Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Avoid lost time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

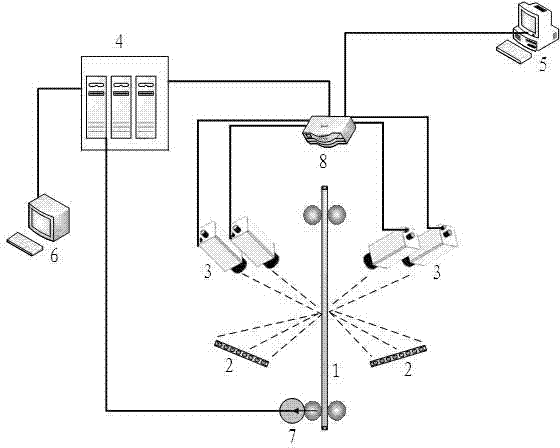

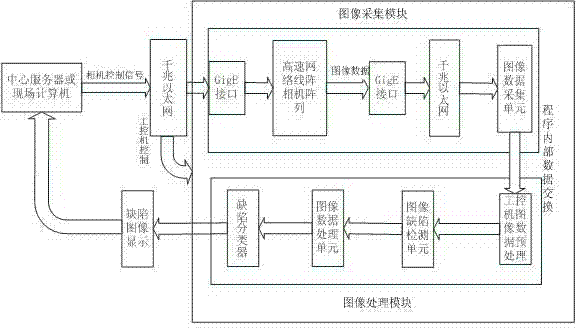

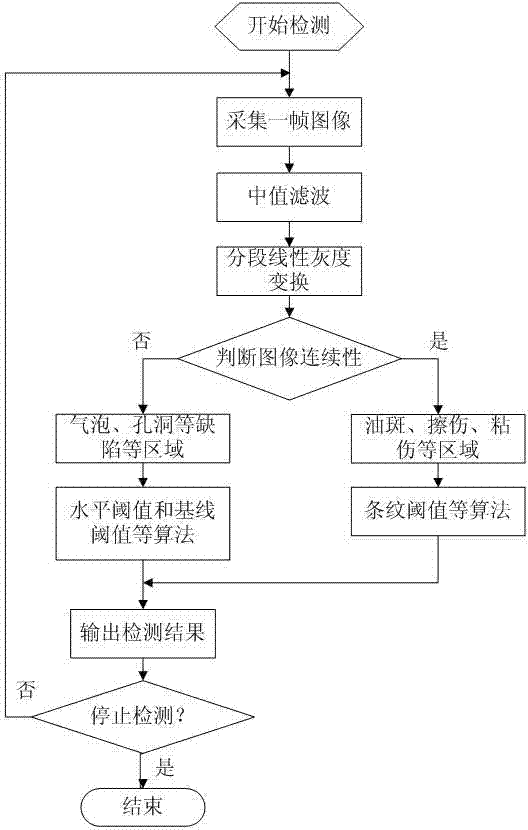

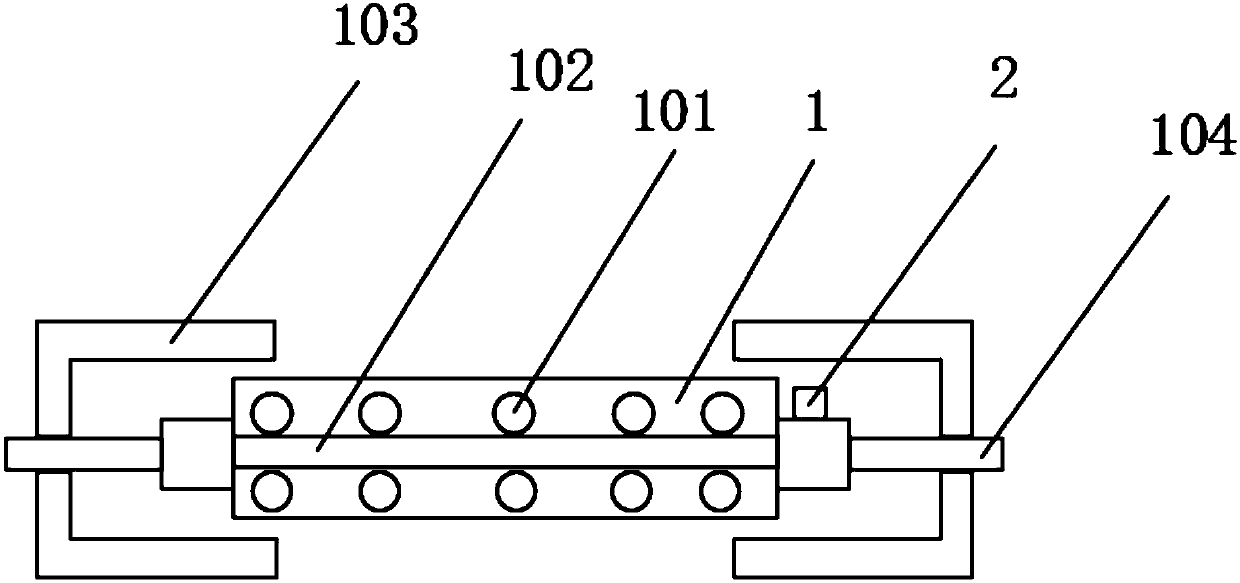

Online detection system for surface defects of coldly-rolled aluminum plate and detection method of online detection system

InactiveCN103399016AQuick collectionFast transferOptically investigating flaws/contaminationCcd cameraLight-emitting diode

The invention relates to the technical field of high-speed detection for surface defects of an aluminum plate and particularly discloses an online detection system for surface defects of a coldly-rolled aluminum plate and a detection method of the online detection system. The online detection system for the surface defects of the coldly-rolled aluminum plate comprises an aluminum plate production line and is characterized in that LED (Light Emitting Diode) light sources and high-speed camera arrays which are arrayed transversely in parallel are mounted on the upper and lower sides of the aluminum plate production line; each high-speed camera array is composed of a plurality of paths of linear array CCD (Charge Coupled Device) cameras; each path of the camera is connected with a respective corresponding industrial personal computer processor through a GigE interface; an Ethernet interface control unit in each industrial personal computer processor is connected to a switchboard through a kilomega network and is connected to a central server or a field computer by an Ethernet switchboard. According to the online detection system provided by the invention, rapid acquisition of defect images is realized by connecting the linear array CCD cameras by the GigE interfaces and the Ethernet; the industrial personal computer processors are used for realizing rapid detection and positioning for the defects of the aluminum plate so as to effectively prevent data from being blocked.

Owner:QILU UNIV OF TECH

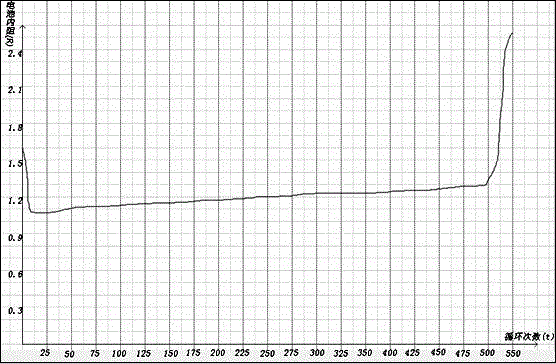

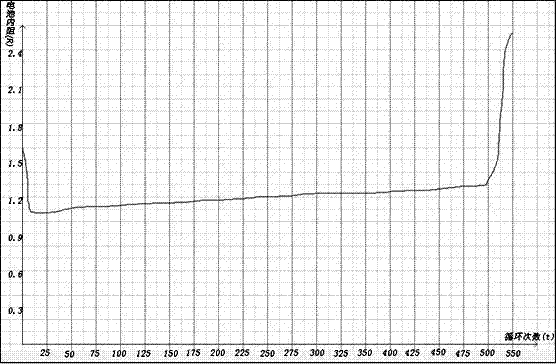

Method for rapidly detecting remaining use times of battery

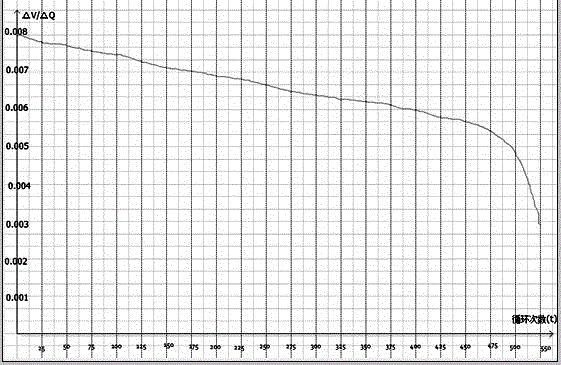

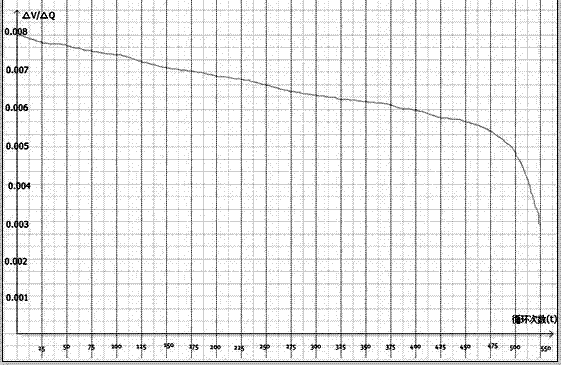

The invention discloses a method for rapidly detecting remaining use times of batteries, and relates to the technical field of batteries. The method is based on the relation between a battery internal resistance and cycle times, can deduct the cycle times corresponding to the battery internal resistance according to the measured internal resistance of the battery, and comprises the steps of: A, measuring internal resistances of batteries of the same model with different cycle times at the same indoor temperature, and drawing a curve chart of relation between the internal resistances and cycle times of the batteries; B, dividing the curve chart into a plurality of stages and measuring the internal resistances of the adopted batteries of the same model; C, judging the corresponding stage in which the batteries are positioned according to the internal resistances measured in the previous step; D, and rapidly detecting the cycle times of the batteries and the remaining cycle times according to the judged stage in which the batteries are positioned. The method for rapidly detecting remaining use times of the batteries has high reliability, and is especially suitable for detecting batteries in mass production or during the process of using.

Owner:JIANGSU BEIXIN NEW ENERGY TECH CO LTD

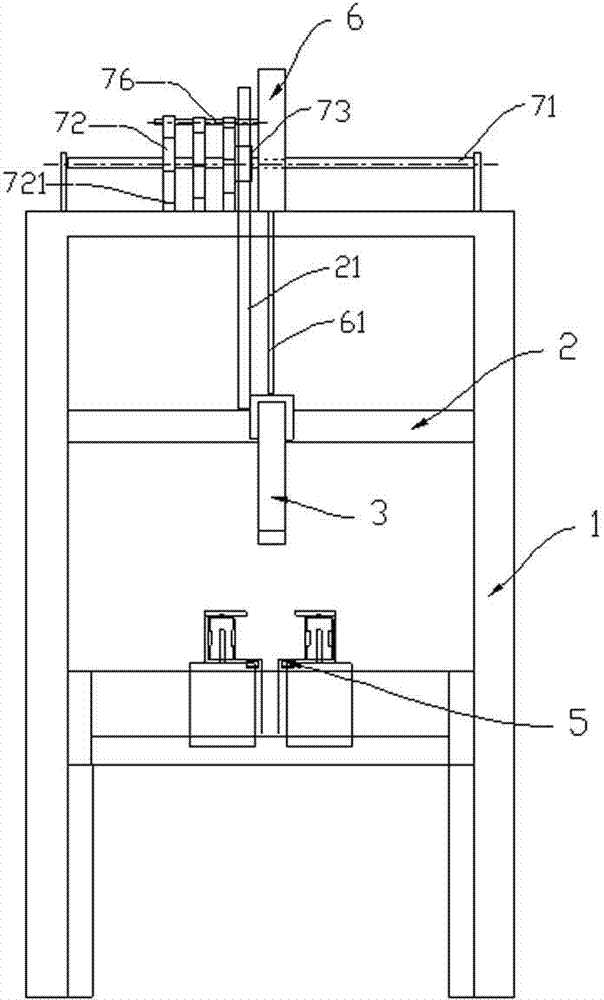

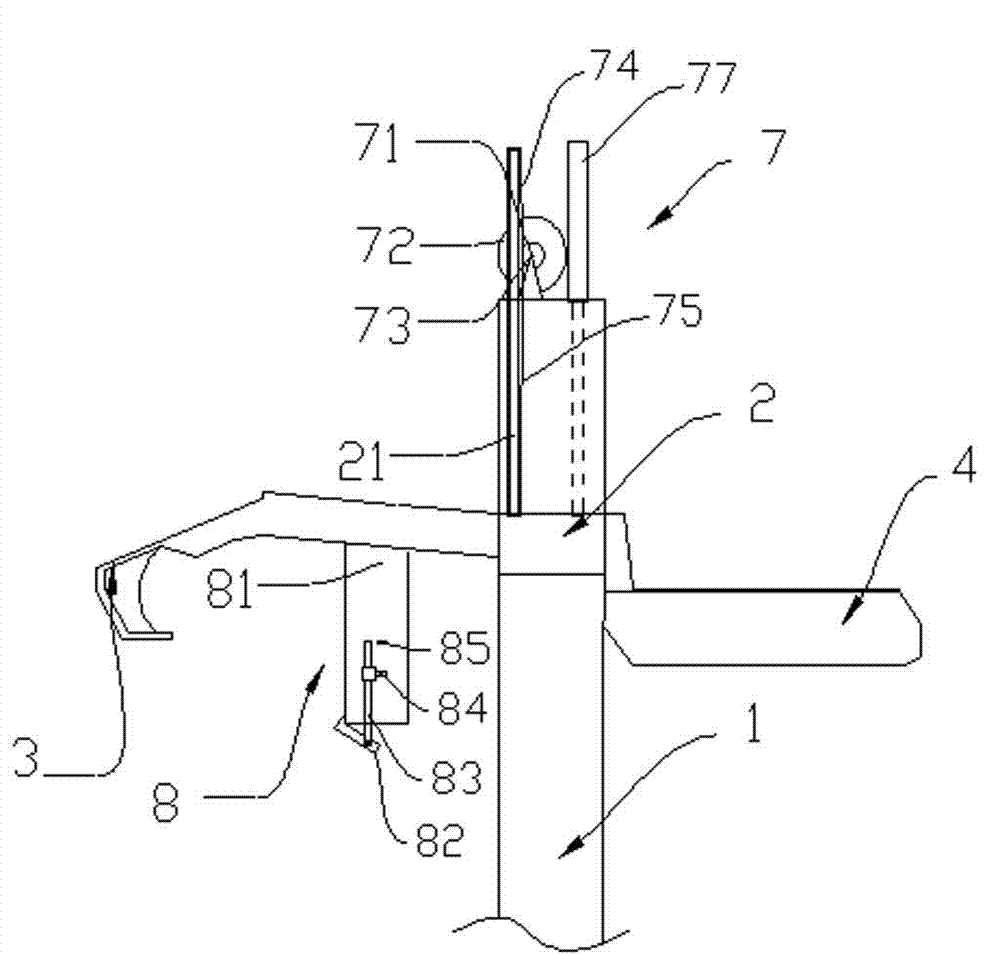

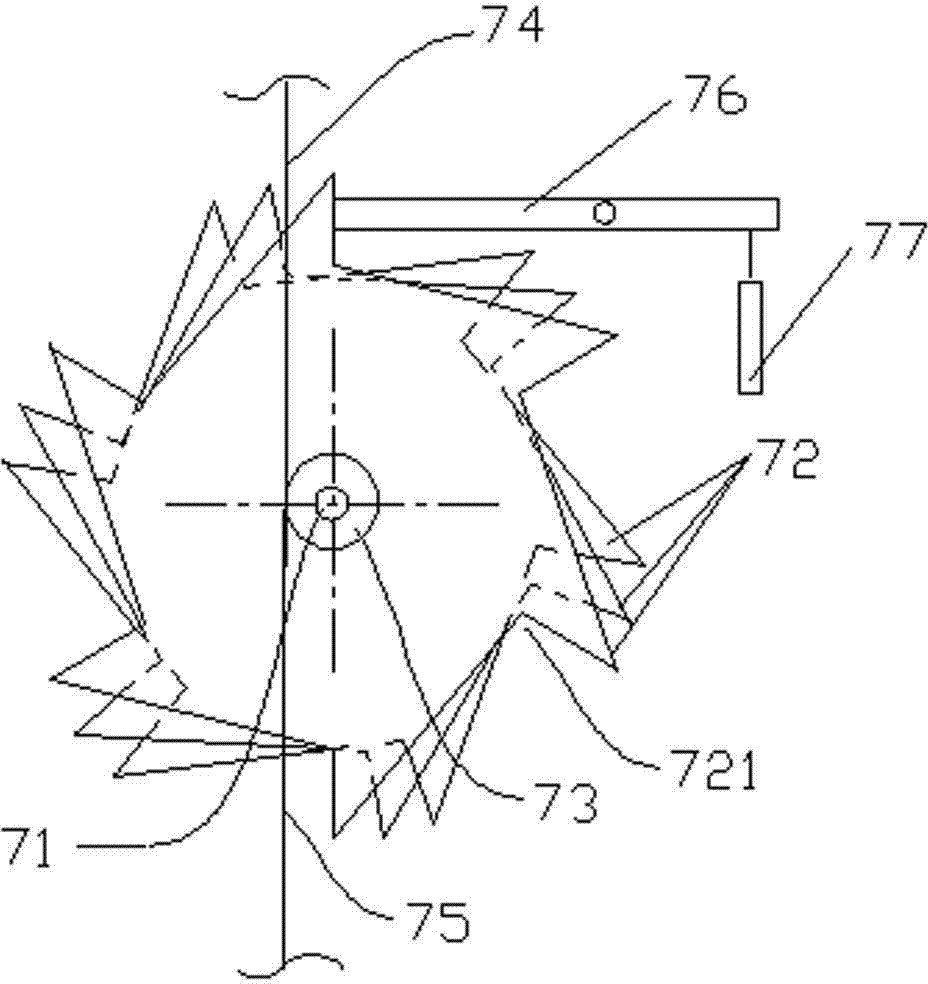

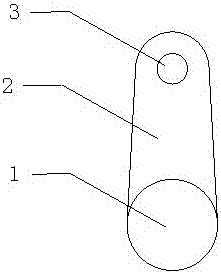

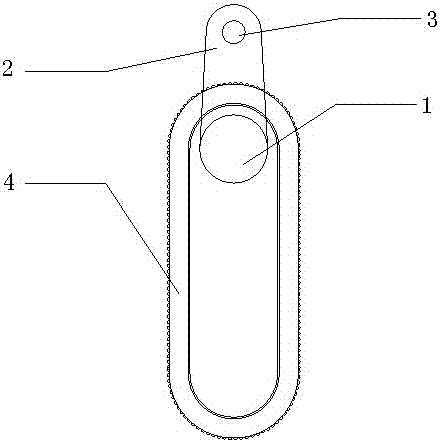

Box sealing machine

The invention relates to a box sealing machine. The box sealing machine comprises a machine base, a machine head arranged on the machine base, a cover folding mechanism, an upper machine core and a conveying rail arranged on the machine base, wherein the cover folding mechanism and the upper machine core are arranged on the machine head, and the machine head can move up and down relative to the machine base so as to adjust the distance between the cover folding mechanism and the conveying rail as well as the distance between the upper machine core and the conveying rail. The box sealing machine further comprises a first air cylinder and a cut-off mechanism, wherein the first air cylinder is installed above the machine head, and a piston rod of the first air cylinder is fixedly connected with the machine head; the cut-off mechanism comprises a rotary shaft rotationally arranged on the machine base, a ratchet wheel, a belt wheel, two belts and a pawl, the ratchet wheel and the belt wheel are fixedly installed on the rotary shaft, the two belts are wound on the belt wheel in the opposite directions, the pawl is rotationally arranged on the machine base, a plurality of notches are formed in the edge of the ratchet wheel and arranged in the circumferential direction of the ratchet wheel, one end of a chain is connected with the machine base through a coiled spring, and the other end of the chain is fixedly connected with the machine head. The box sealing machine is low in cost and safe to use.

