Rod-shaped piezoelectric material mounting equipment

A piezoelectric material, technology for installing equipment, applied in the field of piezoelectric materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

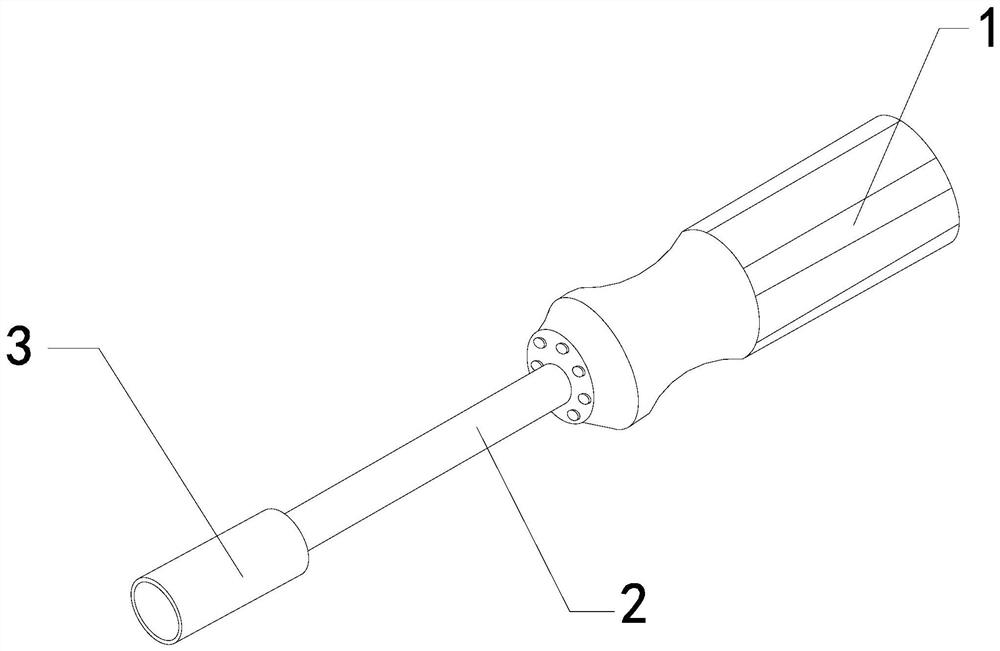

[0026] For example figure 1 -example Figure 5 Shown:

