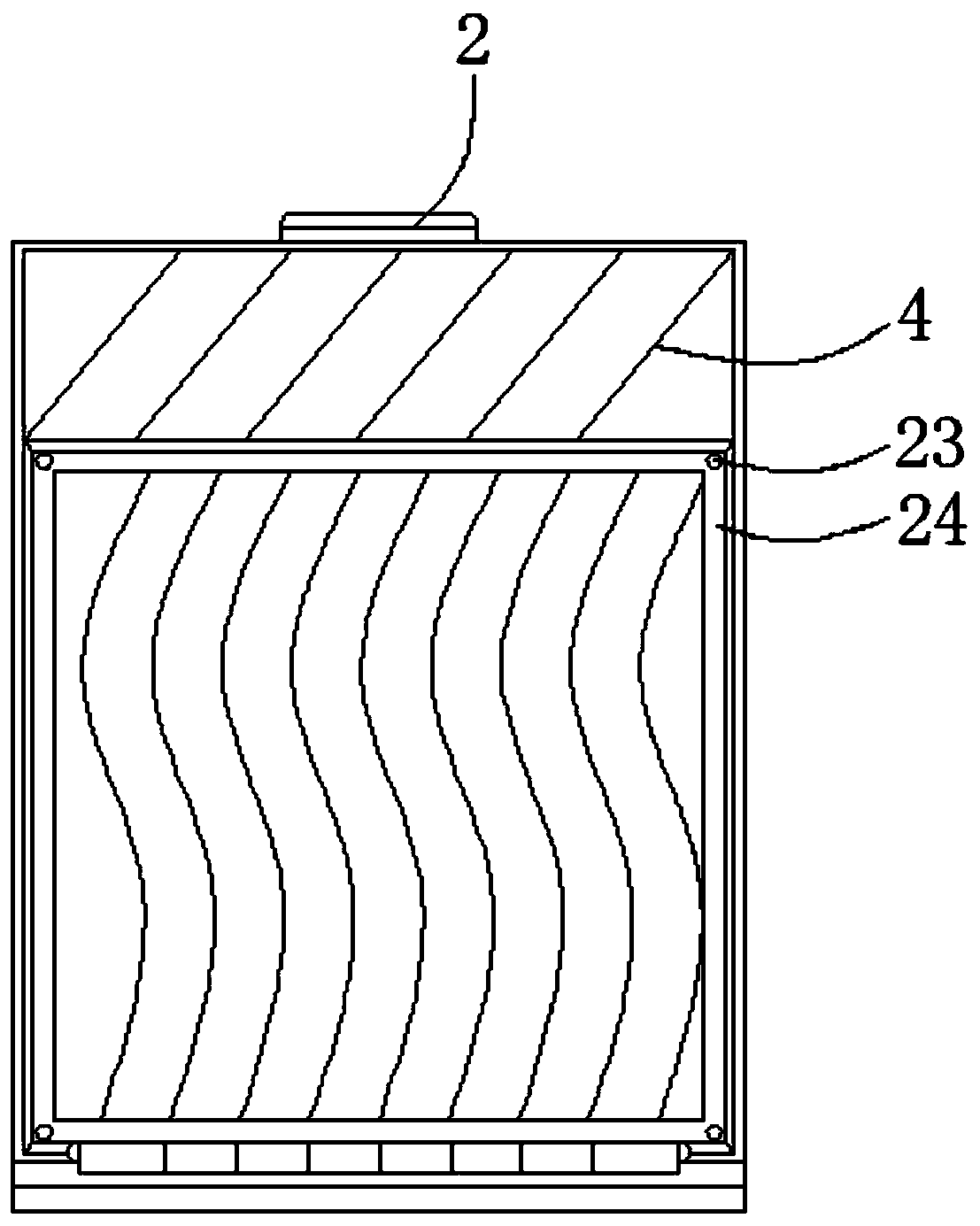

The invention discloses dyeing equipment for textile fabric production. The drying equipment comprises an operation table, wherein the middle of the top of the operation table is fixedly connected toa printing and dyeing box; the right side of the printing and dyeing box is fixedly equipped with a drying device; the top of the drying device is fixedly equipped with an air purifying device; the top of the printing and dyeing box is fixedly equipped with a box cover assembly; five groups of printing and dyeing rollers are alternatively and rotatably connected on the middle in the printing and dyeing box at equal distance; three groups of grooves are formed in the bottom of the printing and dyeing box at equal distance; first drive motors are fixedly mounted inside the grooves; the output ends of the first drive motors are fixedly equipped with stirring frames; and a cloth inlet is formed in the left side of the printing and dyeing box. The dyeing equipment can perform efficient dyeing on the dyed textile fabric, is relatively uniform in dyeing, further can dry better, reduces emission of polluted air, is improved in practicability and environment friendliness, has a wide applicationprospect, and is worthy of being used.

Owner:绍兴宽裕机械股份有限公司

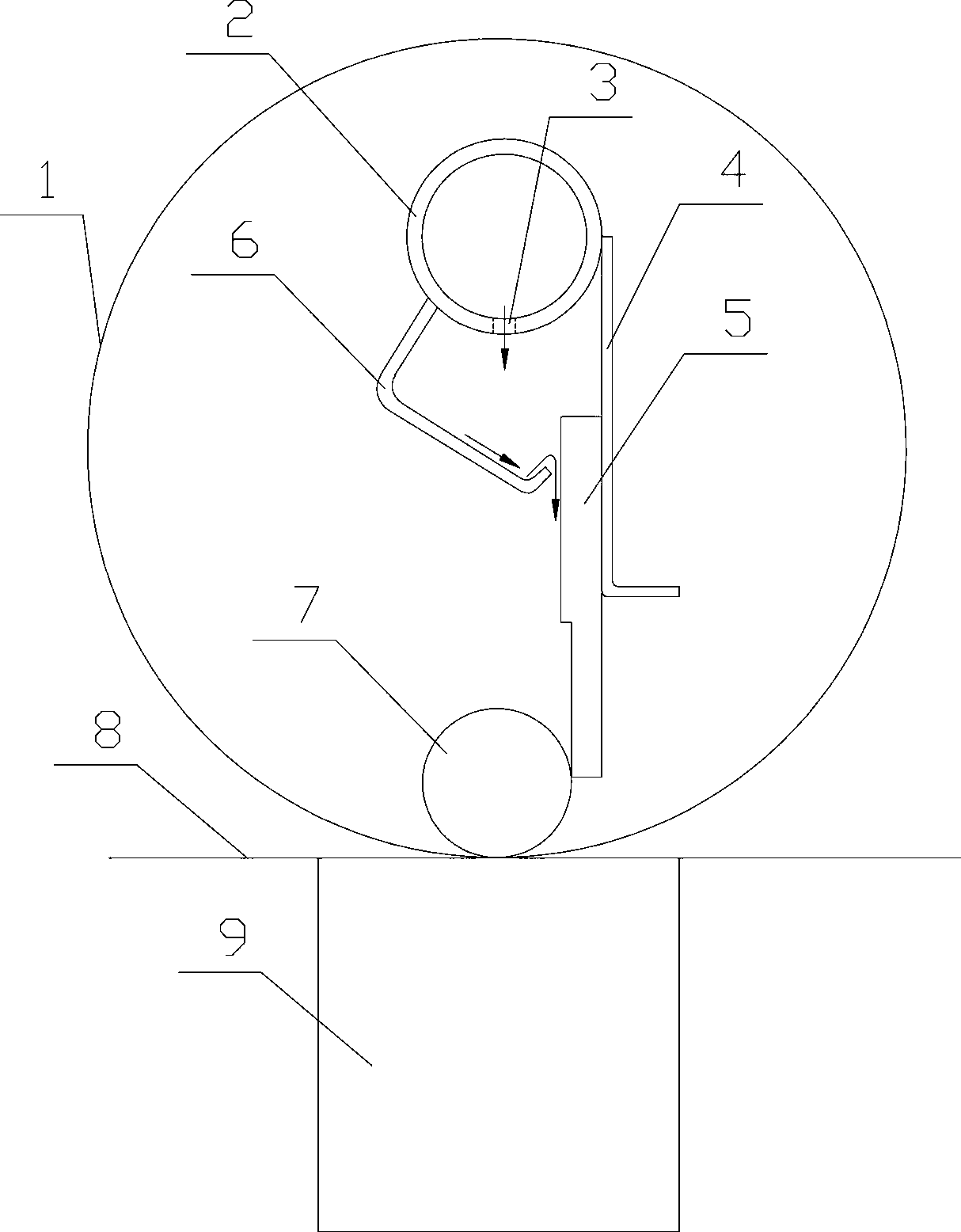

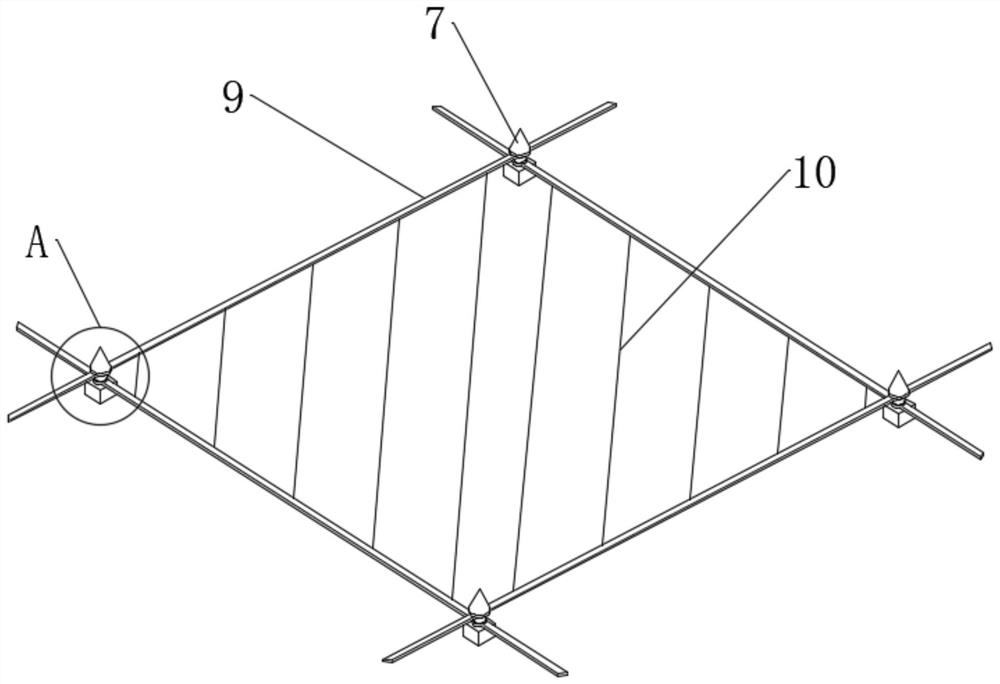

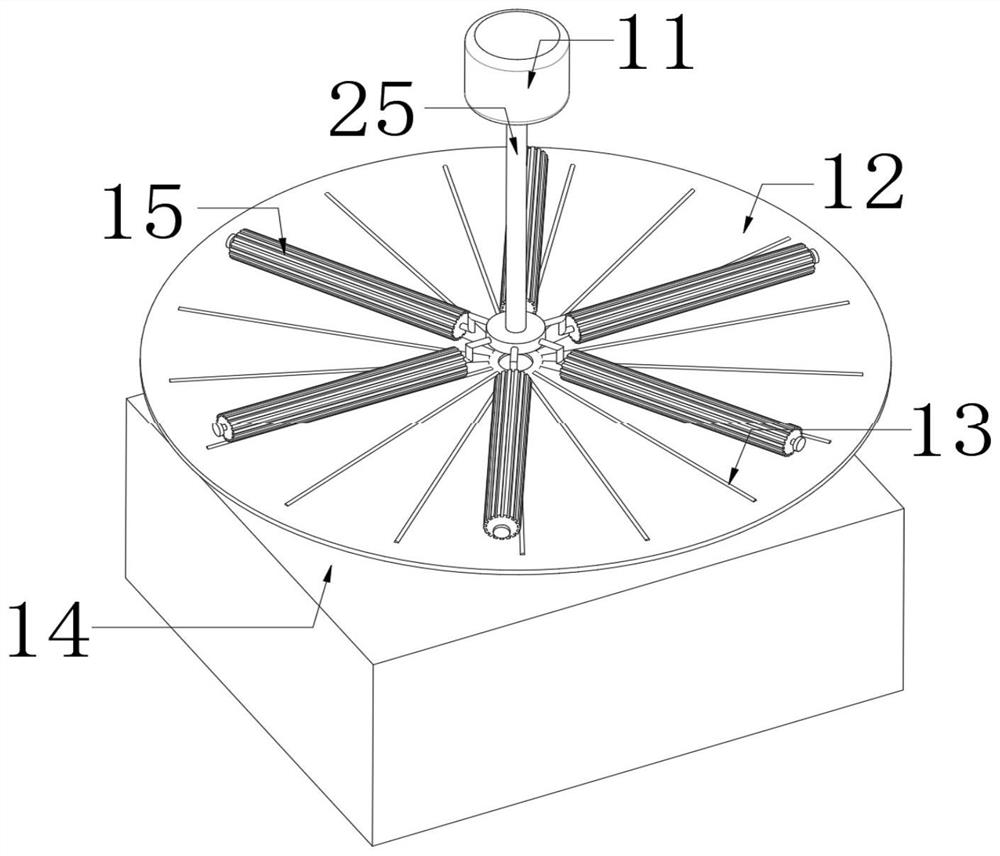

Plant transfer printing equipment and application method thereof

InactiveCN111485345AUniform printing and dyeingAchieve expansionTextile treatment machine arrangementsTextile treatment carriersAgricultural engineeringEngineering

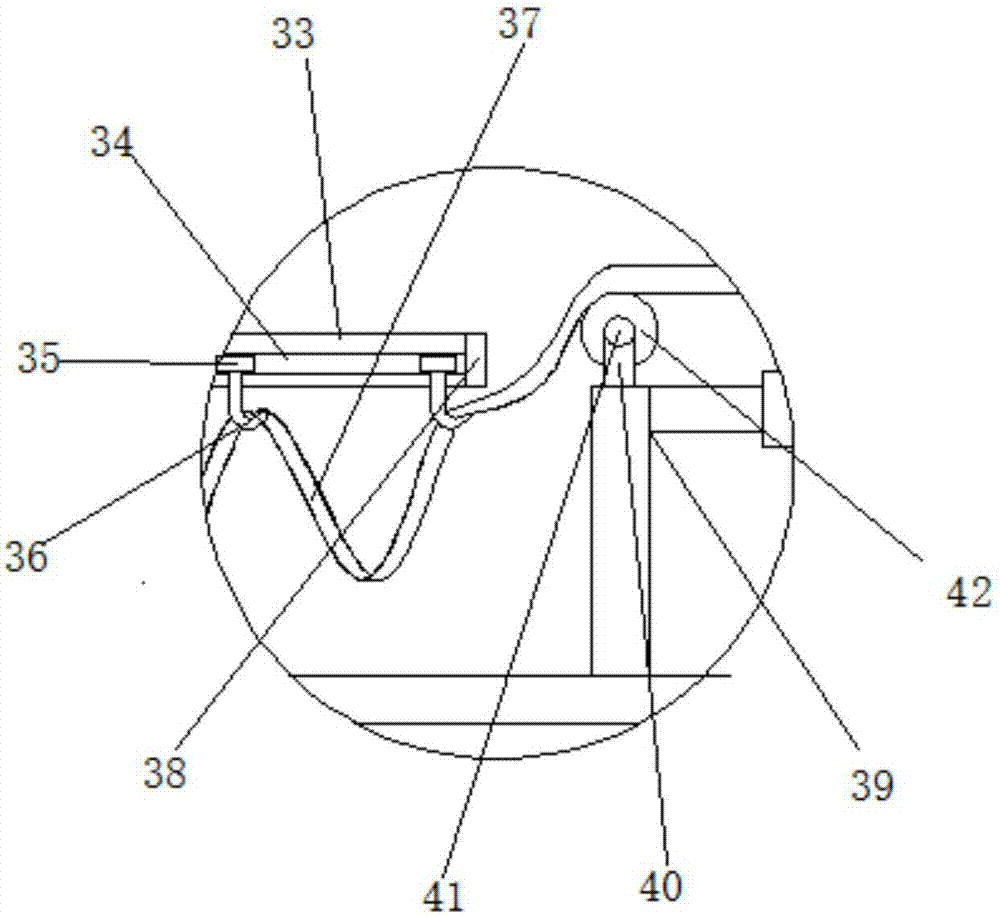

The invention discloses plant transfer printing equipment and an application method thereof and belongs to the technical field of plant transfer printing equipment. The plant transfer printing equipment comprises a supporting plate. A mounting plate, a limiting plate and a worktable are fixedly arranged downward in a vertical direction of the supporting plate successively. A vertical plate is vertically and fixedly arranged on the top of the mounting plate, a reciprocating mechanism is arranged on the side wall of the vertical plate, a telescopic rack is further telescopically connected to thetop of the mounting plate, an output end of the reciprocating mechanism is engaged to the telescopic rack, the outer wall of the bottom end of the telescopic rack is rotatably connected to symmetrical adapting rods, and mounting blocks are fixedly arranged at the bottom ends of the adapting rods through springs. By arranging the reciprocating mechanism to drive a beating disc to stretch to beat plants among fabrics on a turnplate, plant pigments are transfer printed to the fabrics uniformly. In addition, an arranged driving mechanism drives the turnplate to rotate intermittently, so that after the turnplate stops intermittent rotation, the plants are beaten and transfer printed through the beating disc.

Owner:绍兴柯桥富荣纺织有限公司

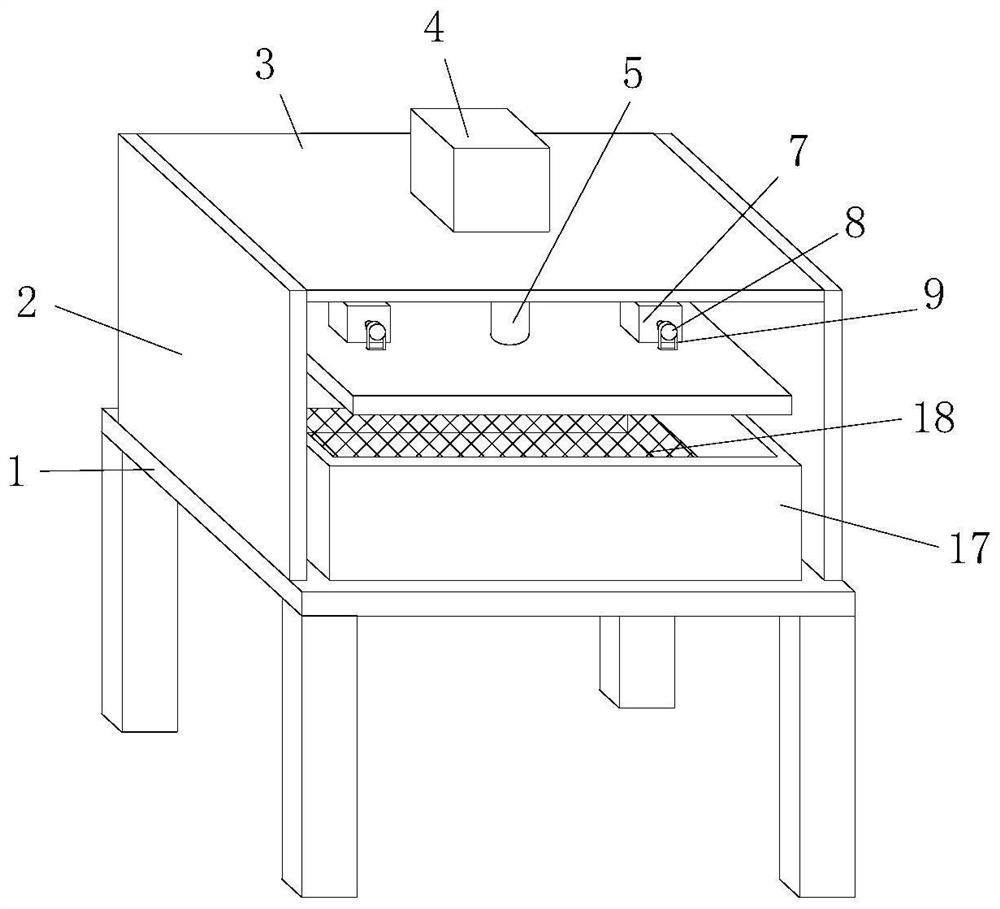

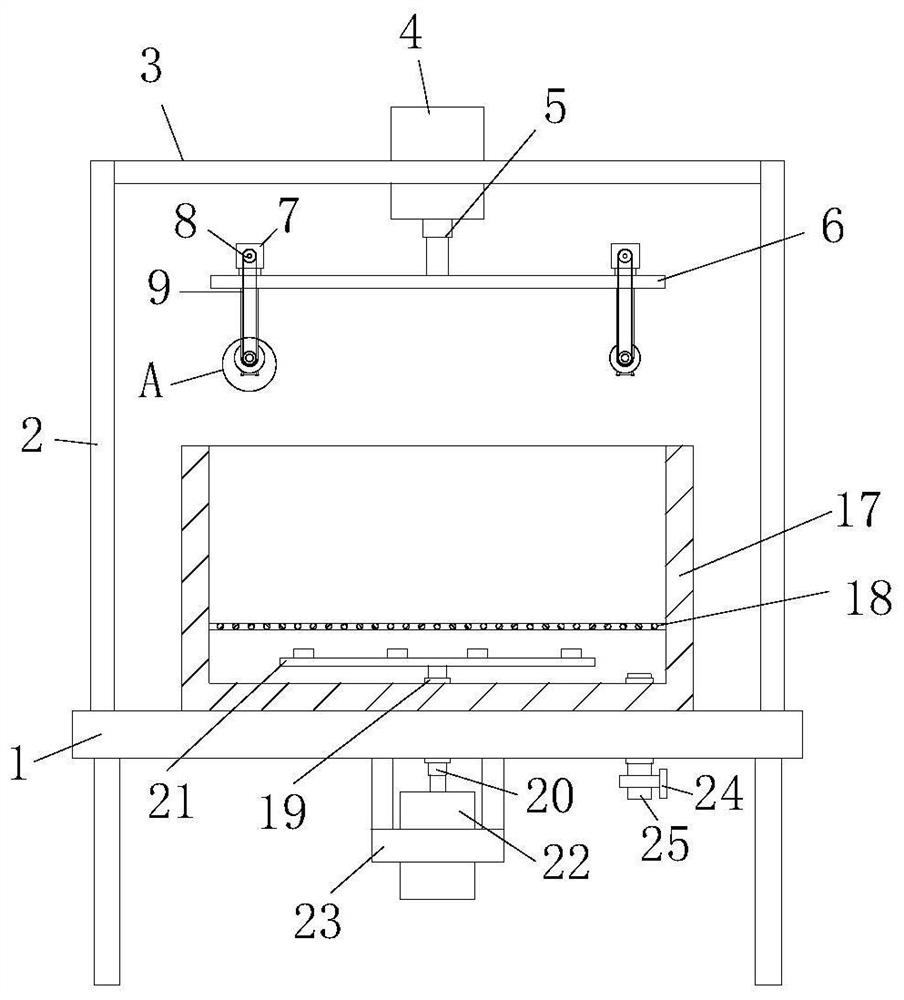

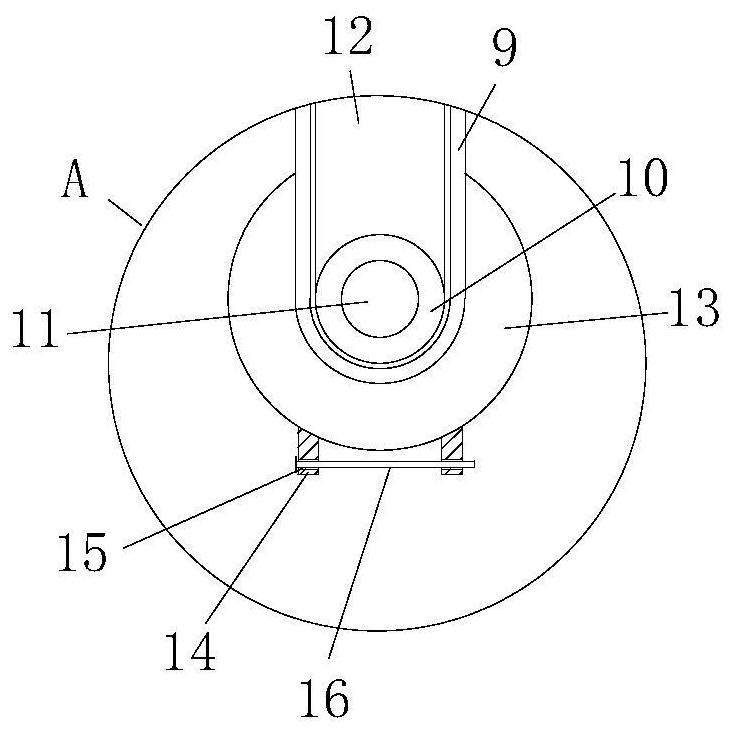

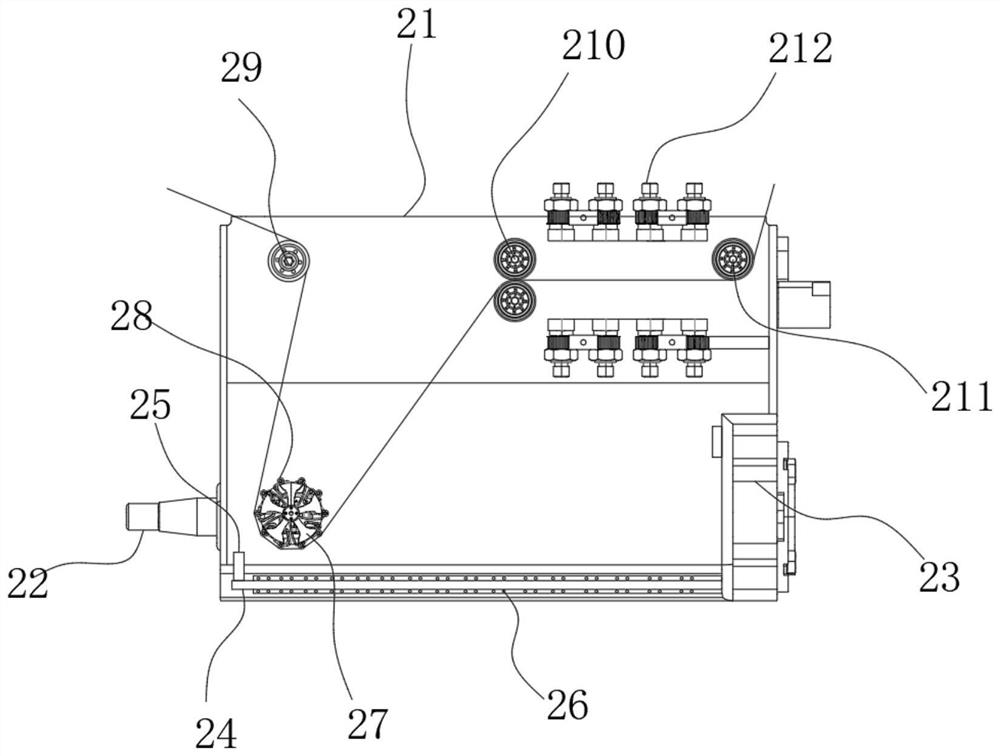

Printing equipment for textile fabric production

InactiveCN111764072AAvoid precipitationImprove printing and dyeing efficiencyTextile treatment machine arrangementsTextile treatment carriersTransmission beltElectric machinery

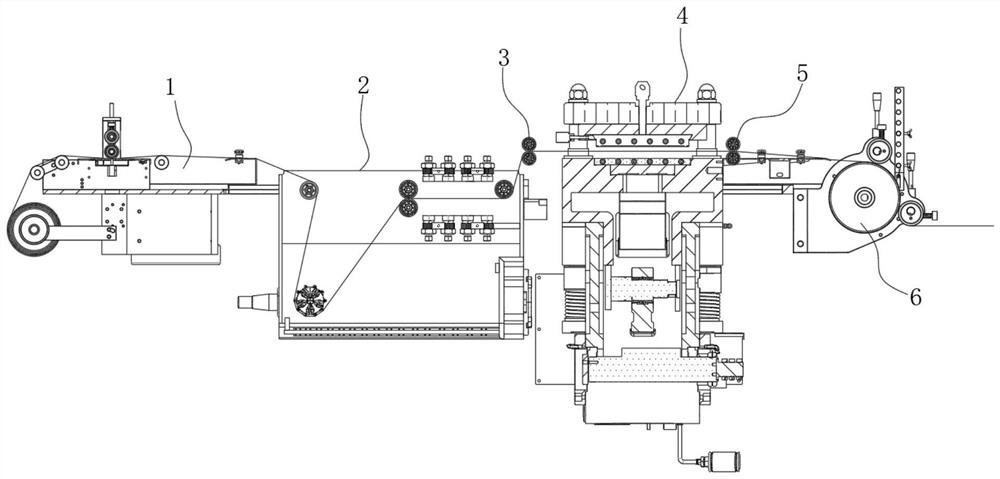

The invention discloses printing equipment for textile fabric production. The equipment comprises a control console, supporting plates, a top plate, a push rod box, an electric push rod, a drive plate, stepping motors, drive belt wheels, transmission belts, driven belt wheels, transmission shafts, supports, rotating rollers, fixing plates, open holes, positioning frames, limiting plates, metal rods, a fuel box, a limiting net, a rotating sealing bearing, a transmission column, stirring blades, a stirring motor, a machine frame, a drainage valve and a drainage pipe. The two stepping motors drive a fabric to reciprocate. After the fabric is soaked with dye, printing can be performed evenly, and the printing efficiency is improved. By arranging a drive motor, in the fabric printing process, the dye is stirred, dye precipitation can be avoided, and therefore the fabric printing effect is affected. Two ends of the fabric can be fixed through the positioning frame, the fabric can be prevented from being disengaged, and therefore the fabric dyeing work can be more completely performed.