Owner:SU ZHOU XUENUO MECHANICAL PROD

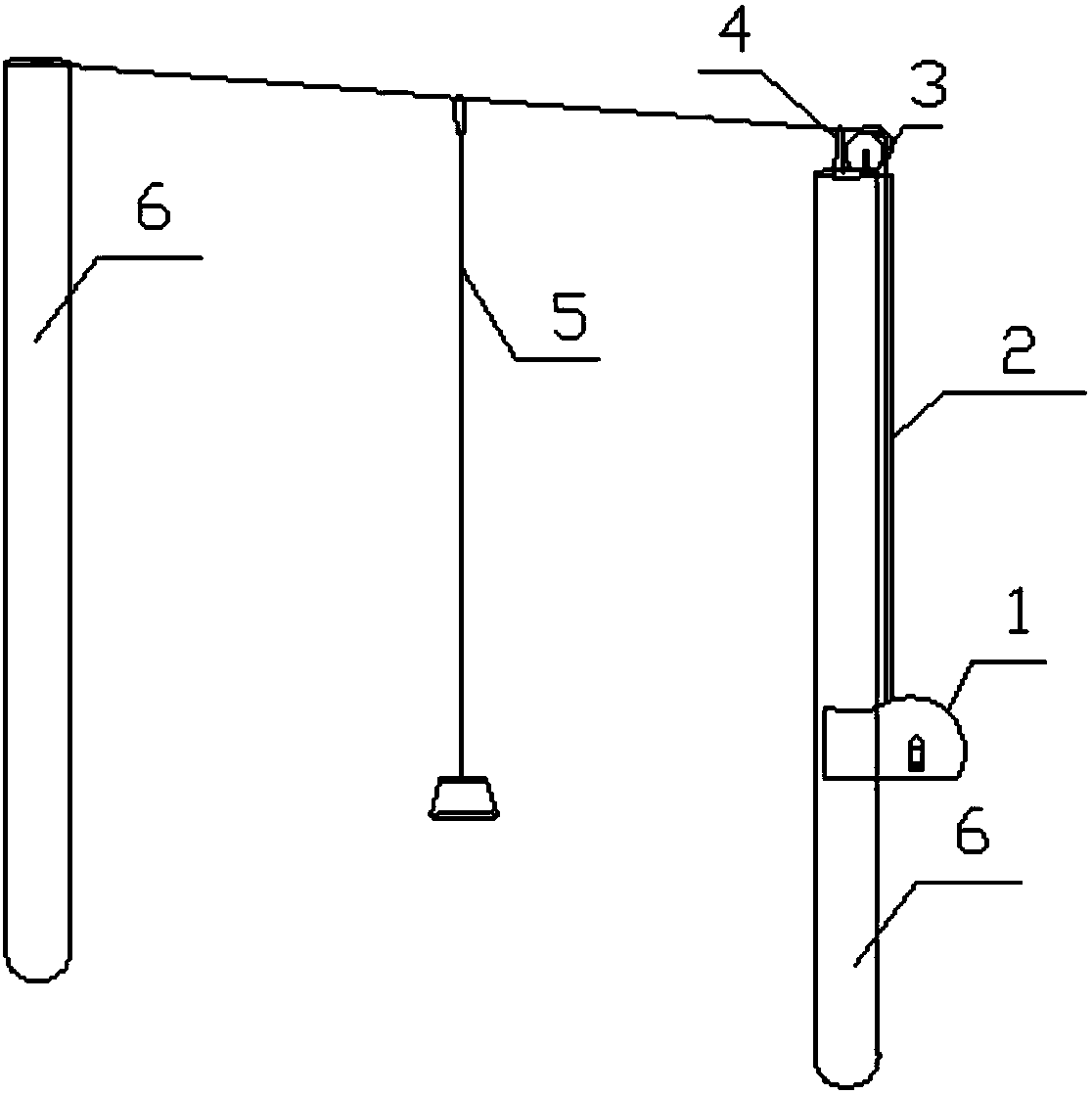

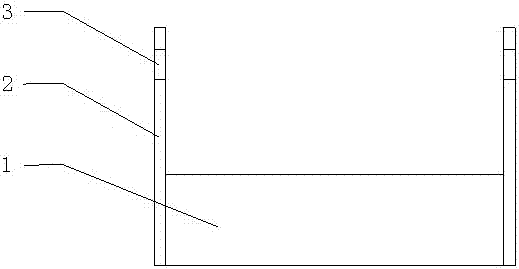

Large angle belt special lifting device

The invention discloses a large angle belt special lifting device. The large angle belt special lifting device comprises a hanging bearing unit and a compacting unit; the hanging bearing unit comprises a fixed panel (5), a movable panel (9), wing edge supporting pipes (11), and a main supporting pipe (12); the compacting unit comprises a cross beam (6), and top rods (7); the cross beam (6) is a channel steel, and the two ends of the channel steel are provided with holes and pin shaft holes; the cross beam (6) is arranged on the fixed panel (5) and above the movable panel (9) via the holes. The large angle belt special lifting device is simple in lifting device structure, is convenient to produce, is excellent in lifting security, and is capable of protecting large angle skirt belts from damage caused by tightening of steel wire rope lifting devices, and avoiding work delay, time delay, and material waste.

Owner:MCC5 GROUP CORP SHANGHAI

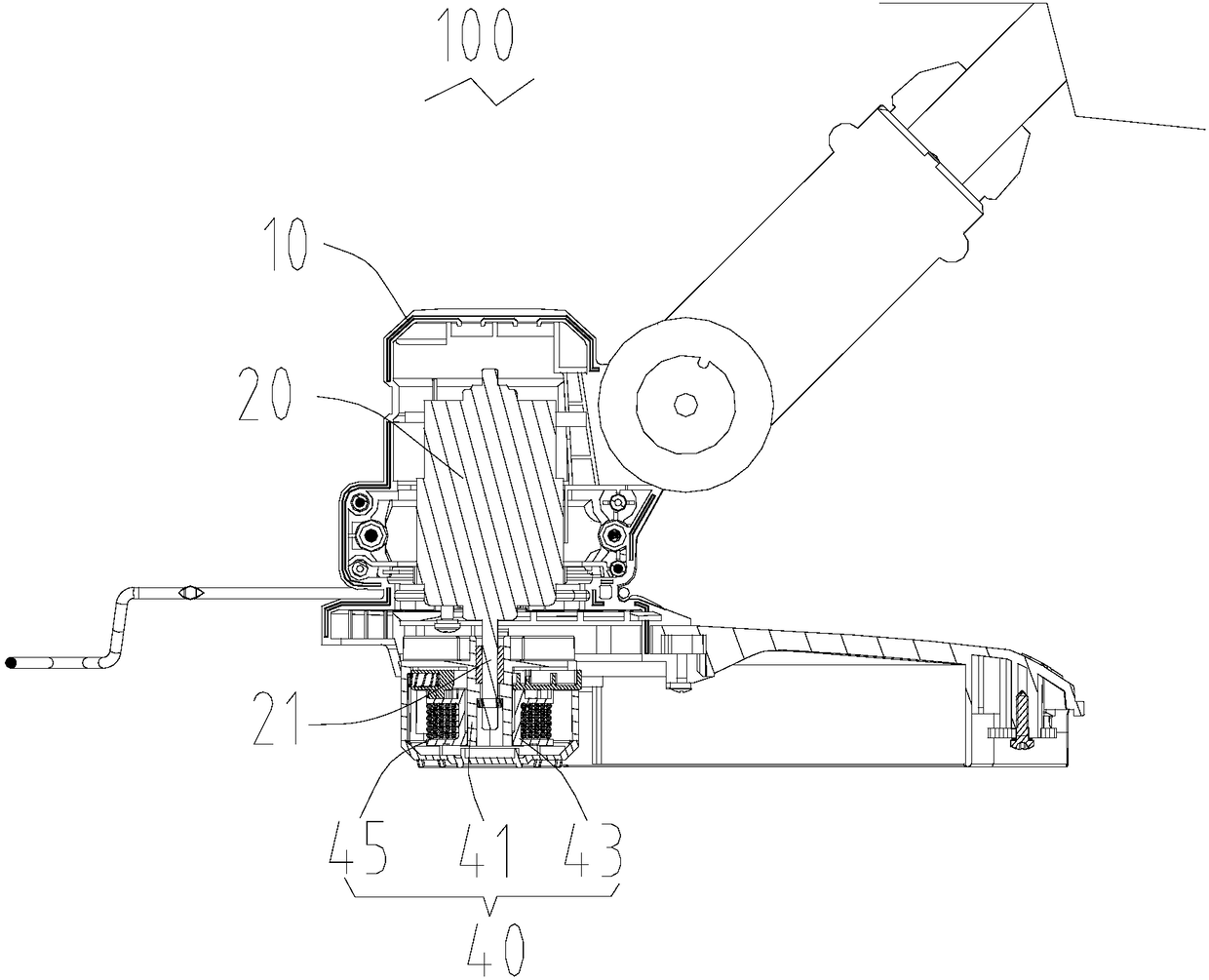

Grass trimmer

PendingCN108617226AAvoid lost timeMowersProgramme control in sequence/logic controllersElectricityEngineering

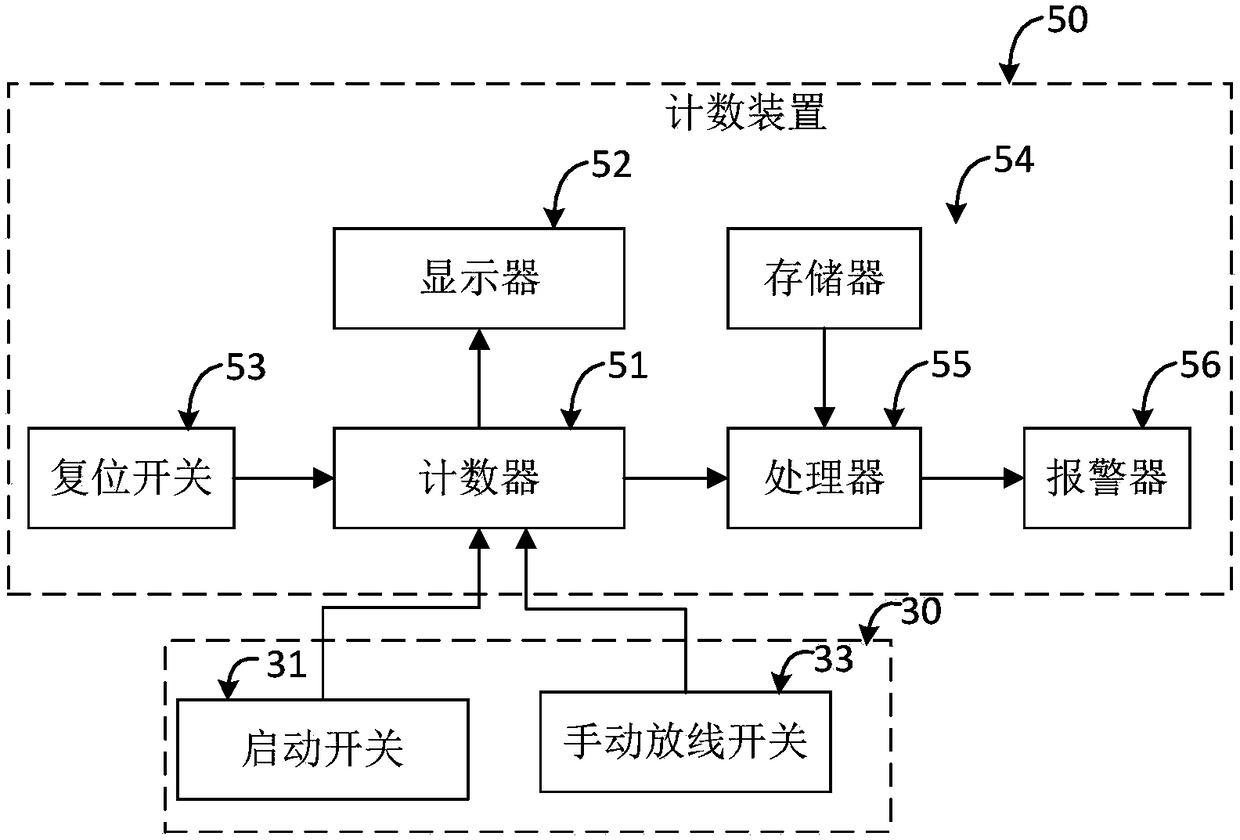

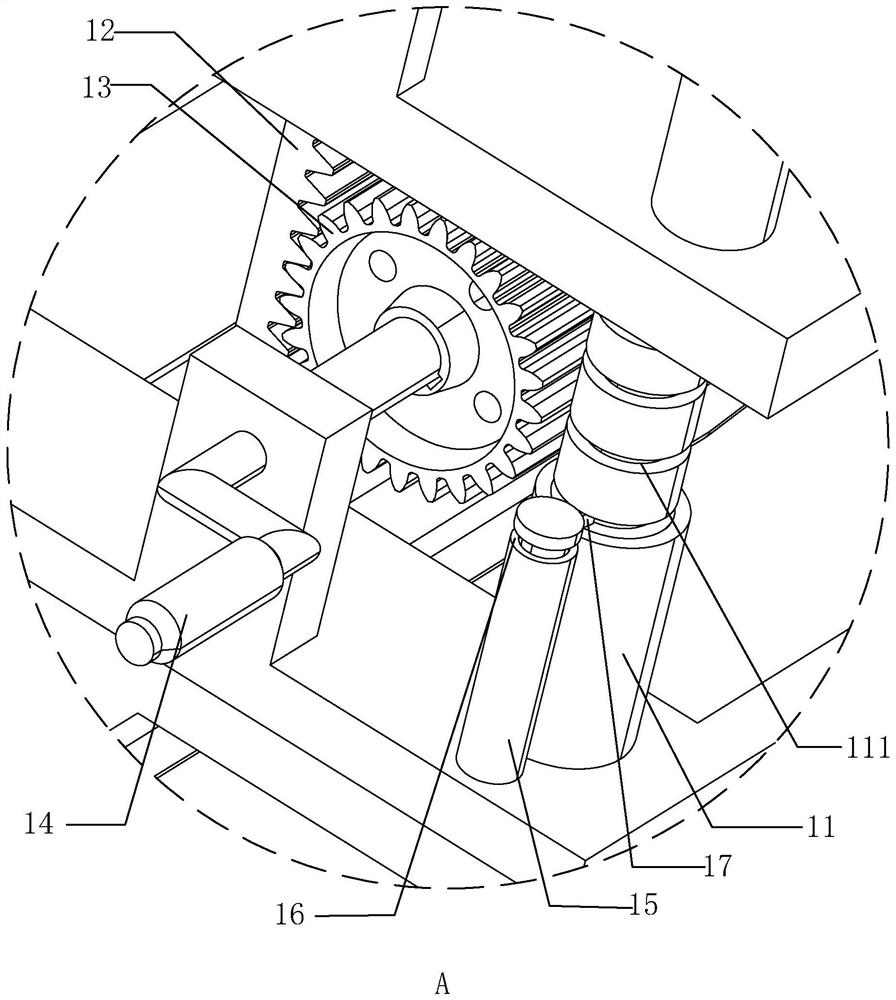

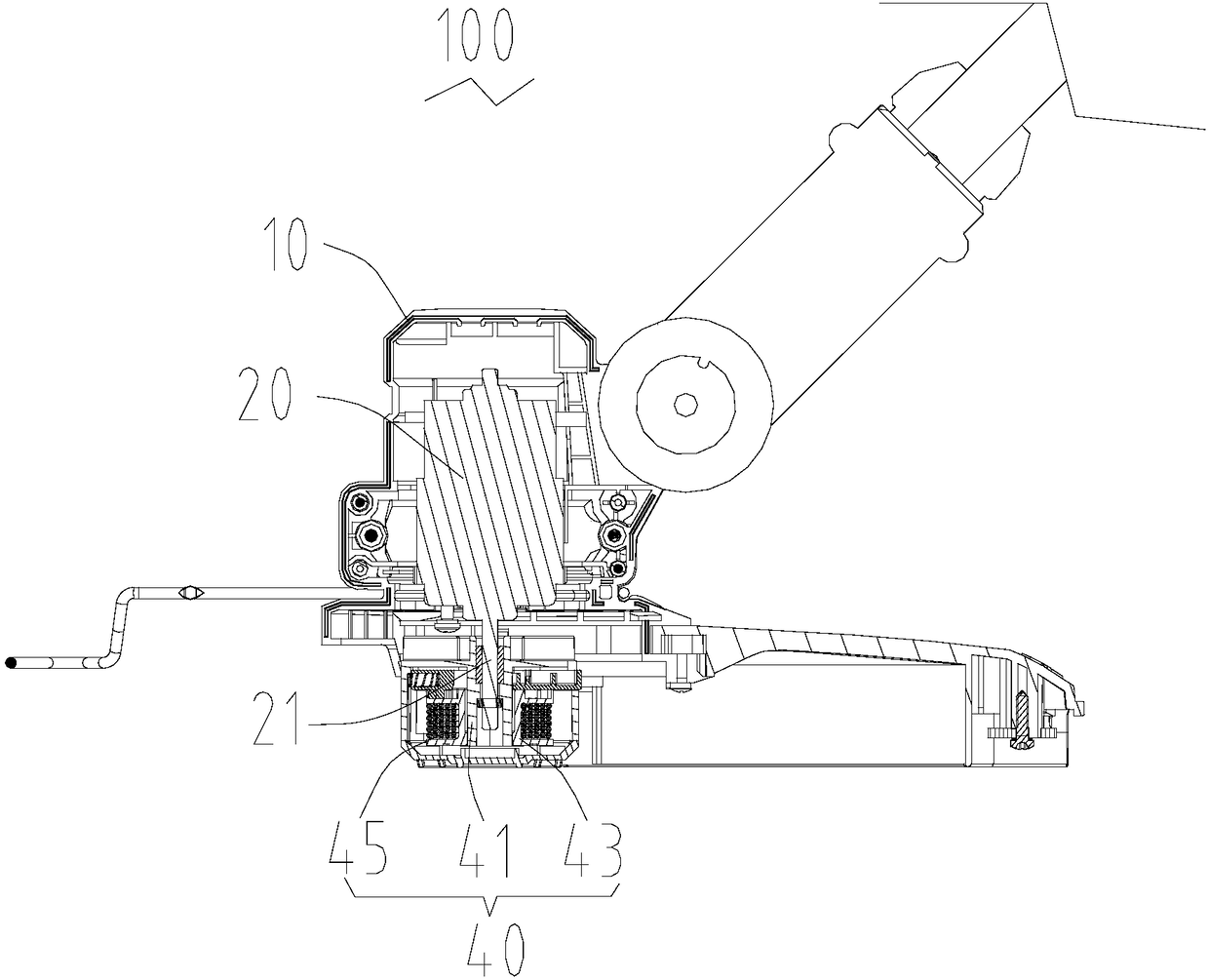

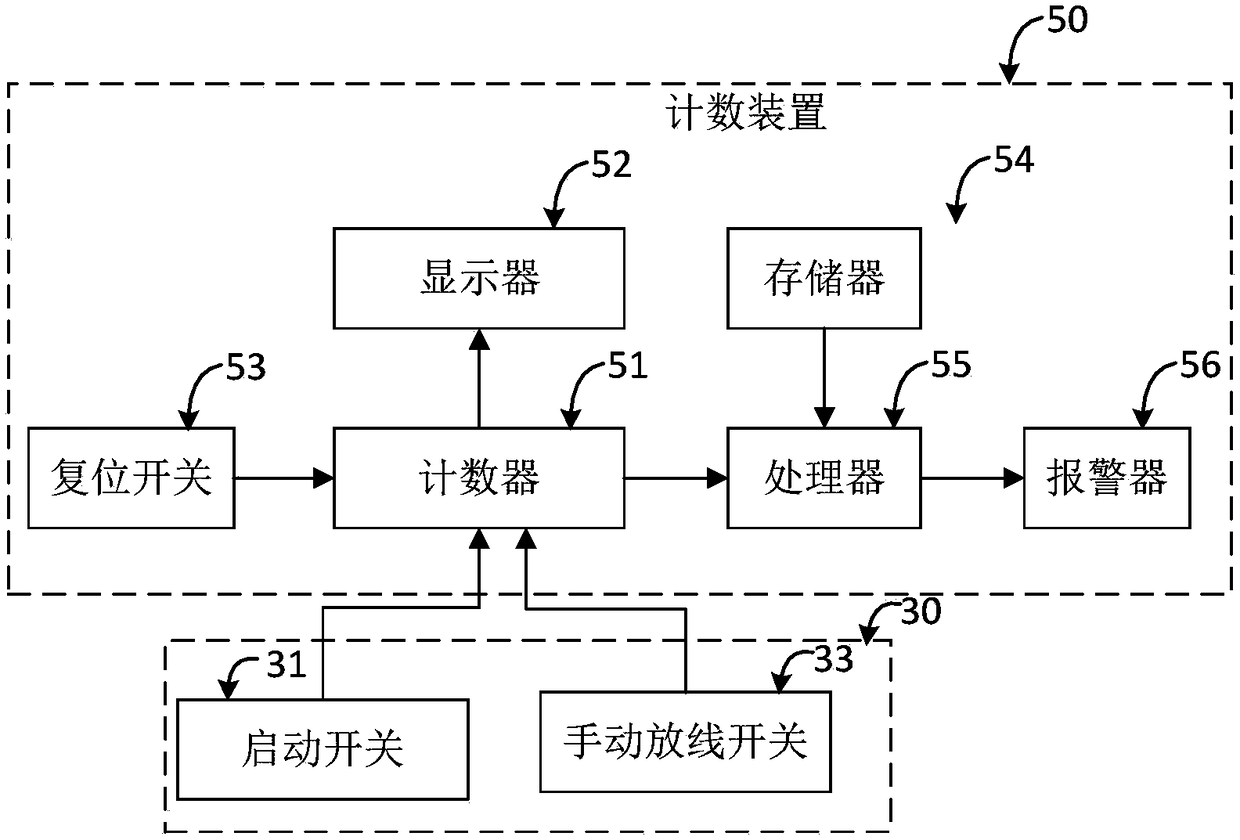

The invention discloses a grass trimmer. The grass trimmer comprises a shell body, a motor, a control switch, a line box and a counting device; the motor is arranged in the shell body and provided with an output shaft; the control switch is electrically connected with the motor and generates a line unwinding signal according to user operation; the interior of the line box is fixedly provided withpositioning columns, line reels movably sleeving the positioning columns, and a grass trimming rope, the output shaft is in drive connection with the line box through the positioning columns, one endof the grass trimming rope is wound on the line reels, and the other end of the grass trimming rope passes out of the line box and has a rated length; and the counting device is used to count used times and / or remaining times of the grass trimming rope according to the line unwinding signal. The grass trimmer disclosed by the invention is provided with the counting device used for counting the used times and / or the remaining times of the grass trimming rope, so that when workable times of the grass trimming rope in the current grass trimmer is less, a user is reminded to replace the grass trimming rope in time to avoid that time and work are delayed because the grass trimming rope is used up.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

