Dyeing equipment for textile fabric production

A dyeing equipment and technology for textile fabrics, applied in the field of textile fabric production, can solve the problems of slow production and processing, inconvenient use, uneven dyeing, etc., and achieve the effects of preventing opening, preventing waste, and uniform printing and dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

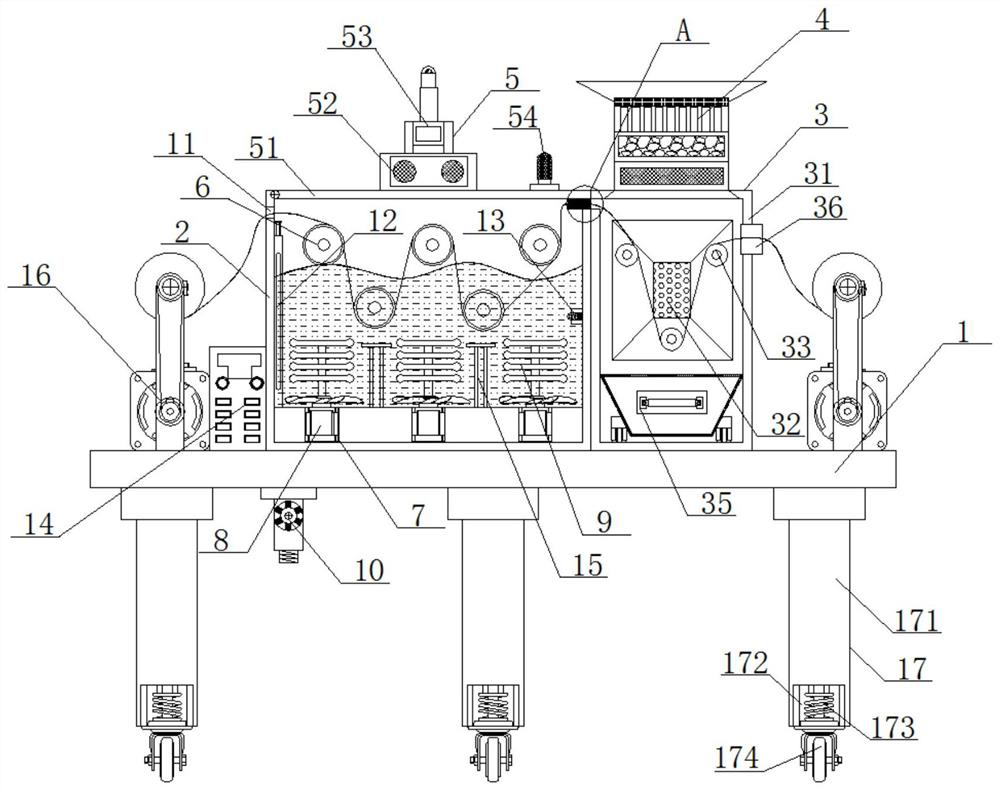

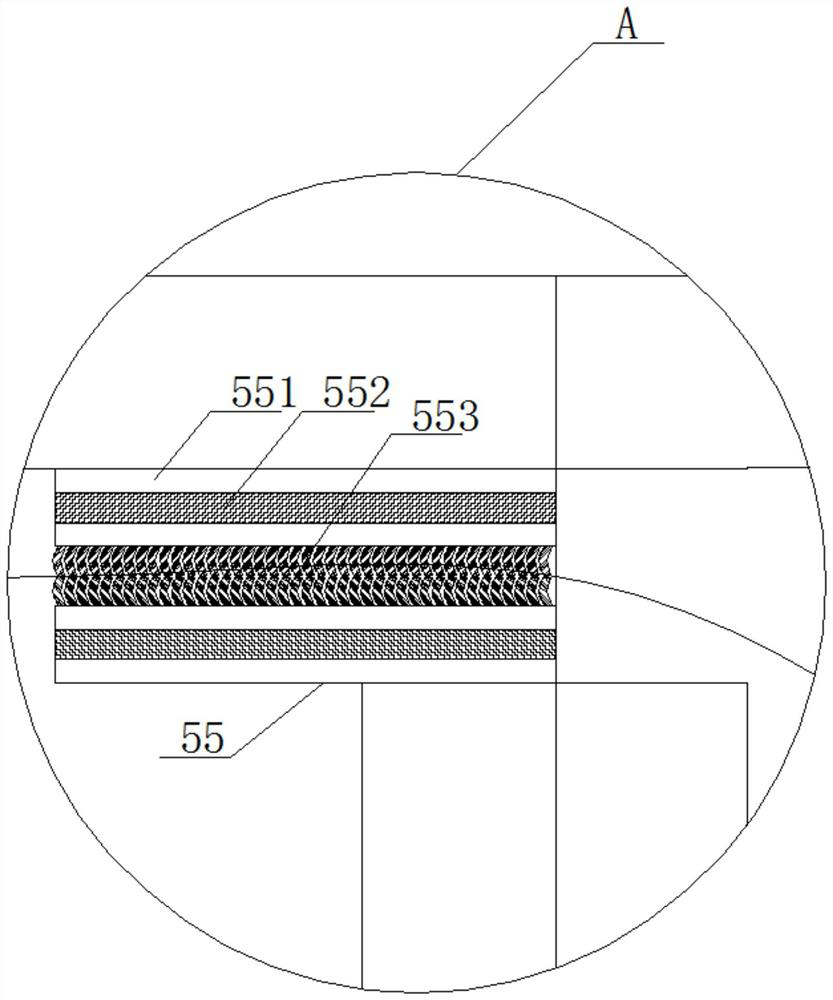

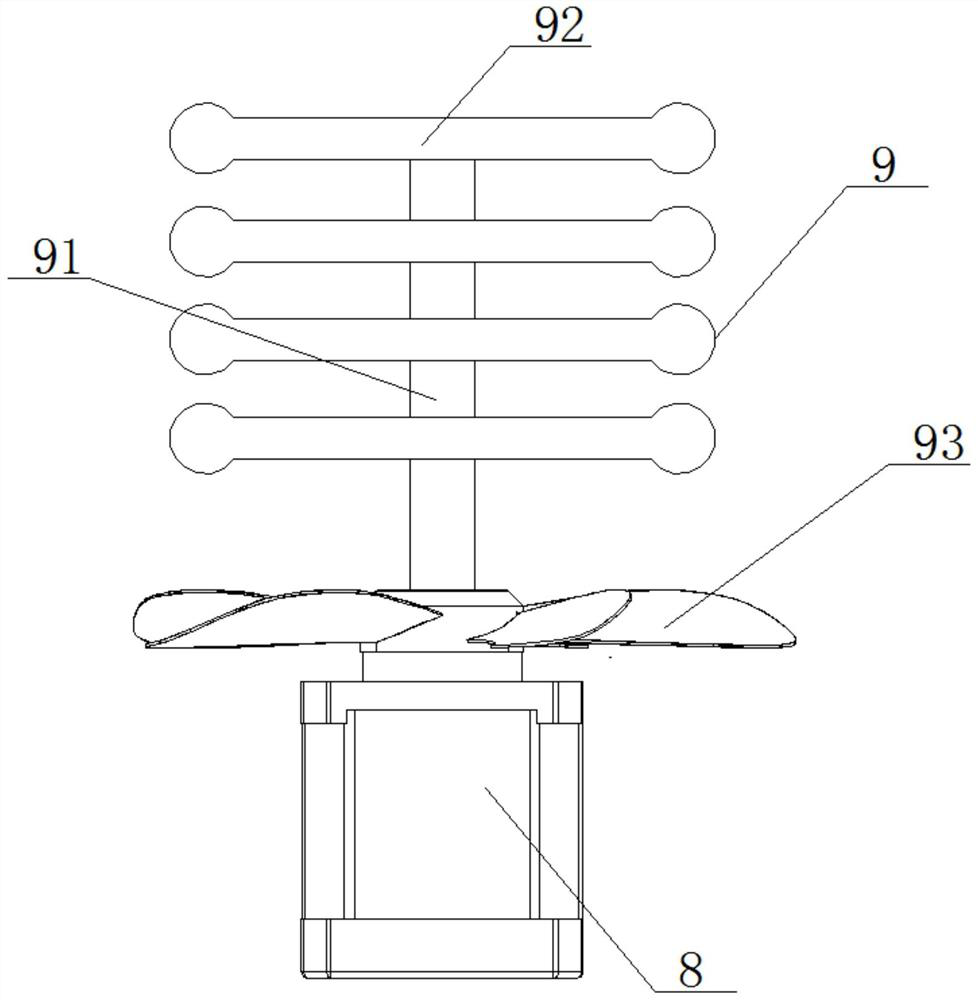

[0039] see Figure 1-8 , a kind of dyeing equipment for the production of textile fabrics, comprising an operation table 1, a printing and dyeing box 2 is fixedly connected in the middle of the top of the operation table 1, and a drying device 3 is fixedly installed on the right side of the printing and dyeing box 2, and the drying device 3 An air purification device 4 is fixedly installed on the top, and a box cover assembly 5 is fixedly installed on the top of the printing and dyeing box 2. Five sets of printing and dyeing rollers 6 are connected to the middle of the printing and dyeing box 2 and rotated at equal intervals, and the bottom of the printing and dyeing box 2 has openings There are three groups of grooves 7, the first drive motor 8 is fixedly installed inside the groove 7, the output end of the first drive motor 8 is fixedly equipped with a stirring frame 9, and the left side of the printing and dyeing box 2 is provided with a cloth feeding port 11, a liquid leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com