Owner:吴江舒宇纺织有限公司

Cloth dyeing machine with stirrers

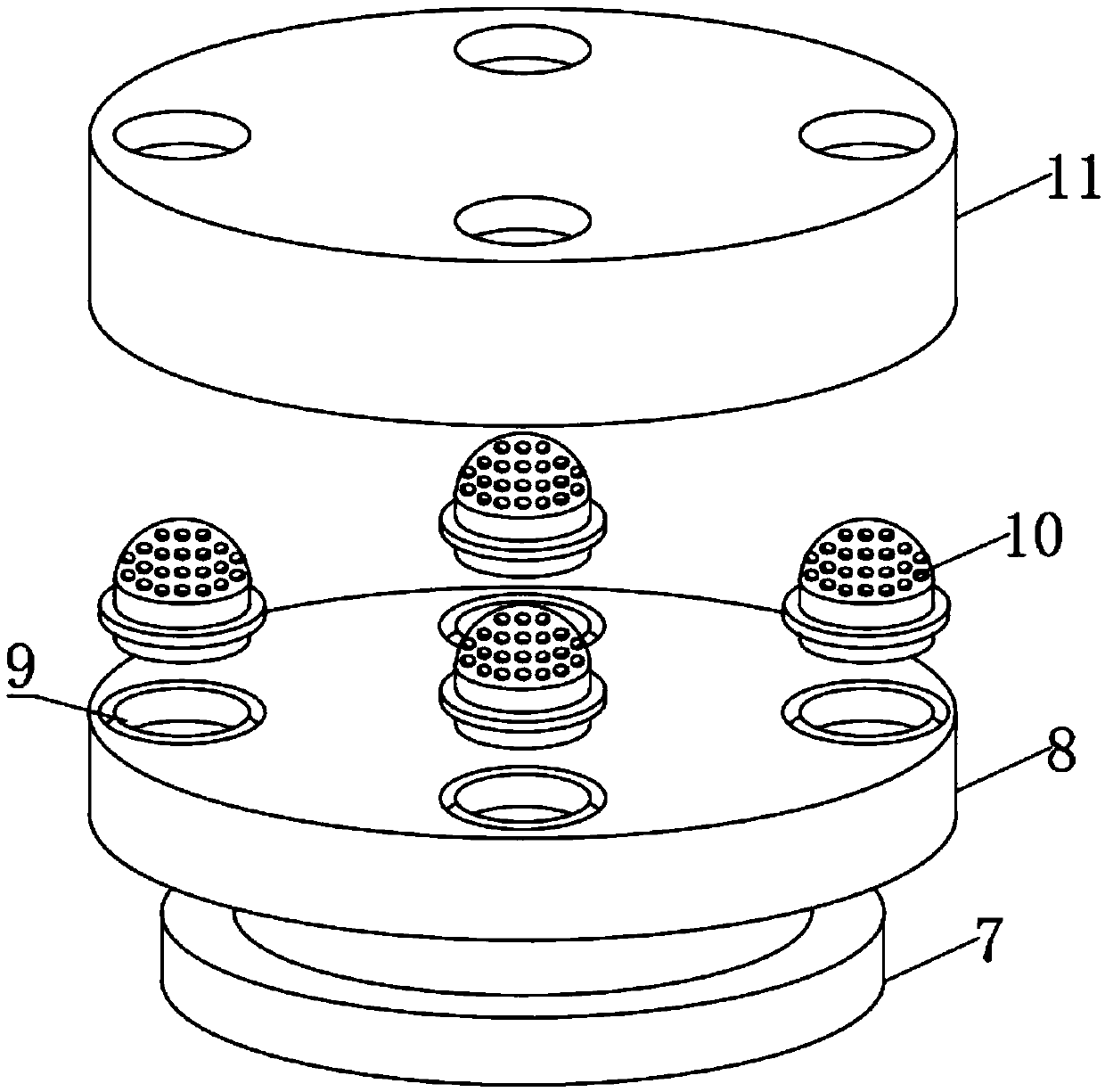

ActiveCN105113161AAvoid collisionAvoid secondary damageTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentMagnetic tension forceEngineering

The invention discloses a cloth dyeing machine with stirrers. The cloth dyeing machine structurally comprises a base, and is characterized by also comprising a cloth dyeing machine body, a magnetic controller, a magnetic sensor and the stirrers, wherein the cloth dyeing machine body is in a hooked cylinder shape; an anti-overflow hole is formed in the cloth dyeing machine body; each stirrer comprises a stirring body and a protecting cover; one cross section of each stirring body is elliptical; each stirring body is made of a magnetic material; each protecting cover is in a hollow spherical shape, and the surface of each protecting cover is covered with a plurality of circular holes; each protecting cover is divided into two semicircles which are connected with each other through threads; the magnetic sensor is positioned below the stirrers and is connected with the magnetic controller; the magnetic controller is positioned below the cloth dyeing machine body. Stirring operation is carried out by the adoption of the stirrers under the action of a magnetic force, and the stirrers are externally provided with the protecting covers, so that the collision between the stirrers is effectively prevented, the service life is prolonged, and dyeing is thorough and more uniform.

Owner:苏州盛泽科技创业园发展有限公司

Textile machinery and equipment facilitating printing and dyeing

InactiveCN107354631AConvenient printing and dyeingEffective heating treatmentTextile treatment machine arrangementsLiquid/gas/vapor treatment of indefinite length materialsAgricultural engineeringSpeed reduction

The invention provides textile machinery and equipment facilitating printing and dyeing, and relates to the field of textile. The textile machinery and equipment facilitating printing and dyeing comprises a printing and dyeing room, a first fabric box is fixedly connected to the top of the printing and dyeing room, a first delivery port is formed in the top of the printing and dyeing room and located at the bottom of the printing and dyeing room, a first bearing is fixedly connected to the back of the first fabric box, a first fabric rotating shaft is fixedly connected to an inner ring of the first bearing in a sleeved mode, a speed reduction wheel is fixedly connected to one end of the first fabric rotating shaft, and the end, far away from the speed reduction wheel, of the first fabric rotating shaft penetrates through the first bearing and the first fabric box in sequence and extends into the first fabric box. According to the textile machinery and equipment facilitating printing and dyeing, by means of a guide rail arranged between two supporting blocks, a sliding sleeve arranged on the outer surface of the guide rail can slide left and right, a spray head has the function of sliding left and right, by means of left-right sliding of the spray head, printing and dyeing of the fabric can be more accurate and attractive, and the printing and dyeing quality is further improved.

Owner:梅明会

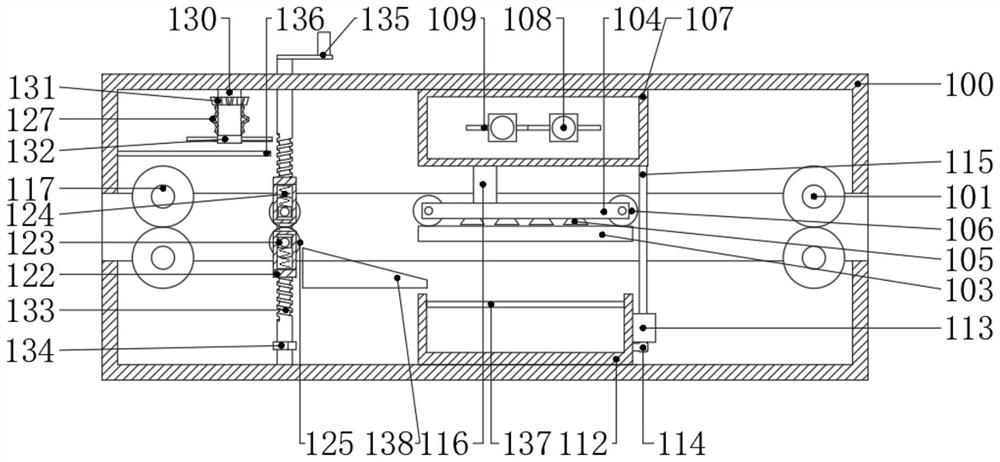

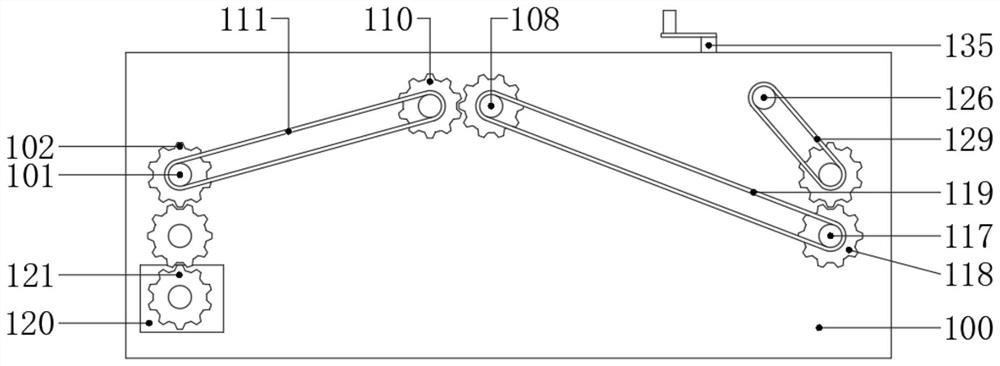

Printing and dyeing equipment for chemical fabric

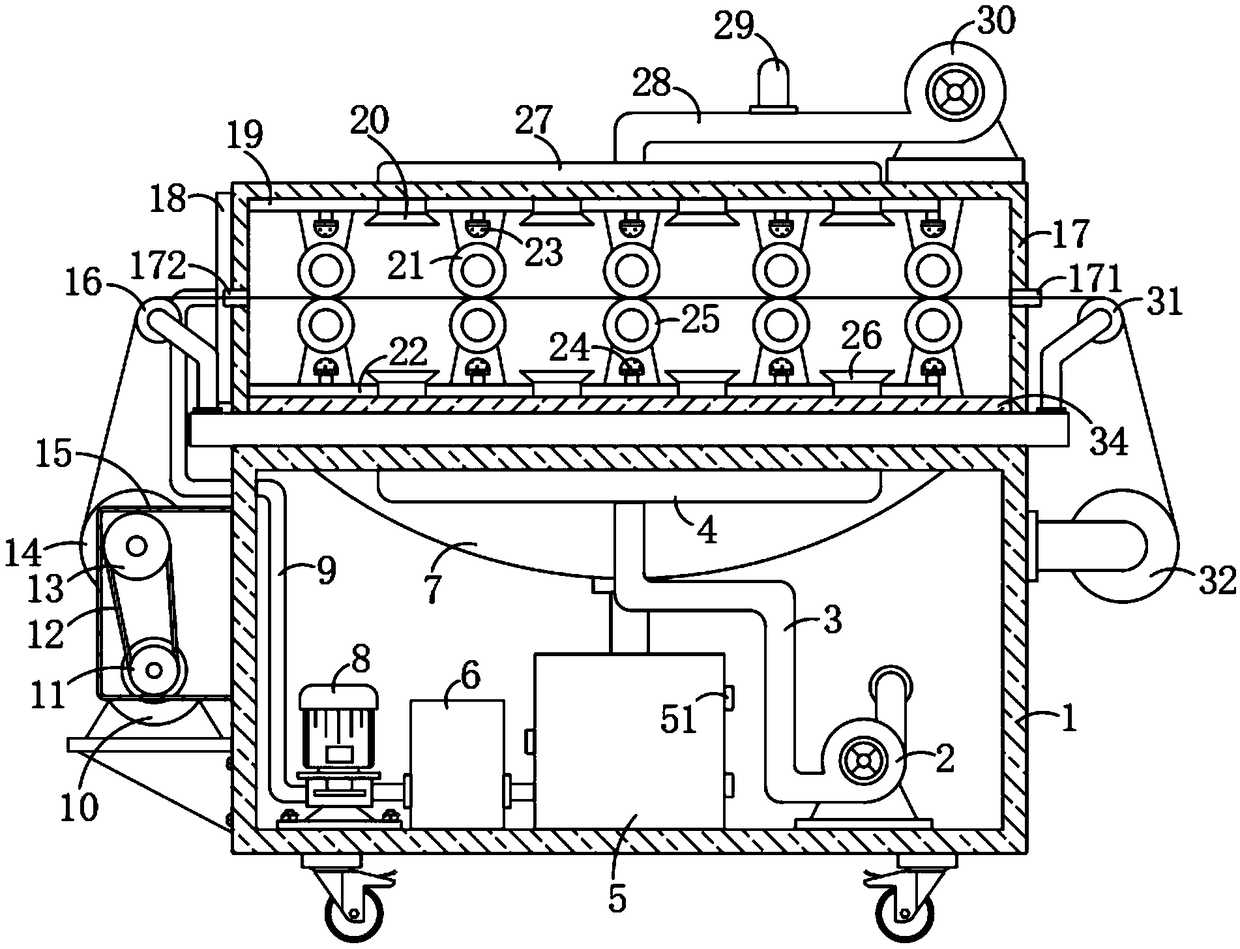

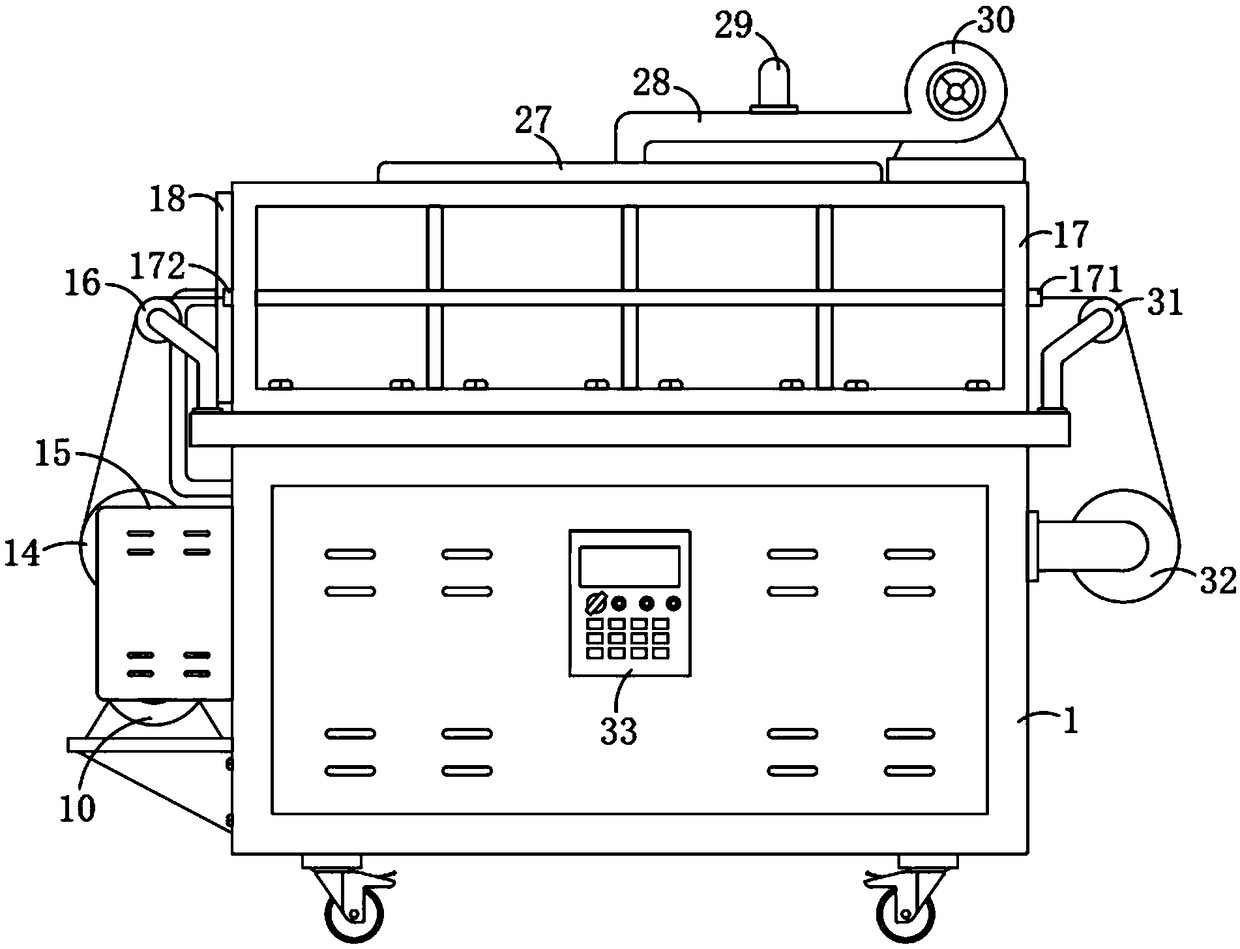

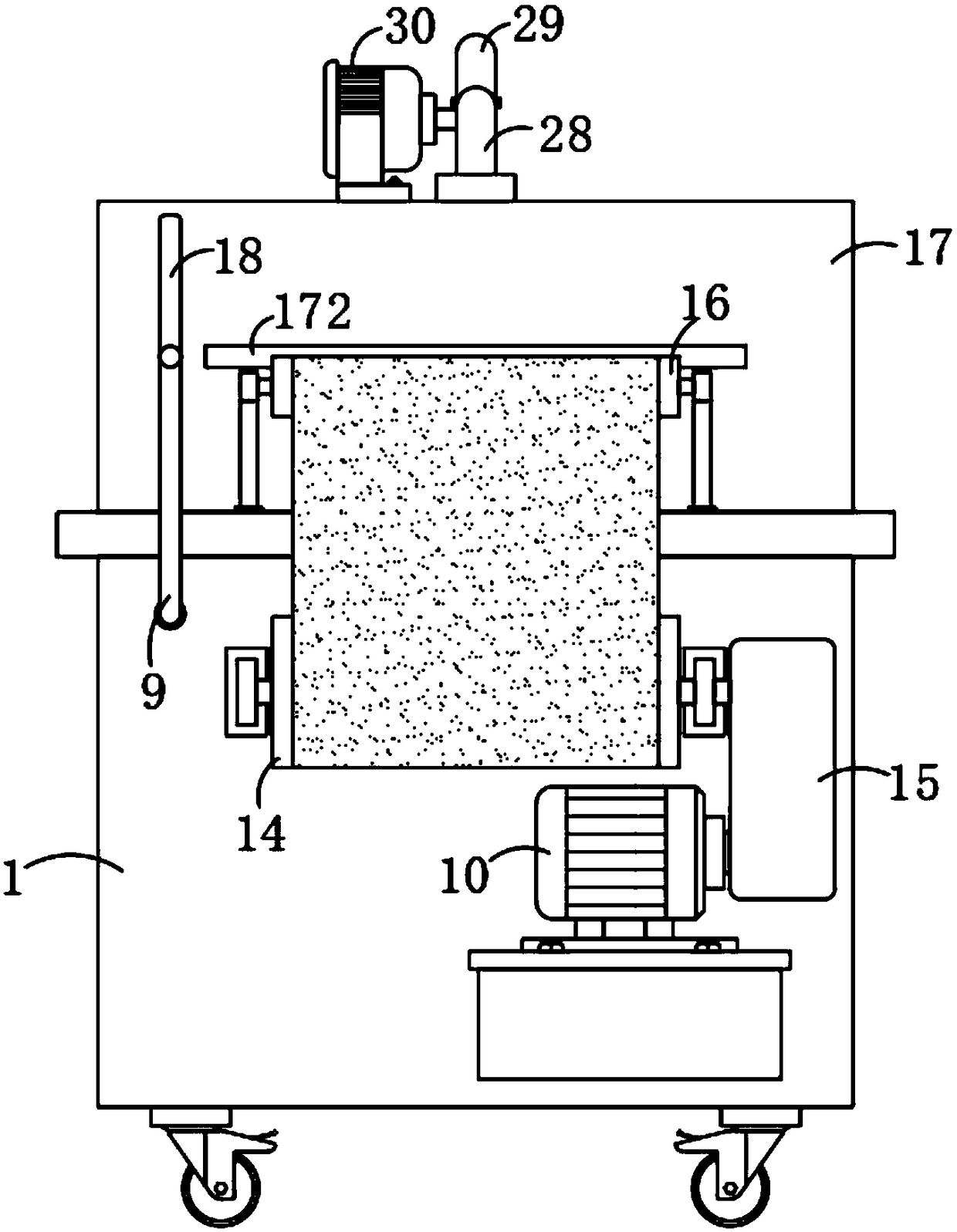

InactiveCN108691130AAchieve recyclingIncrease profitTextile treatment containersTextile treatment machine arrangementsDrive wheelSurface mounting

The invention discloses printing and dyeing equipment for chemical fabric. The printing and dyeing equipment comprises a machine box body. A printing and dyeing bin is installed on the upper surface of the machine box body, a collecting groove communicated with the printing and dyeing bin is formed in the top end in the machine box body, a cloth release roller is fixed to one side of the machine box body through a support, a cloth reeling roller is fixed to the side, opposite to the cloth release roller, of the machine box body through a support, a driven wheel is fixed to one side of the cloth reeling roller, a motor is fixed to the lower portion, close to the cloth reeling roller, of one side of the machine box body through a supporting frame, and one end of the motor is rotationally connected with a driving wheel through a rotary shaft. Through the arrangement of a filter box, a drawer type filter net and a guide plate, dyestuff liquid is recycled and filtered, the utilization rateof resources is increased, the device saves more energy, five upper printing and dyeing rollers, five lower printing and dyeing rollers, upper spray nozzles and lower spray nozzles are arranged, clothis evenly printed and dyed, the printing and dyeing efficiency of the cloth is improved, and production benefits of the equipment are increased.

Owner:黄林

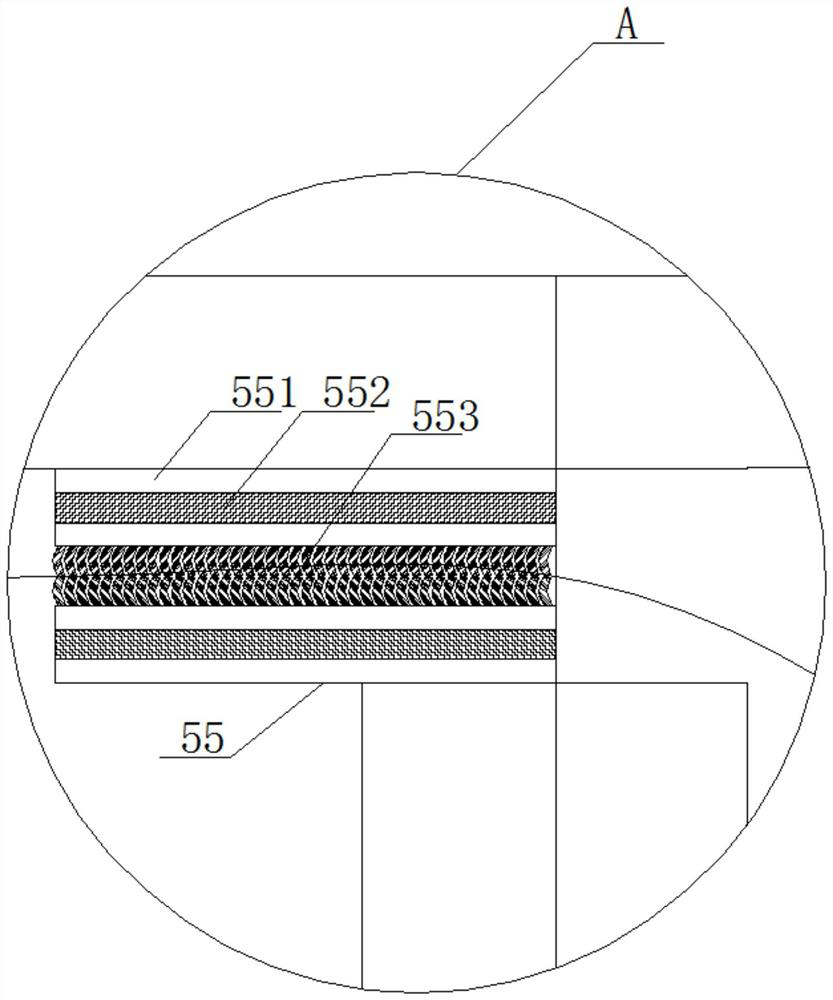

Anti-crease textile processing equipment with flat pressing mechanism

InactiveCN110359199AReasonable structureFunctionalTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingYarnSlide plate

The invention discloses anti-crease textile processing equipment with a flat pressing mechanism. The equipment comprises a textile equipment body, a printing and dyeing frame, a drying frame and a flat pressing frame, and the printing and dyeing frame, the drying frame and the flat pressing frame are arranged on the textile equipment body. Textile cloth is slidably connected to the surface of a processing frame, a rotating table is fixedly connected to each of the upper and lower inner walls of the printing and dyeing frame, a mounting seat is fixedly connected to the surface of each rotatingtable, a filter mesh plate is connectedly clamped in each lower mounting plate, and an upper mounting plate is connectedly clamped on the surface of each lower mounting plate. An extrusion table is slidably connected in the drying frame, and a supporting plate is fixedly connected to the surface of the extrusion table and internally provided with a plurality of meshing grooves. A plurality of groups of flat pressing wheels are adopted for flat pressing of the textile cloth, so that great flat pressing effects are achieved; further, flat pressing quality is guaranteed under the elasticity of second elastic parts. Waste yarns are sucked by suction discs to guarantee quality of the textile cloth, and flat pressing of different types of textile cloth can be realized by position adjustment of inner slide plates. Therefore, the anti-crease textile processing equipment has advantages of time saving and labor saving and is suitable for popularization.

Owner:黄正财

Textile fabric double-sided printing and dyeing equipment for open-width fabric processing

InactiveCN111593512AUniform printing and dyeingImprove permeabilityLiquid/gas/vapor removalTextile treatment machine arrangementsPolymer scienceEngineering

The invention discloses textile fabric double-sided printing and dyeing equipment for open-width fabric processing, and belongs to the technical field of textile fabric printing and dyeing. Accordingto the textile fabric double-sided printing and dyeing equipment for open-width fabric processing, the fact that dyes in a magnetization box are sprayed out is realized through a strip-shaped sprayingnozzle through cooperation of a dye magnetization device and a strip-shaped dye spraying pipe, the jet dyes are uniformly distributed on printing and dyeing rollers, the pair of printing and dyeing rollers print and dye the dyes to the two end faces of a fabric in the opposite rotating movement process, the dyes are printed and dyed to the fabric through transmission of the printing and dyeing rollers, uniform printing and dyeing of the dyes are effectively achieved, the phenomena of uneven dyeing, wrinkling and the like are not likely to be caused; meanwhile, magnetizing the dyes is carriedout in the dye magnetizing device, so that the permeability of the dyes is effectively improved; and in addition, after the fabric is printed and dyed, the fabric is guided out of a fabric guide-out cavity and then heat dissipation and blow-drying are carried out through a heat dissipation and drying mechanism, so that cooling and drying the two end faces of the fabric are realized, and the winding operation is carried out on the dried fabric through a winding roller.