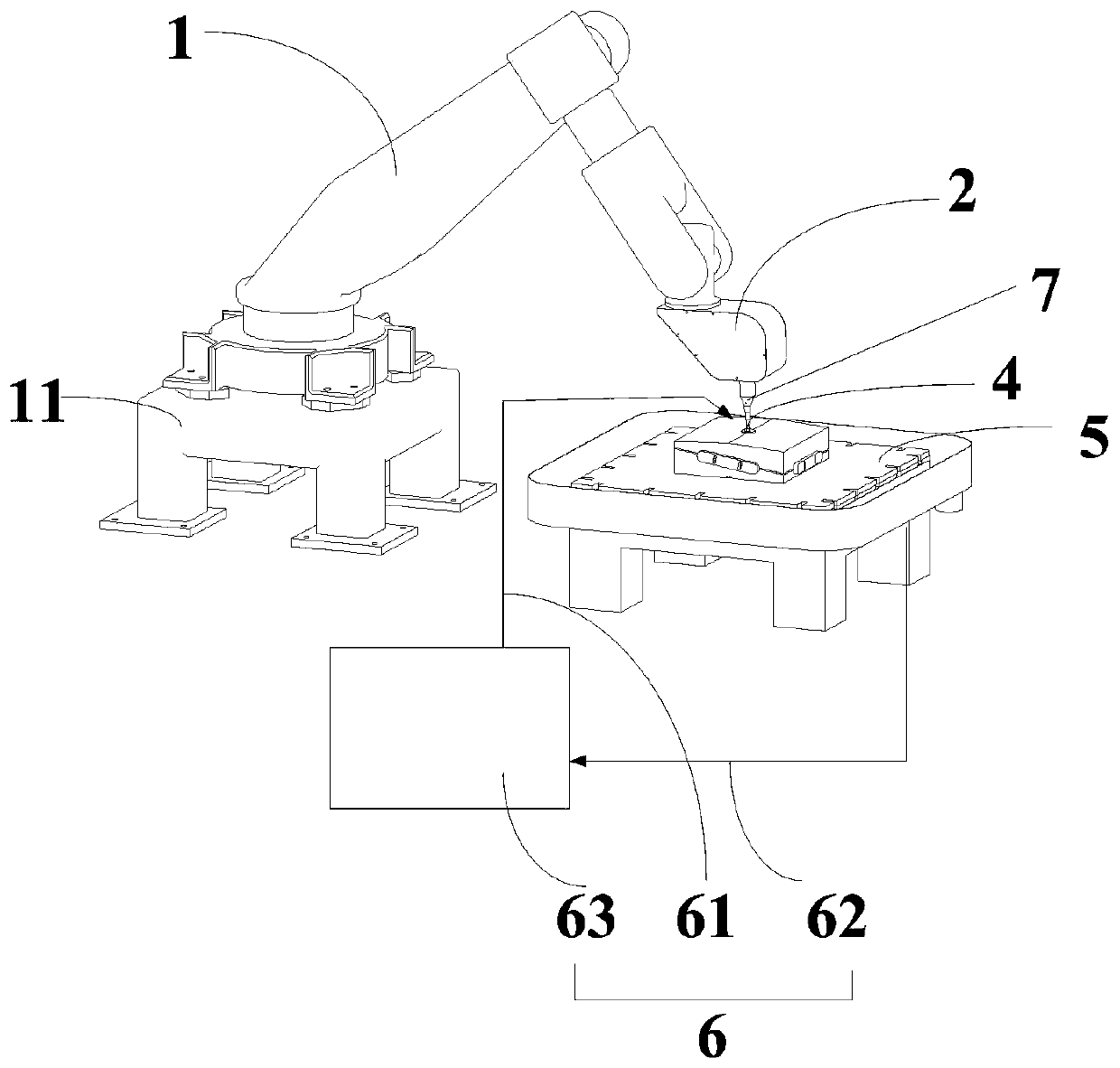

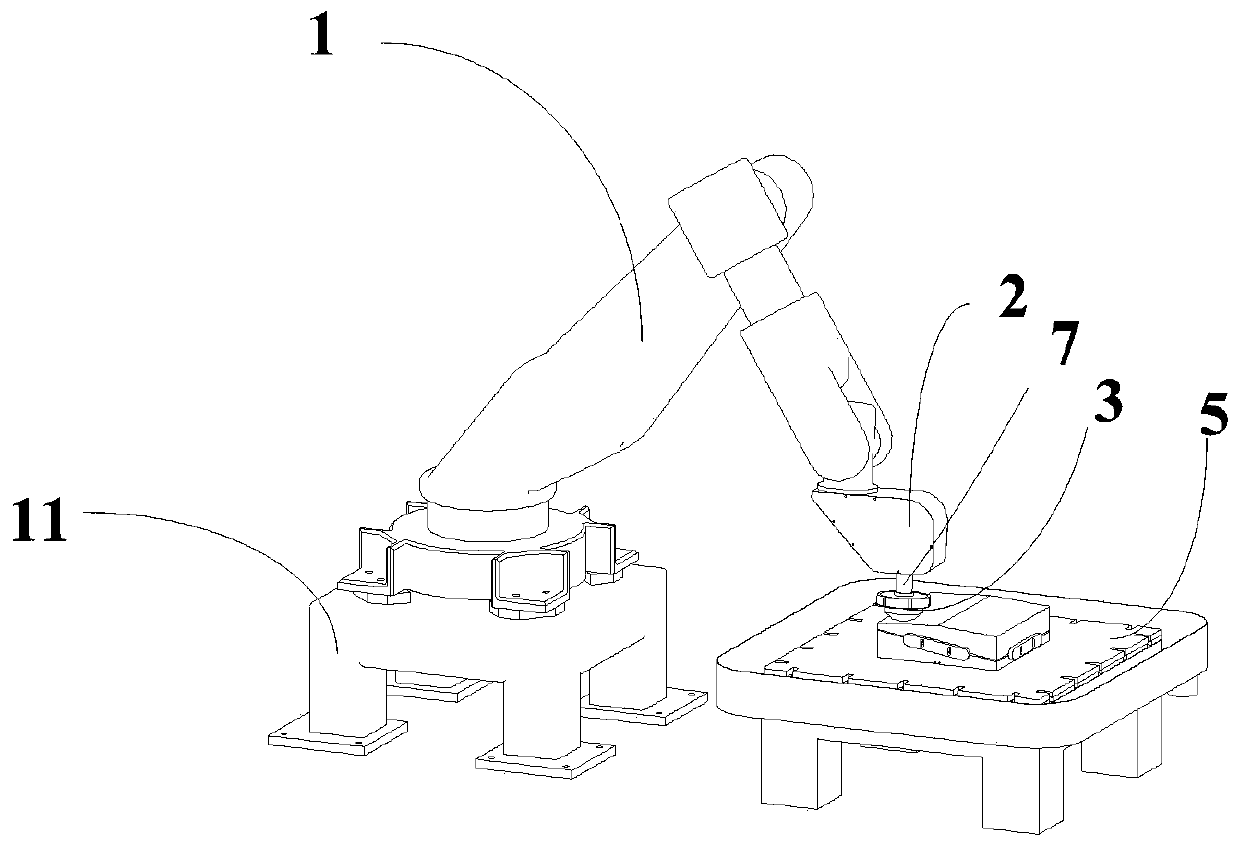

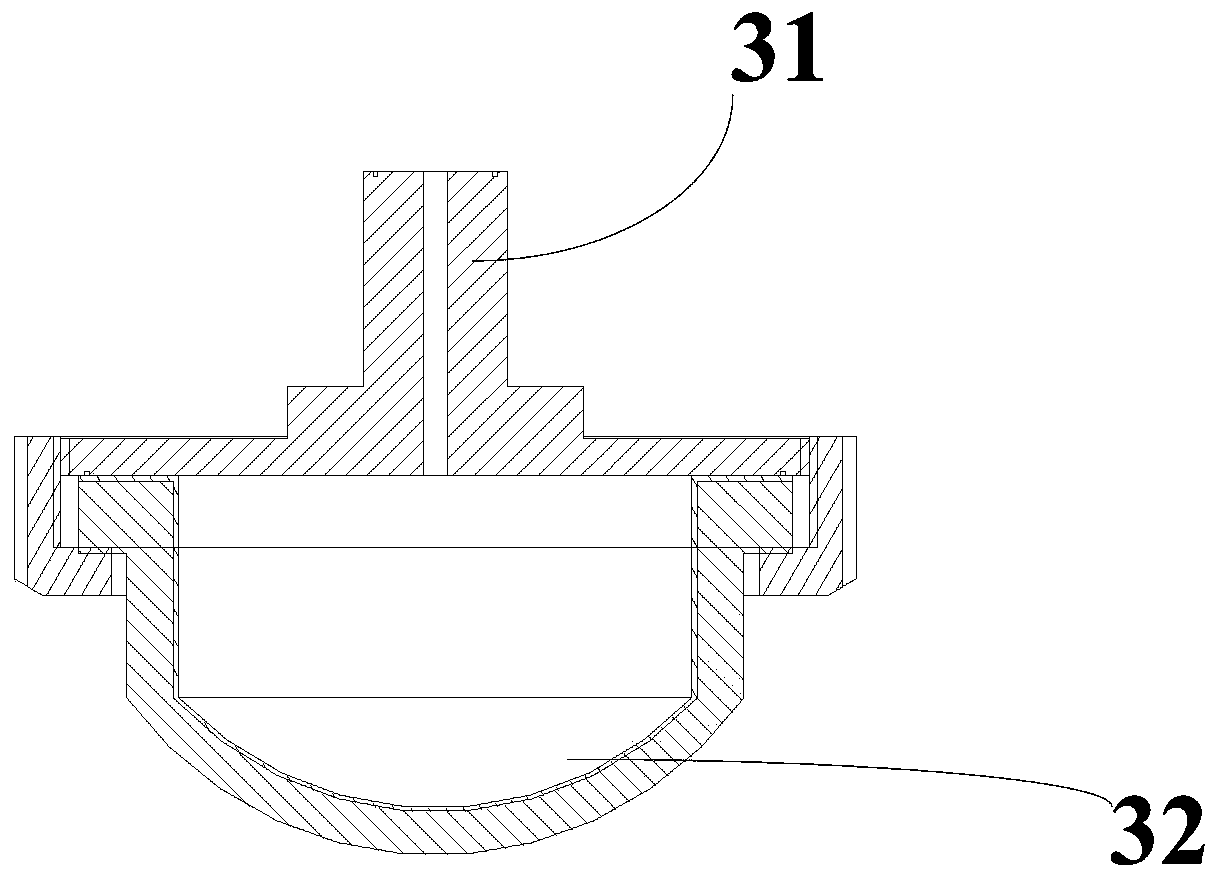

Composite polishing machine tool and machining method thereof

PendingCN110238758AReduce the amount of configurationAvoid lost timeOptical surface grinding machinesManipulatorNumerical controlEngineering

The invention relates to a composite polishing machine tool and a machining method thereof. The composite polishing machine tool comprises a six-joint robot. The bottom of the six-joint robot rotates on a base. A drive device is connected to the operation end of the six-joint robot. A polishing operation mechanism comprises an airbag polishing mechanism and a numerical control polishing mechanism. The connecting end of the airbag polishing mechanism or the numerical control polishing mechanism is detachably connected with the drive device through a hydraulic expanding cover. A polishing table is arranged within the operation range of the operation end of the six-joint robot. An optical element is fixed to the top of the polishing table. The polishing operation mechanism is connected to the outer contour of the optical element in an abutting-against manner. A polishing liquid circular filtering device is arranged close to the polishing table and used for providing clean polishing liquid for the optical element continuously in the polishing process. The polishing technology procedure is preset and / or arranged in a control terminal online. The six-joint robot, the drive device and the polishing liquid circular filtering device are electrically connected with the control terminal. Universality of the machine tool is achieved, and the machining precision and the machining effect of the optical element are improved.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

