Carbon-coated current collector coated with three-dimensional graphene powder and preparation method of carbon-coated current collector

A technology of graphene powder and current collectors, which is applied in the direction of electrode carriers/current collectors, electrical components, battery electrodes, etc., can solve the problems of weak bonding strength between the coating and the substrate, poor conductivity, and high price. Achieving the effects of being conducive to wide popularization and application, simple preparation method and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

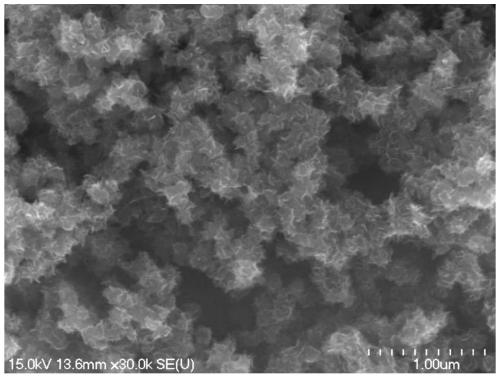

[0034] (1) Preparation of three-dimensional graphene dispersion: select sodium deoxycholate as a dispersant, dissolve a certain amount of sodium deoxycholate in a certain amount of water, then add a certain amount of three-dimensional graphene powder, and stir at a speed of 1200r / min 2h, stir well and evenly to prepare a three-dimensional graphene dispersion. During this process, the concentrations of three-dimensional graphene powder and sodium deoxycholate in the dispersion were 8% and 1%, respectively. Then inject the above-mentioned three-dimensional graphene dispersion liquid into a sand mill for sand milling, the speed of the sand mill is 1500r / min, and the sand milling time is 2h. Subsequently, the dispersion liquid was sieved to remove large particles, and the mesh number of the sieve was 800 mesh. The three-dimensional graphene powder is uniformly dispersed and the particle size is small by sand milling, and the particle size D of the slurry is detected by a laser pa...

Embodiment 2

[0041] In this embodiment, the difference is that there is no sanding treatment step with a sand mill, and other processing steps and parameters are the same as in Embodiment 1.

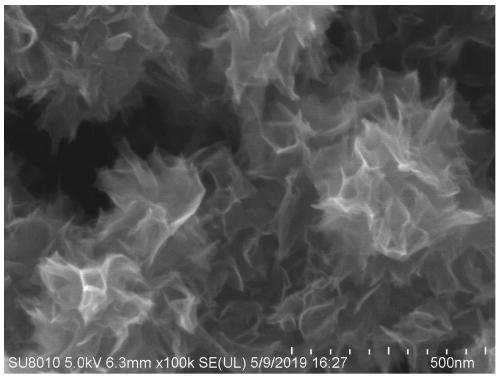

[0042] The test shows that the prepared slurry particle size D of the present embodiment 50 Around 500nm, thicker than Example 1. Figure 5 The SEM photo of the carbon-coated aluminum foil prepared under the above conditions, it can be seen that in this example, due to no pre-dispersion by sanding, the particles of the slurry are relatively large, the distribution of the carbon-coated layer is uneven, and there is a large foil leakage phenomenon , which shows that the sand milling procedure is helpful for the dispersion of three-dimensional graphene powder, effectively reduces the particle size, increases the uniformity of dispersion, and improves the fluidity and film-forming properties of the slurry, thereby effectively avoiding the adhesion between the binder and the three-dimensional graphene pow...

Embodiment 3

[0044] In this embodiment, the difference is that the content of polyacrylic acid in the three-dimensional graphene powder slurry is increased to 4%, and other conditions are the same as in embodiment 1.

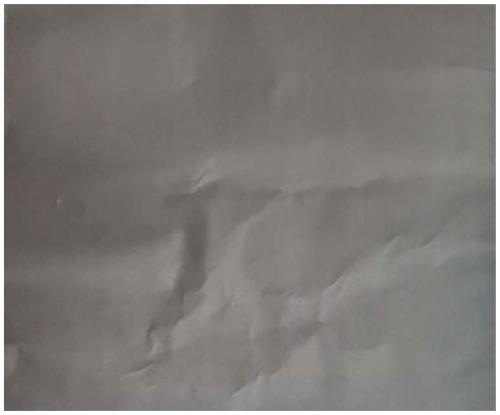

[0045] Figure 6 It is the SEM photo of the carbon-coated aluminum foil prepared in this example. Observations show that the three-dimensional graphene powder is seriously wrapped by the binder, and the exposure of the graphene powder is reduced. The areal density of the coating increases significantly, resulting in increased weight and thicker coatings. Tests show that, compared with Example 1, the bonding strength between the active material coating and the carbon-coated current collector in the final positive electrode sheet is not significantly improved. This is because the unique structure of three-dimensional graphene powder can effectively improve the bonding strength, and increasing the amount of binder does not contribute much to the improvement of bonding strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com