Owner:陈式好

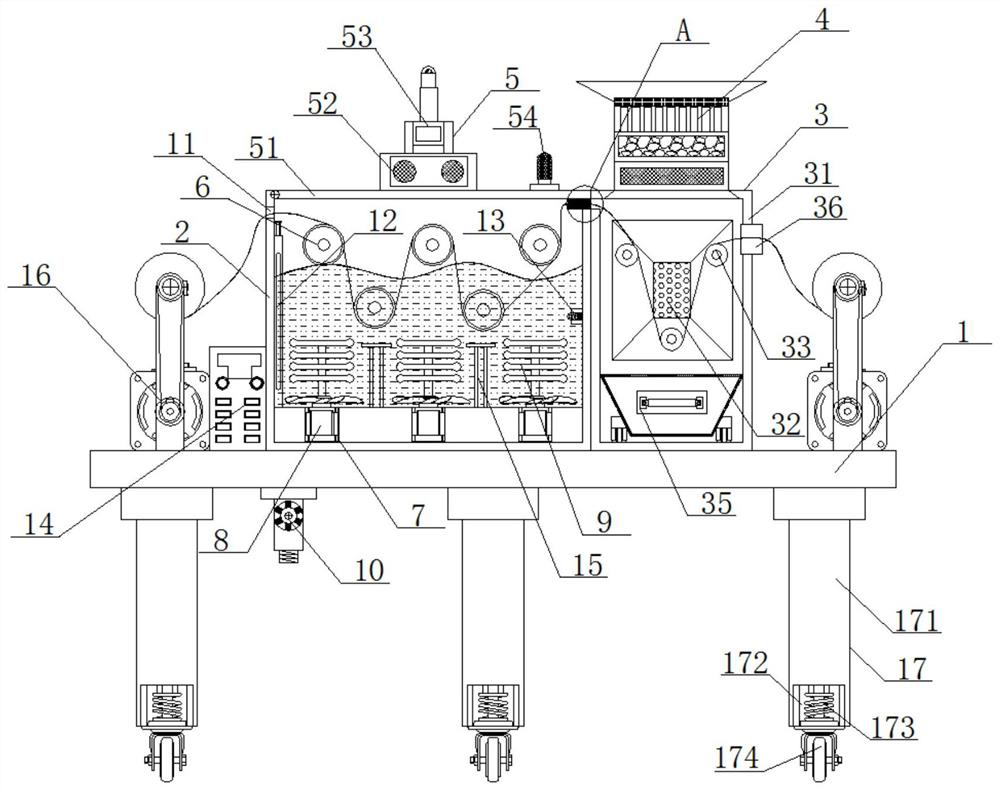

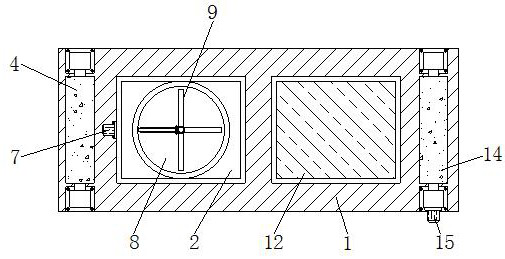

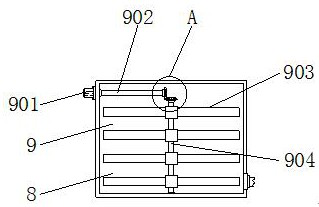

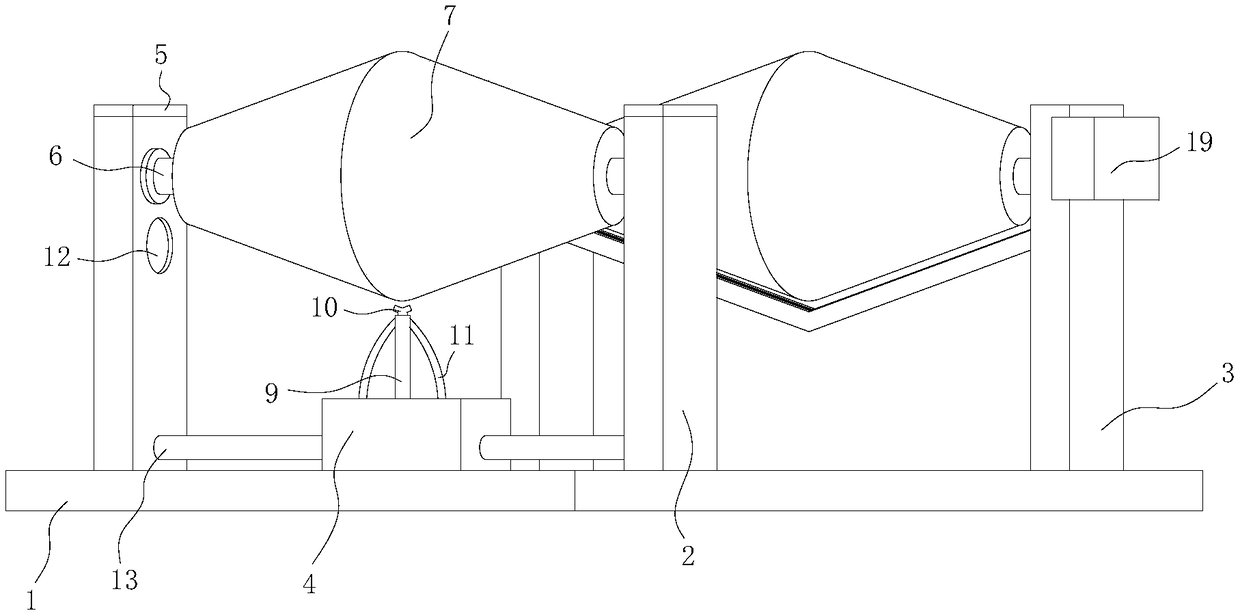

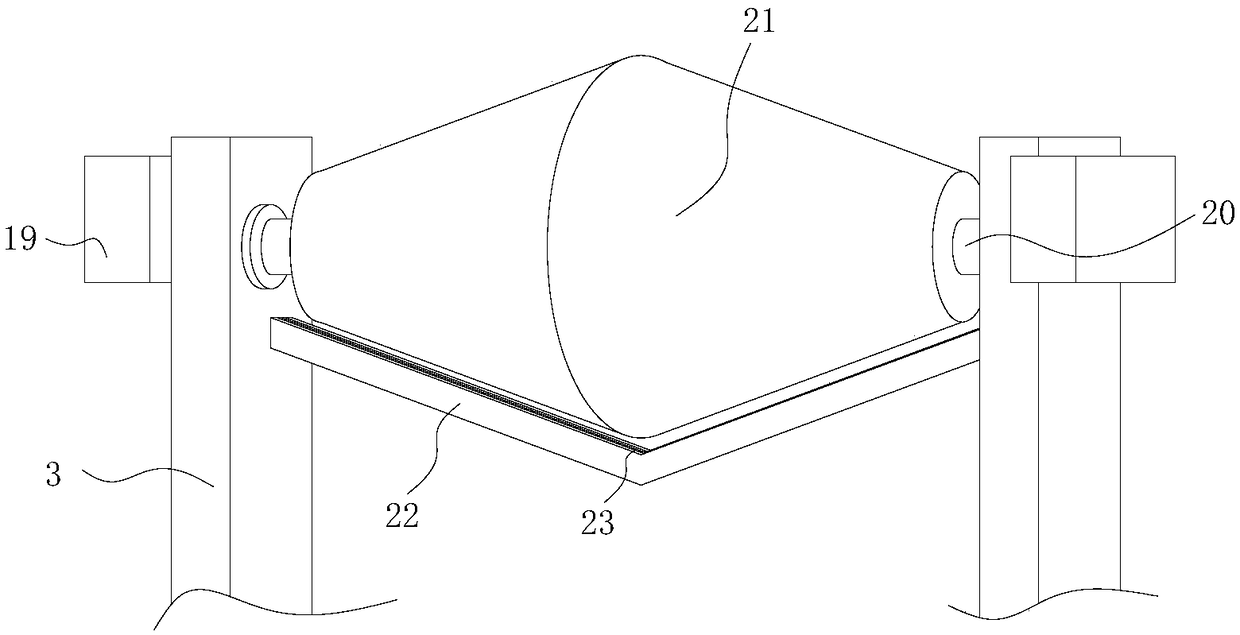

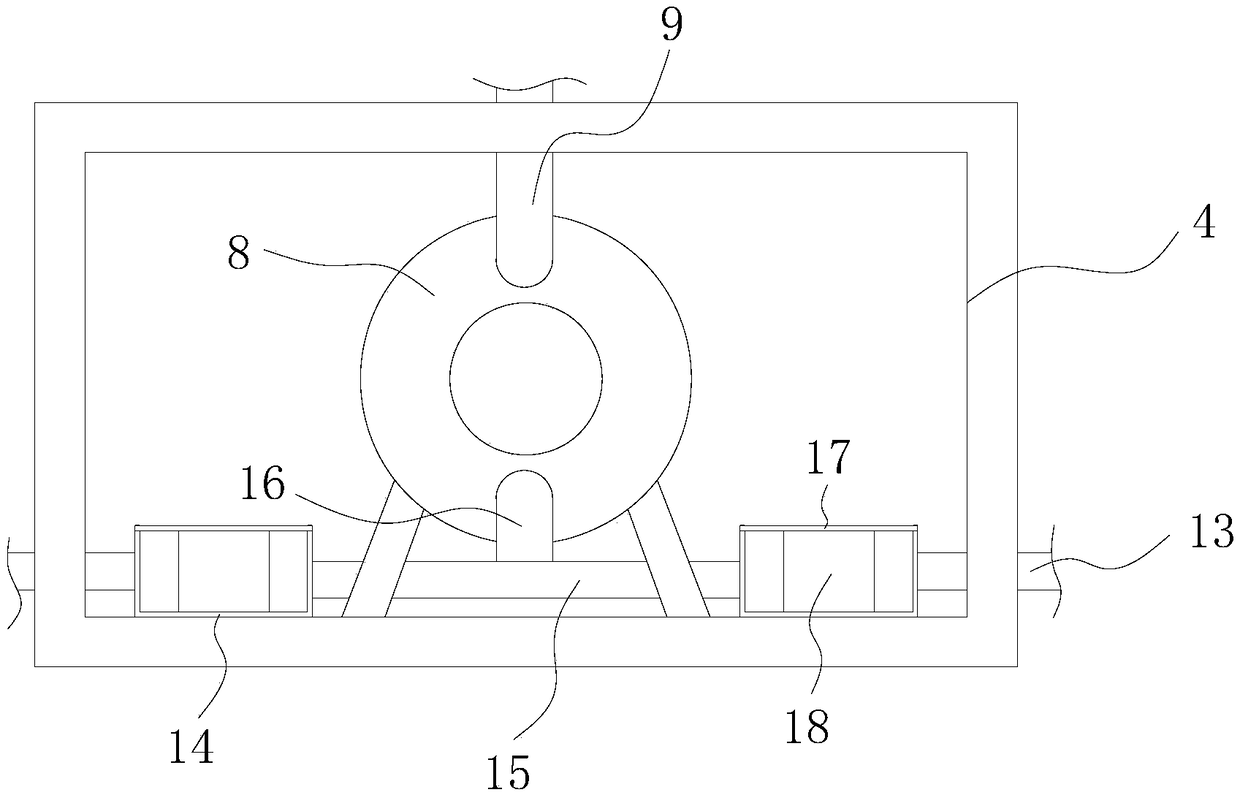

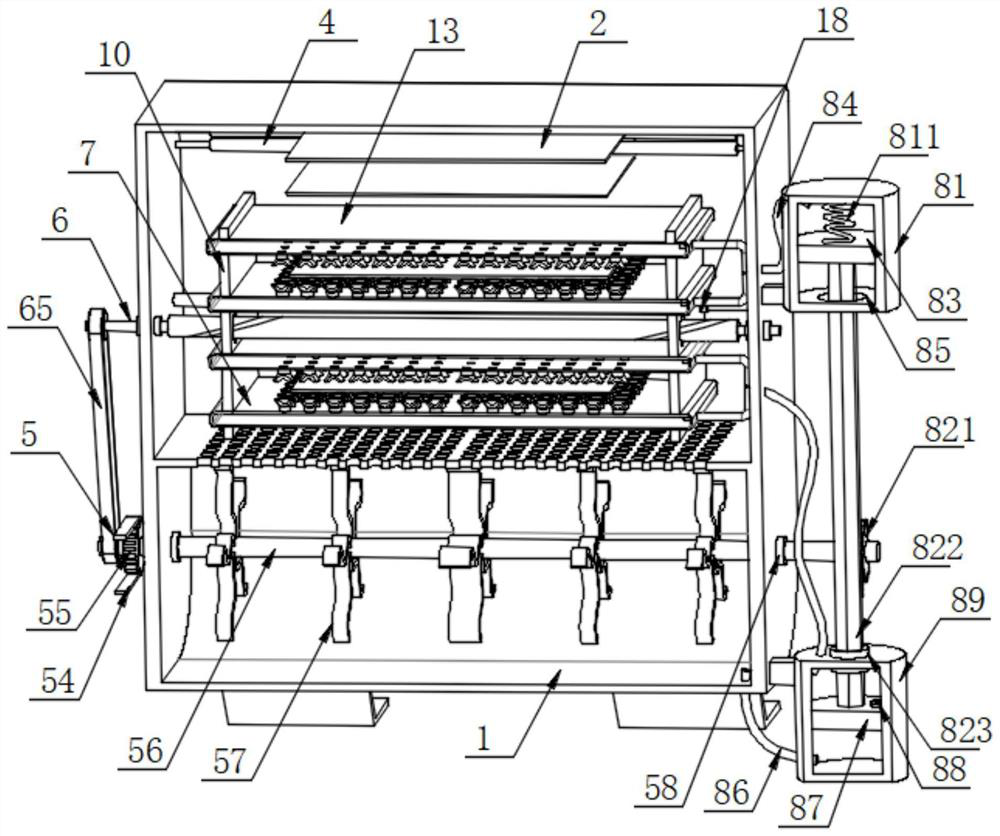

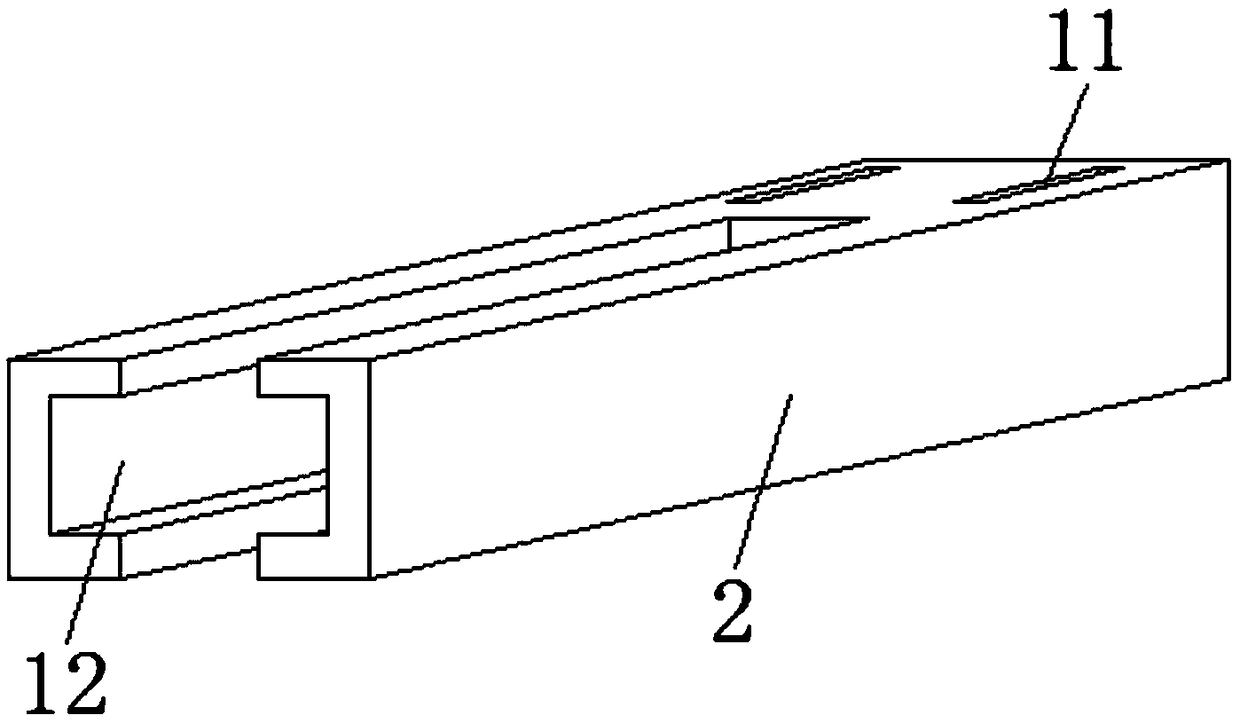

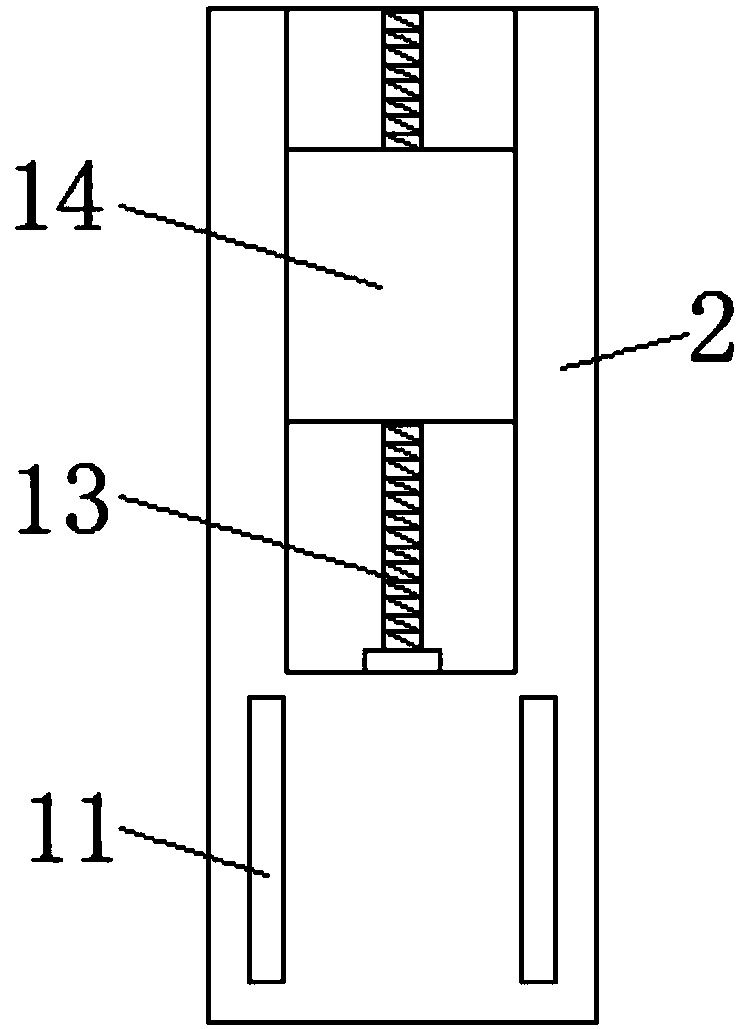

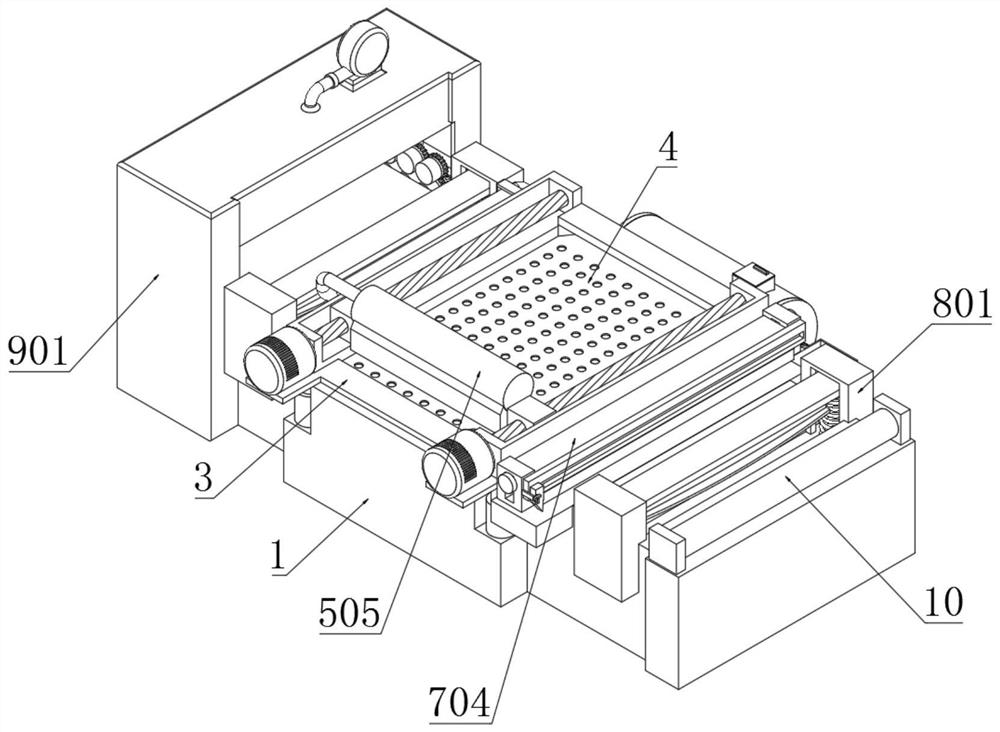

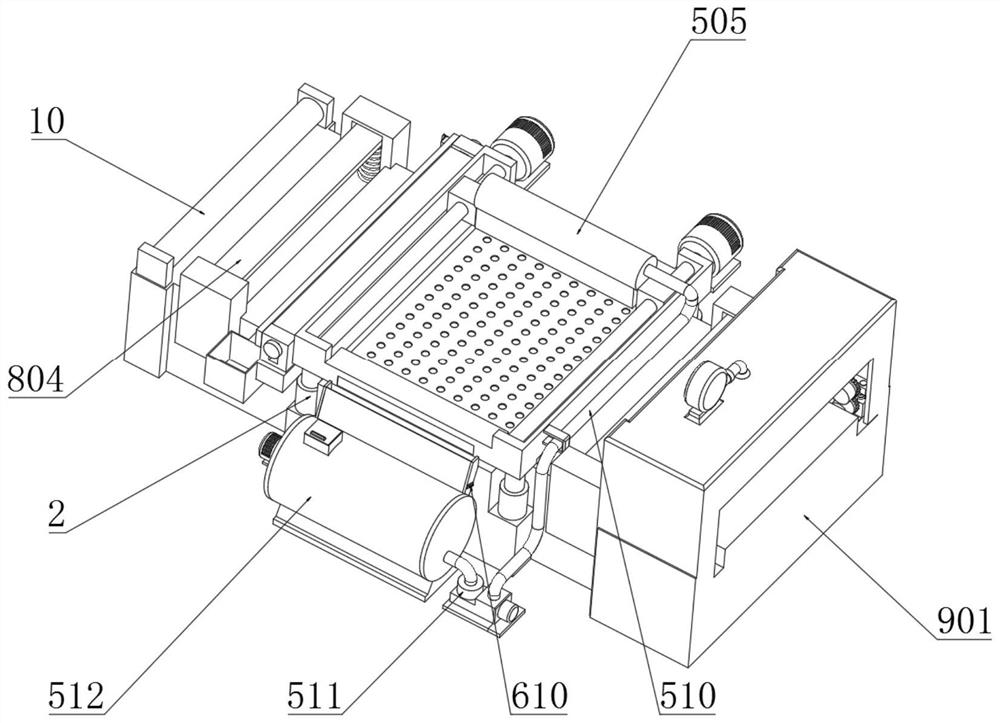

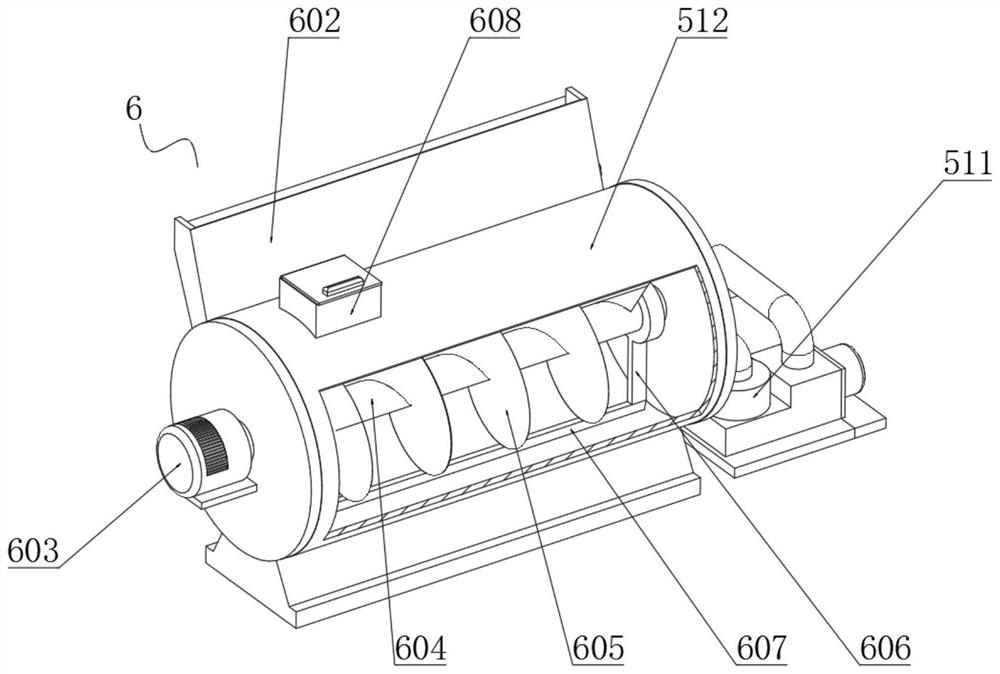

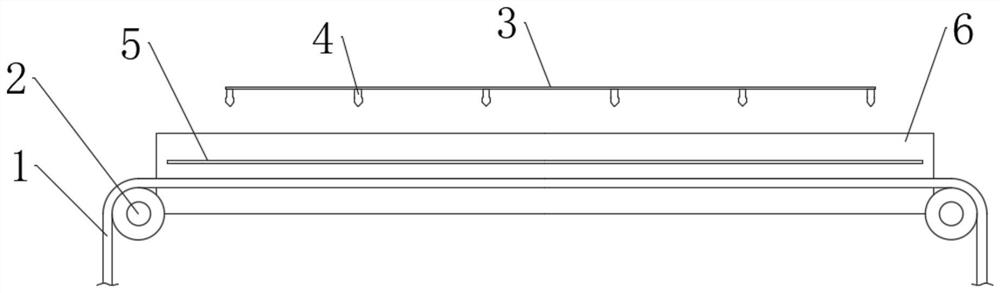

Knitting printing and dyeing all-in-one machine for high-grade textile fabrics

PendingCN112144201AConvenient printing and dyeingImprove practicalityTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsDyeingManufacturing engineering

The invention discloses a knitting printing and dyeing all-in-one machine for high-grade textile fabrics. The machine comprises a bottom plate, a discharging roller and a collecting roller, wherein the discharging roller is fixed to one side of the top end of the bottom plate; a spraying plate is installed in a printing and dyeing box; a spraying head is installed at the bottom end of the sprayingplate; a drying box is arranged on one side of the printing and dyeing box; a drying mechanism is arranged in the drying box; the material collecting roller is installed on the other side of the topend of the bottom plate; and a third servo motor is installed at one end of the material collecting roller. According to the invention, by arranging an adjusting mechanism, a first servo motor is started to drive a rotating rod to rotate, a movable block is driven to move, and then a spraying plate is driven to move; and a worker starts the first servo motor according to actual conditions to uniformly move the spraying plate, so that uniform printing and dyeing of a knitted fabric are facilitated, and the practicability of the printing and dyeing machine in use is greatly improved.

Owner:江门市宏美针织印染有限公司

Printing and dyeing equipment capable of improving color beauty of cloth

InactiveCN109234962AImprove aestheticsImprove competitivenessMechanical cleaningPressure cleaningDyeingEngineering

The invention relates to the technical field of textile equipment, in particular to printing and dyeing equipment capable of improving the color beauty of a cloth. The technical problem to be solved by the invention is that the color of the cloth is unevenly applied during printing. In order to solve the above technical problem, the invention provides the printing and dyeing equipment capable of improving the color beauty of the cloth, the equipment comprises a base, the top of the base is welded with two square support columns, two square fixed columns and a protection box, the correspondingsides of the two square support columns are rotatably connected to rotating shafts through bearing seats, the two rotating shafts are fixedly connected by a first roller, and the bottom of the inner wall of the protection box is fixedly connected with an air blower. The printing and dyeing equipment capable of improving the color beauty of the cloth can spread flatly the cloth on a first roller before the cloth is printed and dyed, batting on the cloth can be taken away, so that the cloth can be printed and dyed smoothly, the cloth is imprinted and dyed more uniformly, and the aesthetics of the cloth after the printing and dyeing is improved.

Owner:绍兴新越机械制造有限公司

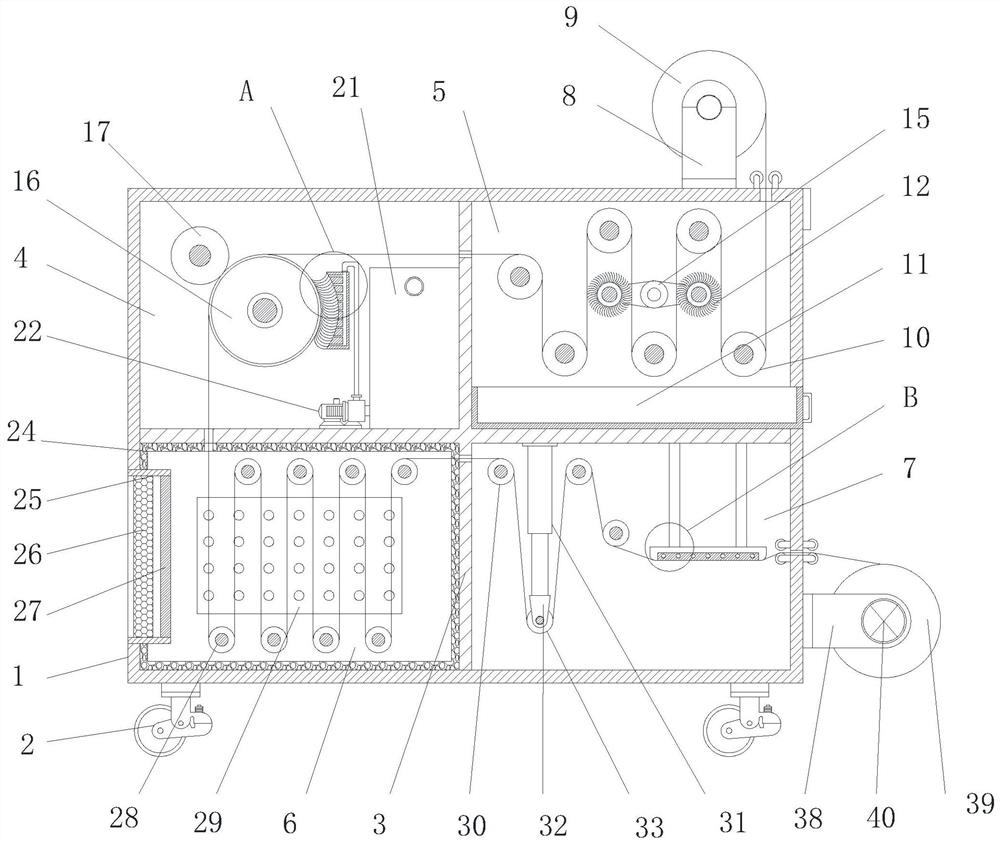

Textile fabric printing and dyeing equipment and printing and dyeing method

InactiveCN112176585AUniform printing and dyeingIncrease the drying areaMechanical cleaningPressure cleaningEngineeringMechanical engineering

Textile fabric printing and dyeing equipment comprises a machine body, a cleaning module and a dye conveying module, wherein a plurality of moving wheels are arranged on the left side and the right side of the lower end of the machine body correspondingly; a cross-shaped partition plate is arranged in the machine body; the interior of the machine body is divided into a printing and dyeing cavity,a cleaning cavity, a drying cavity and an ironing and flattening cavity through the cross-shaped partition plate; a first U-shaped base is arranged on the right side of the upper end of the machine body; a material roller is rotationally connected to the upper portion of the first U-shaped base; and a first guide roller set and a cleaning module are arranged in the cleaning cavity. The fabric dyeing and finishing machine works in a partitioned mode and does not interfere with one another. According to the textile fabric printing and dyeing equipment and printing and dyeing method, fluff impurities on a dyeing and finishing face of a fabric can be removed, cloth quality can be improved, the fabric is uniformly printed and dyed, dye is saved, the printing and dyeing quality is improved, thefabric drying area is large, the work efficiency is high, pollutants and peculiar smells in polluted air can be filtered out, standardized discharge is achieved, fabric wrinkles are flattened througha heat conducting plate, and thus the quality and competitiveness of products are improved.