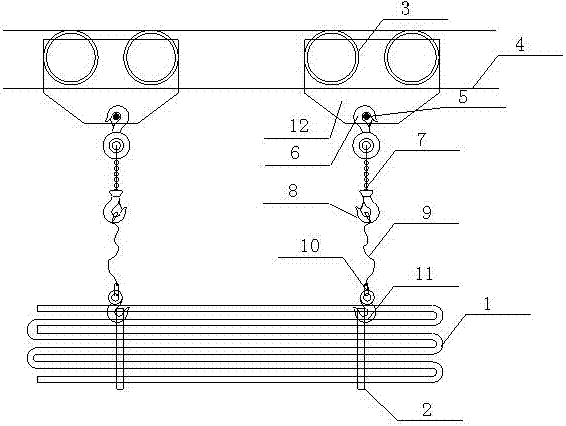

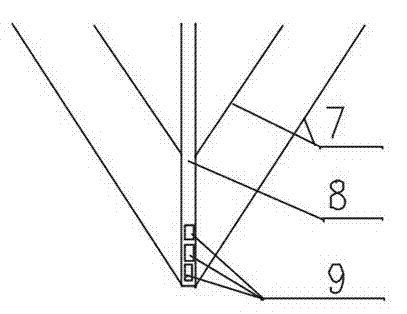

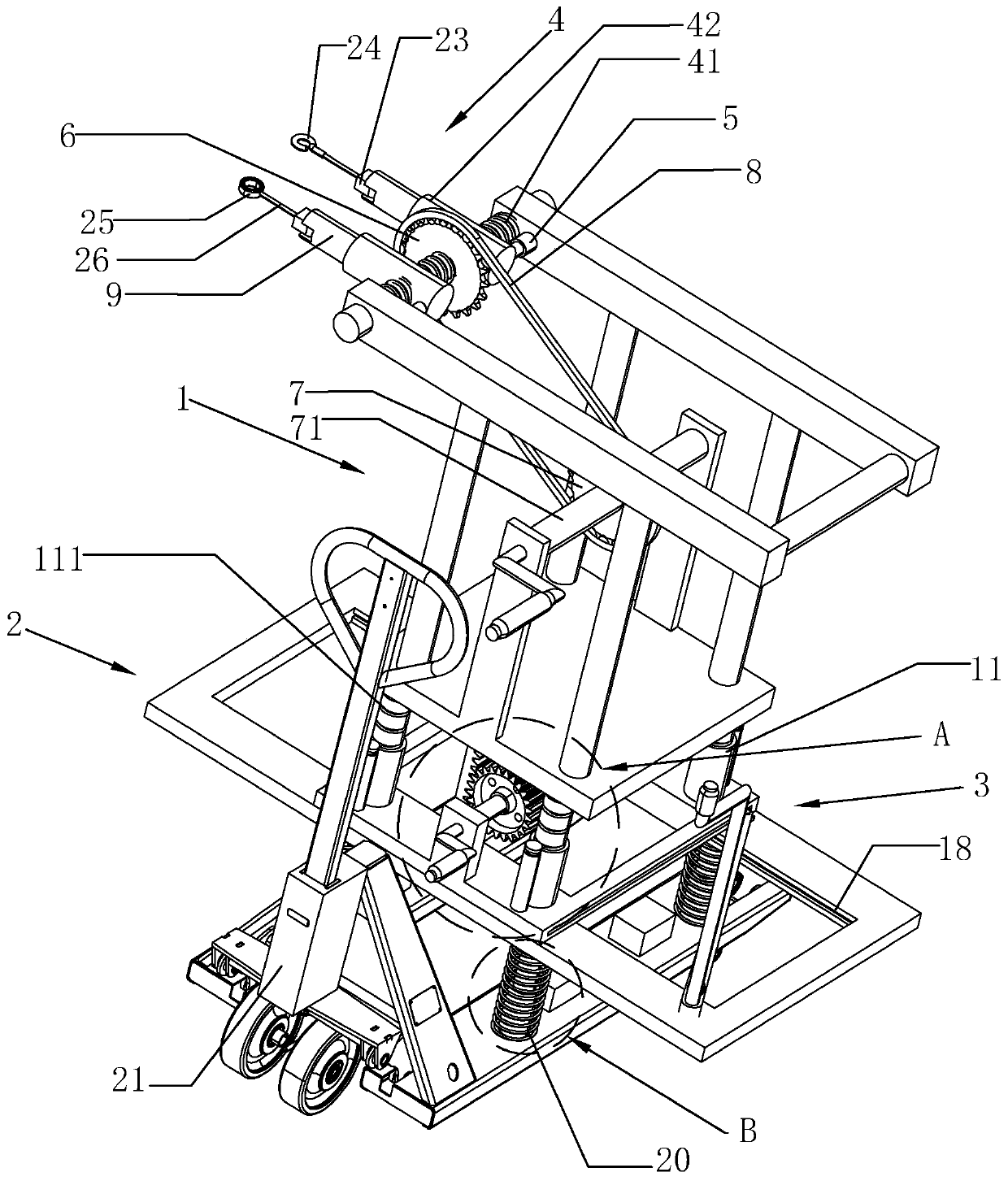

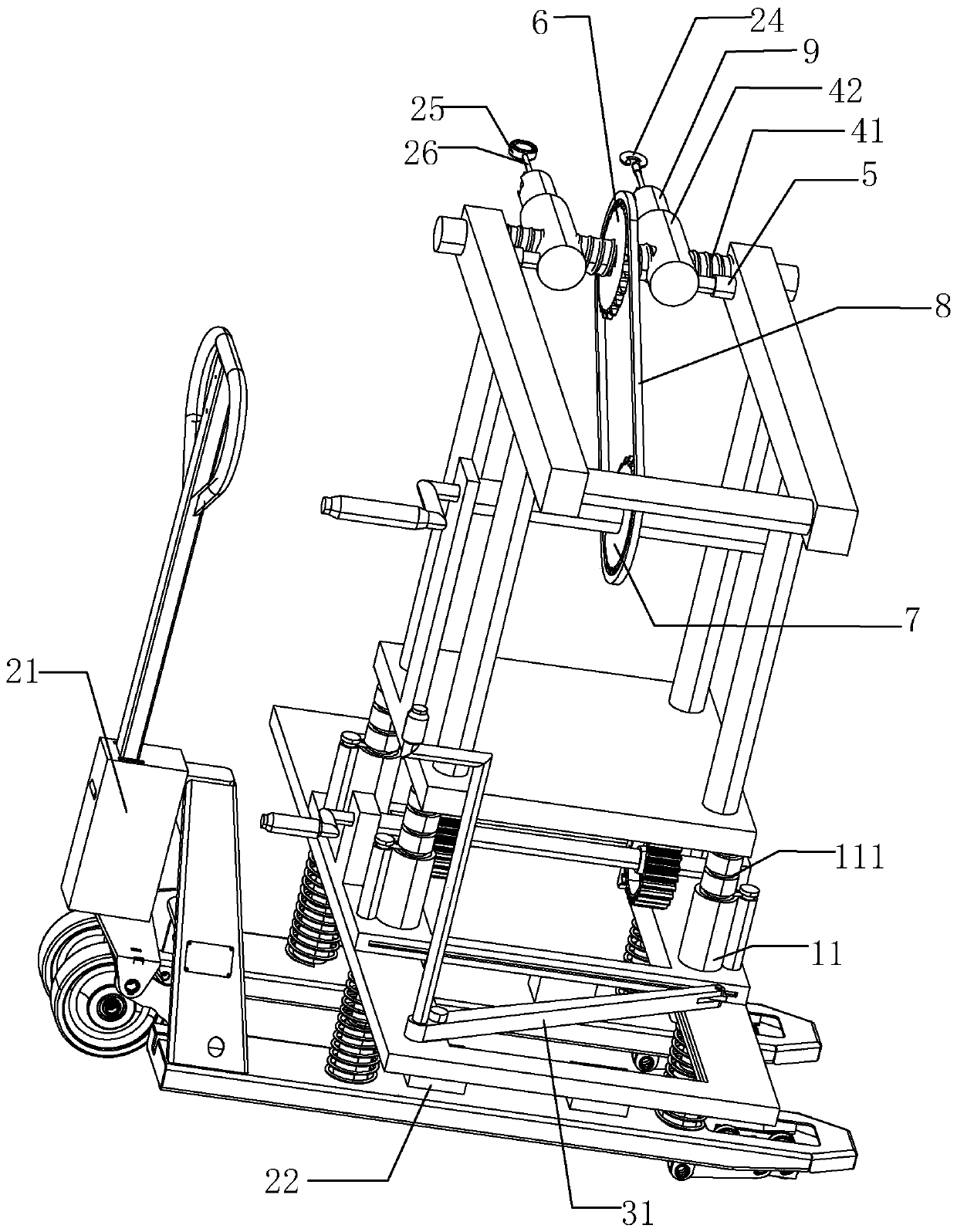

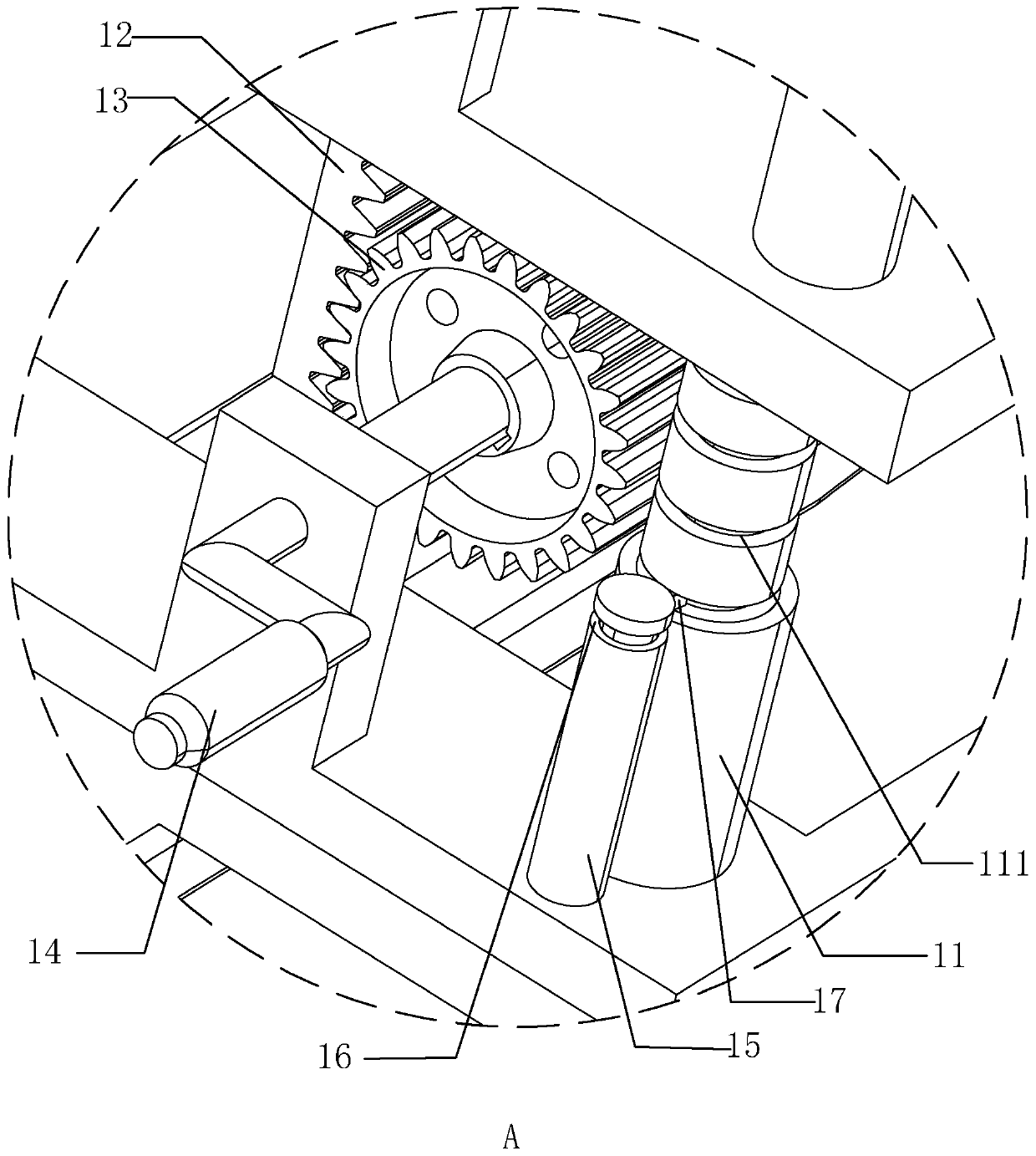

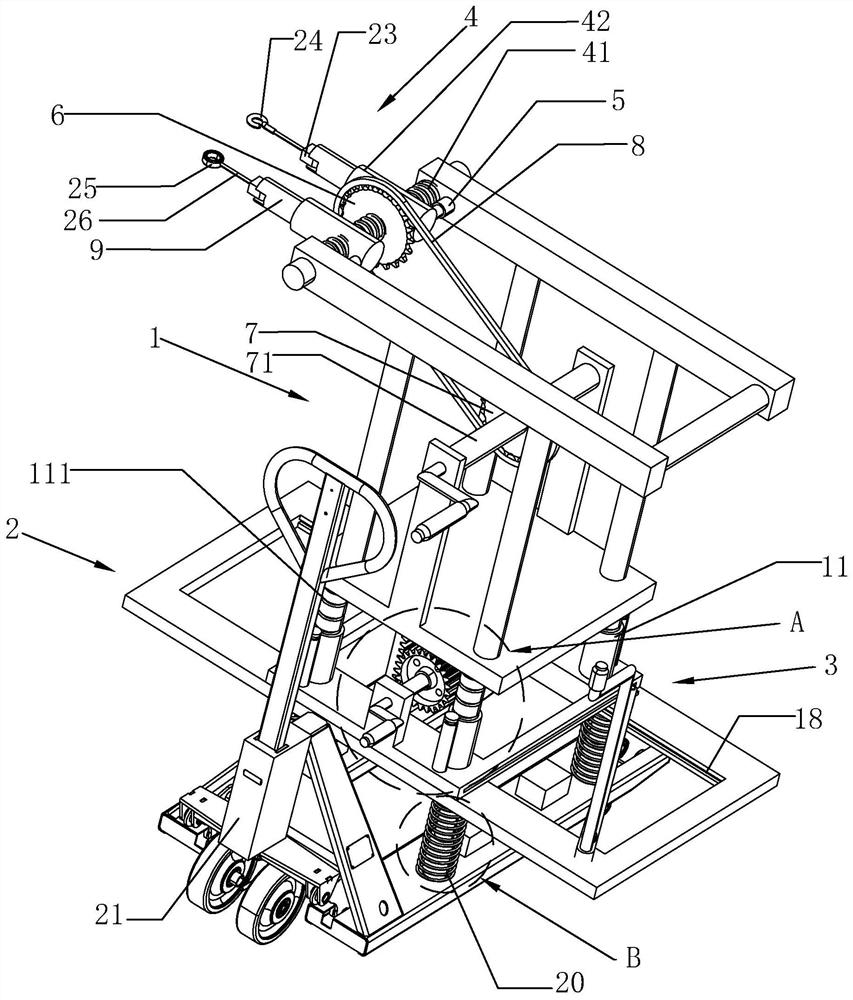

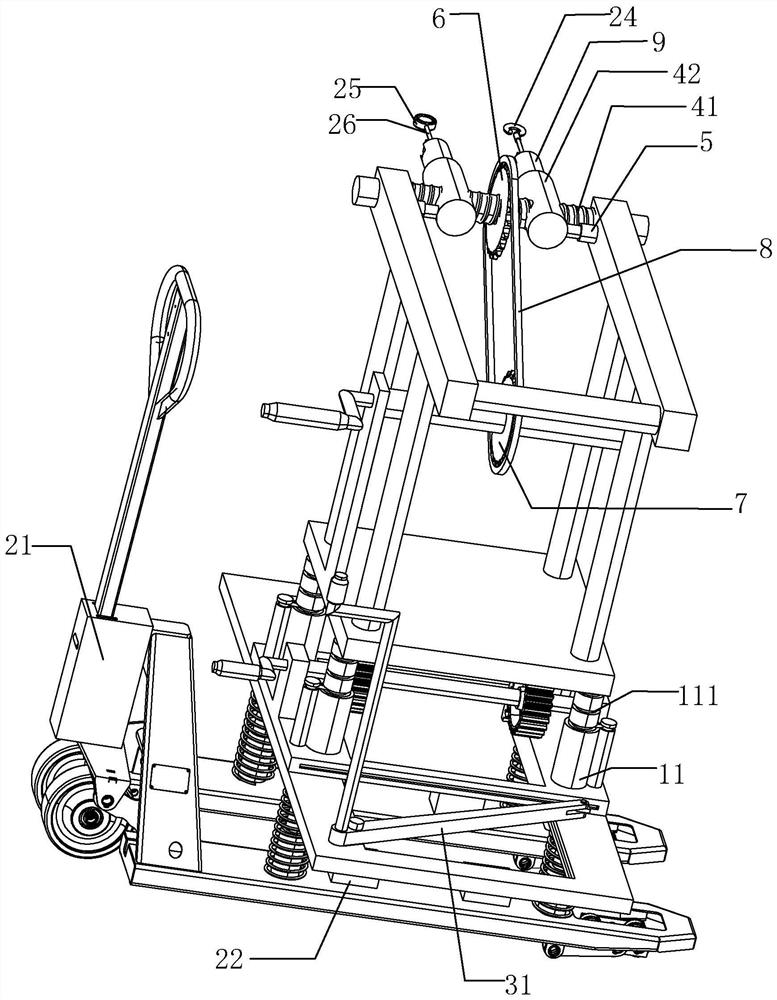

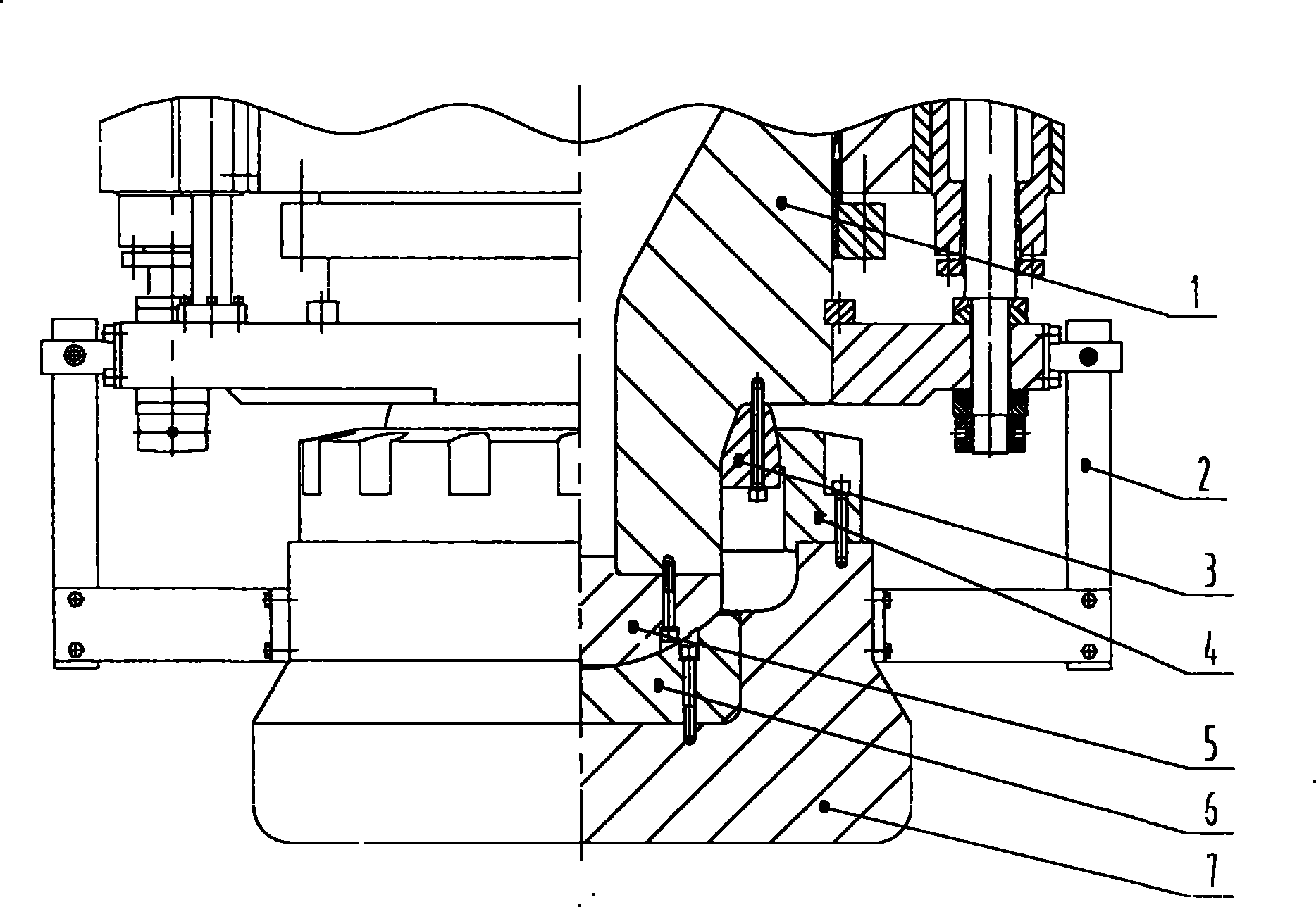

Coke dry quenching boiler economizer serpentine pipe in-place installation lifting device and use method thereof

InactiveCN107416690ASimple structureEasy to manufactureTrolley cranesLoad-engaging elementsQuenchingEconomizer

The invention relates to a coke dry quenching boiler economizer serpentine pipe in-place installation lifting device, which comprises a rail, a pulley lifting frame, hand chain hoists (7) and diamond brackets (2), wherein the rail is a section of a steel I-beam (4), the steel I-beam is horizontally arranged above a coke dry quenching boiler economizer serpentine pipe installation position, the pulley lifting frame is provided with two side plates (12), the upper portions of the two side plates are respectively provided with two pulleys (3), the first lifting hook (6) of the hand chain hoist (7) is hooked in the hook shaft (5) of the pulley lifting frame, a second lifting hook (8) is connected to one end of a lifting cable, the other end of the lifting cable is connected to a third lifting hook (10) through a fixation ring, and the third lifting hook (10) is movably connected to the diamond bracket (2) in a clamped manner. According to the present invention, the coke dry quenching boiler economizer serpentine pipe in-place installation lifting device has advantages of simple structure, convenient production, good lifting safety, construction efficiency improving and engineering cost reducing, can prevent the serpentine pipe from inverse running damage, and can avoid work delaying, time delaying and material loss.

Owner:MCC5 GROUP CORP SHANGHAI

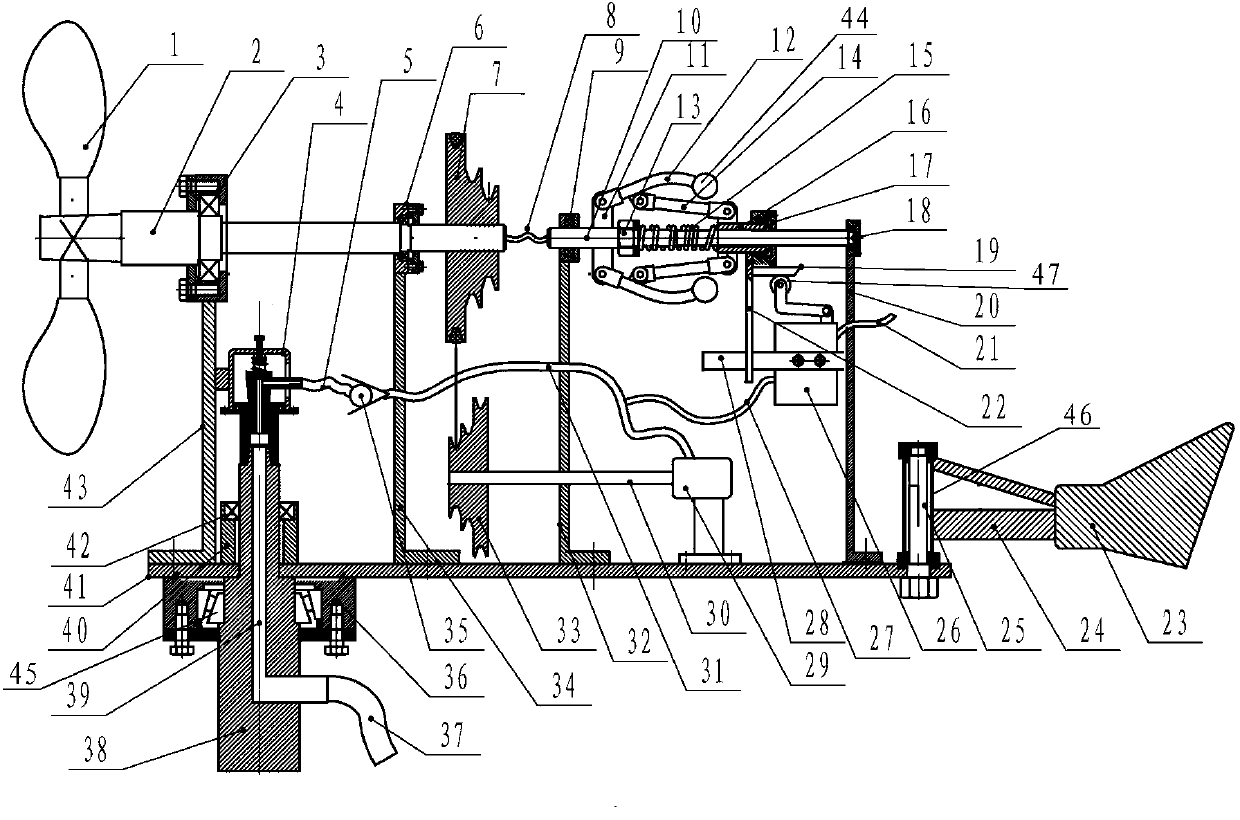

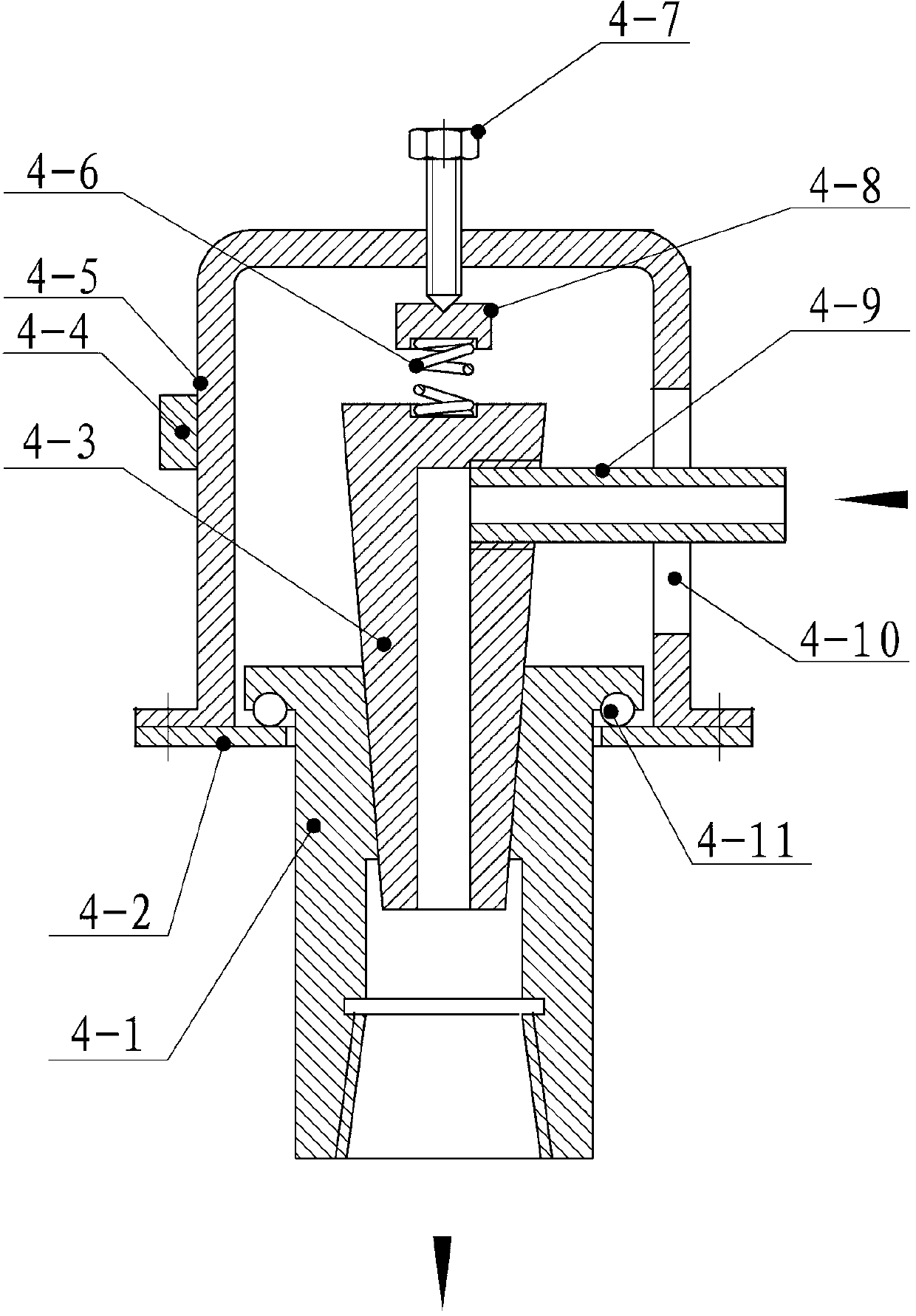

Wind power air compressor system

InactiveCN103343736AIncrease profitFlexible sealPiston pumpsPositive-displacement liquid enginesGas compressorAir compressor

The invention discloses a wind power air compressor system. The wind power air compressor system comprises a stand column with a gas transmission channel, a wind power mechanism, an air compressor sub-system and a load-free centrifugal start control mechanism, wherein the wind power mechanism comprises fan blades, a main shaft, a driving pulley, a rotating chassis and a tail wing; the air compressor sub-system comprises an air compressor, a driven pulley arranged on a power shaft of the air compressor, a normal close button valve and a rotating joint; the rotating joint comprises a static joint, a moving joint and a hold-down mechanism; the lower end of the moving joint is inserted into the static joint, and the contacting surface of the moving joint and the static joint is a cone surface; the hold-down mechanism comprises a shield, an annular shield base, an adjustable bolt, a pressure spring and an upper spring base, the moving joint is communicated with an air channel of the static joint, and the load-free centrifugal start control mechanism comprises a centrifugal shaft, a pair of driving centrifugal rods, a centrifugal ball, a pair of driven centrifugal rods, a shaft sleeve and a button valve control mechanism. The wind power air compressor system provided by the invention has the advantages that the load-free starting is adopted, the utilization rate of wind energy is high, and the rotation is flexible.

