Gas atomization pulverizing device capable of reducing satellite powder

A pulverizing device and gas atomization technology, which is applied in the field of gas atomization pulverizing device, can solve the problems of low yield of fine powder, large number of powder cohesion and agglomeration satellite powder, etc., so as to avoid cohesion and agglomeration and improve the running trajectory. , the effect of reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

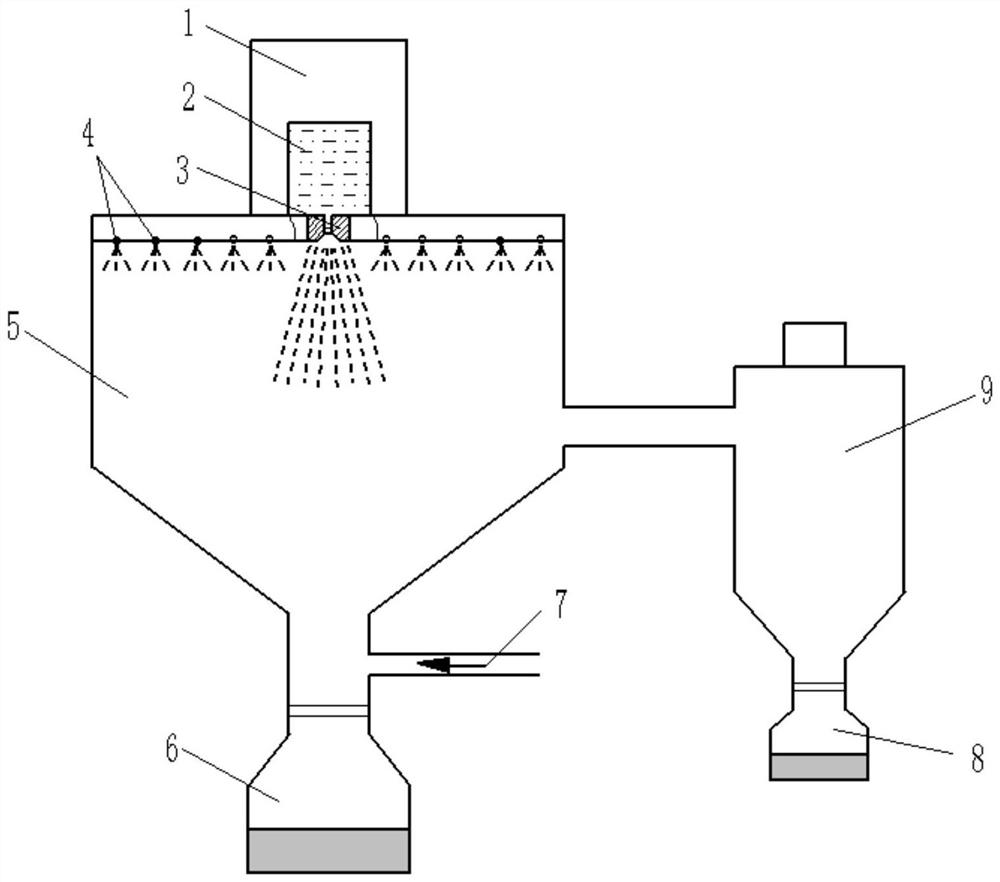

[0020] A gas atomization powder making device for reducing satellite powder, the device includes an atomization chamber body 5, a smelting chamber 1 is arranged above the atomization chamber body 5, and a smelting crucible 2 for melting metal is arranged in the smelting chamber 1, and the smelting crucible The first nozzle is installed below the 2, and the first nozzle communicates with the top of the atomization chamber body 5, and the outlet 3 of the smelting chamber 1 corresponds to the first nozzle; The bottom of the atomization chamber body 5 is connected to the powder collection tank 6, and the side wall of the atomization chamber body 5 is connected with a second nozzle 7, the second nozzle 7 is located above the connection between the atomization chamber body 5 and the powder collection tank 6, and the atomization The side wall of the chamber body 5 is also communicated with the cyclone classification system 9, and the bottom of the cyclone classification system 9 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com