Owner:SUZHOU BABEL TEXTILE TECH CO LTD

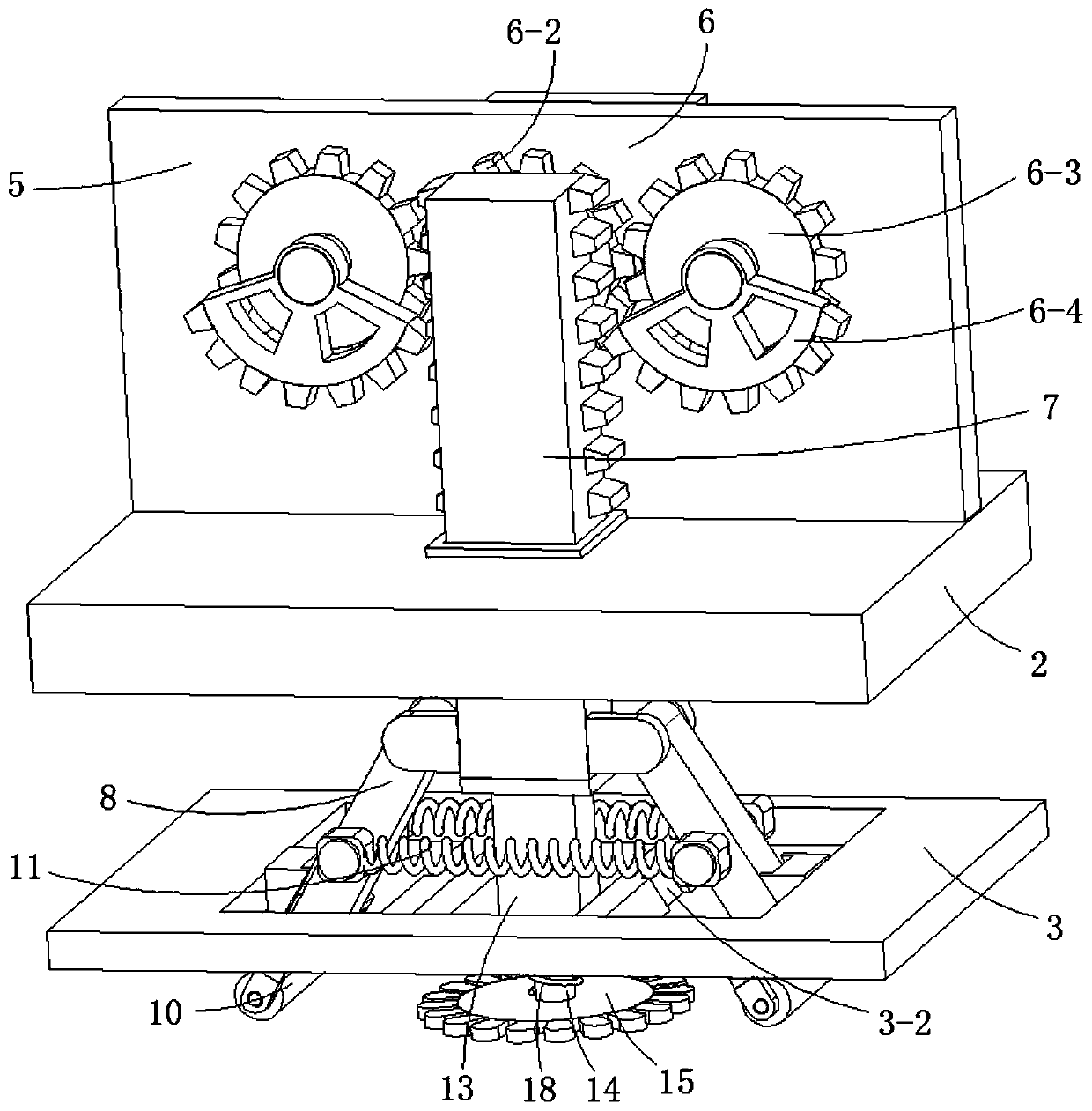

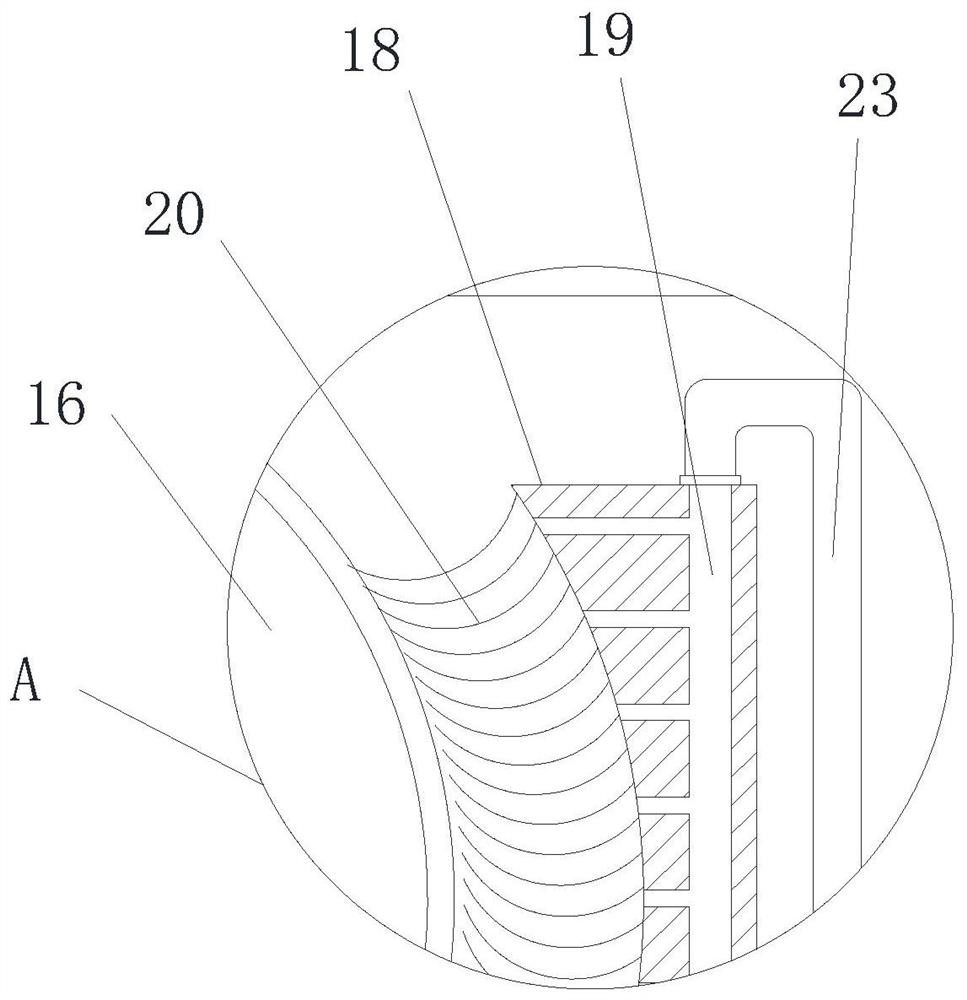

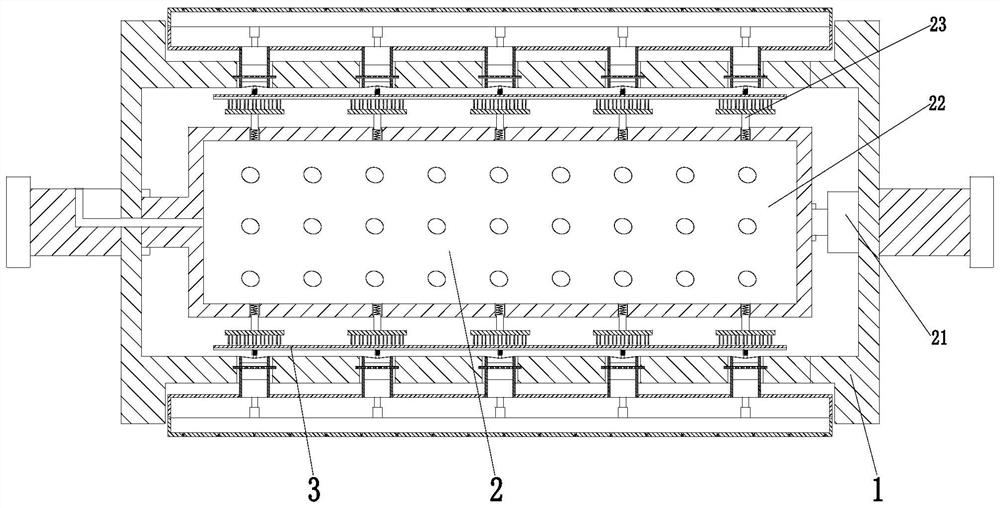

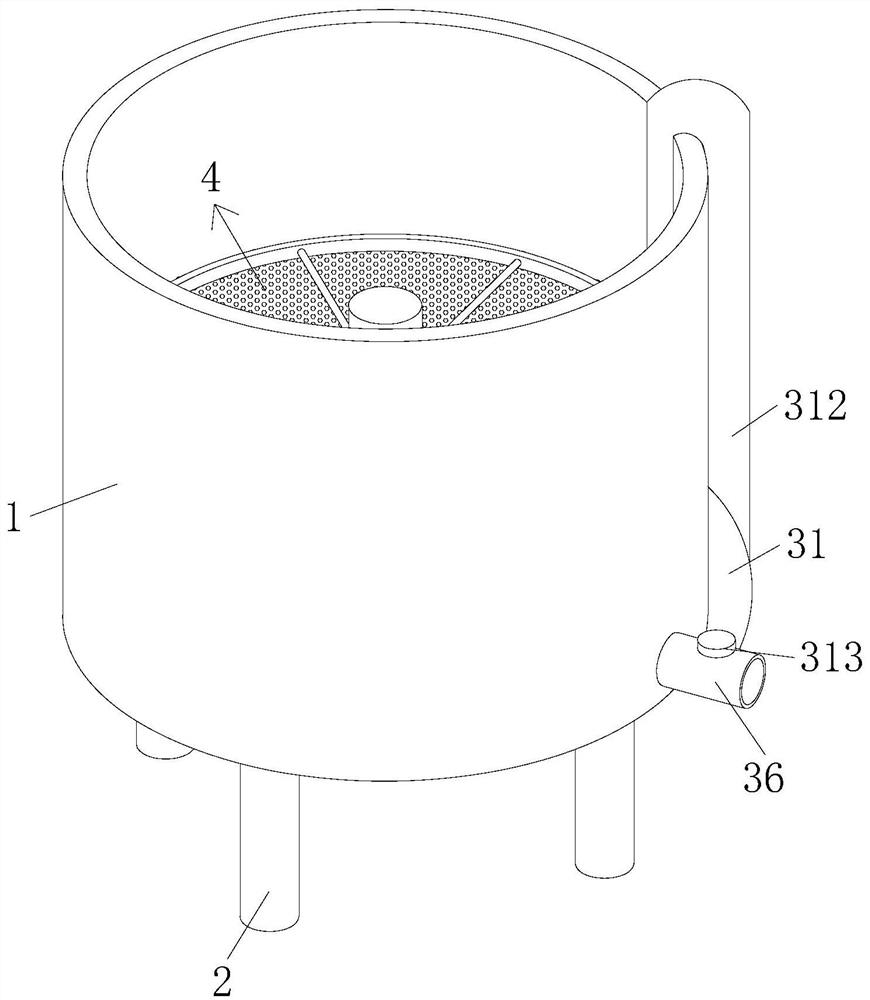

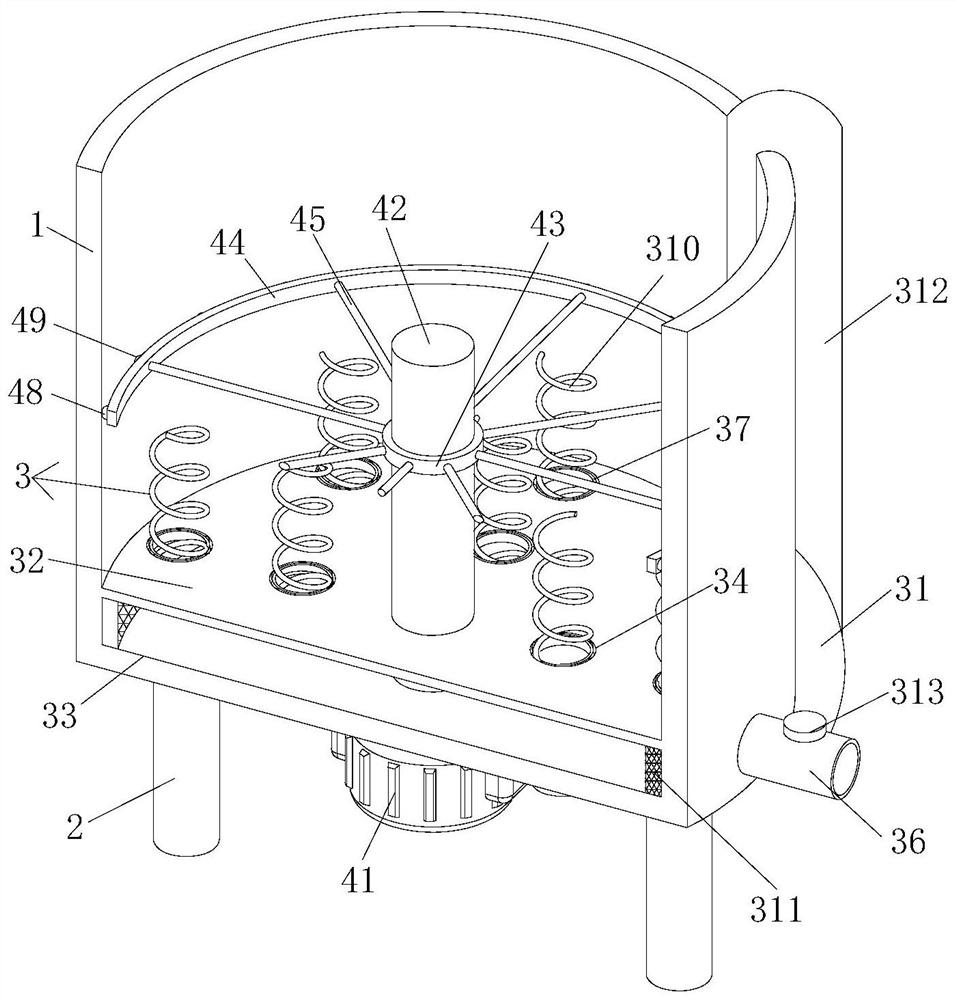

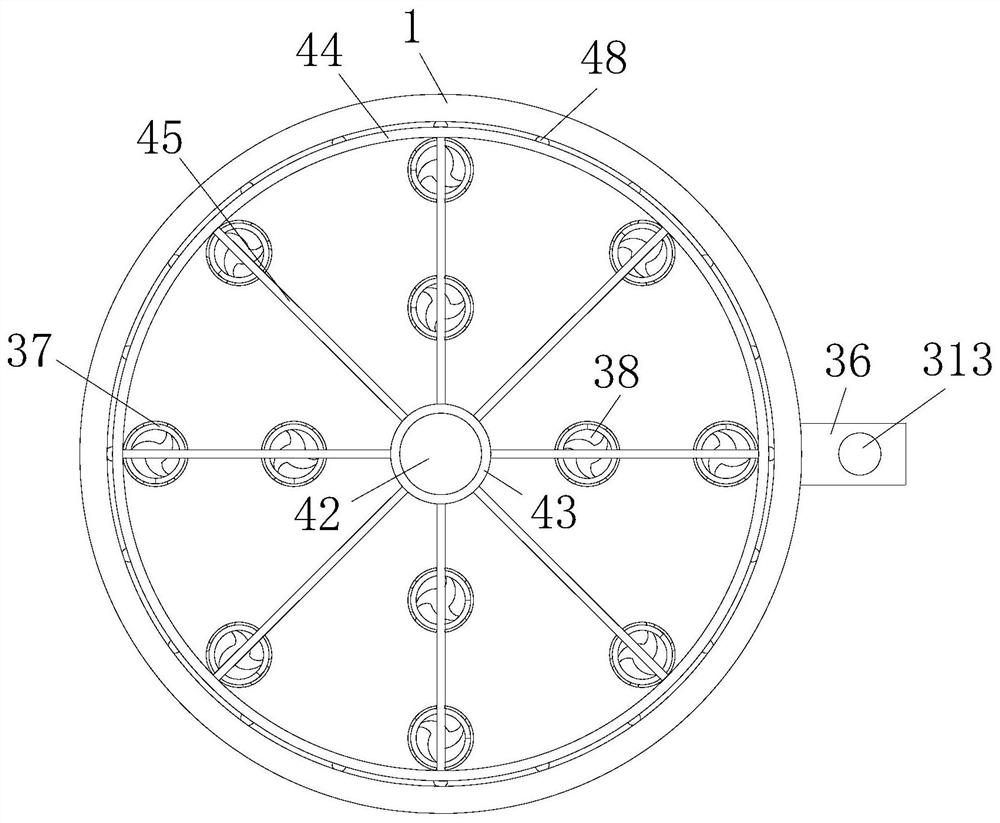

Anti-printing and dyeing pulped block attaching-based hollowed-out braided fabric printing and dyeing device

InactiveCN111705457AUniform printing and dyeingImprove qualityTextile treatment machine arrangementsVibration treatmentTextile printerPulp and paper industry

The invention provides an anti-printing and dyeing pulped block attaching-based hollowed-out braided fabric printing and dyeing device, and relates to the field of textile printing and dyeing. The printing and dyeing device comprises a braided fabric printing and dyeing barrel for printing and dyeing of a braided fabric, supporting legs for supporting the braided fabric printing and dyeing barrel,a movable pulp removing printing and dyeing mechanism for promoting uniform printing and dyeing of the braided fabric and removing a printing and dyeing pulped block, and a porous support plate usedfor supporting the movable pulp removing printing and dyeing mechanism. According to the anti-printing and dyeing pulped block attaching-based hollowed-out braided fabric printing and dyeing device, based on the problem of the pulped block existing in an existing braided fabric printing and dyeing process, a mechanism capable of spreading the fabric in the moving process is designed, and comprehensive pulp removing is performed by using the suction force with the high pertinence while the uniform printing and dyeing is completed, so that the problems that a general braided fabric has a large number of hollowed-out portions, the surface friction force is large, stubborn pulped blocks are prone to be retained in the pulped material printing and dyeing process, and thus the quality of the fabric is affected, the energy consumption of subsequent processing is large, and the overall production efficiency is also greatly affected are effectively solved.

Owner:赵彩朝

Water-saving and energy-saving processing technology of polyester fabric

ActiveCN109487465AReduce tensionReduce dosageChemical fixing of textilesLiquid/gas/vapor removalPolyesterWater saving

The invention discloses a water-saving and energy-saving processing technology of a polyester fabric, which comprises the steps of selecting raw materials of polyester yarns - dyeing yarns - winding yarns - weaving and cutting, and selecting high-density NC polyester yarns as raw materials of the polyester fabric. By means of the technology, the beneficial effects comprises: compared with the traditional method for integrally printing and dyeing the polyester fabric, the method of printing and dyeing is more comprehensive for polyester fabric , the polyester fabric is dyed by the dye solution,the process flow of dyeing the polyester fabric is reduced, the printing and dyeing efficiency is improved, by printing and dyeing a plurality of polyester yarns respectively, the dyeing solution consumption of the mechanism is less, so that the process is more energy-saving, water-saving and cost-saving when dyeing the polyester yarns; and the dye solution used for spraying and dyeing can flow into the packing groove by improving the sleeve groove, and the packing groove guides the dye solution into the dye solution refilling bucket, so that people can conveniently collect and process the dye solution which is not attached and dyed with the polyester yarns filament, thereby ensuring the environmental protection and saving printing and dyeing cost.

Owner:JIANGSU HUAYI GARMENT CO LTD

Graphene-containing textile fabric printing and dyeing device and printing and dyeing method thereof

PendingCN114703612AGuaranteed uniformityReduce use costLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsReciprocating motionProcess engineering

The invention discloses a graphene-containing textile fabric printing and dyeing device and a printing and dyeing method thereof, and belongs to the technical field of textile fabric printing and dyeing. The graphene-containing textile fabric printing and dyeing device comprises a treatment box, a drainage gas transmission assembly is arranged on the right side of the outer surface of the treatment box, and a stirring device is arranged on one side of the drainage gas transmission assembly and located in the treatment box; the stirring device is in transmission connection with a reciprocating motion structure, and the reciprocating motion structure is located in the treatment box. According to the graphene-containing textile fabric printing and dyeing device and the printing and dyeing method thereof, the stirring device, the drainage gas transmission assembly and the reciprocating motion structure are arranged, and under transmission cooperation of the stirring device, the drainage gas transmission assembly and the reciprocating motion structure, stirring, printing and dyeing and drying work can be synchronously driven; multiple processing modes of the device are integrated, the uniformity of printing, dyeing and drying can be guaranteed, intervention of too many driving devices is not needed, and the overall use cost is greatly reduced.