Owner:张家政

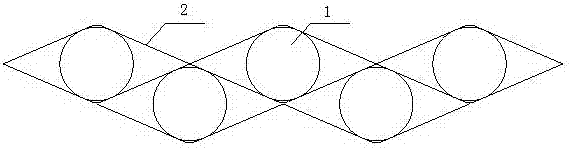

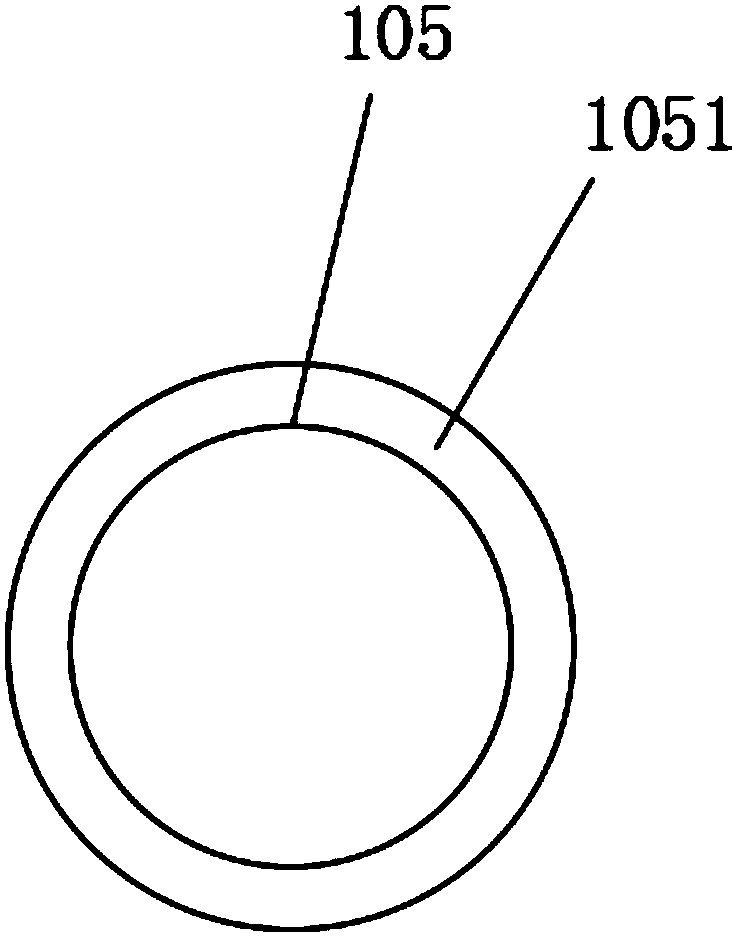

Guide mechanism for printing guide roller

InactiveCN107745570AReduce high temperatureExtended service lifeRotary pressesPulp and paper industryHigh heat

The invention discloses a guide mechanism for a printing guide roller, which comprises a device main body, an air inlet is arranged at the front end of the device main body, and the air inlet is fixedly connected with the device main body, and the left and right sides of the device main body are provided with a main shaft, and the main shaft is connected to the main body of the device. The main body of the device is movably connected, and the upper end of the main shaft is provided with a fixed part, and the fixed part is movably connected with the main shaft. There is a roller inside the main body of the device, and the roller is movably connected with the main body of the device. This kind of printing guide roller is provided with an air outlet. The air holes can effectively reduce the high temperature generated by the guide roller during printing, and prevent the deformation of the printed paper or cloth, thereby improving the work efficiency. Compared with the previous device, the guide roller is also equipped with stainless steel, which can effectively The corrosion resistance of the guide roller is greatly improved, thereby prolonging the service life of the guide roller. The X-shaped thread on the surface of the guide roller can increase the friction of the guide roller during printing.

Owner:陈雪峰

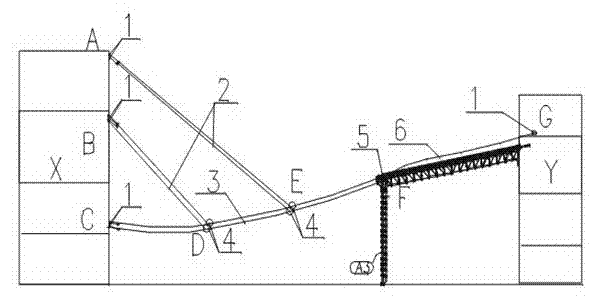

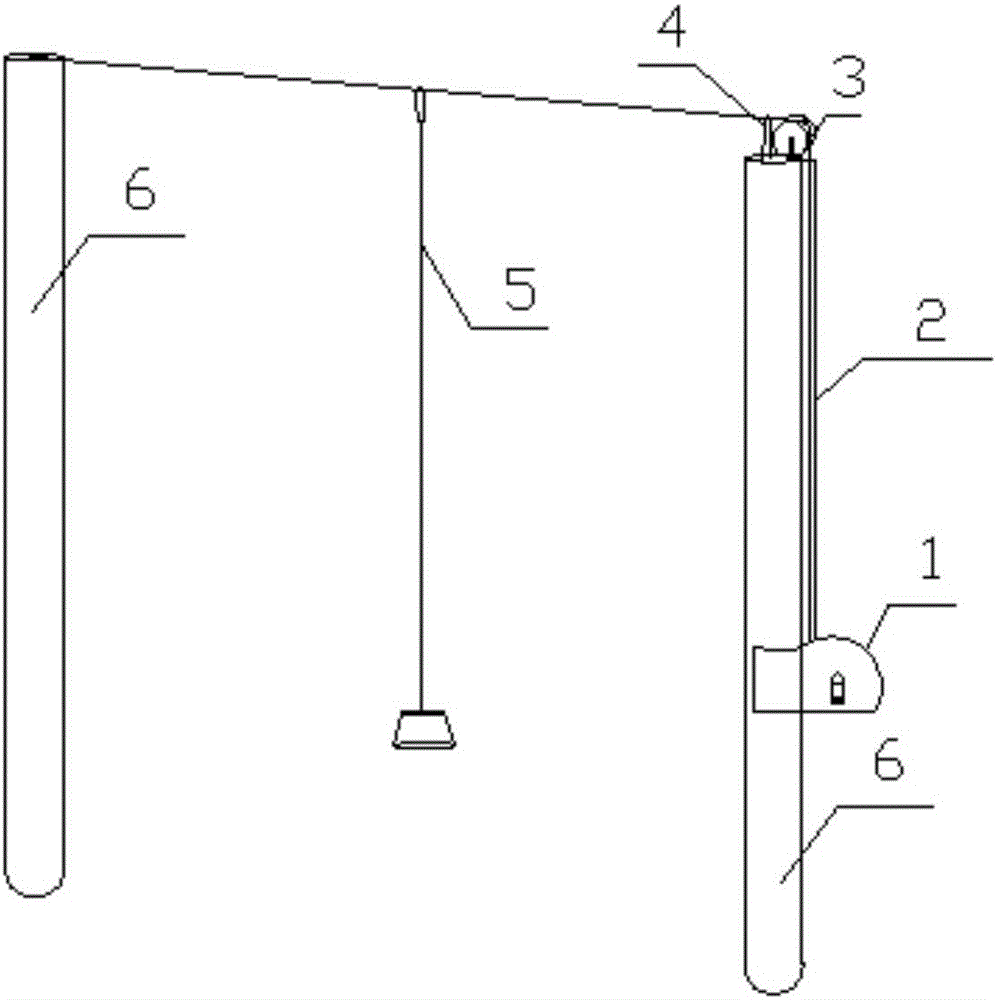

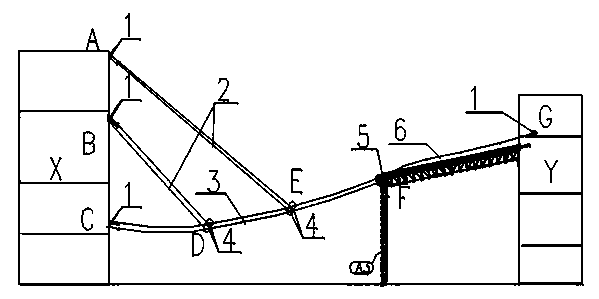

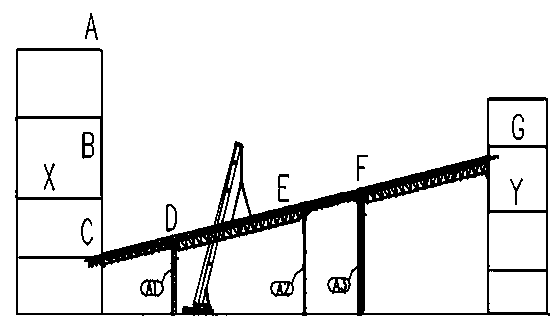

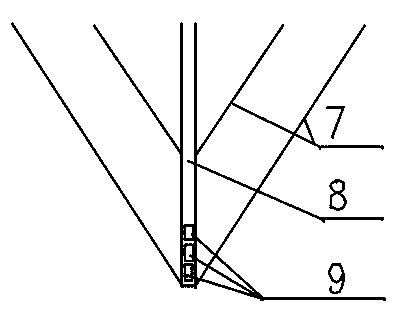

Cable-stayed suspension combined suspending method for cable protection in gallery inspection

ActiveCN102361273AAvoid influenceReduce construction costsPipe supportsCable installation apparatusElectricityCable stayed

The invention provides a cable-stayed suspension combined suspending method for cable protection in gallery inspection, belonging to the technical fields of equipment inspection and overhaul. The suspending method mainly comprises the following steps of: machining lifting lugs, manufacturing and installing a tensile supporting frame, and fixing and suspending a chain block; releasing a cable, connecting and adjusting; and pulling the cable out of a bridge frame and restoring. In the invention, complex processes such as removing the used cable from an electricity utilization site, drawing out, putting in, wiring, checking and the like are avoided, influence from the used cable when a truss is removed is effectively overcome, hardly predicated hidden dangers appearing after the cable is cut off are avoided, the construction cost of an overhaul or technical modification project is reduced, the overhaul or technical modification construction period is shortened, and a new method for effectively solving the problem of overhaul or technical modification for an entire removing gallery overspan building in a plant area is provided. The method provided by the invention has the advantages of capability of operating in advance, safety and reliability, high overhaul work efficiency, high economic benefit and the like.

Owner:CHINA MCC17 GRP

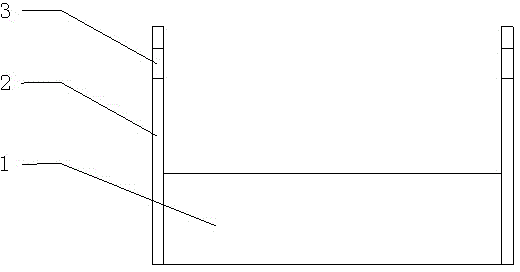

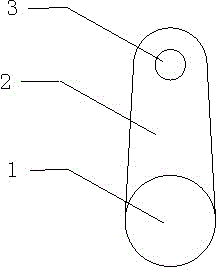

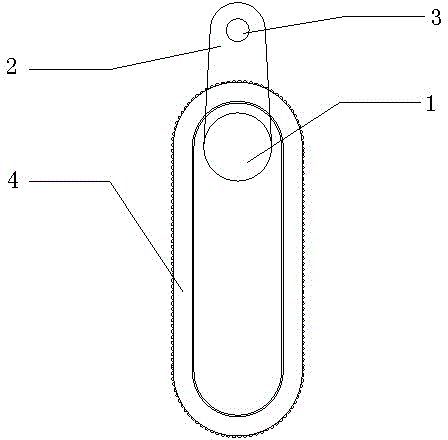

Setting-out device for ceiling roof

ActiveCN105863282AReasonable structureDisadvantages of Changing Routine OperationsBuilding material handlingRubber materialEngineering

The invention provides a setting-out device for a ceiling roof. The setting-out device comprises an ink fountain. A coil is arranged in the ink fountain. A central rotary shaft is arranged in the center of the coil. A rotary handle is externally arranged at one end of the central rotary shaft. One end of the coil is fixed to the center of a rod through a flexible wire pipe, a pulley, a wire pressing ring, a line snapping rope and a groove in the top end of the rod. The flexible wire pipe is a transparent plastic pipe. The pulley is made of hard wood. The wire pressing ring is made of galvanized round steel. A main rope of the line snapping rope is made of elastic rubber materials. The periphery of an operating rod is made of hard round wood. Compared with a former construction method, the setting-out device is simple and convenient to use, practical and reasonable in structure, the defects of conventional operation are overcome, the construction period is shortened, equipment investment is reduced, the cost is reduced, construction is arranged reasonably through the change of the objective environment, measuring and setting-out as well as installation operation can be implemented independently, and thus construction delay is avoided.

Owner:CHINA MCC17 GRP

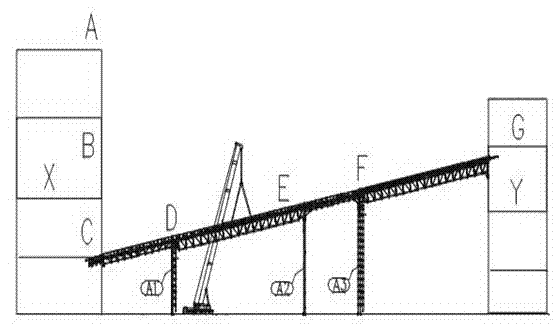

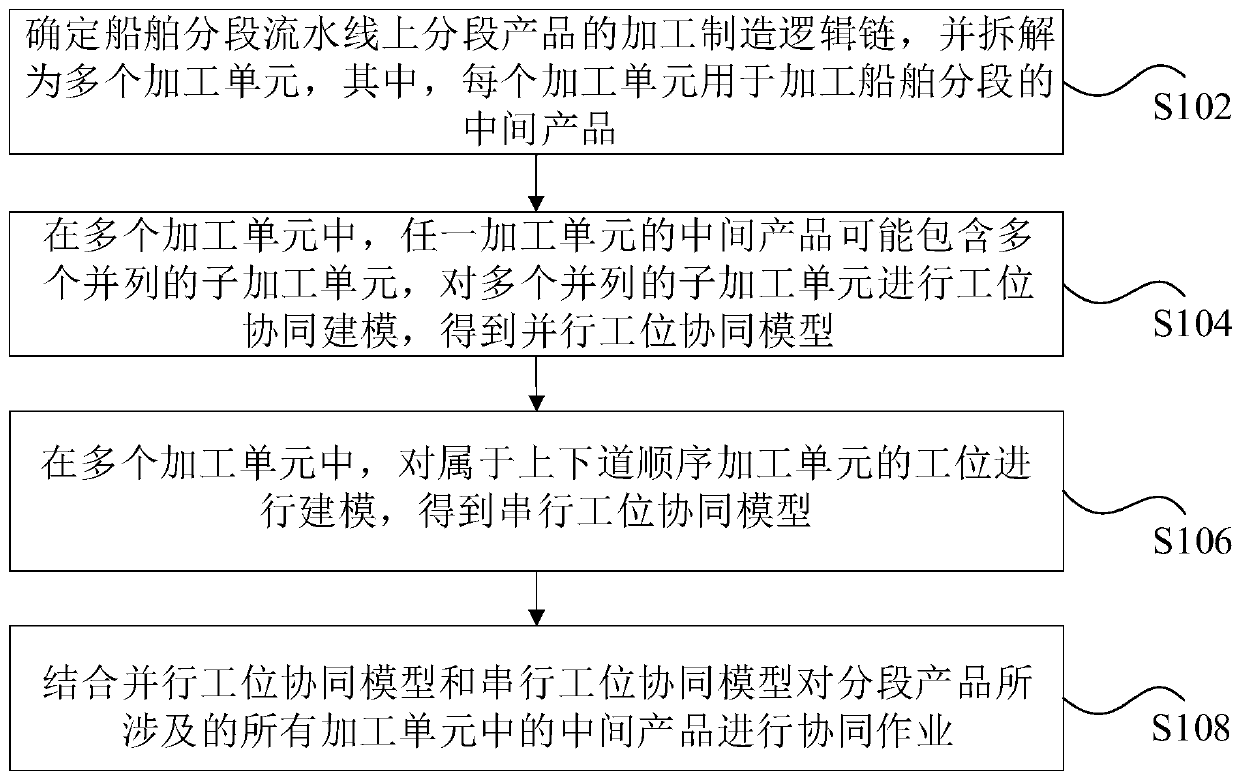

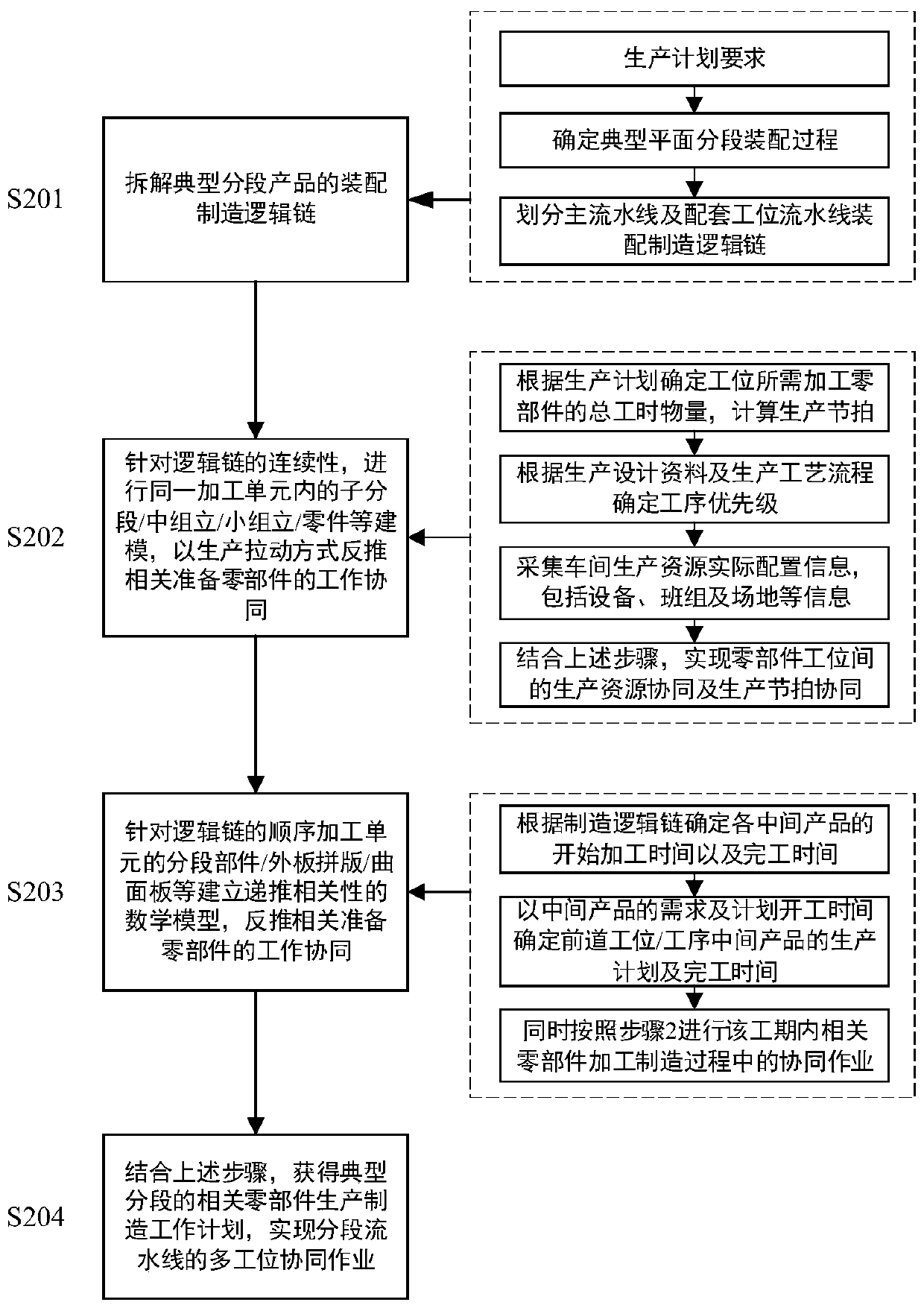

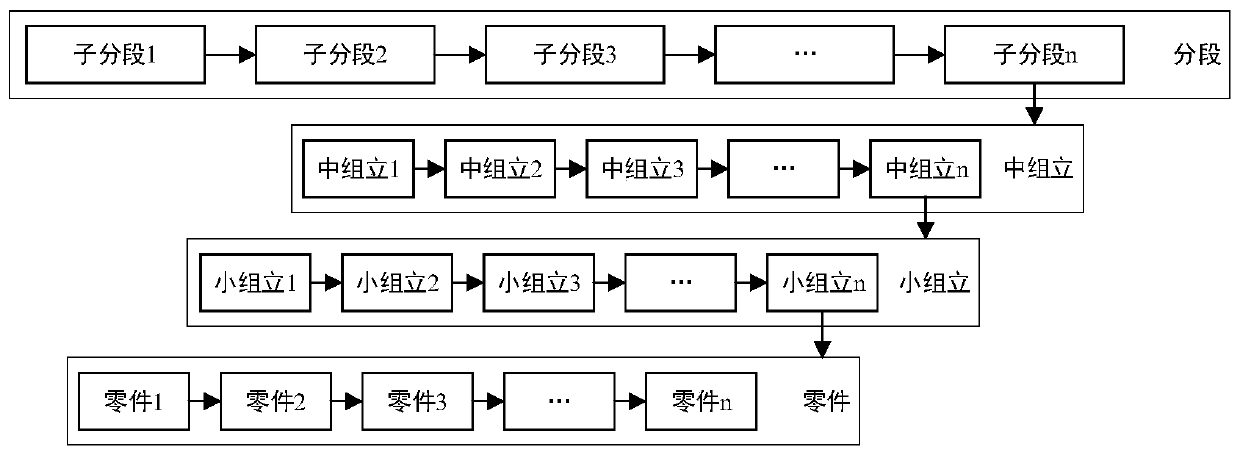

Multi-station coordination method for ship segmented manufacturing pipeline

InactiveCN110040216ASolve efficiency problemsSolve the technical problem of large cacheVessel designingProcess engineeringEngineering