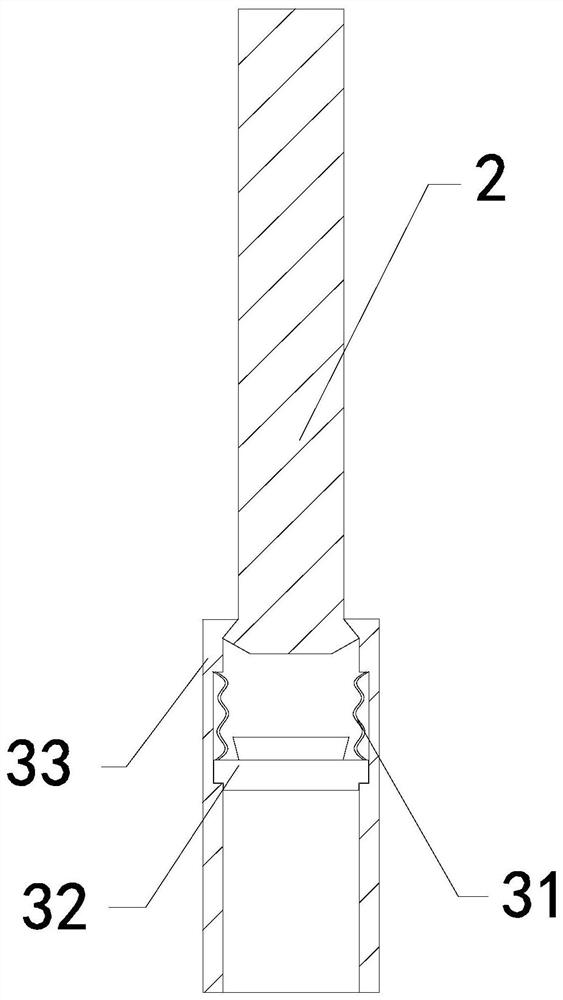

[0027] The invention provides a rod-shaped piezoelectric material installation device, the structure of which includes a handle 1, a linkage rod 2, and a press-in head 3. The linkage rod 2 is embedded in the inner position of the handle 1. The press-in head 3 and the linkage rod The bottom of 2 is welded; the press-in head 3 includes a booster bar 31, a pressure plate 32, and an outer frame 33, and the booster bar 31 is installed between the upper end of the pressure plate 32 and the inner wall of the outer frame 33, The pressure receiving plate 32 is movably engaged with the inside of the outer frame 33 .

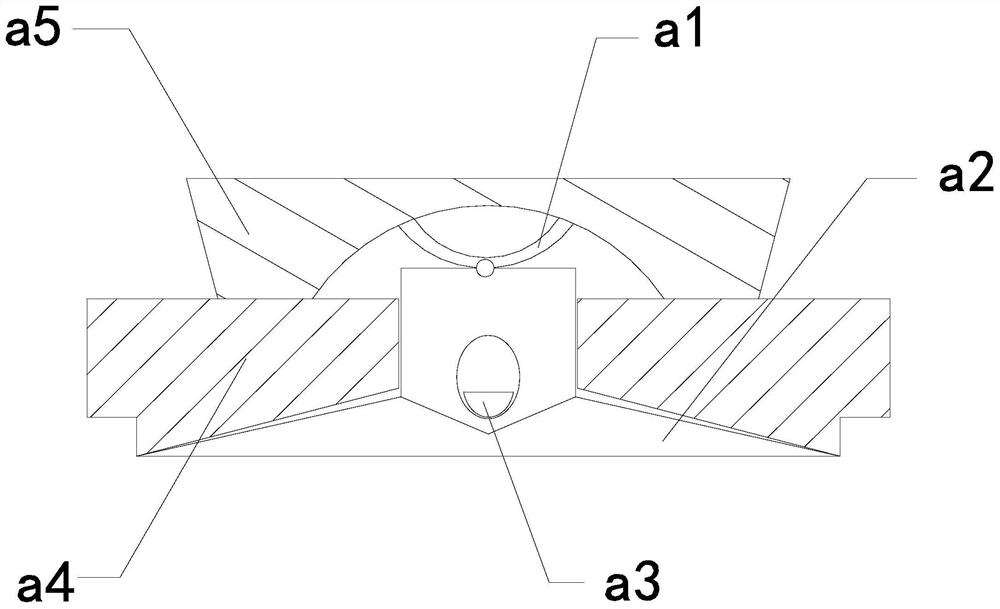

[0028] Wherein, the pressure receiving plate 32 includes an elastic piece a1, a lower stretching plate a2, a vibrating block a3, a receiving plate a4, and a top plate a5. Between the upper ends, the lower extension plate a2 is in sliding fit with the interior of the receiving plate a4, the vibrating mass a3 is matc...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the linkage rod 2 includes an connecting plate c1, a sliding rod c2, a connection bar c3, and a push-down block c4. The inner position of the board c1, the push-down block c4 is embedded and fixed at the bottom position of the sliding rod c2, and the two connecting strips c3 are arranged symmetrically on the left and right sides of the sliding rod c2. The electric strip c3 can lead out the electric charge conducted on the sliding rod c2.

[0036]Wherein, the push-down block c4 includes a position fixing plate c41, a side sliding plate c42, a sliding aid mechanism c43, and a pull-back bar c44. The side sliding plate c42 is movably engaged with the bottom of the positioning fixing plate c41. Embedded in the inner position of the side slide c42, the pull-back strip c44 is installed between the side slide c42 and the inner wall of the position fixing plate c41, the side slide c42 is provided with two, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com