Owner:江苏申久纺织科技有限公司

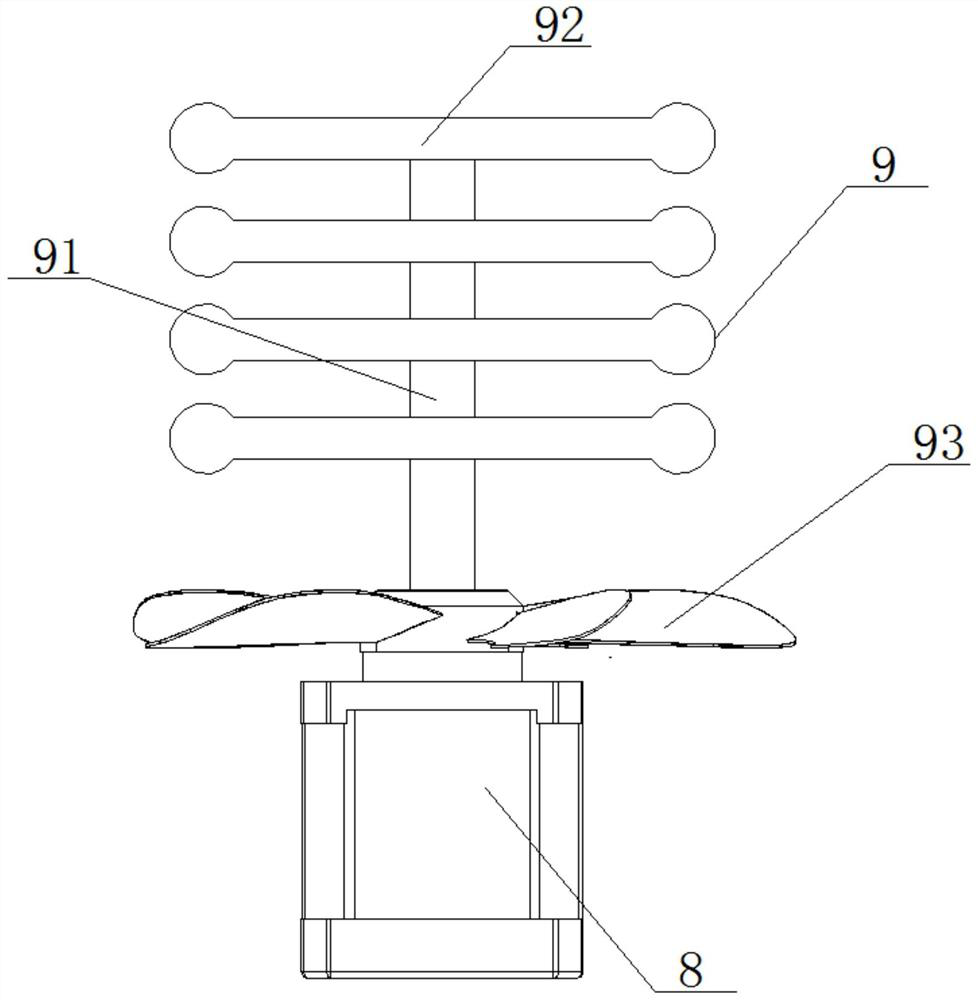

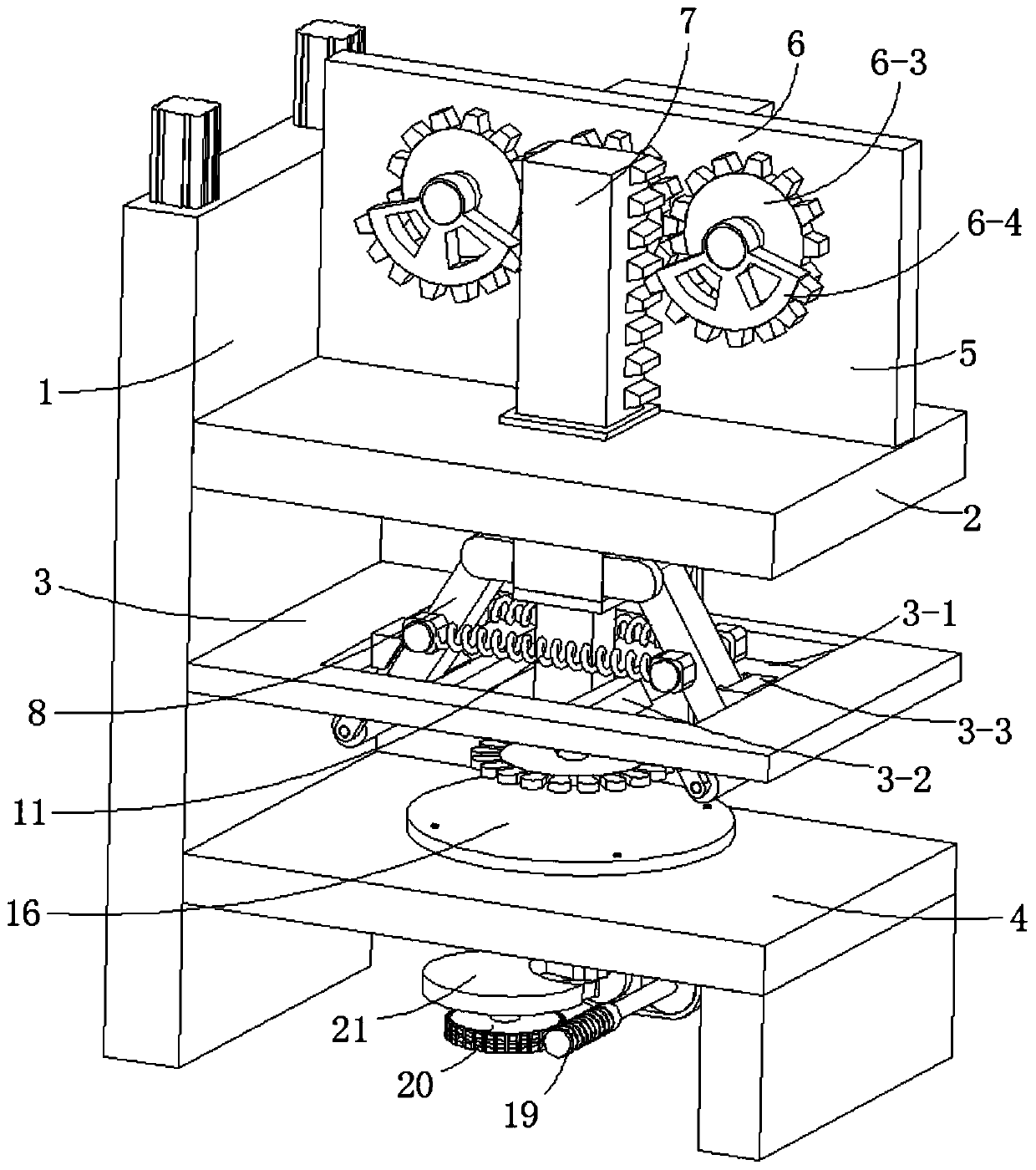

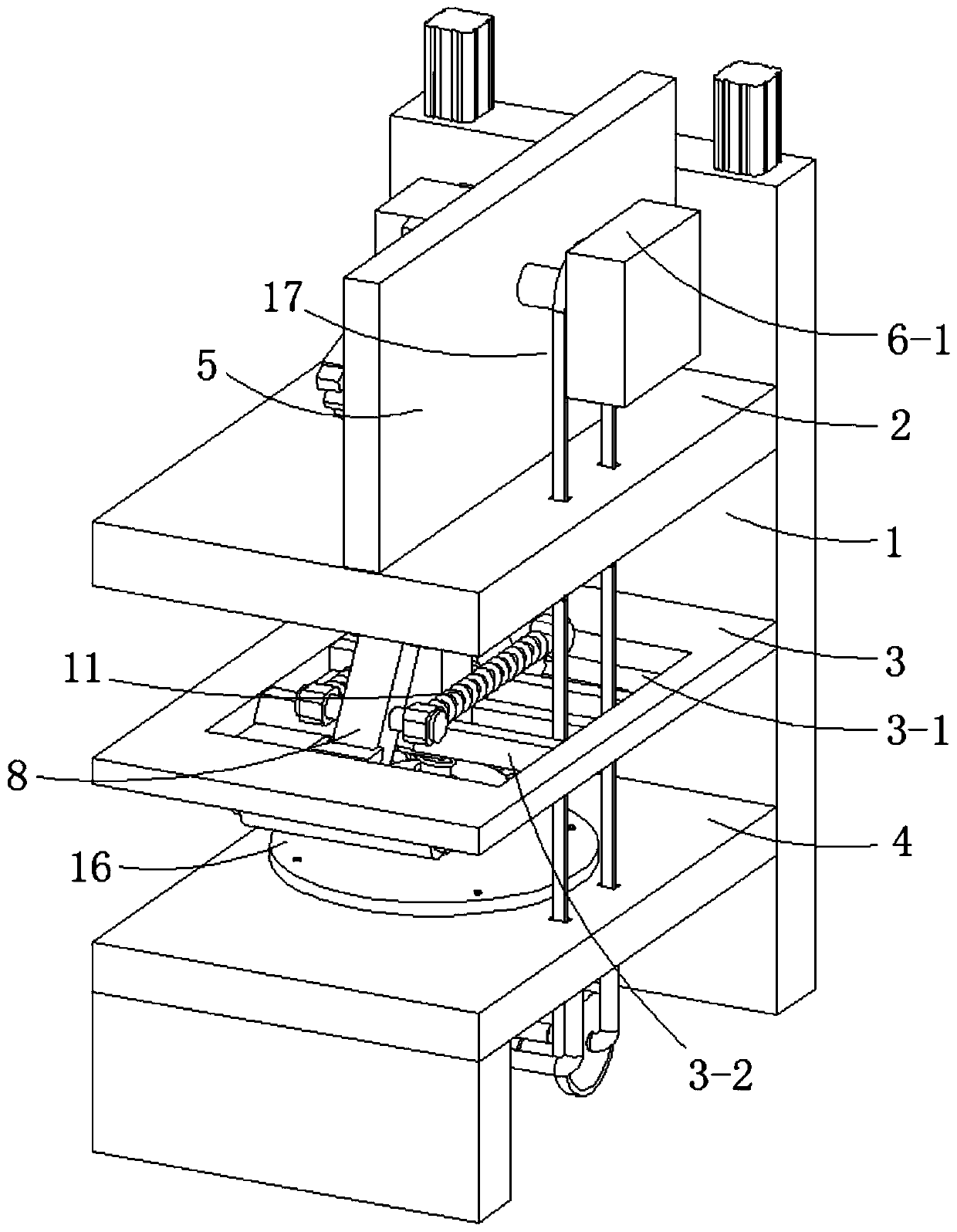

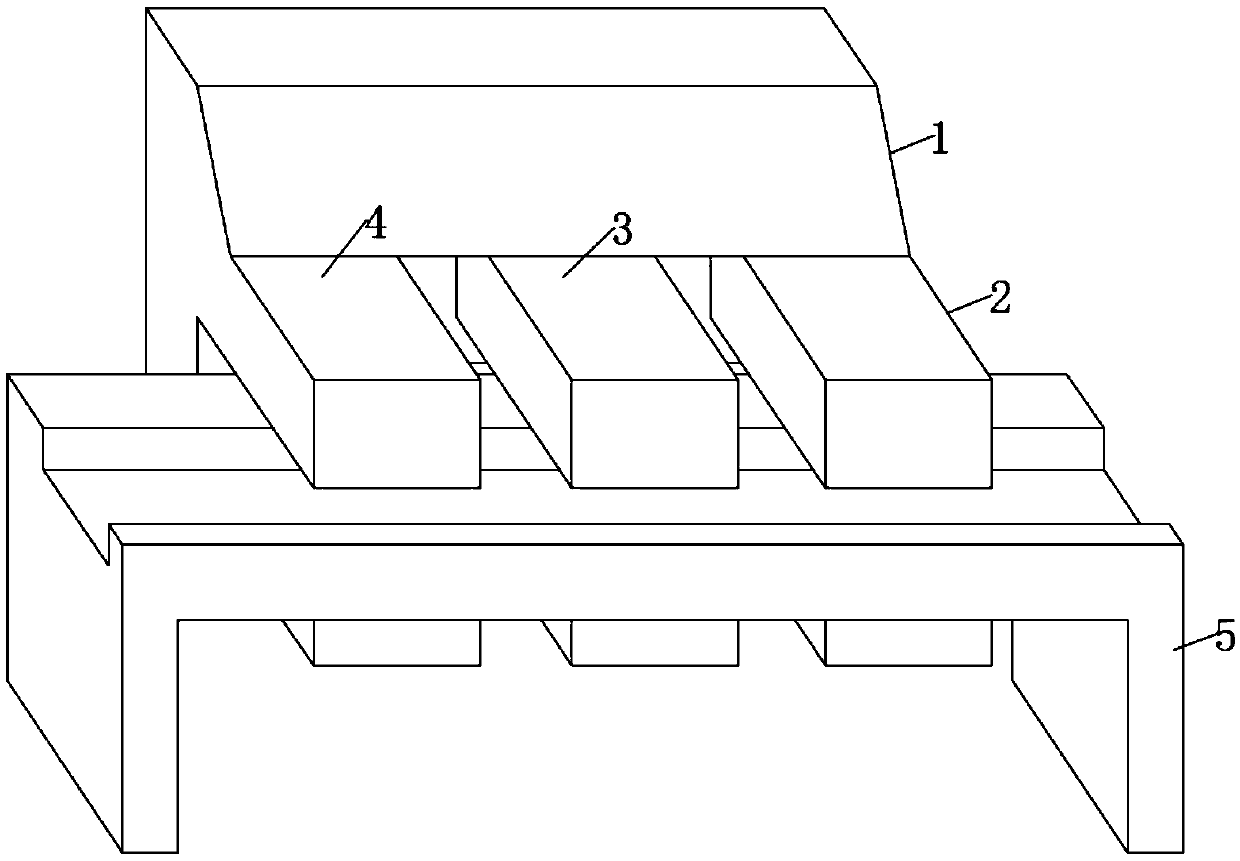

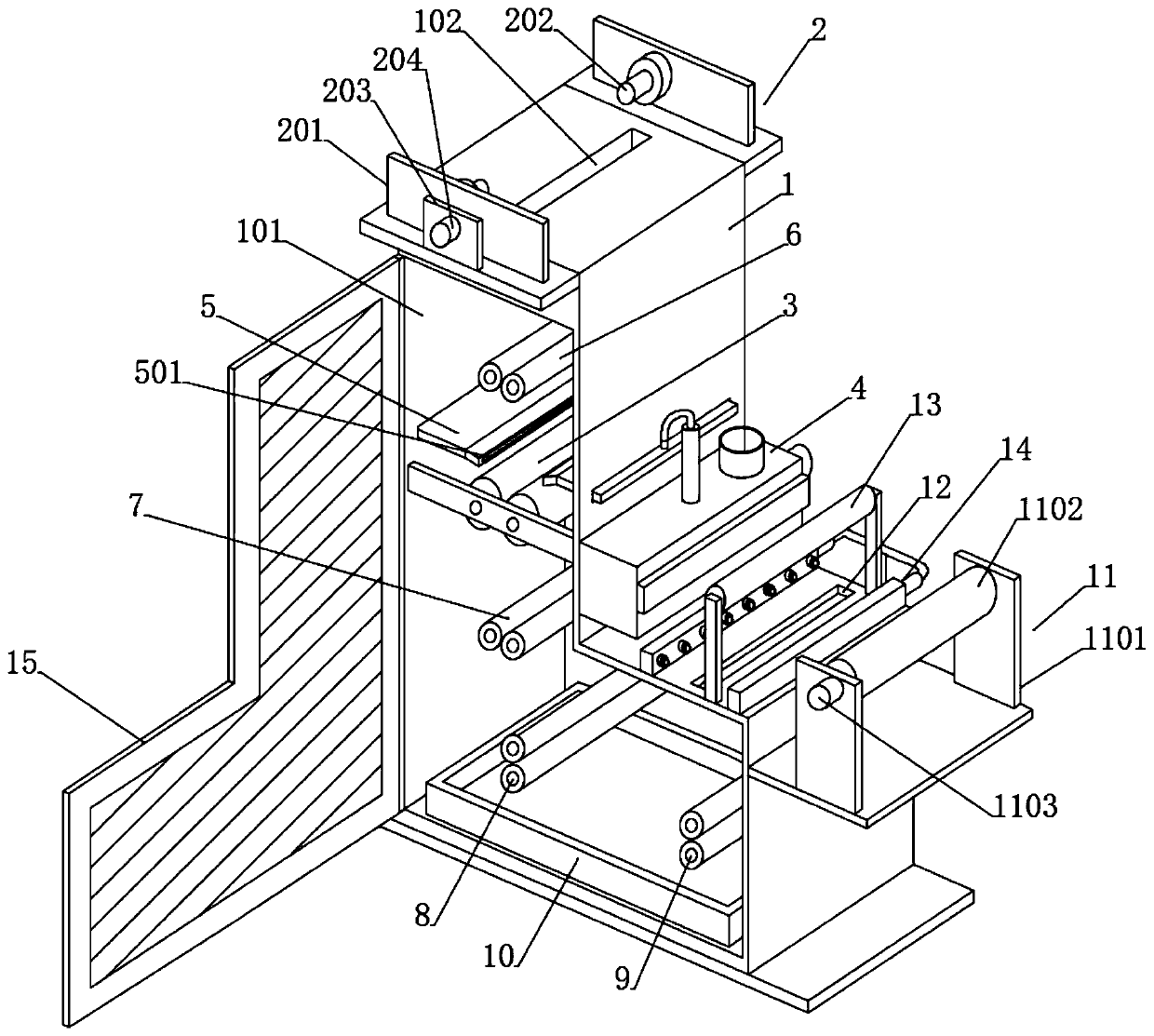

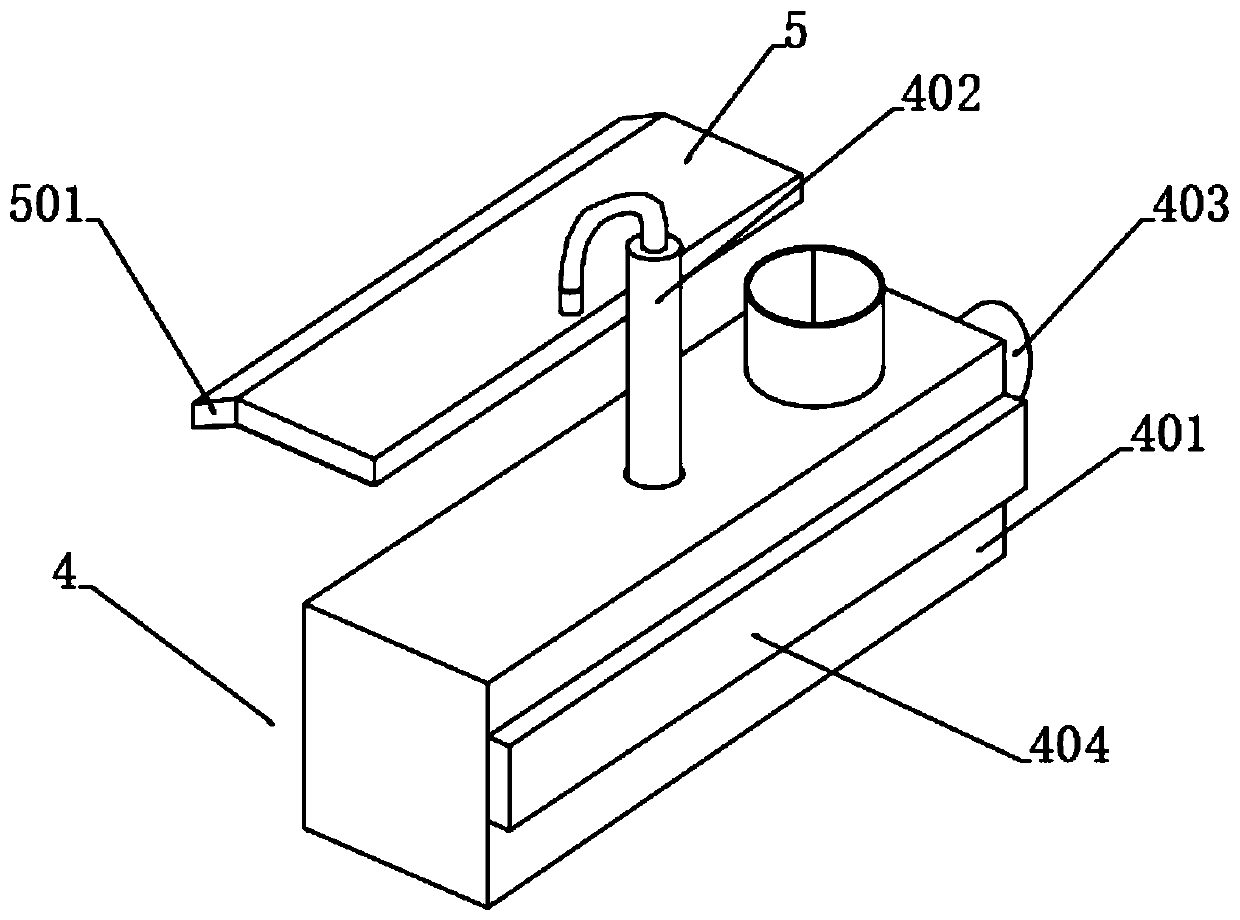

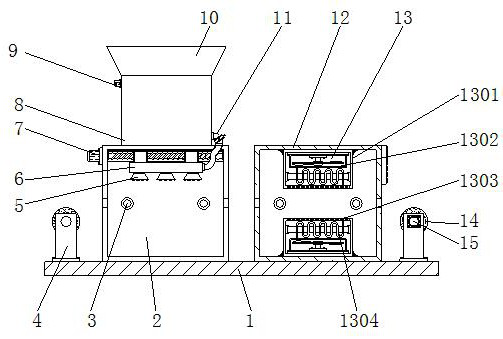

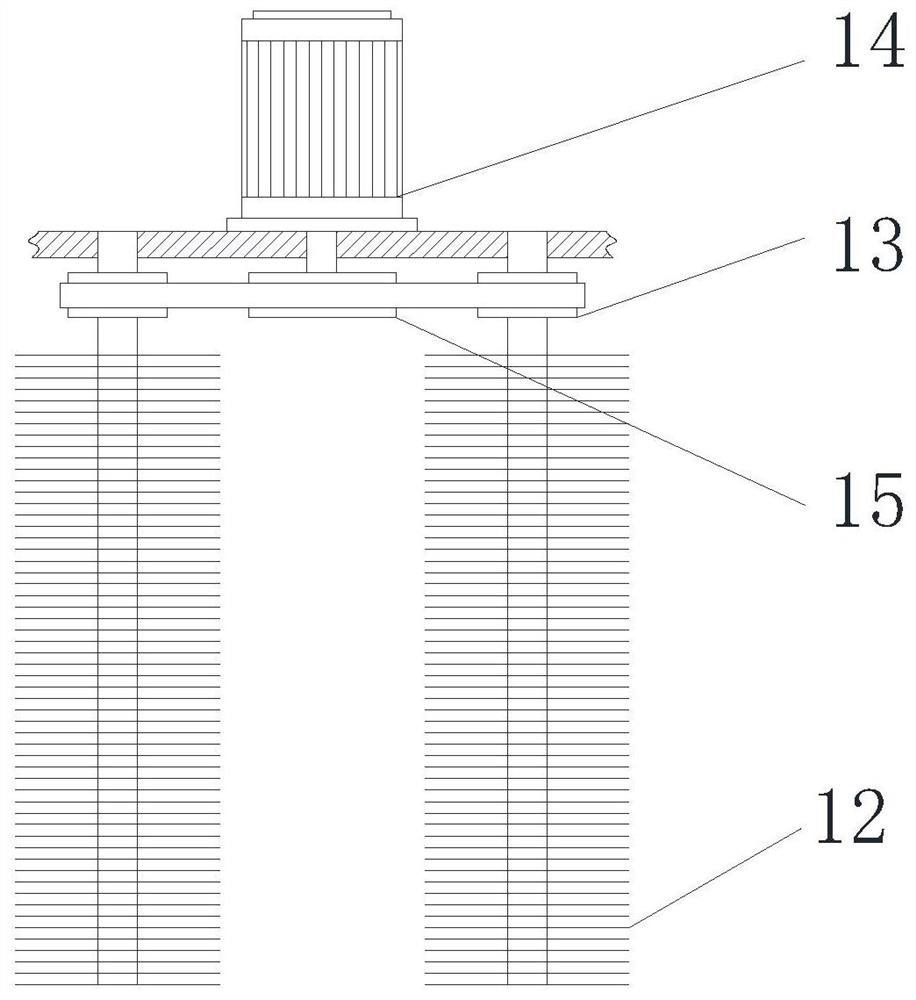

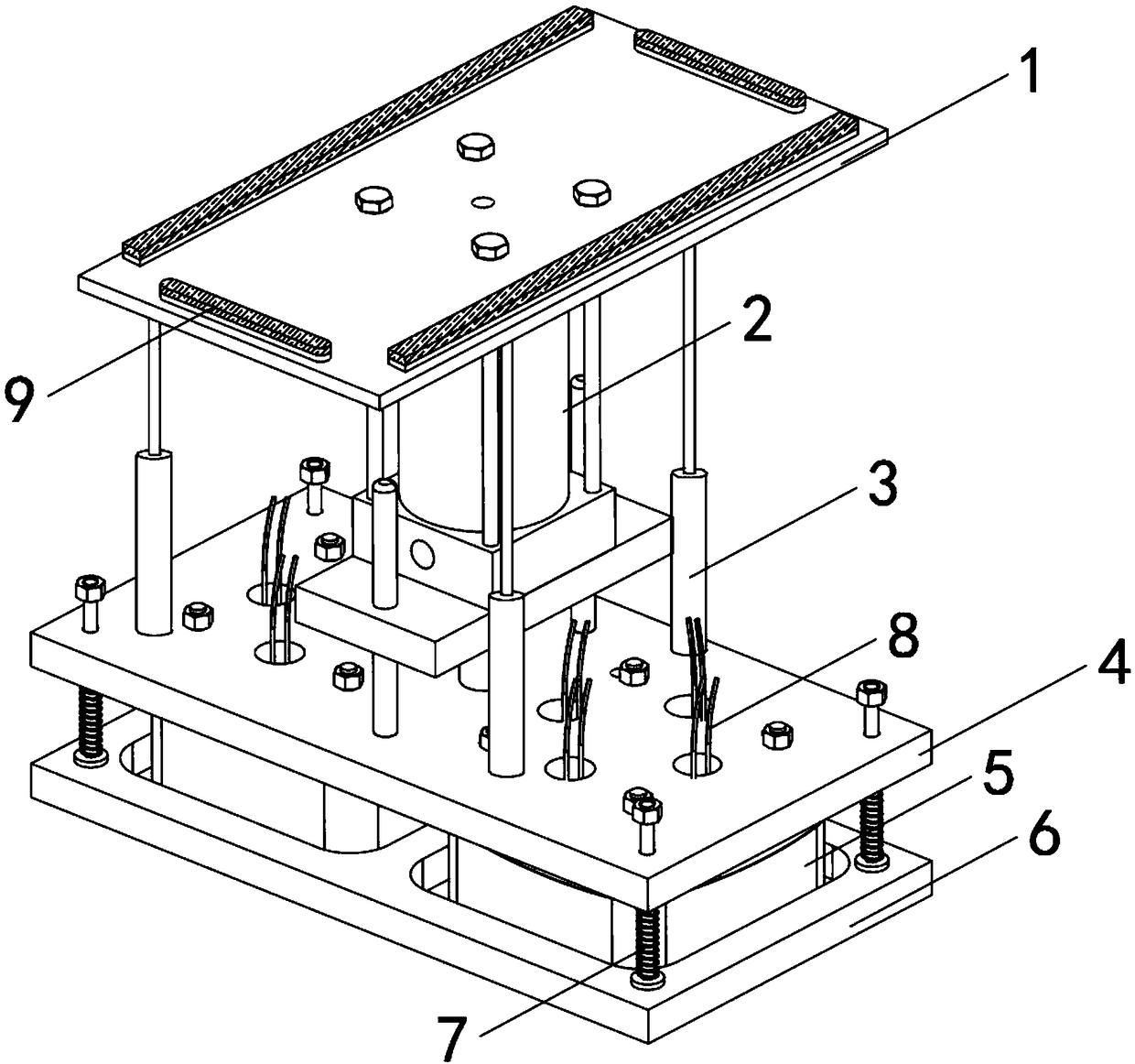

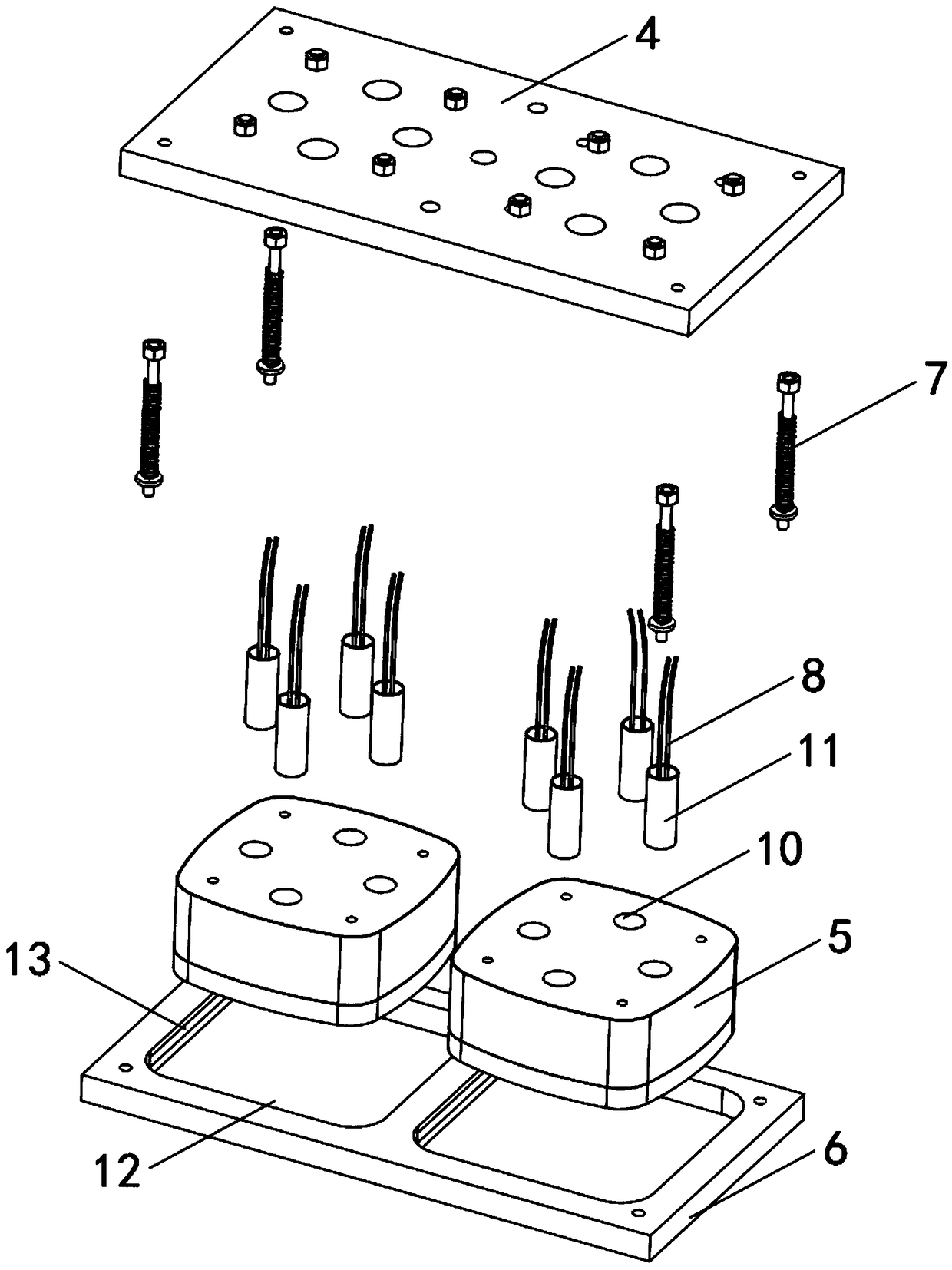

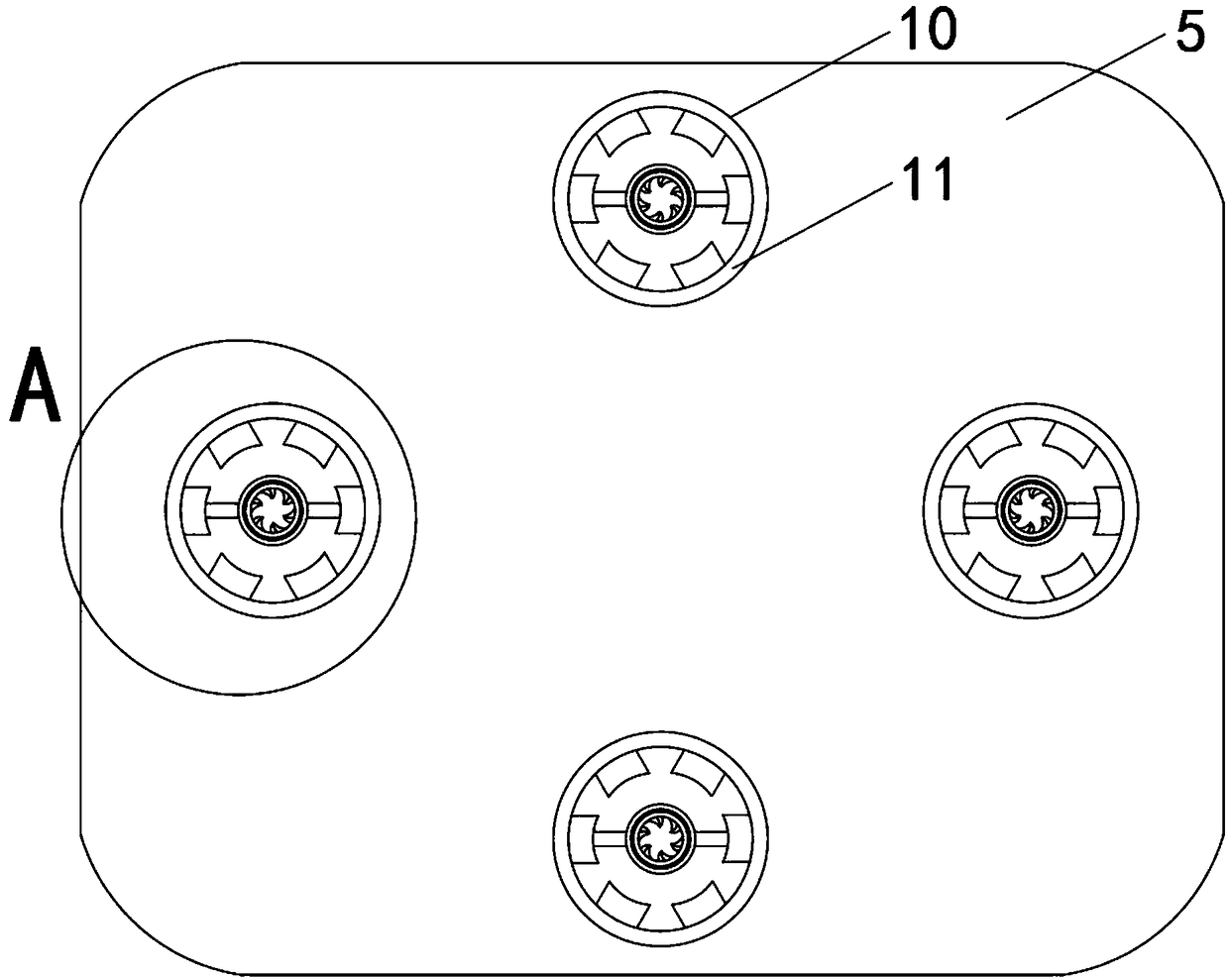

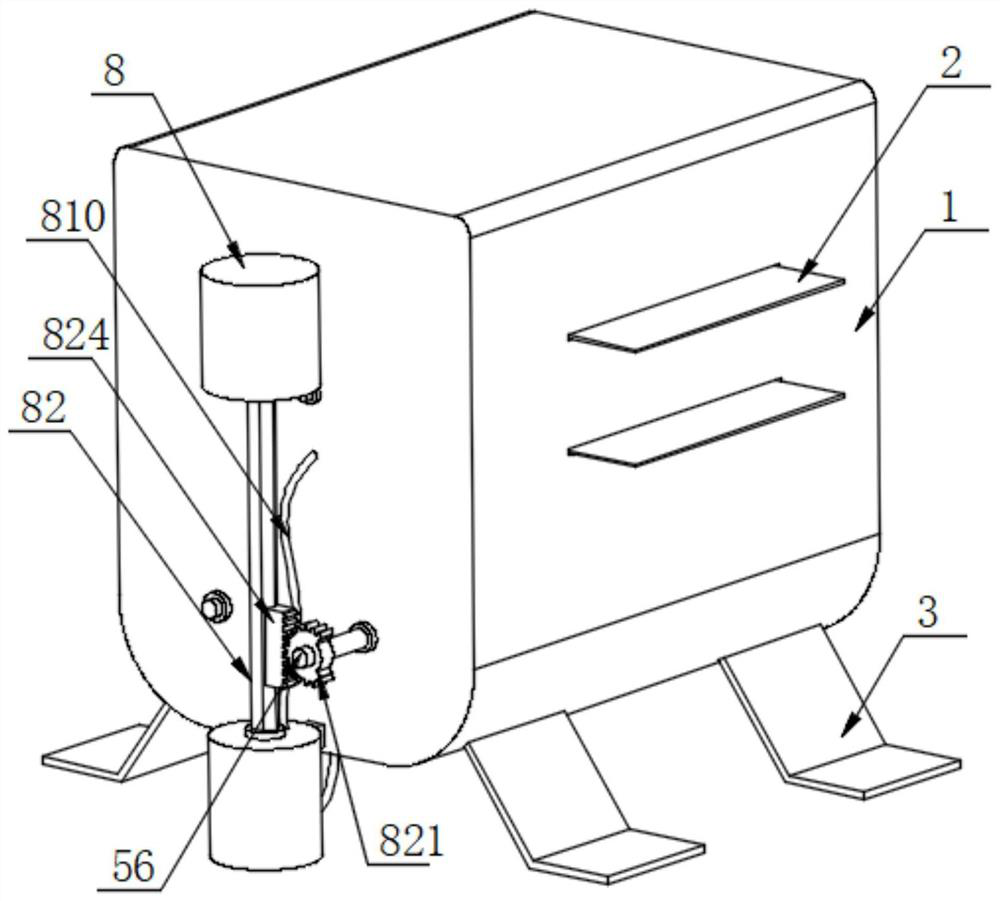

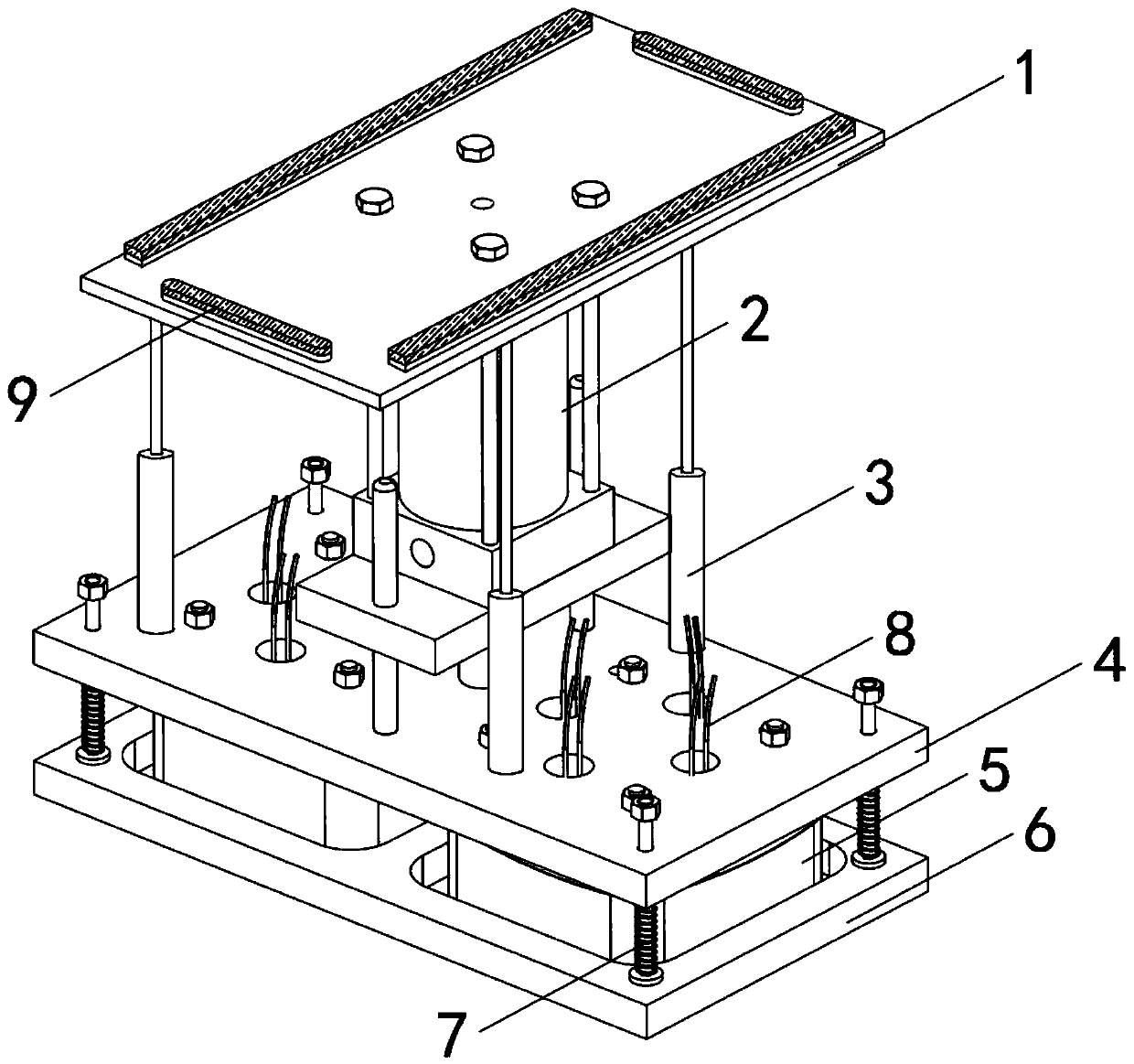

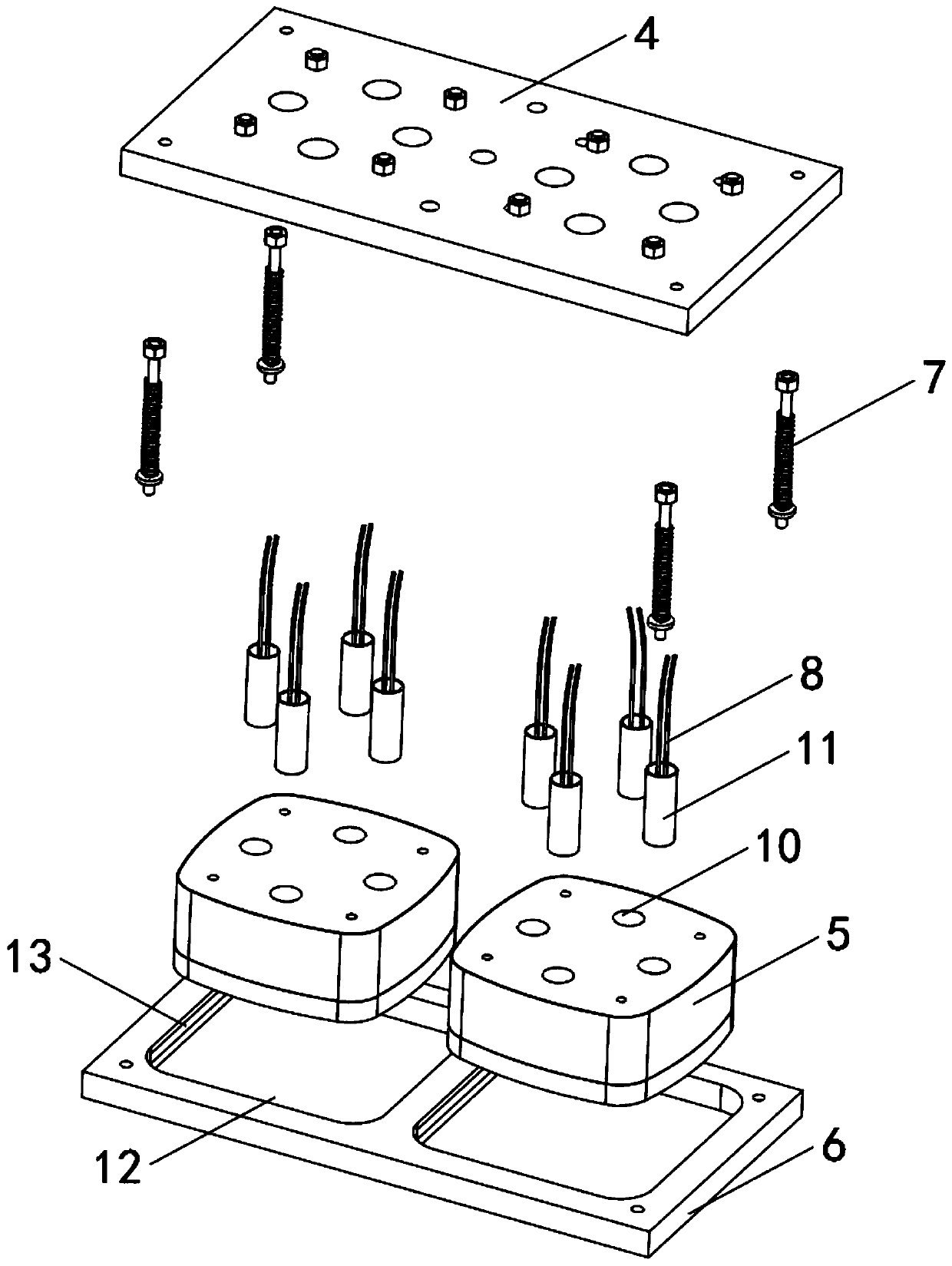

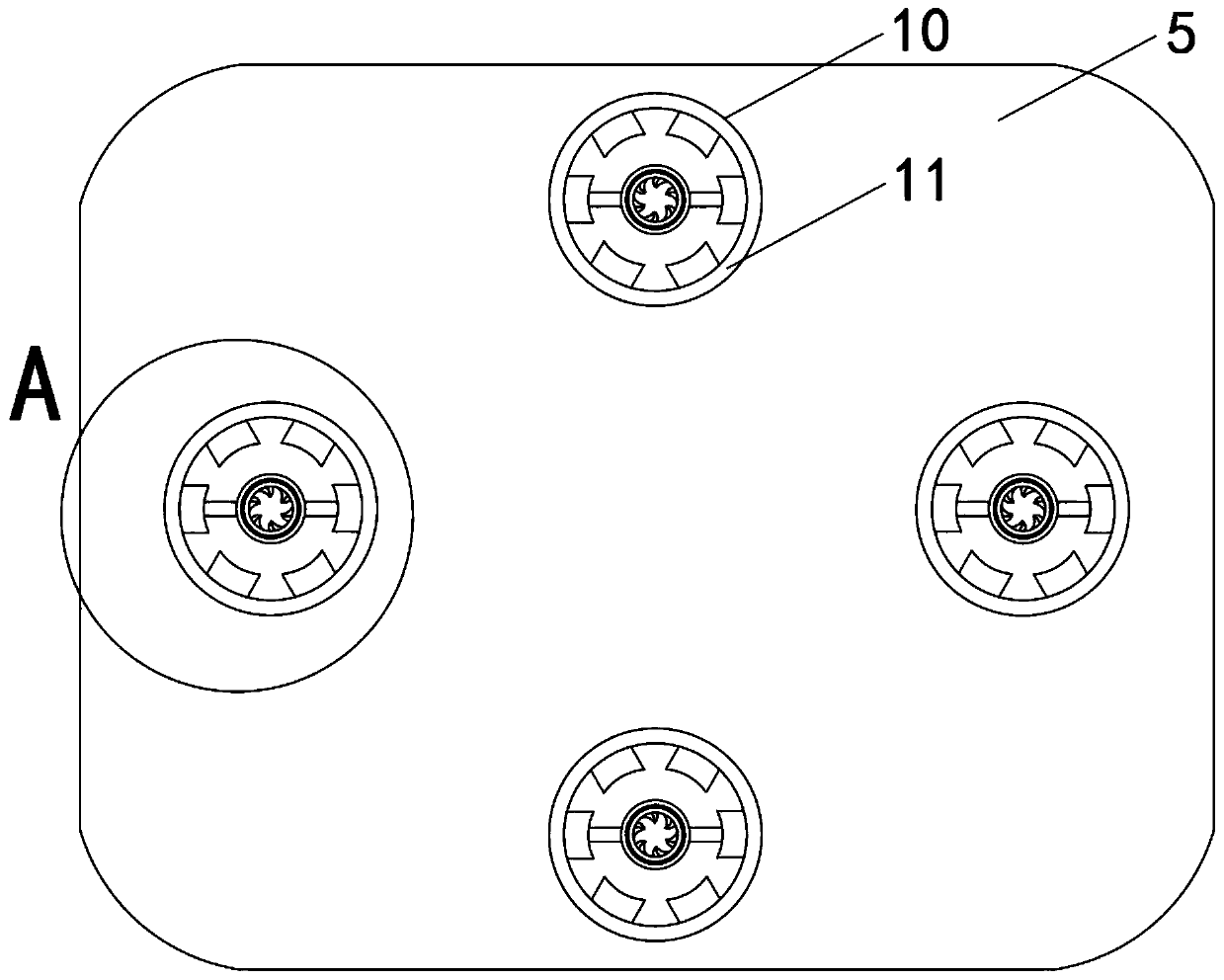

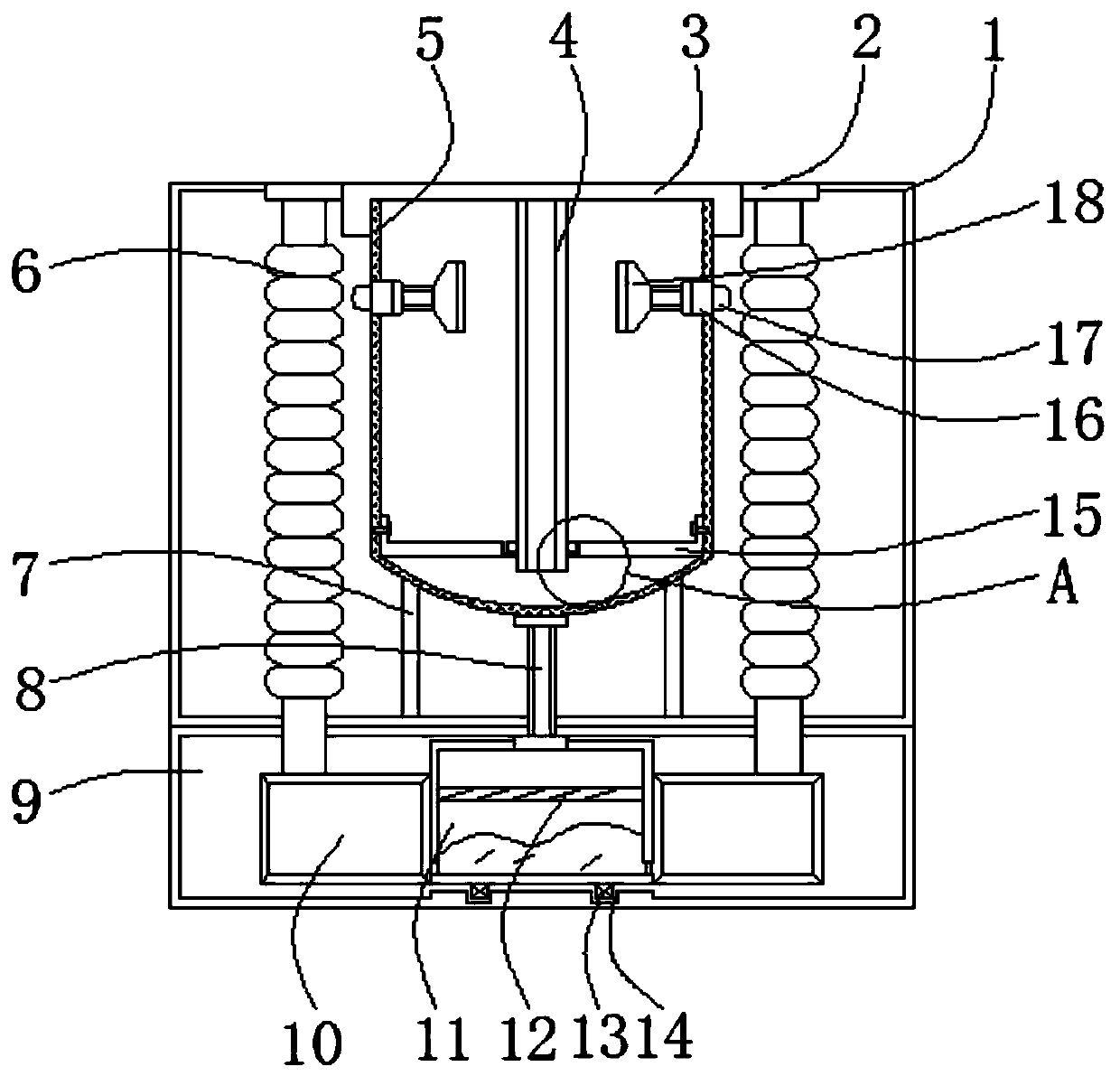

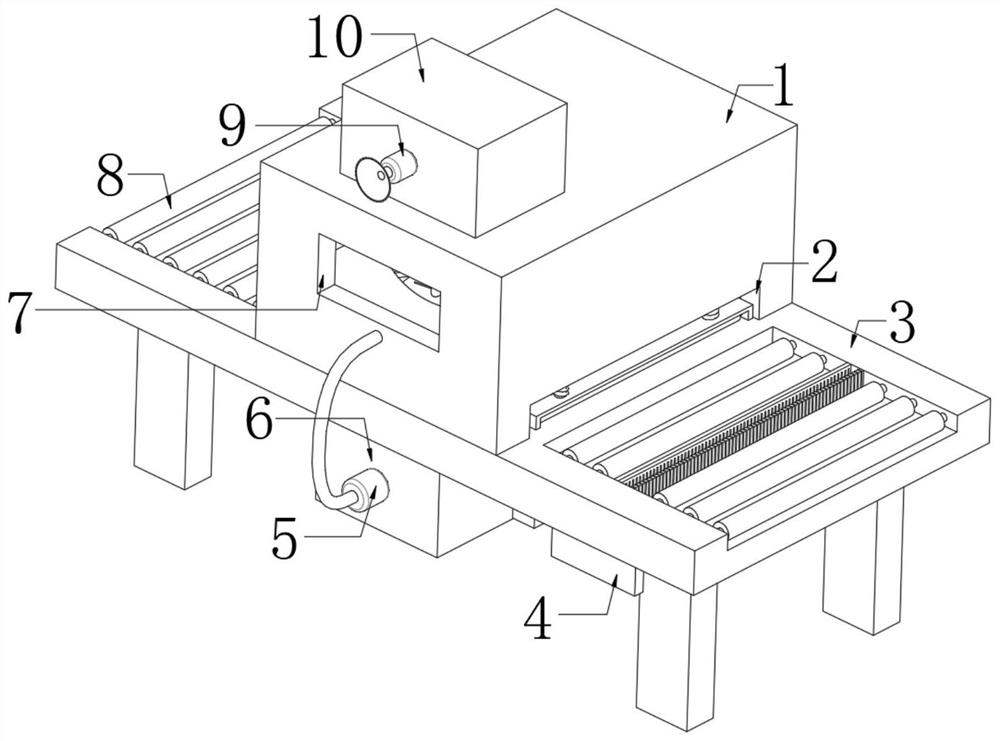

Power device for spinning

InactiveCN108754929AFlexible useUniform printing and dyeingTextile treatment containersTextile treatment machine arrangementsEngineeringPower apparatus

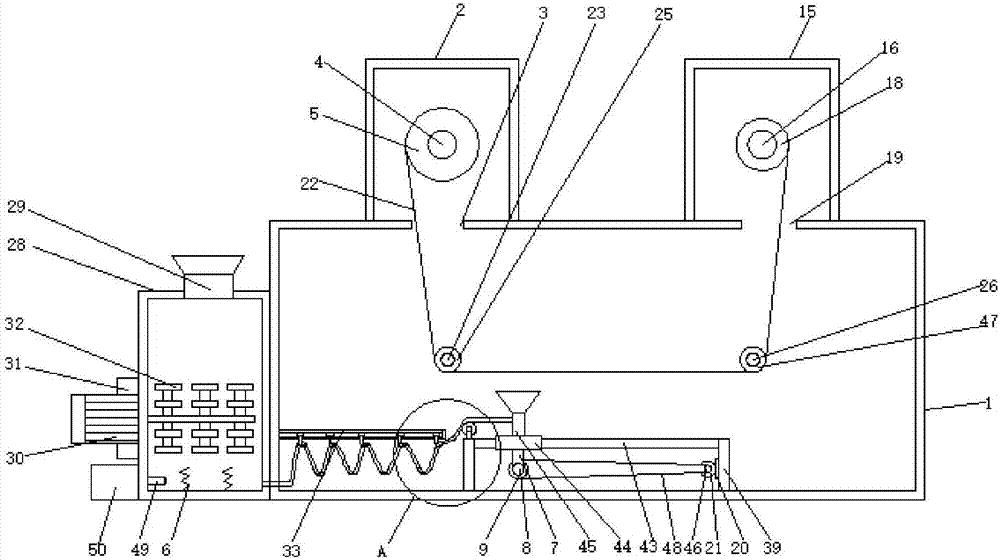

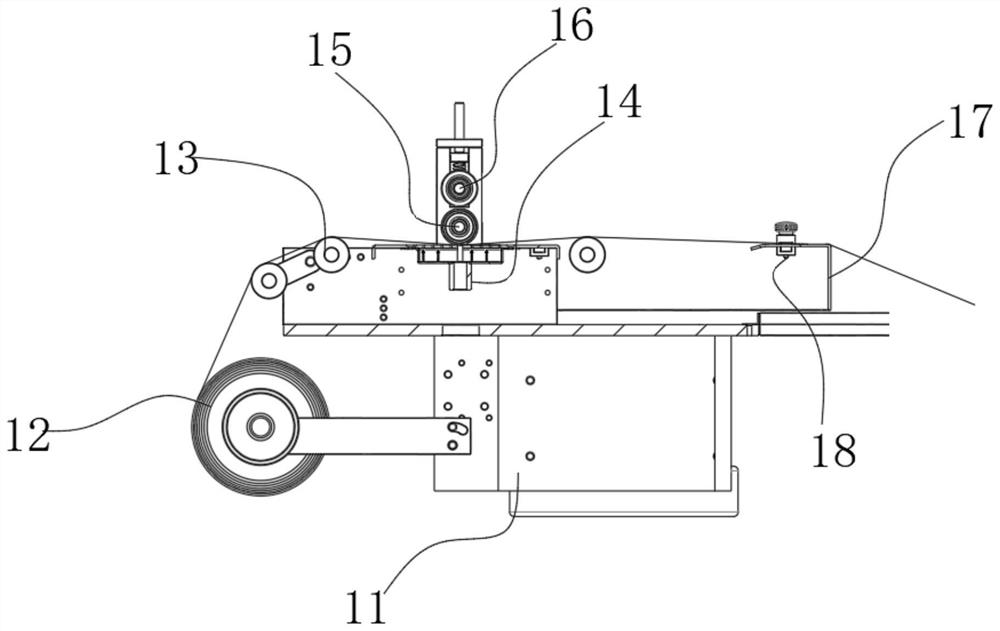

The invention provides a power device for spinning and relates to the field of textile machinery. The power device comprises a base, wherein supporting plates are fixedly arranged on two sides of thetop of the base, a top plate is fixedly arranged at the tops of the supporting plates, and mounting grooves are formed in the supporting plates; screw rods are arranged in the mounting grooves, and the two ends of each screw rod are connected with the corresponding supporting plate and the top plate respectively; the top of each screw rod penetrates through the top plate and is fixedly provided with a first transmission wheel, and a first servo motor is fixedly arranged in the middle of the top plate; the first servo motor is in transmission connection with a second transmission wheel througha rotating shaft arranged at one end of the first servo motor, and the first transmission wheels and the second transmission wheel are connected through belts. According to the power device for spinning, a conveying mechanism is driven to move up and down through the first servo motor and the screw rods so that in the processing process, the relative positions of the conveying mechanism and a feeding groove can be adjusted, the device can be applied to different textile fabrics, and the device is more flexible to use.