The invention discloses a multi-station coordination method for a ship segmented manufacturing pipeline. The multi-station coordination method comprises the steps that an assembly manufacturing logicchain of segmented products on the ship segmented pipeline is determined, and the assembly manufacturing logic chain is disassembled into a plurality of processing units (that is, a plurality of processing steps), wherein each processing unit is used for processing intermediate products of ship segments; in the multiple processing units, the intermediate product of any processing unit possibly includes a plurality of parallel sub-processing units, and station coordination modeling is performed on the multiple parallel sub-processing units to obtain a parallel station coordination model; in themultiple processing units, stations belonging to the upper and lower sequential processing units are subjected to modeling to obtain a serial station coordination model; and the parallel station coordination model and the serial station coordination model are combined to perform coordination operation on the intermediate products of all processing units involved in the segmented products. Throughthe multi-station coordination method, multi-station coordination of the ship segments is realized, intermediate buffer is effectively reduced, and the effect of improving the ship segmented manufacturing efficiency is achieved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

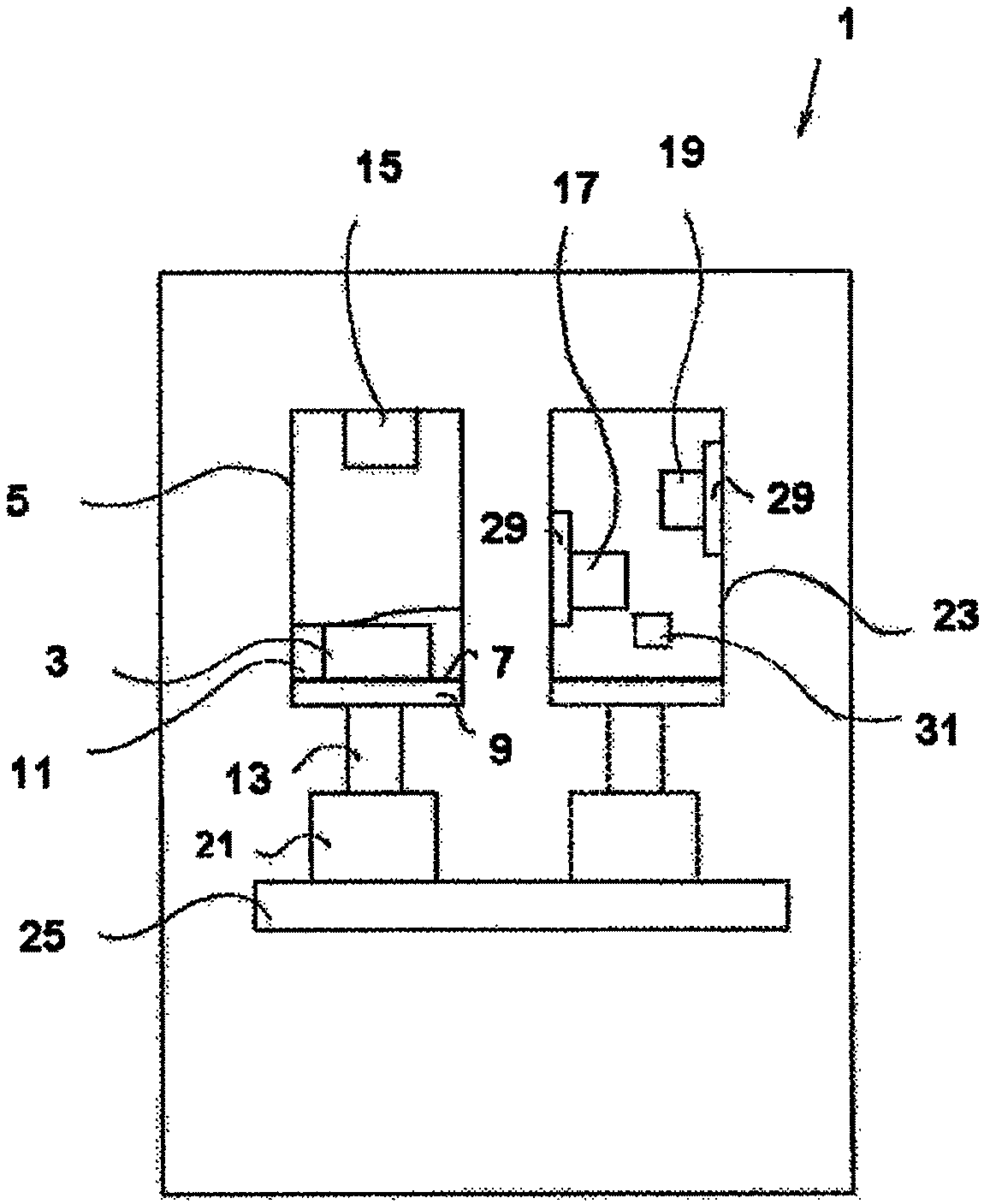

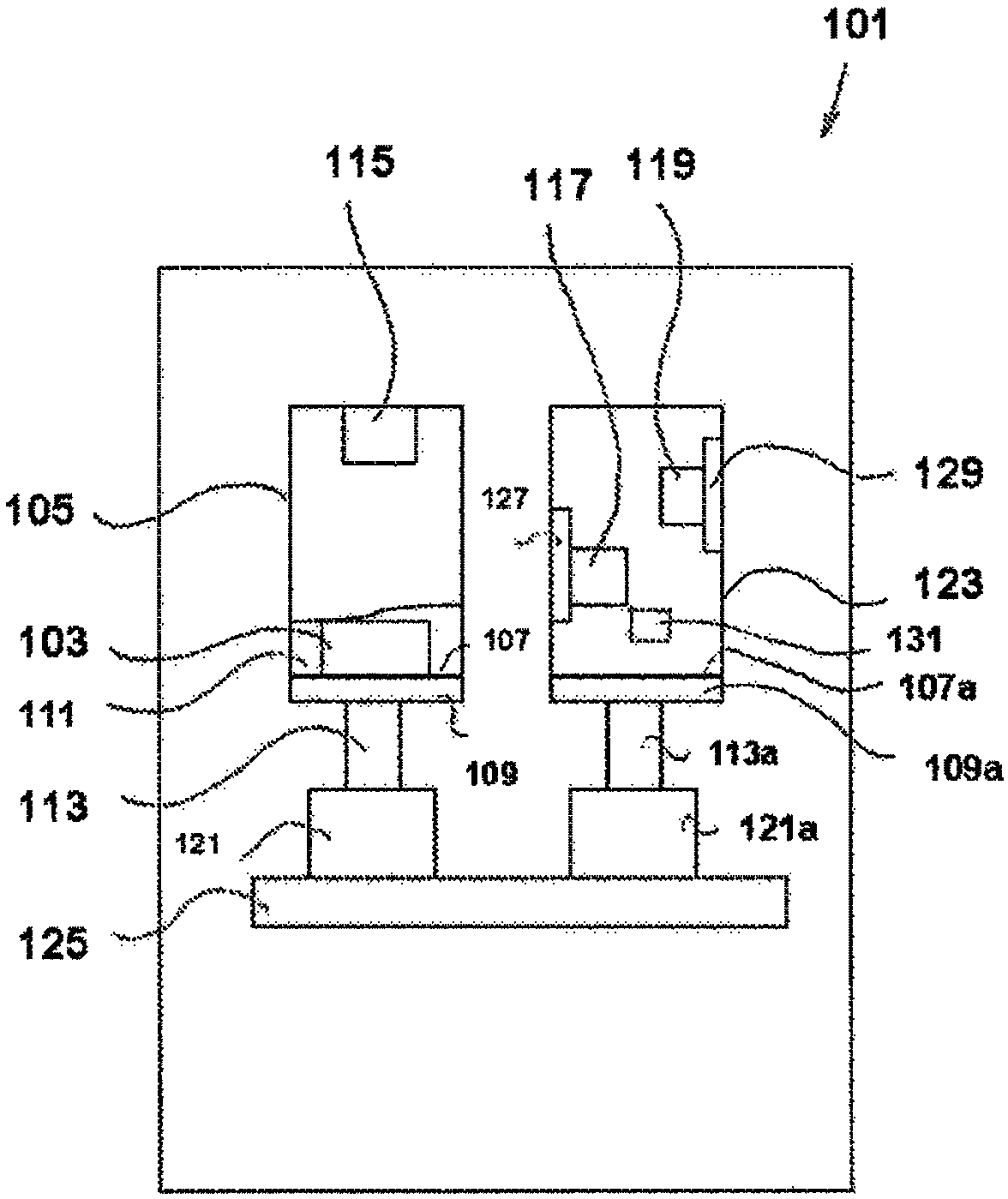

Apparatus for producing an object by means of additive manufacturing and method of using the apparatus

InactiveCN109689252AImprove productivityAvoid lost timeAdditive manufacturing apparatusIncreasing energy efficiencyProcess engineeringAdditive layer manufacturing

Apparatus for producing an object by means of additive manufacturing includes a processing chamber for receiving on a build surface of a build plate a bath of powdered material which can be solidified; a support for positioning the build plate in relation to a surface level of the bath of material; a solidifying device for solidifying a selective part of the material; and a build plate preparationmeans for preparation of the build surface of the build plate such that the object can be build on the build surface of the build plate. A method of producing an object by means of additive manufacturing on a build surface of a build plate using such an apparatus is also provided.

Owner:ADDITIVE IND

Wind shield transportation support for paint spraying

ActiveCN110921276ASave construction siteContinuous workSpraying apparatusLifting framesClassical mechanicsStructural engineering

Owner:CCCC TUNNEL ENG +1

A method for quickly detecting the remaining battery usage times

ActiveCN105005001BAvoid wastingAvoid lost timeElectrical testingInternal resistanceElectrical battery

Owner:JIANGSU BEIXIN NEW ENERGY TECH CO LTD

A ceiling wire release device

ActiveCN105863282BReasonable structureDisadvantages of Changing Routine OperationsBuilding material handlingRubber materialEngineering

The invention provides a setting-out device for a ceiling roof. The setting-out device comprises an ink fountain. A coil is arranged in the ink fountain. A central rotary shaft is arranged in the center of the coil. A rotary handle is externally arranged at one end of the central rotary shaft. One end of the coil is fixed to the center of a rod through a flexible wire pipe, a pulley, a wire pressing ring, a line snapping rope and a groove in the top end of the rod. The flexible wire pipe is a transparent plastic pipe. The pulley is made of hard wood. The wire pressing ring is made of galvanized round steel. A main rope of the line snapping rope is made of elastic rubber materials. The periphery of an operating rod is made of hard round wood. Compared with a former construction method, the setting-out device is simple and convenient to use, practical and reasonable in structure, the defects of conventional operation are overcome, the construction period is shortened, equipment investment is reduced, the cost is reduced, construction is arranged reasonably through the change of the objective environment, measuring and setting-out as well as installation operation can be implemented independently, and thus construction delay is avoided.

Owner:CHINA MCC17 GRP

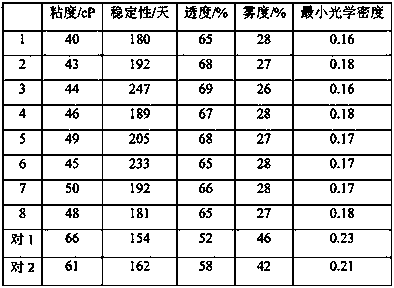

Preparation technology of ethylhexyl salicylate emulsion

InactiveCN110079172ABrittleEasy to GrindUnspecified rubber coatingsThermosensitive paintsETHYLHEXYL SALICYLATEEmulsion

The invention discloses a preparation method of ethylhexyl salicylate emulsion. The method comprises the following steps: (1) crushing, namely, crushing blocky solid ethylhexyl salicylate into small blocky materials through a crushing machine; (2) freezing, namely, freezing the small blocky materials crushed in step (1) into a refrigerator or a cold storage; (3) powdering, namely, grinding the materials obtained in step (2) into powder through a powdering machine; (4) milling, namely, mixing the powder obtained in step (3), a binder water solution, a dispersant and water; and milling through amilling machine to obtain the ethylhexyl salicylate emulsion. The ethylhexyl salicylate remains good and long-lasting dispersing stage, and the obtained heat-sensitive image is high in quality.

Owner:南阳九鼎材料科技股份有限公司 +1

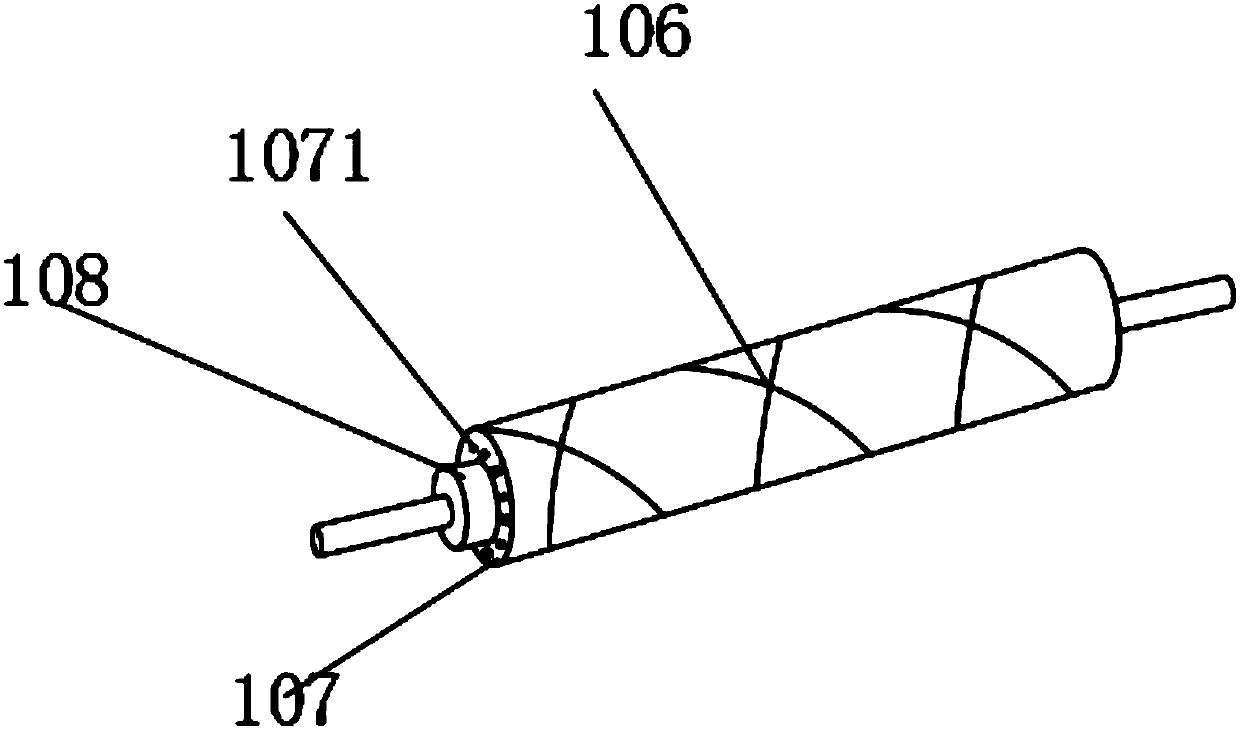

Transmission device of shot blasting device

InactiveCN107745339AEasy to replaceEasy to manufactureImpeller wheelsRotor bladesImpellerDrive shaft

The transmission device of the shot blasting device of the present invention relates to the field of mechanical equipment, in particular to the transmission device of the shot blasting device, comprising a shot separation wheel, which is sleeved on the connection seat of the shot separation wheel, and axially separates the shot blasting wheel through a cap nut. The shot wheel is fastened on the left end of the shot wheel connecting seat, the shot wheel connecting seat is connected with the transmission shaft, and the boss of the shot wheel connecting seat is covered with an impeller connecting plate, and the shot wheel connecting seat and the impeller Gaskets are arranged between the connection pads. The invention can quickly and conveniently replace the blasting wheel and the connecting seat of the blasting wheel after the shot blasting machine works for a long time without changing the transmission shaft of the shot blasting machine.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

A windshield transportation bracket for painting

ActiveCN110921276BSave construction siteContinuous workSpraying apparatusLifting framesStructural engineeringIndustrial engineering

The invention discloses a transport bracket for a windshield used for painting, and relates to the technical field of the transport bracket. Its technical points are: including the sliding frame and the lower frame, the sliding frame is located on the upper side of the lower frame and the sliding frame and the lower frame are connected by a sliding mechanism, the lower side of the lower frame is provided with a sliding device, the lower frame is fixedly connected with the sliding device, and the upper end of the sliding frame There is a plug-in device on one side. The plug-in device includes a stud bolt plugged into the sliding frame. The two ends of the stud bolt are not threaded and are rotatably connected to the sliding frame. The windshield is picked up by the plug joint and slides Go to a suitable location for drying, saving the construction site, making it possible to work continuously, and avoiding delays in the drying process.

Owner:CCCC TUNNEL ENG +1

Grass trimmer

The grass trimmer comprises a shell, a motor, a control switch, a wire box and a counting device, wherein the motor is arranged in the shell and is provided with an output shaft; the control switch iselectrically connected with the motor and generates a paying-off signal according to user operation; a positioning column, a winding plate and a grass trimming rope are fixedly arranged in the wire box, and the positioning column is movably sleeved with the winding plate; the output shaft is in transmission connection with the wire box through the positioning column, one end of the grass trimmingrope is wound on the winding plate, and the other end of the grass trimming rope penetrates out of the wire box and has a rated length; the counting device is used for counting application times and / or remaining times of the grass trimming rope according to the paying-off signal. Therefore, when the number of application times of the grass trimming rope in a current grass trimmer is small, a useris reminded to replace the grass trimming rope in time, and the situation that during use, the grass trimming rope runs out and accordingly time and labor delay is avoided.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