Owner:湖州南浔善琏众粮毛纺有限公司

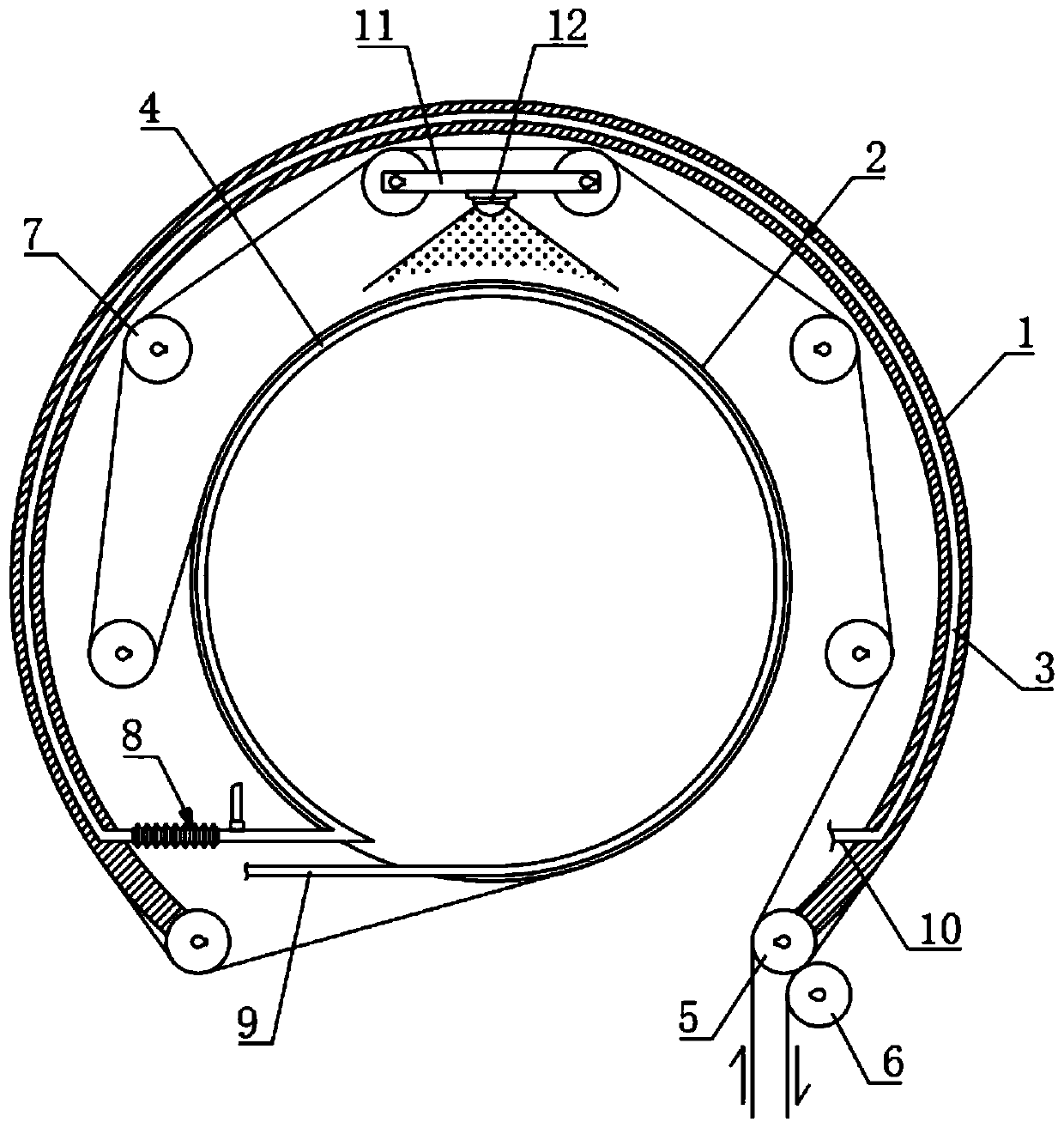

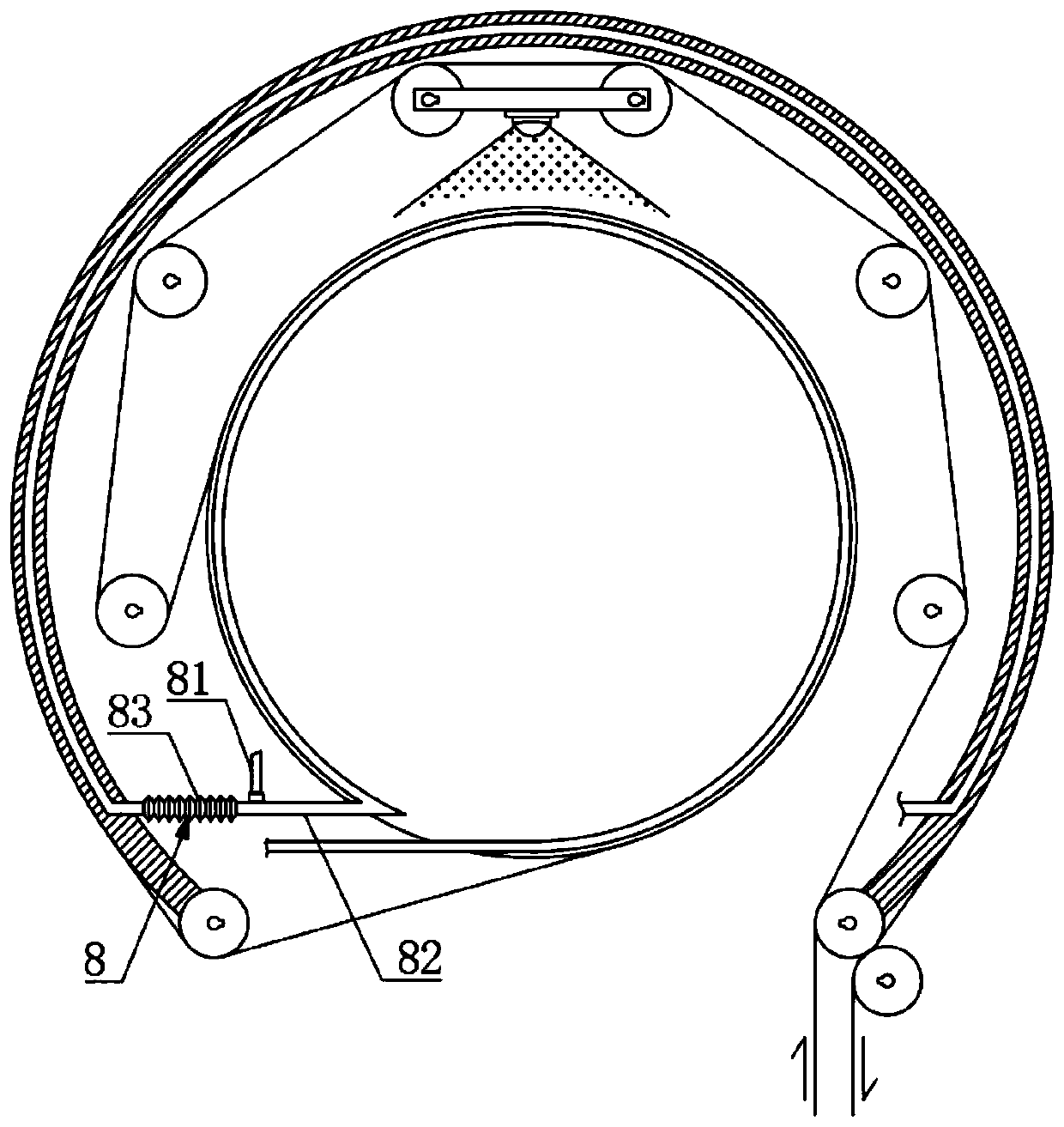

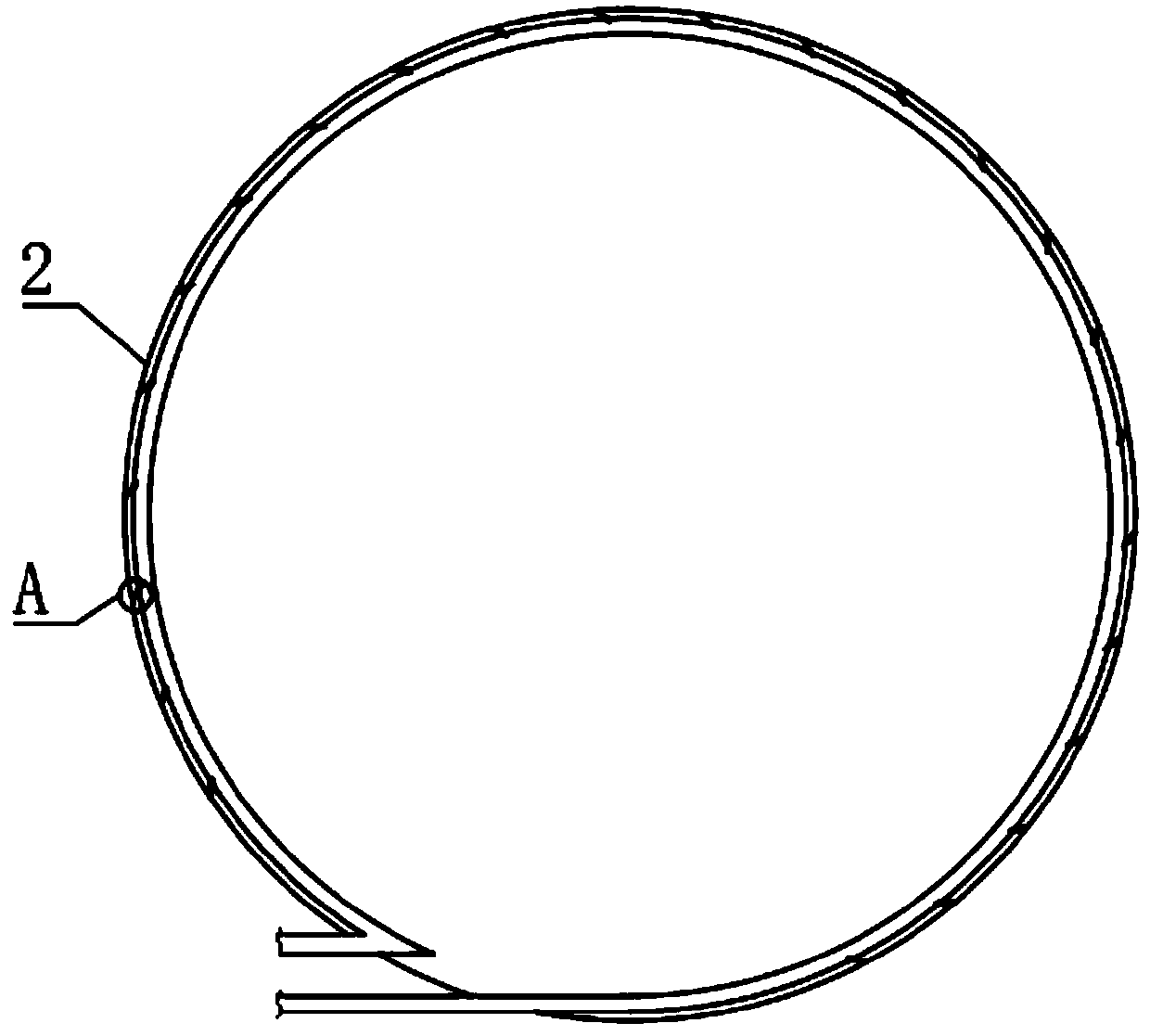

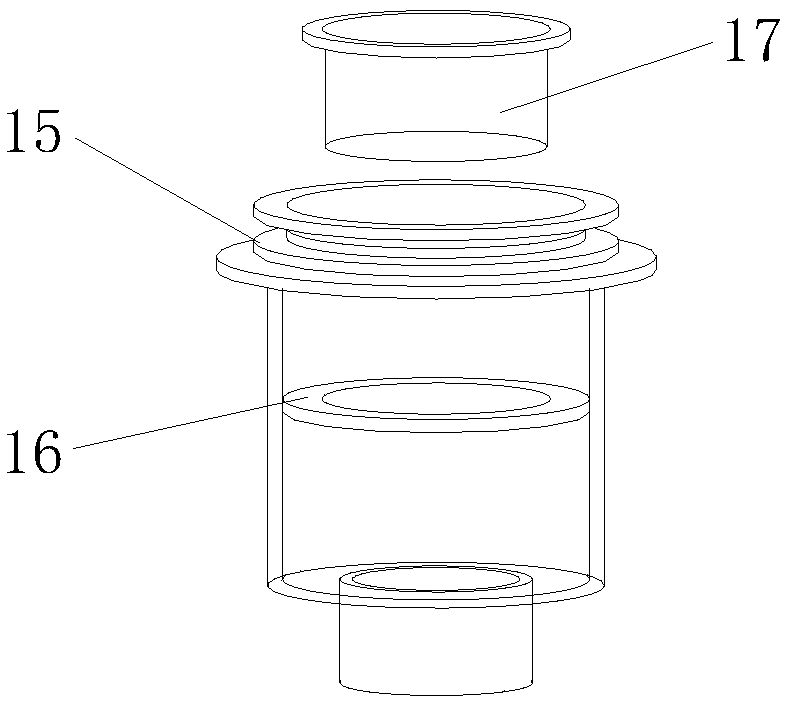

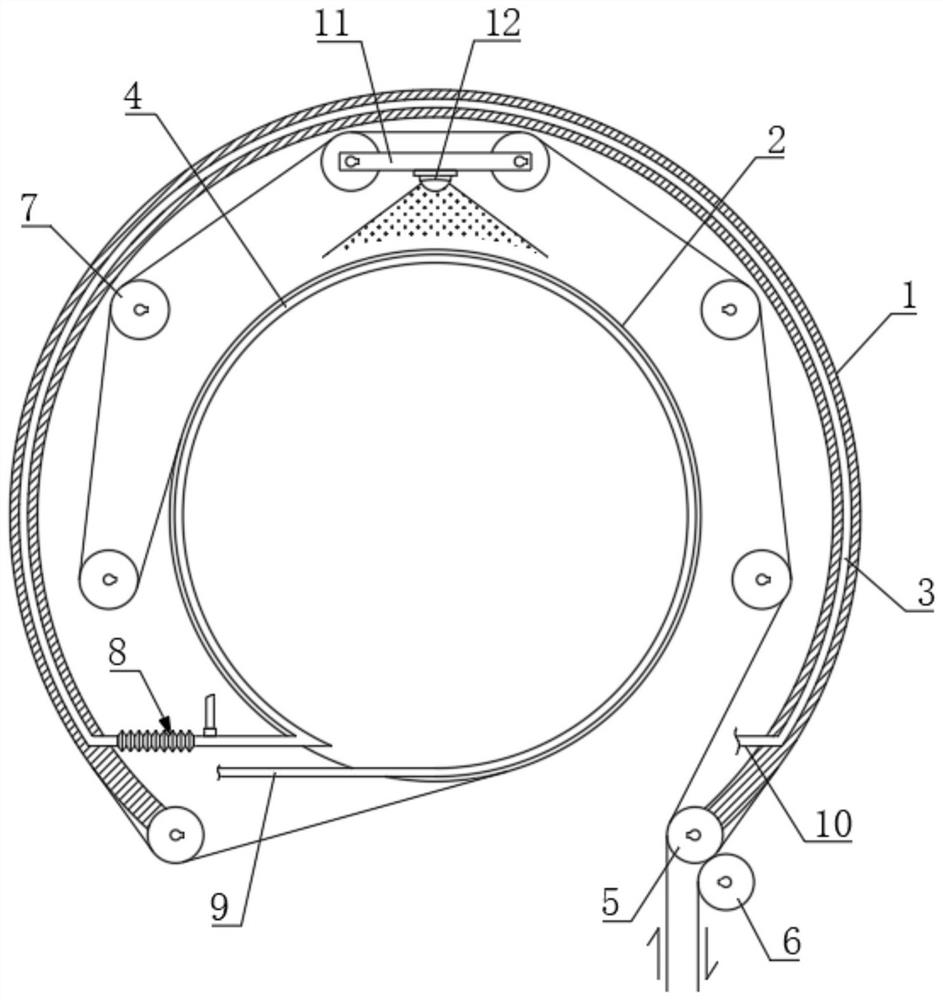

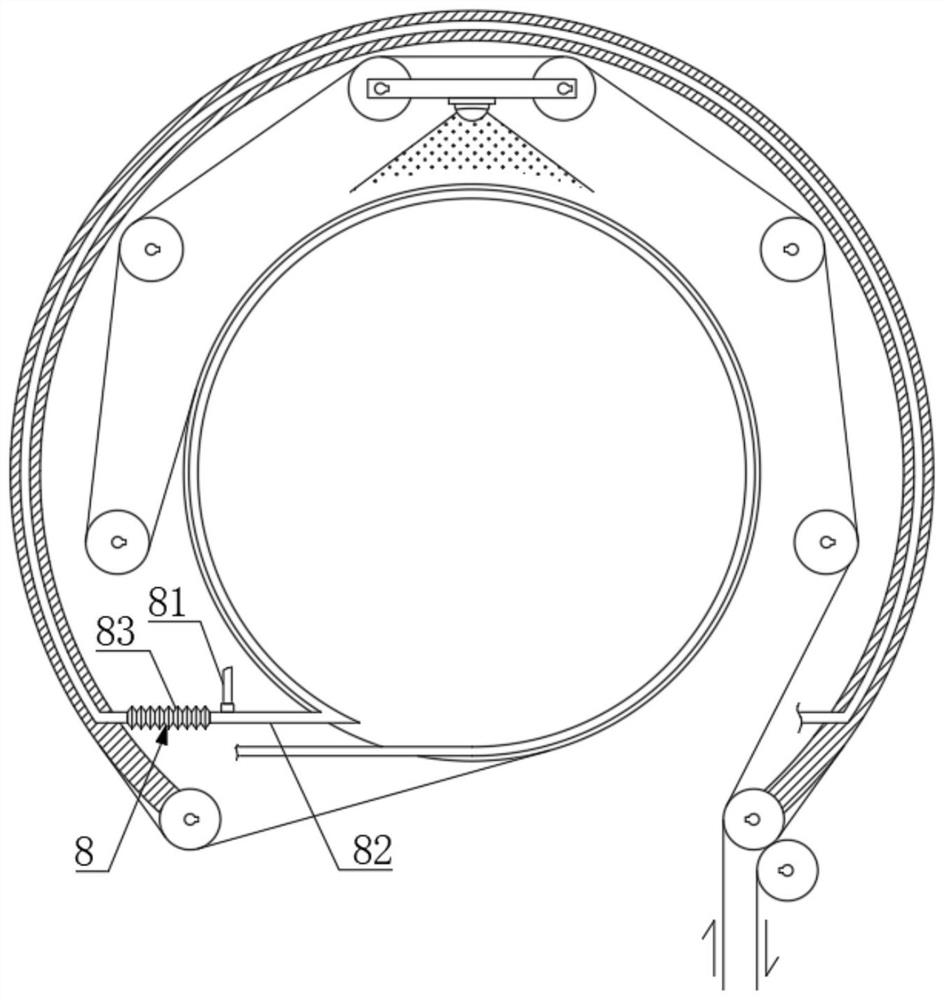

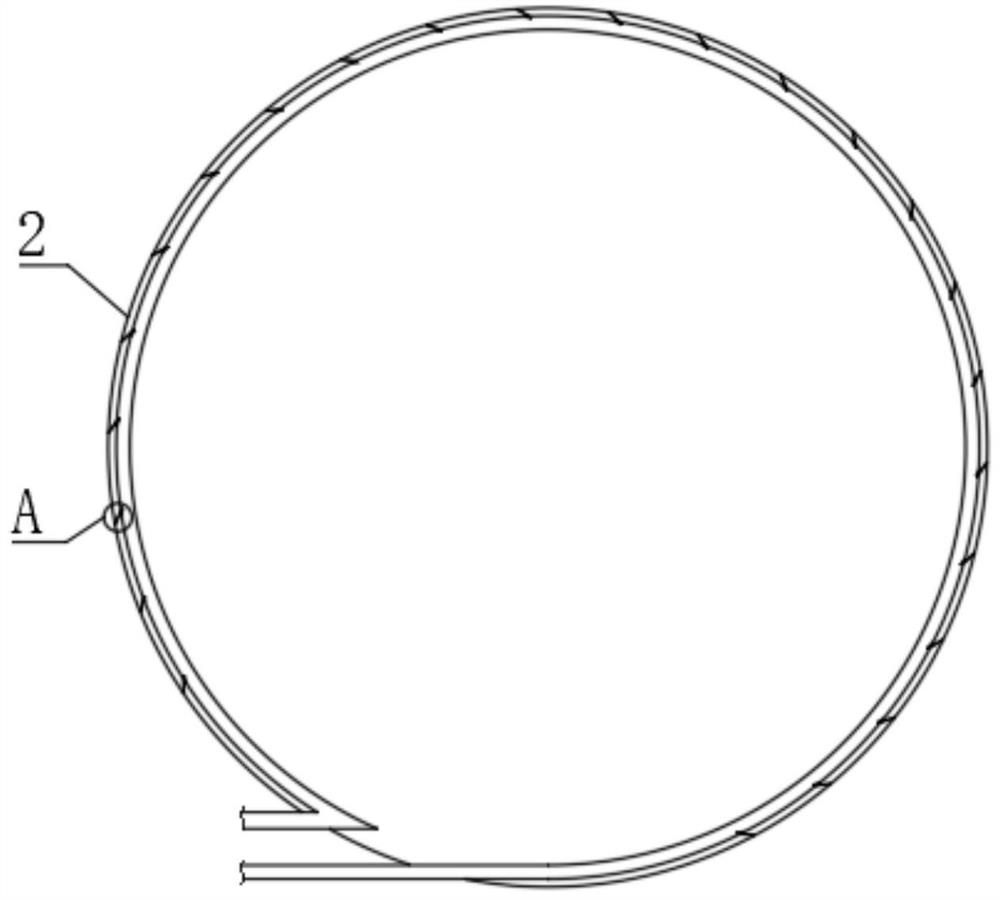

Atmosphere printing and dyeing device for cloth

ActiveCN110699884AUniform printing and dyeingReduce surface tensionTextile treatment machine partsTextile treatment by spraying/projectingCold airThermodynamics

The invention discloses an atmosphere printing and dyeing device for cloth, and relates to the technical field of printing and dyeing devices. The atmosphere printing and dyeing device for the cloth comprises an outer barrel and an inner barrel, wherein a vortex tube is arranged between the outer barrel and the inner barrel and comprises an air inlet pipe, a hot air outlet end and a cold air output end; a circle of outer cavity is formed in the inner wall of the outer side of the outer barrel; one side of the outer cavity communicates with the cold air output end; the other side of the outer cavity communicates with a cold air exhaust pipe; a circle of inner cavity is formed in the inner wall of the outer side of the inner barrel; one side of the inner cavity communicates with the hot airoutput end; and the other side of the inner cavity communicates with a hot gas exhaust pipe. By arrangement of the vortex tube and during atmosphere spraying, hot air preheats the cloth through heat conduction of the inner barrel, so that when dye is in contact with the cloth, the surface tension of the dye is reduced, and the dye penetrates into the deep part of the cloth; and when the cloth is conveyed to the outer surface of the outer barrel, the cloth is cooled, and meanwhile, the surface tension of the dye at the undried position is reduced, so that printing and dyeing are uniform.

Owner:WUXI HUIZE GENERAL MACHINERY

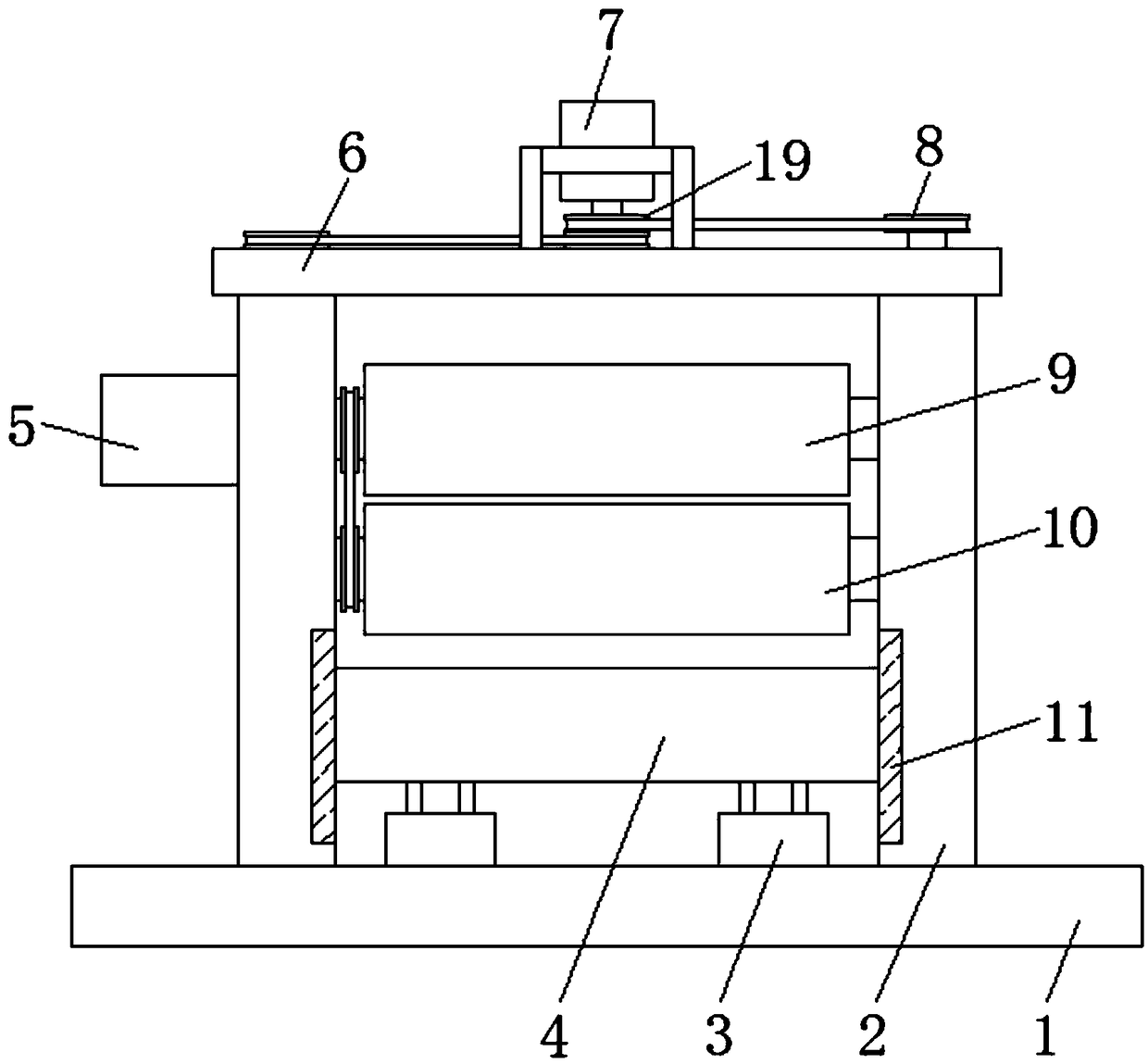

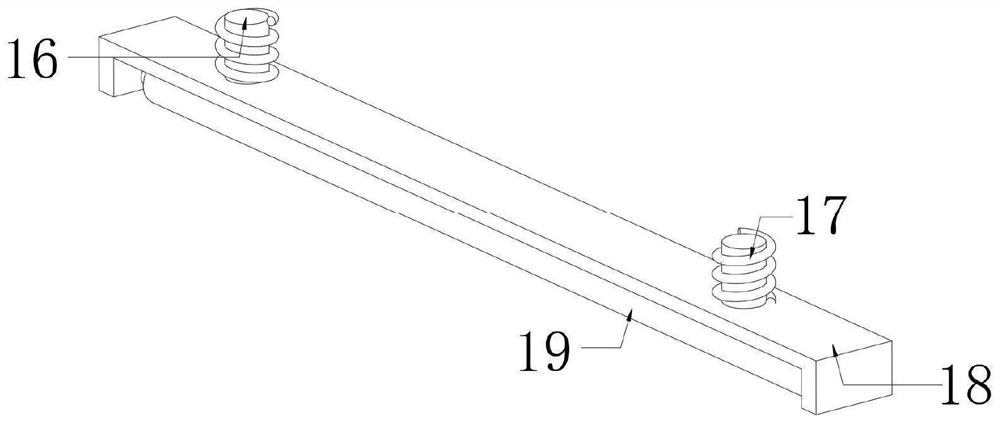

A printing and dyeing treatment device capable of improving the printing and dyeing quality of printed and dyed cloth

ActiveCN111591009BScientific and reasonable structureEasy to useMechanical cleaningInking apparatusStructural engineeringMechanical engineering

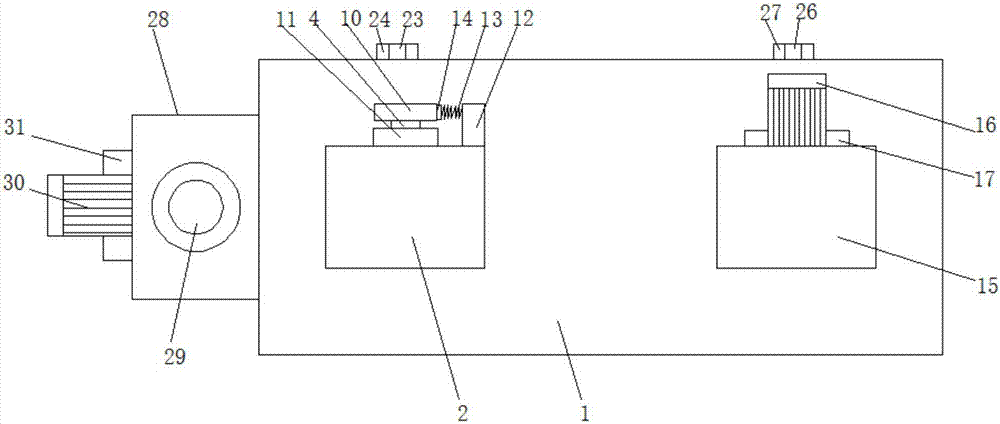

The invention discloses a printing and dyeing treatment device capable of improving the printing and dyeing quality of printed and dyed cloth. The two ends of the top of the base are symmetrically fixed with fixed seats, and the middle part of the fixed seat is provided with a rectangular groove, and an extrusion spring is fixedly installed inside the rectangular groove. The top of the extrusion spring is fixedly connected with a connecting plate, the middle part of the bottom end of the connecting plate is fixedly connected with an adjusting plate, one end of the bottom of the adjusting plate is fixedly connected with a leveling plate, and the two side walls inside the fixing seat are symmetrically provided with chute. The invention has a scientific structure. Reasonable, safe and convenient to use, through the combined use of the adjusting plate and the extrusion spring, the tension of the cloth during the running process can be dynamically adjusted to avoid the deformation of the cloth caused by excessive pulling when the cloth is running, and the pattern of printing and dyeing of the cloth will occur after the deformation of the cloth Change, through the use of the leveling plate, it has a leveling effect on the cloth, preventing the cloth from being wrinkled during the traveling process and causing the cloth to be unable to be printed, dyed, processed and rolled normally.

Owner:普宁市鸿骏实业有限公司

Dyeing machine with agitator

ActiveCN105113161BAvoid collisionAvoid secondary damageTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentMagnetic tension forceEngineering

The invention discloses a cloth dyeing machine with stirrers. The cloth dyeing machine structurally comprises a base, and is characterized by also comprising a cloth dyeing machine body, a magnetic controller, a magnetic sensor and the stirrers, wherein the cloth dyeing machine body is in a hooked cylinder shape; an anti-overflow hole is formed in the cloth dyeing machine body; each stirrer comprises a stirring body and a protecting cover; one cross section of each stirring body is elliptical; each stirring body is made of a magnetic material; each protecting cover is in a hollow spherical shape, and the surface of each protecting cover is covered with a plurality of circular holes; each protecting cover is divided into two semicircles which are connected with each other through threads; the magnetic sensor is positioned below the stirrers and is connected with the magnetic controller; the magnetic controller is positioned below the cloth dyeing machine body. Stirring operation is carried out by the adoption of the stirrers under the action of a magnetic force, and the stirrers are externally provided with the protecting covers, so that the collision between the stirrers is effectively prevented, the service life is prolonged, and dyeing is thorough and more uniform.

Owner:苏州盛泽科技创业园发展有限公司

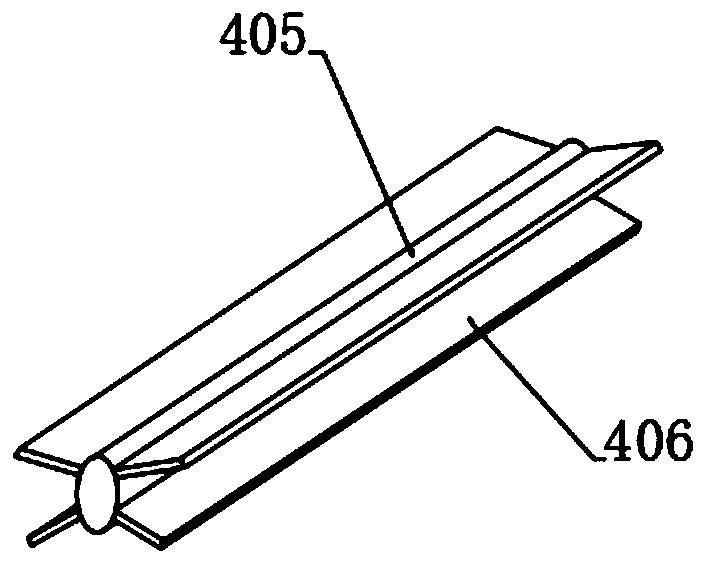

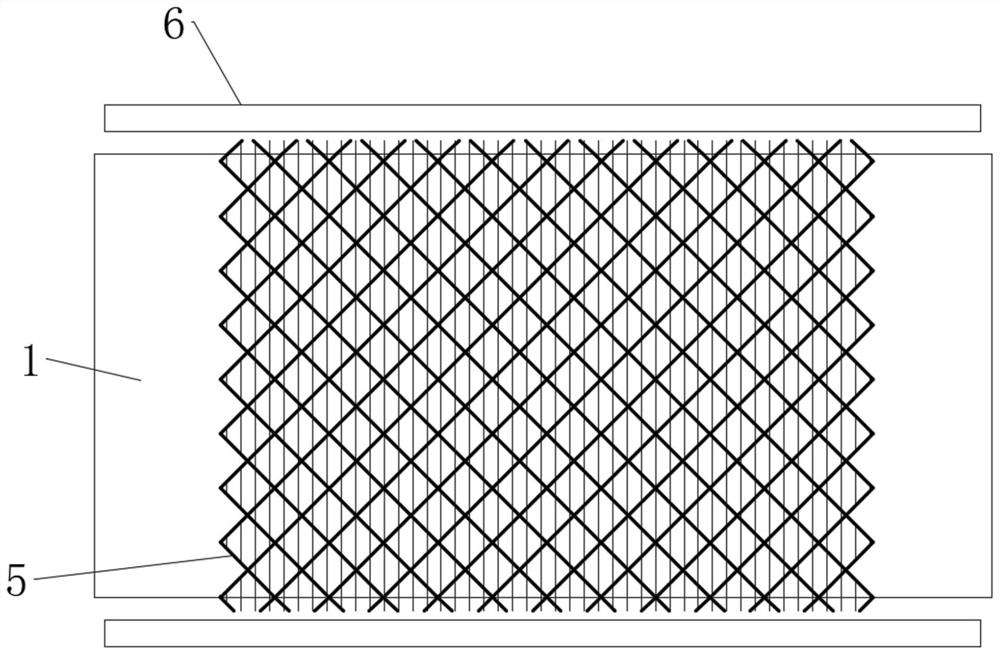

Magnetic bar scraper with paste blocking plate

InactiveCN111284126AUniform printing and dyeingImprove printing and dyeing qualityScreen printersEngineeringSlurry

The invention relates to the field of printing and dyeing machinery, in particular to a magnetic bar scraper with a paste blocking plate. The magnetic bar scraper comprises a paste inlet pipe mountedin a circular screen. A plurality of paste outlet holes are formed in the bottom of the slurry outlet pipe. A supporting plate is welded to one side of the outer wall of the paste inlet pipe. A rubberbaffle making contact with a magnetic bar is fixedly mounted at the lower end of the supporting plate. The outer wall of the paste inlet pipe is also welded with a C-shaped paste blocking plate. Theupper end of an opening of the C-shaped paste blocking plate is welded to the outer wall of the paste inlet pipe. The lower end of the opening of the C-shaped paste blocking plate is obliquely upward.An overflow gap exists between the paste blocking plate and the rubber baffle. Color paste sprayed out of the paste outlet holes flows into the C-shaped paste blocking plate and then flows onto the magnetic bar and the rubber baffle from the overflow gap. By means of the magnetic bar scraper, the printing and dyeing quality is improved.

Owner:黄石市金球机械制造厂

Textile printing and dyeing device based on high-energy microbubble technology

InactiveCN111826832AReduce dosageWide range of splashesTextile treatment machine arrangementsTextile treatment by spraying/projectingTextile printerMicro bubble

The invention discloses a textile printing and dyeing device based on a high-energy microbubble technology, and belongs to the field of textile printing and dyeing devices. For the textile printing and dyeing device based on the high-energy microbubble technology, according to the technical scheme, a technology similar to drip irrigation is utilized, the amount of dye liquor is reduced, the dye liquor is converted into high-energy microbubbles, dye liquid drops forming the high-energy microbubbles are enabled to splash around by instantaneous impact generated by explosion of the high-energy microbubbles, then the dye liquid drops uniformly spread on the surface of a textile main body, macroscopically, uniform printing and dyeing of the whole textile main body are realized through the continuously sprayed high-energy microbubbles, the explosion height of the high-energy microbubbles is controlled by utilizing a telescopic belt, so that the range of splashing of the dye liquid drops of the high-energy microbubbles is wider, then the printing and dyeing efficiency is improved, a large amount of dye liquor does not need to be prepared in advance, then the water consumption in the textile printing and dyeing process can be greatly reduced, the utilization efficiency of water resources and dye is improved, meanwhile, the production rate of wastewater in the production process is reduced, and thus the wastewater treatment cost in the printing and dyeing process is reduced.

Owner:王海燕

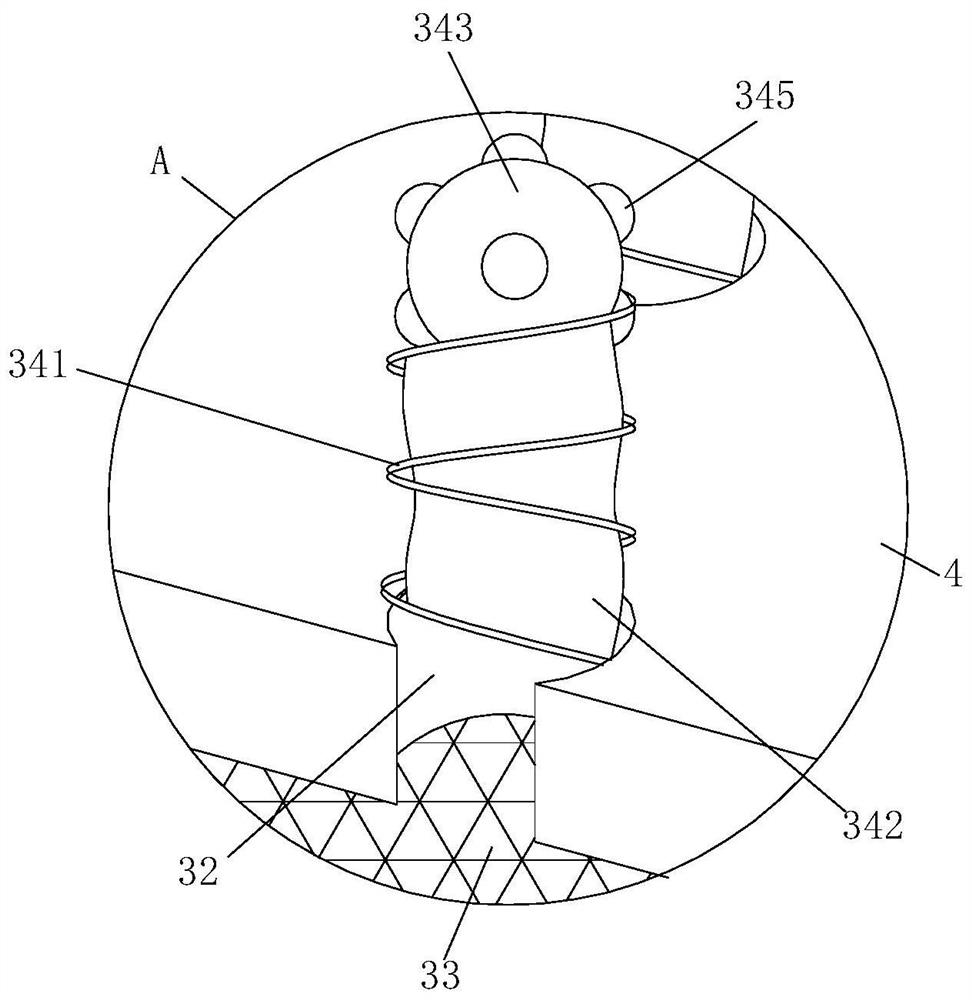

An inking roller for a printing machine

ActiveCN110271275BControl flowUniform printing and dyeingPrinting press partsPrinting pressMechanical engineering

The invention provides an inking roller for a printing machine. The inking roller comprises an outer roller, an inner extrusion mechanism and an inking mechanism. According to the inking roller, the problems that the amount of ink attached to the ink roller at the tail end is reduced due to the action of multiple ink transferring rollers in an existing inking roller in the moving process, so that the printing and dyeing of a printing and dyeing product by the ink roller is influenced, and the phenomenon that the printing product is dark in the front and light in the back can be easily caused, meanwhile, the ink at an inking port can be easily sprayed and dropped in the uniform inking process of the inking roller, so that the printing and dyeing product is scrapped, and meanwhile, the ink coagulation is prone to occur in the inking process of the existing inking roller, and the uniform flowing of the ink is influenced are solved.

Owner:温州运城制版有限公司

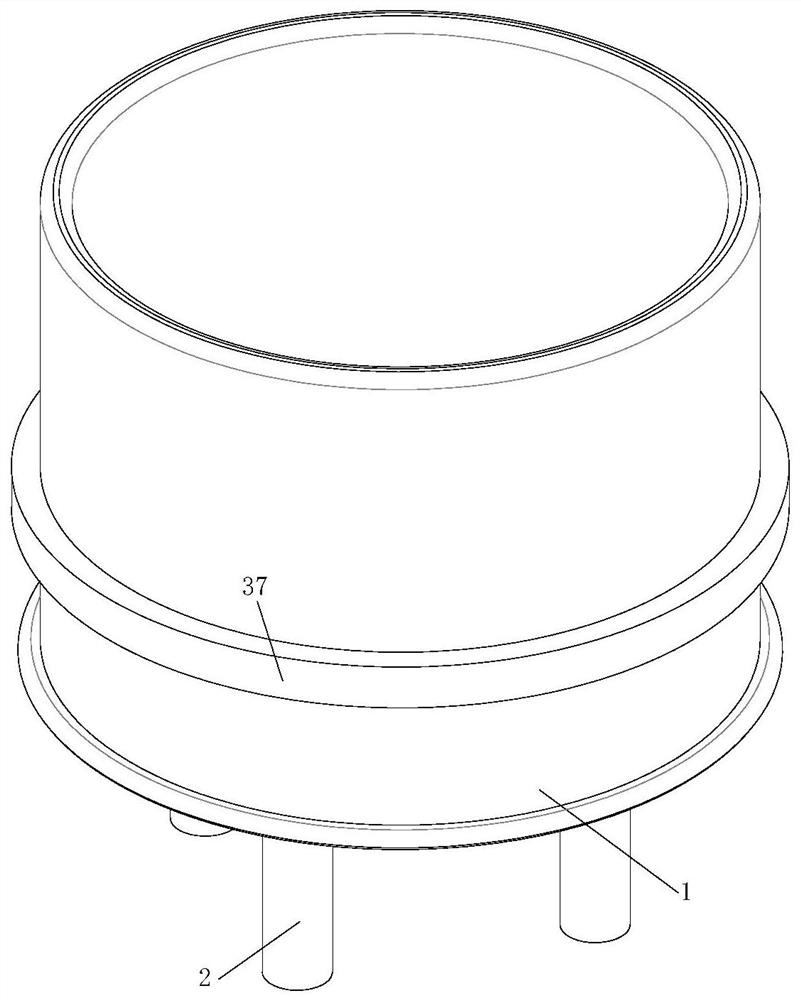

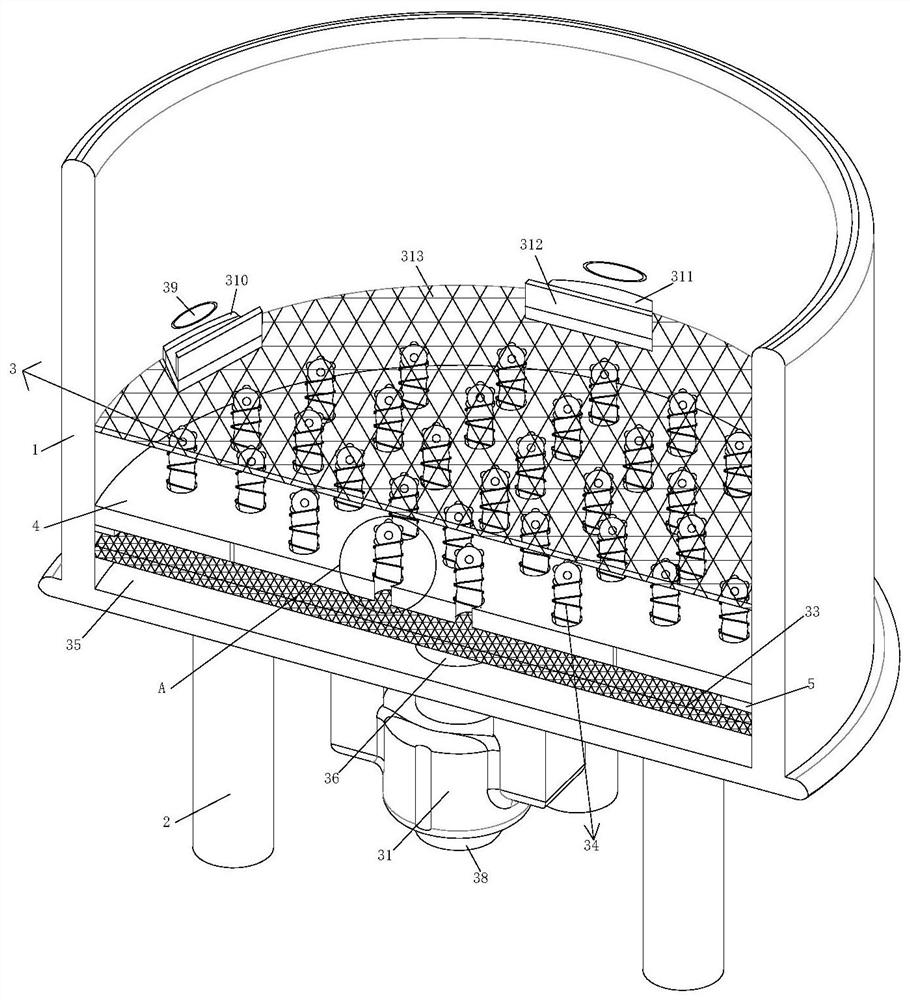

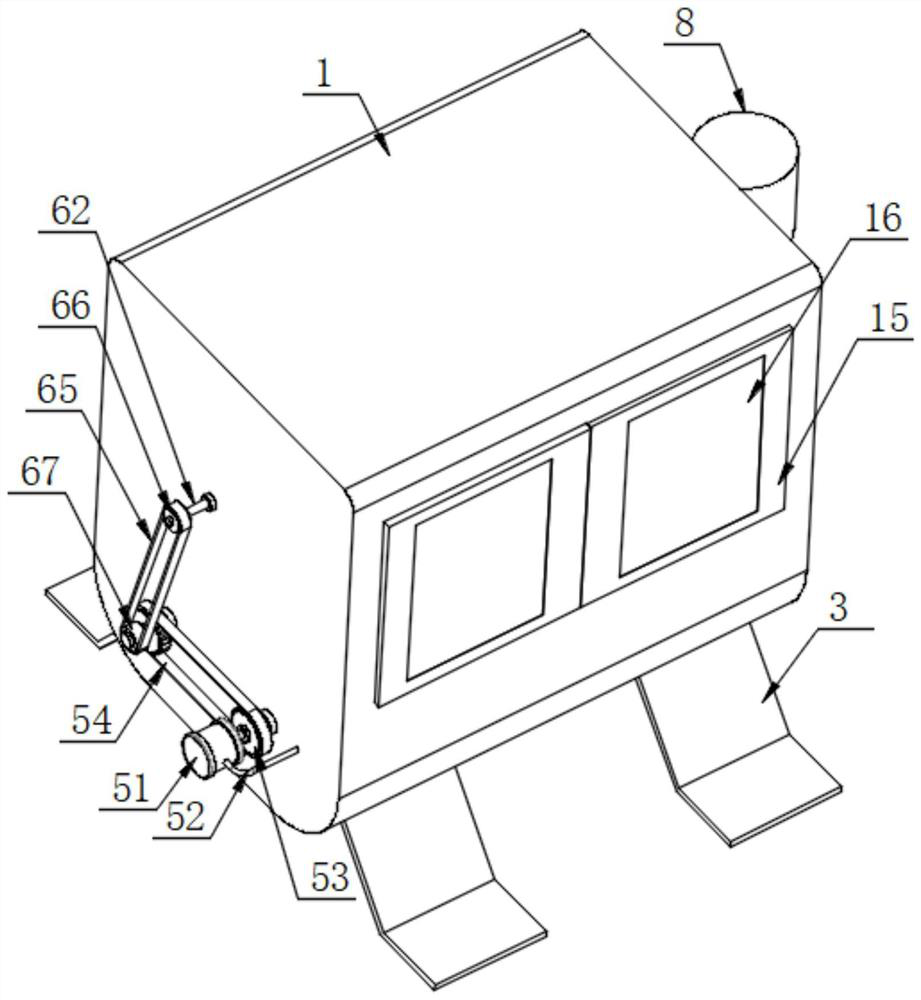

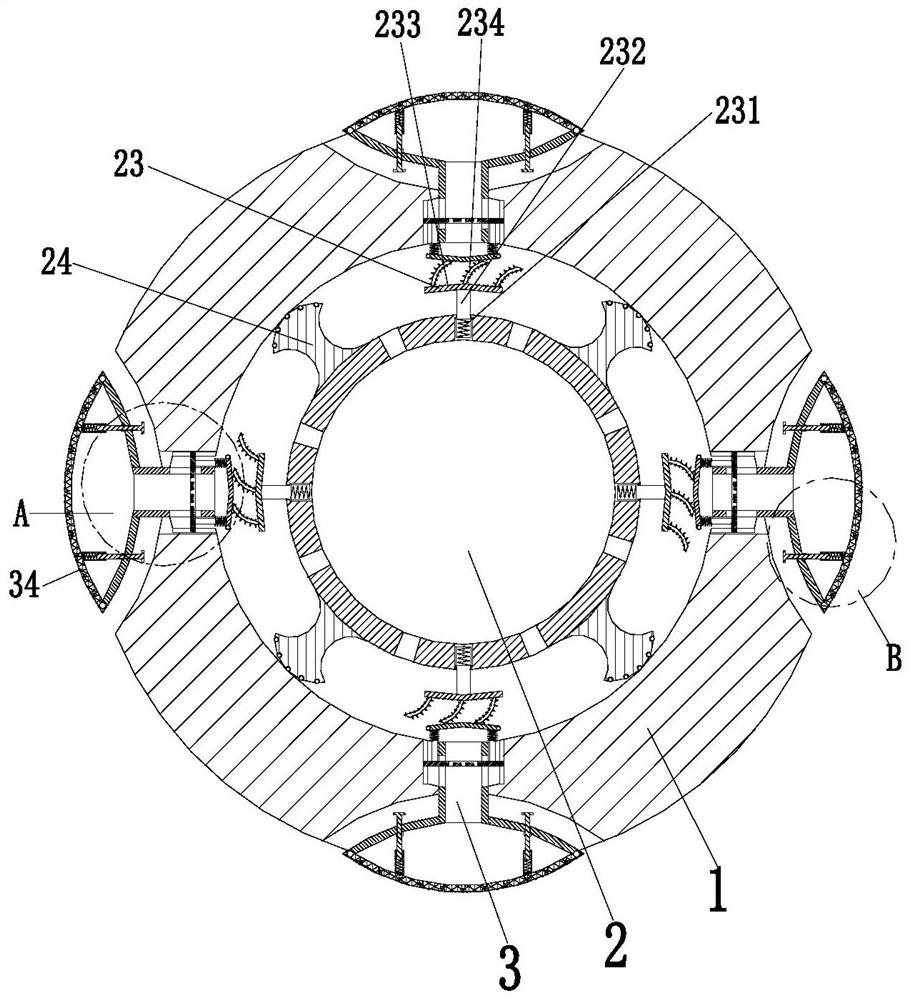

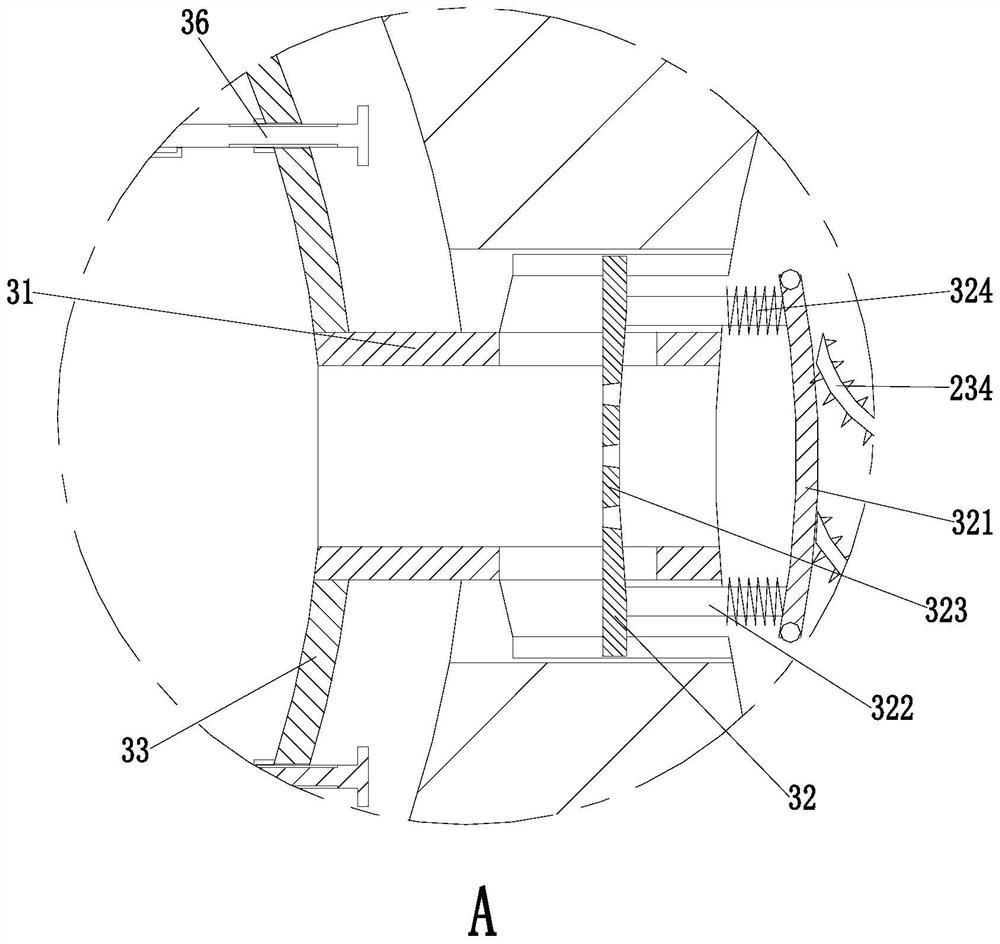

Flocking printing and dyeing device for spinning based on miscellaneous fluff removal

InactiveCN112226946APrevent precipitationEvenly mixedMechanical cleaningPressure cleaningTextile printerPolymer science

The invention provides a flocking printing and dyeing device for spinning based on miscellaneous fluff removal. The flocking printing and dyeing device comprises a printing and dyeing box for textileprinting and dyeing, supporting legs for supporting the printing and dyeing box, a vortex fluff removal mechanism for removing miscellaneous fluff in the printing and dyeing box and a heteromagnetic movable printing and dyeing mechanism for printing and dyeing, wherein the bottom of the printing and dyeing box is fixedly connected with the supporting legs, and the vortex fluff removal mechanism isarranged on the printing and dyeing box. The flocking printing and dyeing device relates to the field of textile printing and dyeing. According to the flocking printing and dyeing device for spinningbased on miscellaneous fluff removal, a special structure capable of achieving special fluff removal and uniform printing and dyeing at the same time is designed according to the problems existing inflocking printing and dyeing in combination with fluid mechanics and magnet magnetism, fluff removal and printing and dyeing are conducted at the same time during printing and dyeing, processes are reduced, and therefore the problems that as for common flocking printing and dyeing, separate printing and dyeing of base cloth and a fluff material are complex in processing technology and long in consumed time, work efficiency is affected to a certain extent, and uneven printing and dyeing easily occurs after flocking of the base cloth, and quality of printed and dyed finished products is affected are effectively solved.

Owner:绍兴明悠纺织科技有限公司

Cloth rapid printing, dyeing and drying equipment for garment making

PendingCN114164581AUniform printing and dyeingEasy to recycleLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsDyeingManufacturing engineering

The invention relates to the technical field of printing, dyeing and drying equipment, and discloses rapid cloth printing, dyeing and drying equipment for garment making. The rapid cloth printing, dyeing and drying equipment for garment making comprises a printing and dyeing mechanism and a drying mechanism, and the drying mechanism is located on the left side of the printing and dyeing mechanism; the printing and dyeing mechanism comprises a plate box, positioning rollers are arranged on the upper sides and the lower sides of the front side wall and the rear side wall of an inner cavity of the plate box, and the rear ends of the positioning rollers penetrate through the rear side wall of the plate box and are provided with first gears. Non-uniform printing and dyeing caused by wrinkles of the cloth is effectively avoided, and the dye is convenient to recycle and reuse; and through cooperation of the supporting frame, the sliding blocks, the springs and other devices, the device can conveniently extrude and dry the cloth, rapid drying operation on the cloth is facilitated, and the working efficiency of workers is improved.

Owner:益阳市小星星服饰有限公司

Cloth printing and dyeing device

PendingCN109137341AEasy to operateUniform printing and dyeingTextile treatment containersSucessive textile treatmentsWater storageFixed frame

The invention discloses a cloth printing and dyeing device, which comprises a supporting stand and a printing and dyeing box. The left rear side of the upper end of the supporting stand is welded witha mounting frame, a stabilizing base is fixed under the front end of the mounting frame, a water storage cavity is formed inside the stabilizing base, a bump is fixed at the central position of the lower end inside the water storage cavity, first driving roller sets are mounted on the side edges of the bump, the printing and dyeing box is fixed at the right side of the mounting frame, the printing and dyeing box and the supporting stand are welded and fixed with each other, second driving roller sets are fixed to the two side wall surfaces in the printing and dyeing box, a fixing frame is mounted at the upper end inside the printing and dyeing box, and atomizing sprayers are arranged on the lower end surface of the fixing frame at equal distance. According to the cloth printing and dyeingdevice, the bump of a trapezoidal cube structure is arranged inside the water storage cavity, so that the first driving roller sets arranged on two sides can effectively utilize the water resources inside the water storage cavity, the moisture of the box body is fully utilized for rapidly soaking the printed and dyed cloth in advance, the time and effort are saved, and the operation is convenient.

Owner:嘉兴成杰服饰有限公司

Water-saving and energy-saving processing technology of polyester fabric

ActiveCN109487465BReduce tensionReduce dosageChemical fixing of textilesLiquid/gas/vapor removalPolyesterYarn

The invention discloses a water-saving and energy-saving processing technology of a polyester fabric, which comprises the steps of selecting raw materials of polyester yarns - dyeing yarns - winding yarns - weaving and cutting, and selecting high-density NC polyester yarns as raw materials of the polyester fabric. By means of the technology, the beneficial effects comprises: compared with the traditional method for integrally printing and dyeing the polyester fabric, the method of printing and dyeing is more comprehensive for polyester fabric , the polyester fabric is dyed by the dye solution,the process flow of dyeing the polyester fabric is reduced, the printing and dyeing efficiency is improved, by printing and dyeing a plurality of polyester yarns respectively, the dyeing solution consumption of the mechanism is less, so that the process is more energy-saving, water-saving and cost-saving when dyeing the polyester yarns; and the dye solution used for spraying and dyeing can flow into the packing groove by improving the sleeve groove, and the packing groove guides the dye solution into the dye solution refilling bucket, so that people can conveniently collect and process the dye solution which is not attached and dyed with the polyester yarns filament, thereby ensuring the environmental protection and saving printing and dyeing cost.

Owner:JIANGSU HUAYI GARMENT CO LTD

An atmosphere printing and dyeing device for cloth

ActiveCN110699884BUniform printing and dyeingReduce surface tensionTextile treatment machine partsTextile treatment by spraying/projectingCold airMechanical engineering

Owner:WUXI HUIZE GENERAL MACHINERY

Printing and eyeing machine capable of filtering printing and dyeing sewage

InactiveCN111020920AEasy height adjustment workImprove printing and dyeing work efficiencyTextile treatment machine arrangementsTextile treatment by spraying/projectingSewageMechanical engineering

The invention relates to a printing and dyeing machine capable of filtering printing and dyeing sewage. The printing and dyeing machine comprises a main body, a supporting seat and a telescopic rod, wherein a movable cover is mounted on the top of the main body and is in threaded connection with the main body; a movable plate is movably arranged in the middle of the top of the movable cover; a movable frame is connected to the bottom of the movable plate; and the movable frame is fixedly connected with the movable plate. The printing and dyeing machine has the beneficial effects that a communicating box, a storage tank, an air pipe, a filter screen and the main body are arranged, the communicating box and the storage tank are of a communicating structure, and when the inner side of a printing and dyeing bin conducts printing and dyeing work on garment fabric, generated printing and dyeing sewage flows into the storage tank along a connecting pipe in the middle of the bottom of the printing and dyeing bin, under the action of the communicating box forming the communicating structure with the storage groove, the printing and dyeing sewage flows into the communicating box, the gas pressure intensity between the printing and dyeing sewage and the inner sides of branch pipes is increased, the branch pipes made of elastic materials rise upwards, and the movable plate and the movableframe are lifted.

Owner:HANGZHOU JIANYI TECHNOLOGY CO LTD

Dyeing and finishing equipment and process for knitted antibacterial underwear fabric

PendingCN114717774AGuaranteed cleanlinessImprove stabilityMechanical cleaningPressure cleaningProcess engineeringDyeing

According to the dyeing and finishing equipment and process for the knitted antibacterial underwear fabric, a leveling and scrap-removing assembly can conduct leveling and scrap-removing treatment on the fabric before printing and dyeing of the fabric, the cleanliness of printing and dyeing pigment is guaranteed, the fabric can enter a printing and dyeing assembly in a flat posture, printing and dyeing of the fabric are uniform, and in addition, the dyeing and finishing efficiency of the fabric is improved. The drying and leveling assembly can conduct drying and secondary leveling treatment on the fabric, the size stability is improved, a dryer is arranged in the printing and dyeing assembly, and primary drying of the fabric can be achieved.

Owner:ZHEJIANG LANGSHA UNDERWEAR

Automatic dye spraying device for textile printing and dyeing

InactiveCN112323290AUniform printing and dyeingPrinting and dyeing fullyMechanical cleaningPressure cleaningTextile printerElectric machinery

The invention belongs to the technical field of automatic dye spraying, particularly relates to an automatic dye spraying device for textile printing and dyeing. Aiming to solve the problems that although an existing automatic dye spraying device is relatively high in fuel spraying efficiency and relatively low in dye consumption, the contact time of dye and cloth is relatively short by adopting aspraying mode, once the cloth is thick, the cloth cannot be fully printed and dyed, and consequently the printing and dyeing effect is poor, the following scheme is provided: the automatic dye spraying device comprises a workbench, wherein a printing and dyeing box is fixed to the outer wall of the top of the workbench through bolts, and a motor is fixed to the outer wall of the top of the printing and dyeing box through bolts. A printing and dyeing roller can be matched with a barrier strip on a circular plate to fully print and dye the cloth while rotating, the printing and dyeing roller can fully press the dye onto the cloth while rotating, the dye can be prevented from being accumulated together, and the cloth can be evenly printed and dyed.

Owner:范子玲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com