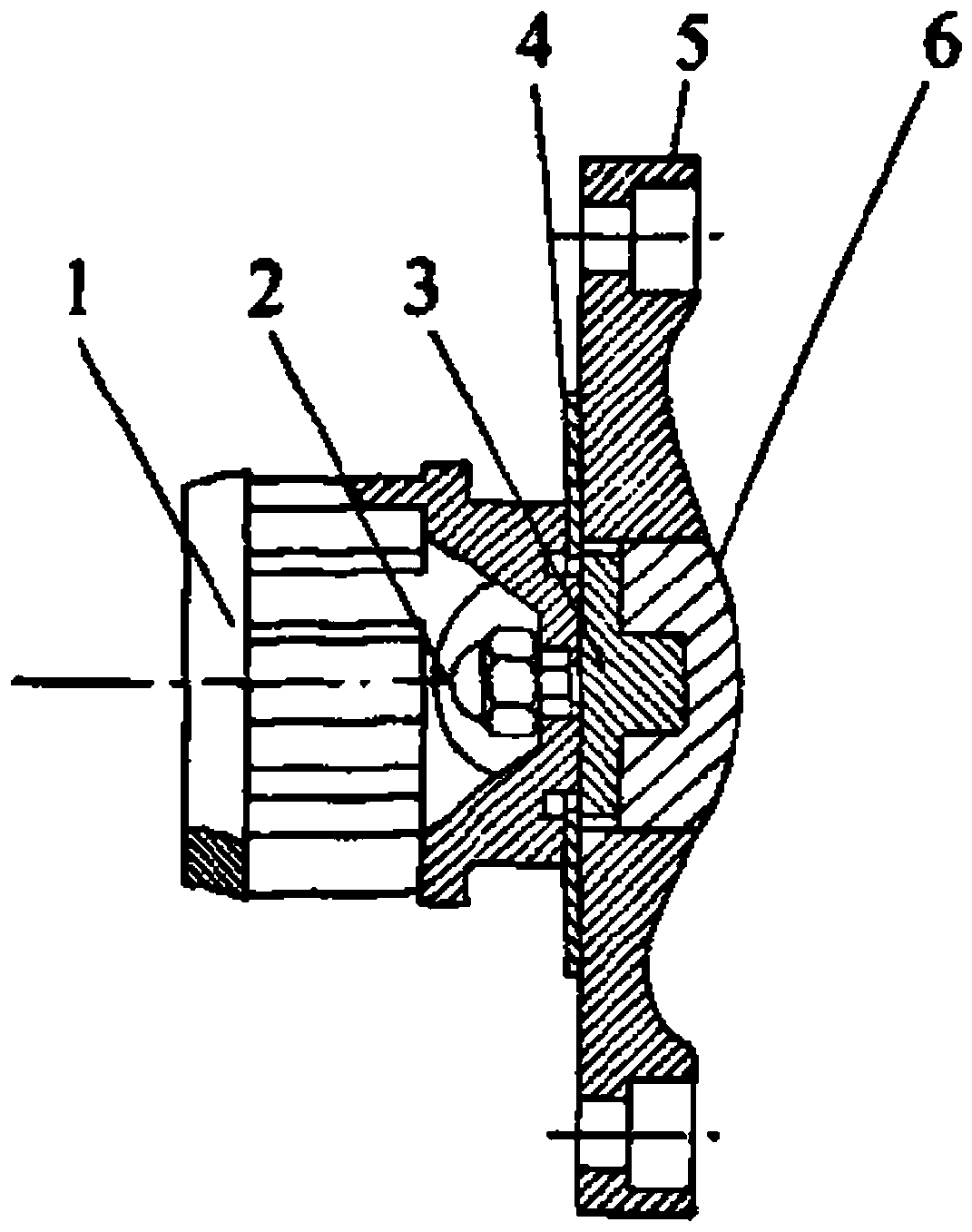

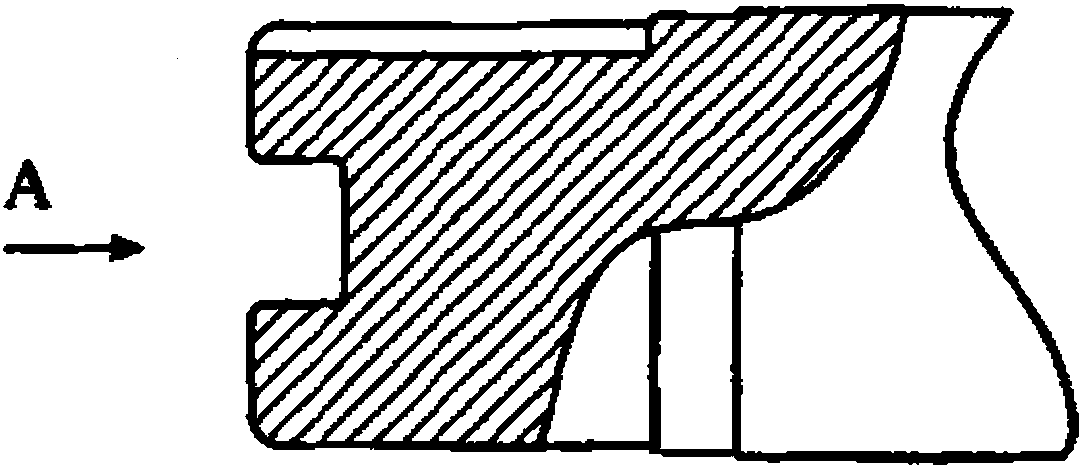

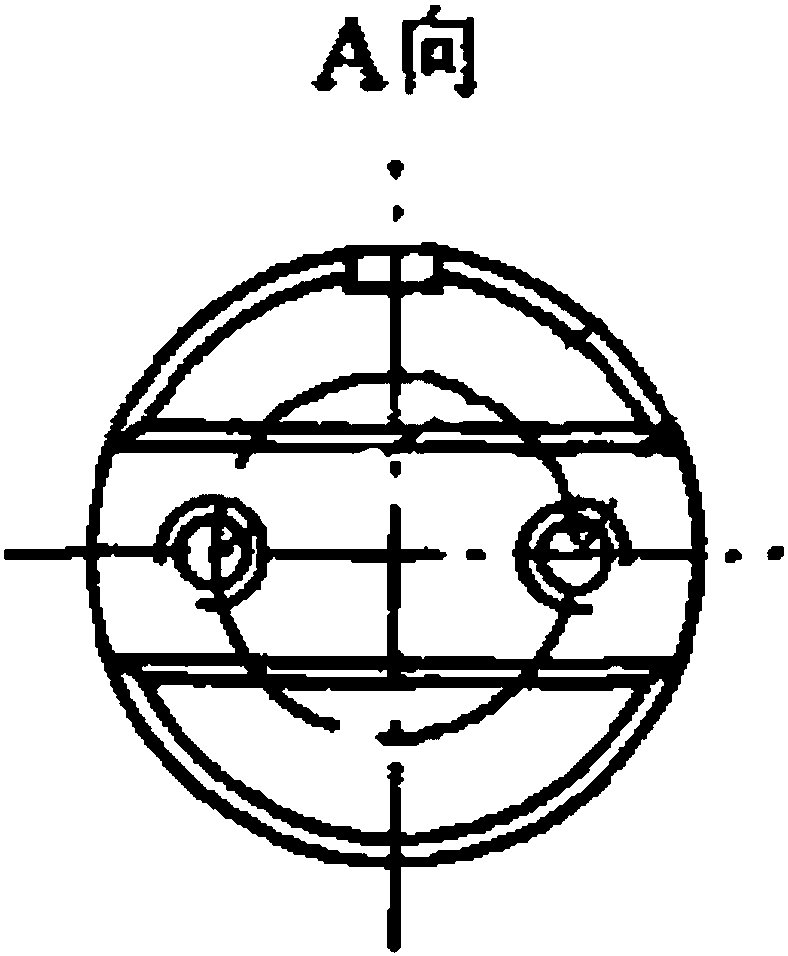

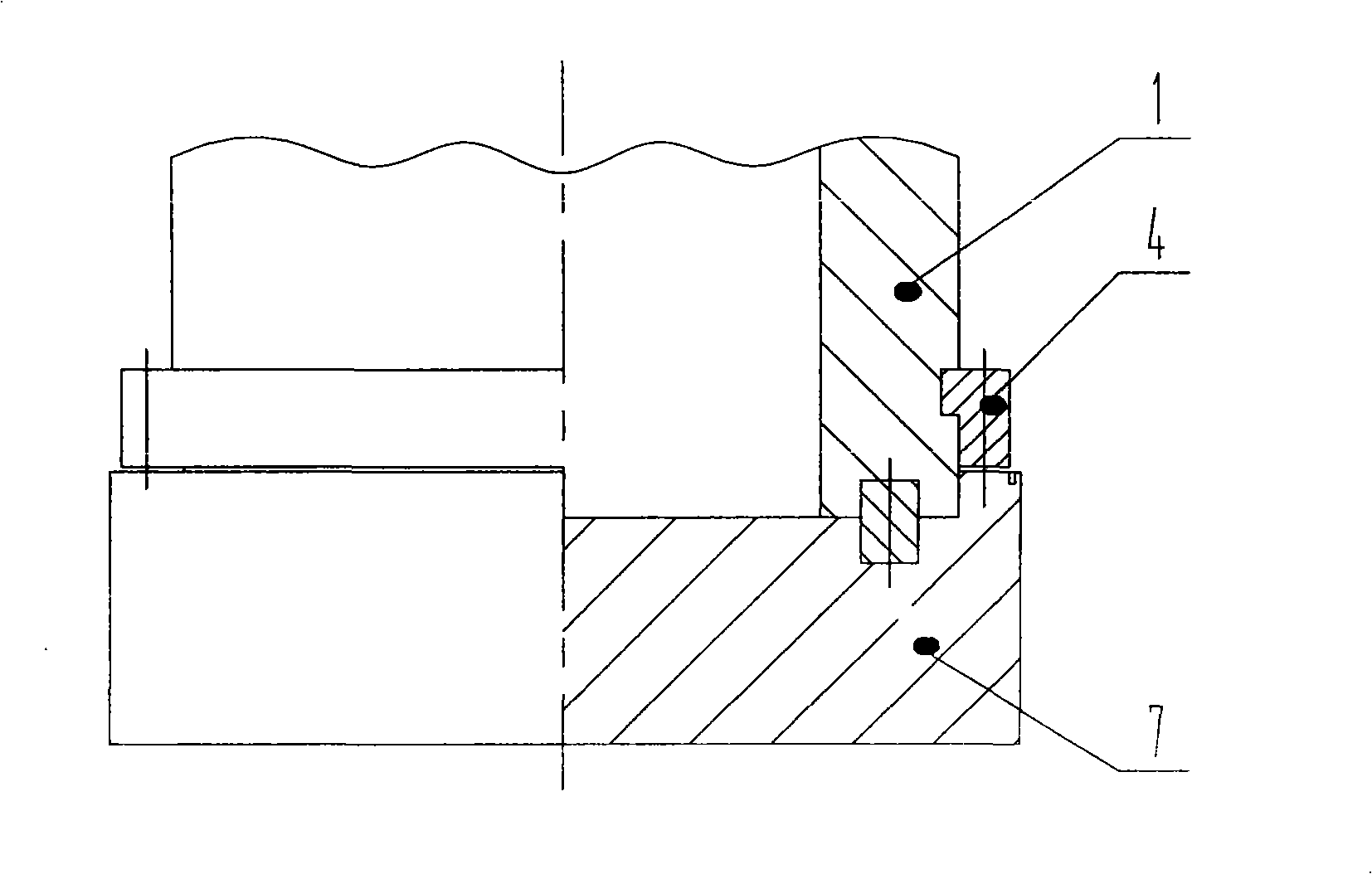

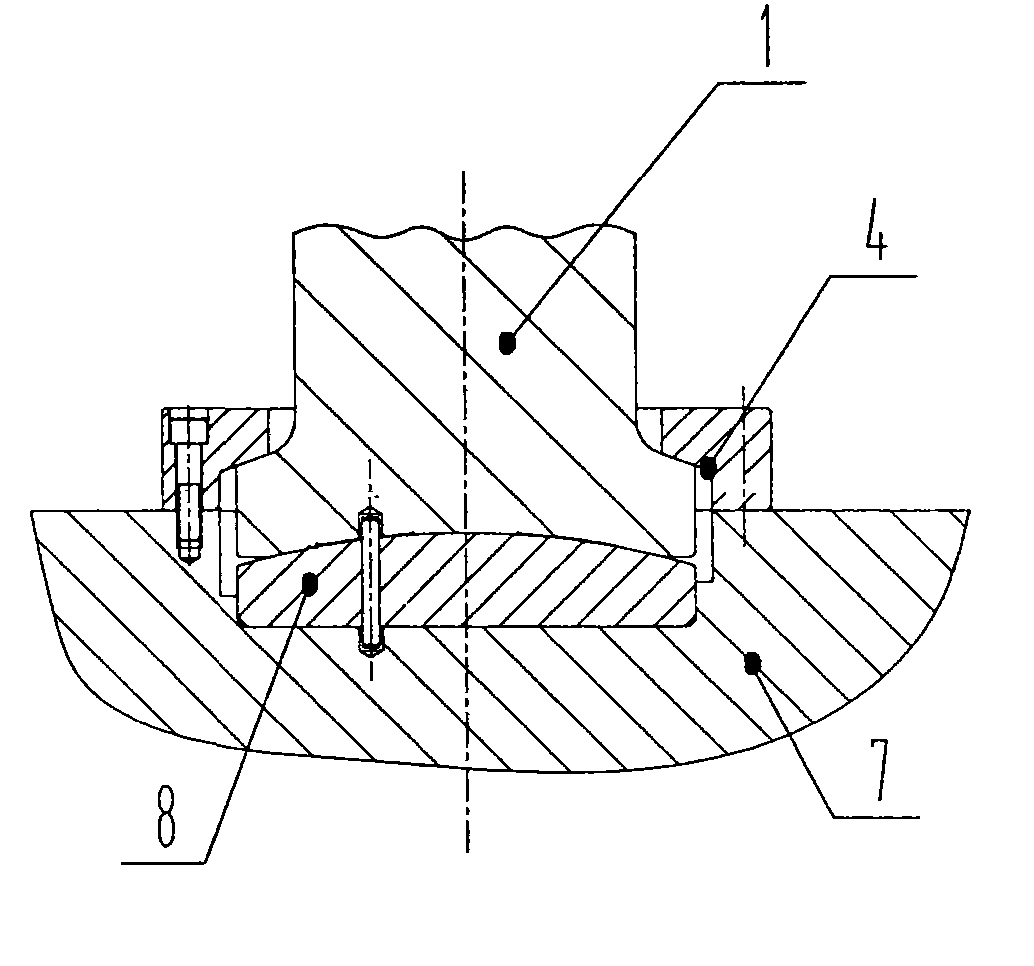

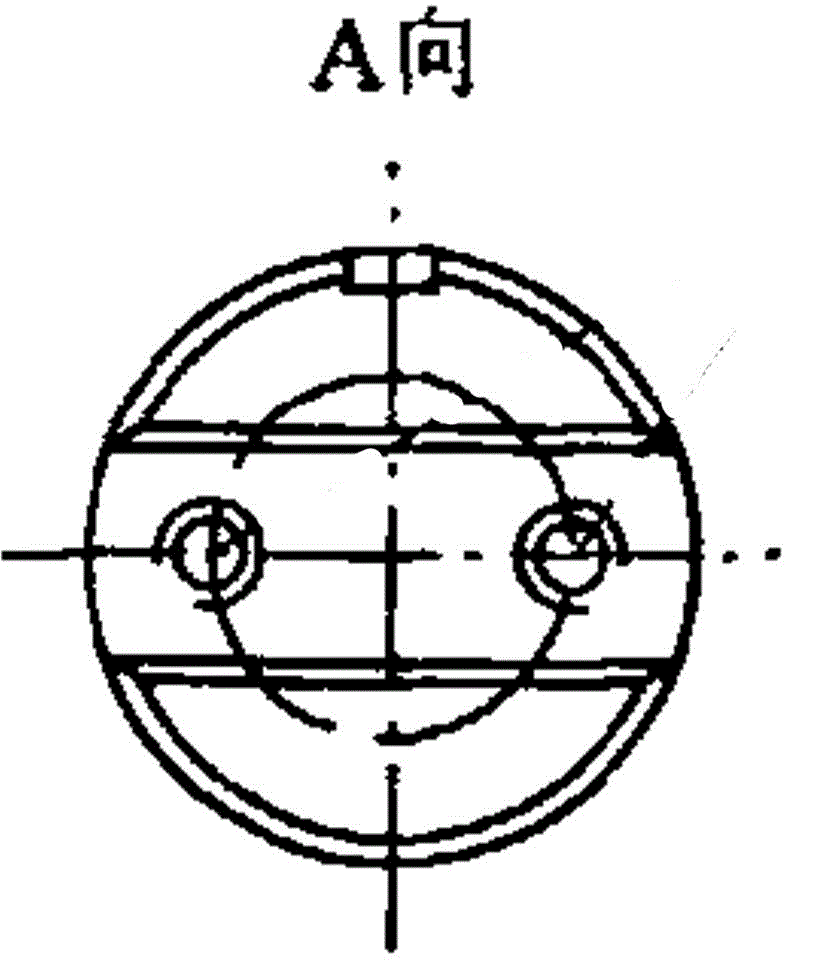

Connection device of vertical hydraulic press main plunger and pressure head

The invention discloses a device for connecting a main plunger and a pressure head of a vertical hydraulic machine and relates to a vertical hydraulic machine. The device is characterized in that the main plunger and the spherical surface of an upper sphere body are contacted and connected through a bolt; the main plunger and the plane of a lower sphere body are connected through the bolt; the upper sphere body and the lower sphere body have the same sphere center; the pressure head and the plane of a sphere supporting pad are connected through the bolt; the spherical surface of the sphere supporting pad is contacted with the spherical surface of the lower sphere body; a pressure flange and the pressure head are connected through the bolt; and the side curved surface of the pressure flange is contacted with the side curved surface of the upper sphere body. The device solves the problems that in a structure of directly connecting the main plunger and the pressure head through the pressure flange, a copper sleeve of a main cylinder has serious uneven wear of the seal caused by uneven loading of a presser and in a structure of adopting single spherical surface contact and pressure flange connection between the main plunger and the pressure head, the bolt for connecting the pressure flange and the pressure head is easy to break.

Owner:TAIYUAN HEAVY IND

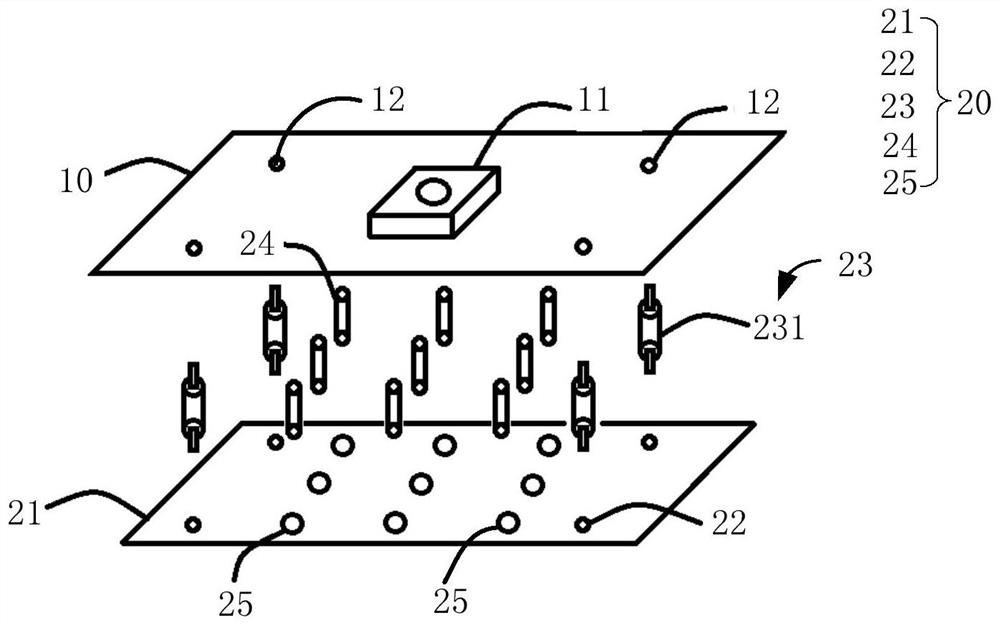

Chip testing device

PendingCN112285534ASolve the problem of super standard warpingAvoid lost timeElectronic circuit testingComputer hardwareElectrical performance

The invention provides a chip testing device, which is used for testing the electrical performance of a chip to be tested. The device comprises a testing printed circuit board comprising a front surface and a back surface which are oppositely arranged, wherein a chip testing socket is fixed on the front surface, and the chip testing socket is used for inserting a to-be-tested chip; and a supporting structure which is fixed and connected to the back surface of the test printed circuit board and is used for supporting the chip test socket from the back surface. According to the invention, the problem of over-standard warping of the test printed circuit board is solved through the support structure, the influence of the over-standard warping on the test result is reduced, and the machine-hourloss and the production delay are avoided.

Owner:SINO IC TECH

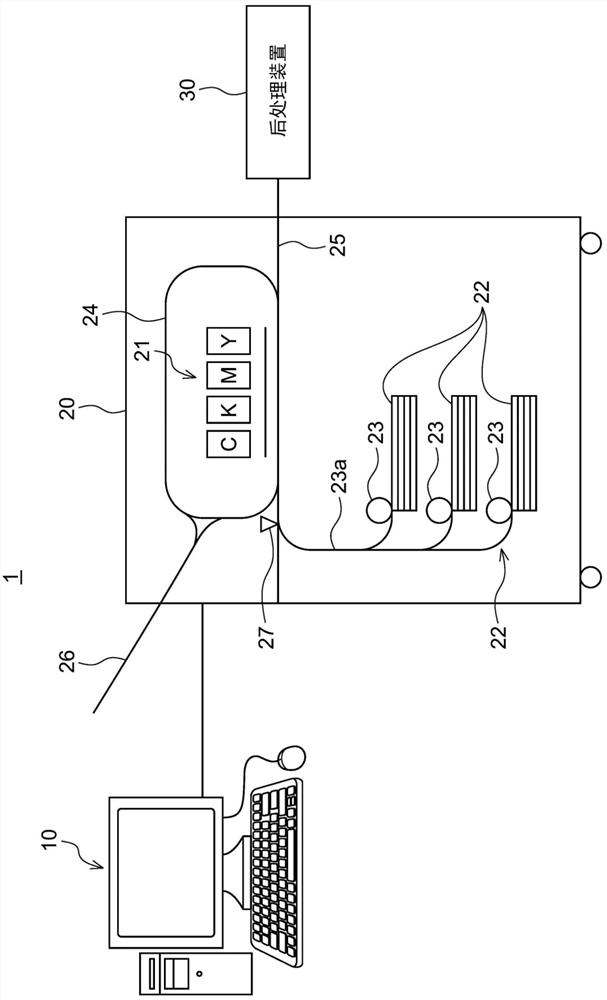

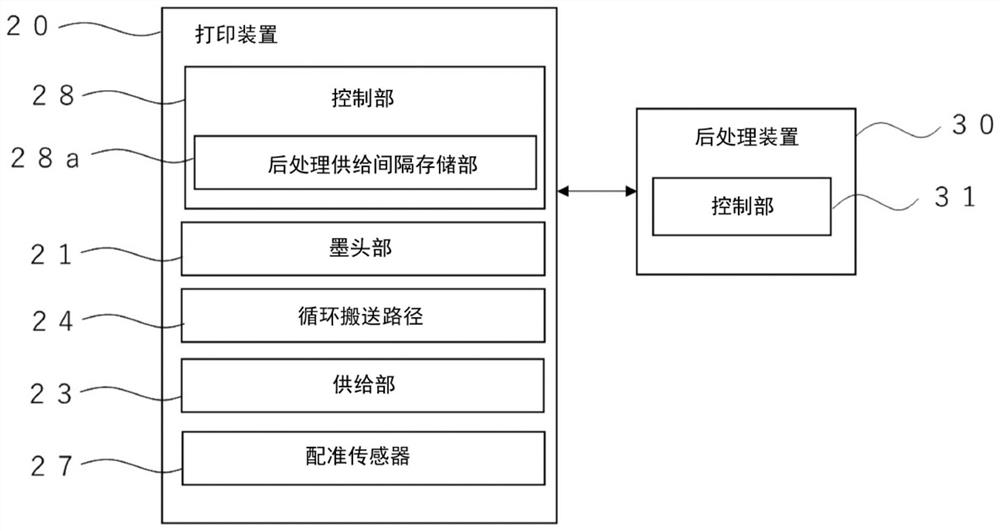

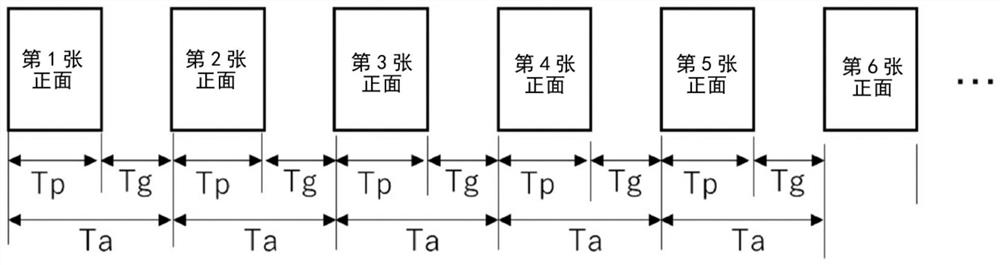

Supply device

PendingCN114763036ANo loss of productivityAvoid lost timeTypewritersOther printing apparatusIndustrial engineeringOperations management

The invention provides a supply device capable of performing supply control in consideration of post-processing time without causing a decrease in productivity. The printing apparatus includes: a supply unit (23) for sequentially supplying a plurality of printing media; and a control unit (28) that controls the supply unit (23) in a case where a predetermined post-processing supply interval (Ts) longer than the supply interval (Tb) needs to be secured while the plurality of printing media are sequentially supplied at the supply interval (Tb). The control unit (28) compares a reference supply interval (Tr), which is based on a time point obtained by multiplying the supply interval (Tb) by a natural number, with the post-processing supply interval (Ts), and when the post-processing supply interval (Ts) differs from the reference supply interval (Tr), the supply is performed at the post-processing supply interval (Ts).

Owner:RISO KAGAKU CORP

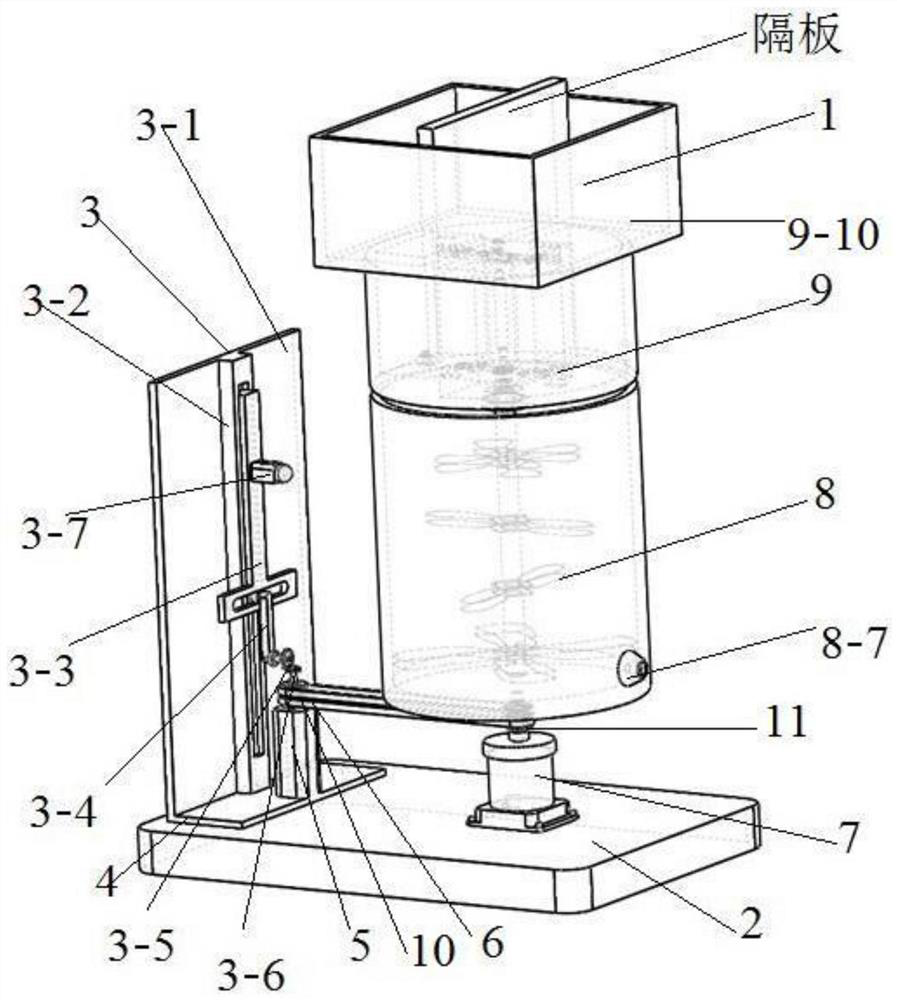

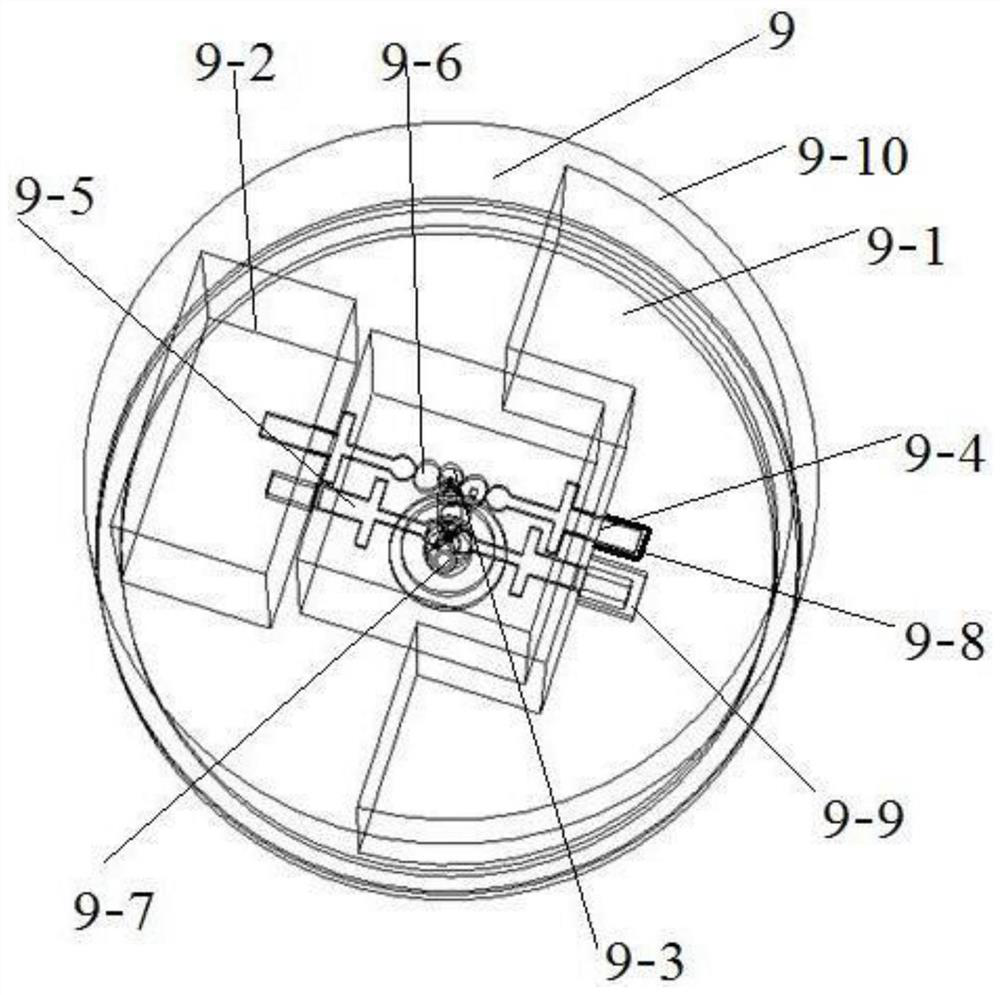

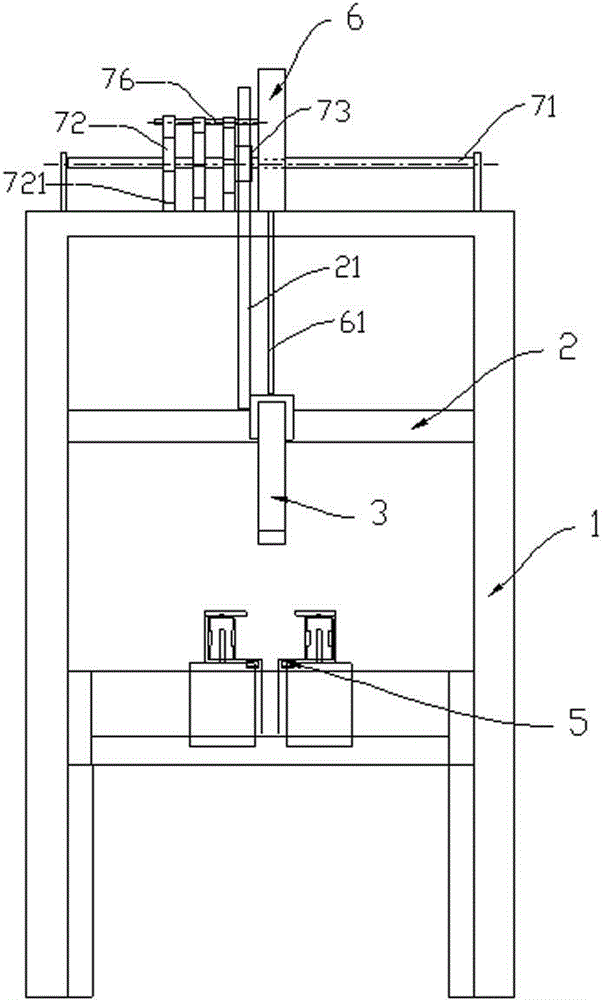

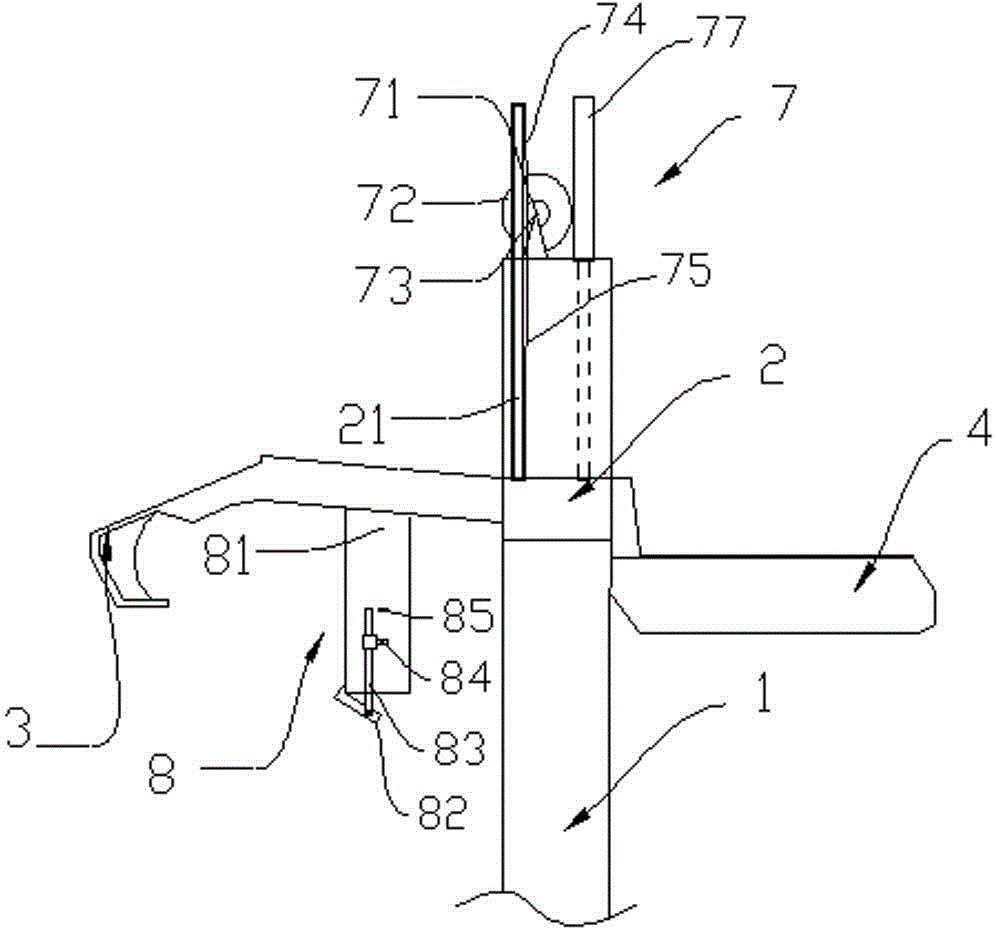

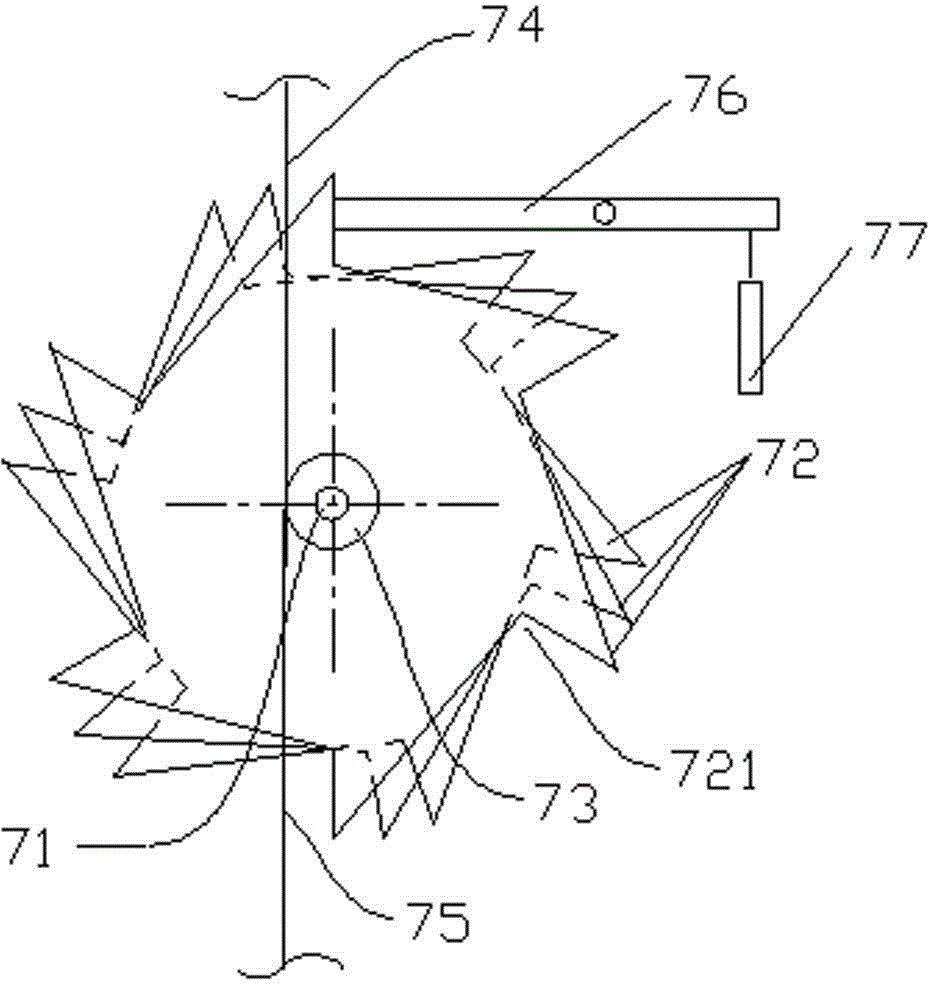

Thin-layer chromatography adsorbent homogenate preparation device and adsorbent homogenate preparation method

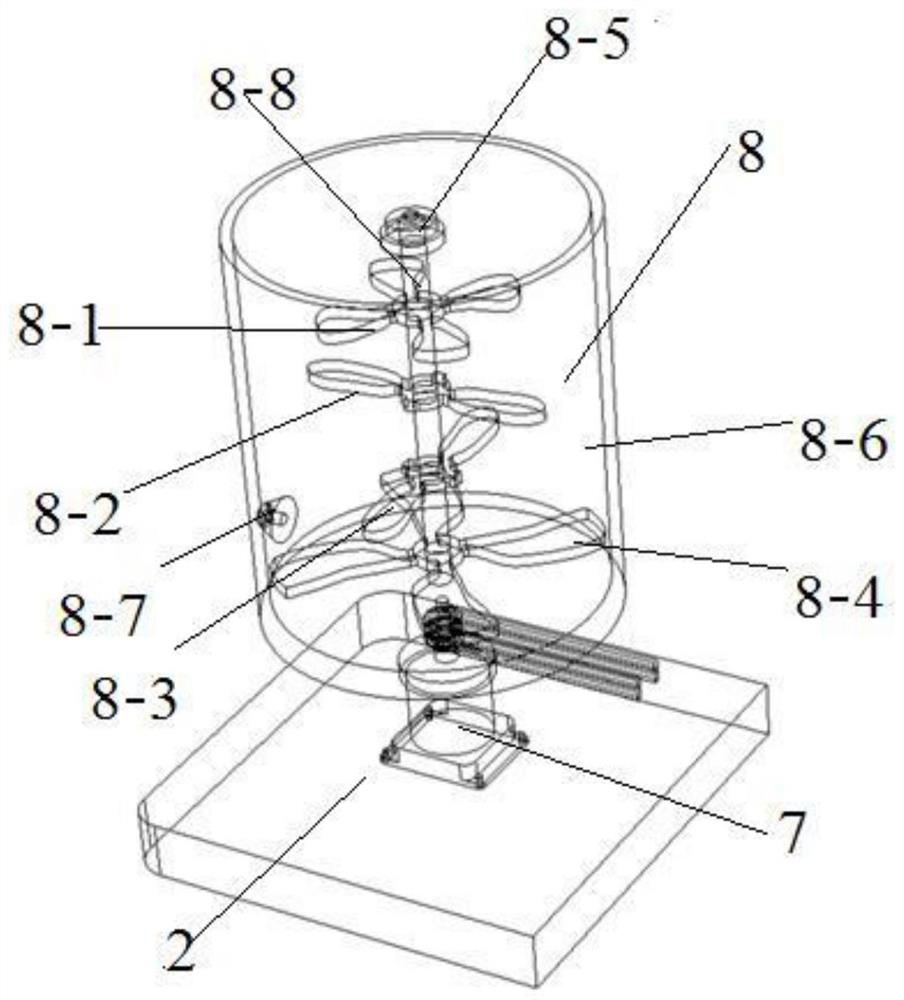

ActiveCN109289617BEliminate Bubble ProblemsImprove visibilityTransportation and packagingRotary stirring mixersMotor driveElectromagnetic clutch

The invention discloses a preparation device for thin-layer chromatography adsorbent homogenate, which comprises a material box a, a material box mechanism assembly is arranged at the bottom of the material box a, the material box mechanism assembly is connected with a stirring mechanism assembly through an electromagnetic clutch, and the stirring mechanism assembly The bottom is connected with a motor, the motor is arranged at one end of the base, and the electromagnetic clutch and the motor are respectively connected with the system controller. The preparation device for thin-layer chromatography adsorbent homogenization of the present invention solves the problems of uneven coating thickness, many bubbles, poor uniformity, and time-consuming and labor-intensive operation when manually preparing thin-layer chromatography plates, and the device of the present invention is driven by a single motor system, the cost is relatively low.

Owner:XIAN MEDICAL UNIV

A special spreader for belts with large inclination angle

A special spreader for a belt with a large inclination angle, including a hanging load-bearing unit and a pressing unit, characterized in that: the hanging load-bearing unit includes a fixed panel (5), a movable panel (9), a flange trusteeship (11) and a main Hosting (12), the pressing unit includes a beam (6) and a push rod (7), the beam (6) is a channel steel with holes and pin holes at both ends, the beam (6) is erected through the hole At fixed panel (5), the top of movable panel (9). The special spreader for high-inclination belts of the present invention has the advantages of simple structure, convenient manufacture, good hoisting safety, and prevents damage to the high-inclination skirt belt due to the tightening of the steel wire rope spreader, avoiding delays in work, time and material loss.

Owner:MCC5 GROUP SHANGHAI CORPORATION LIMITED

Cable-stayed suspension combined suspending method for cable protection in gallery inspection

ActiveCN102361273BReduce construction costsAvoid hidden dangersPipe supportsCable installation apparatusElectricityCable stayed

Owner:CHINA MCC17 GRP

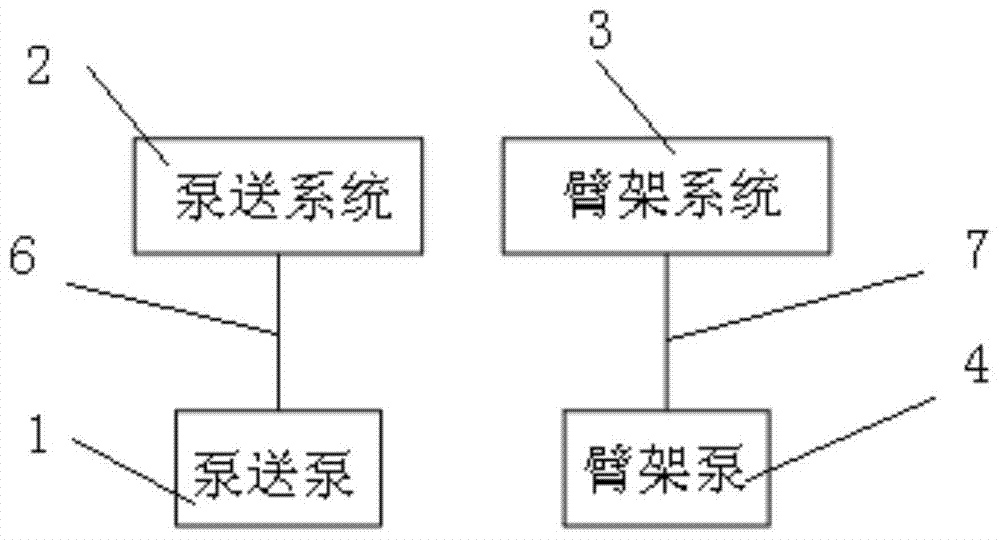

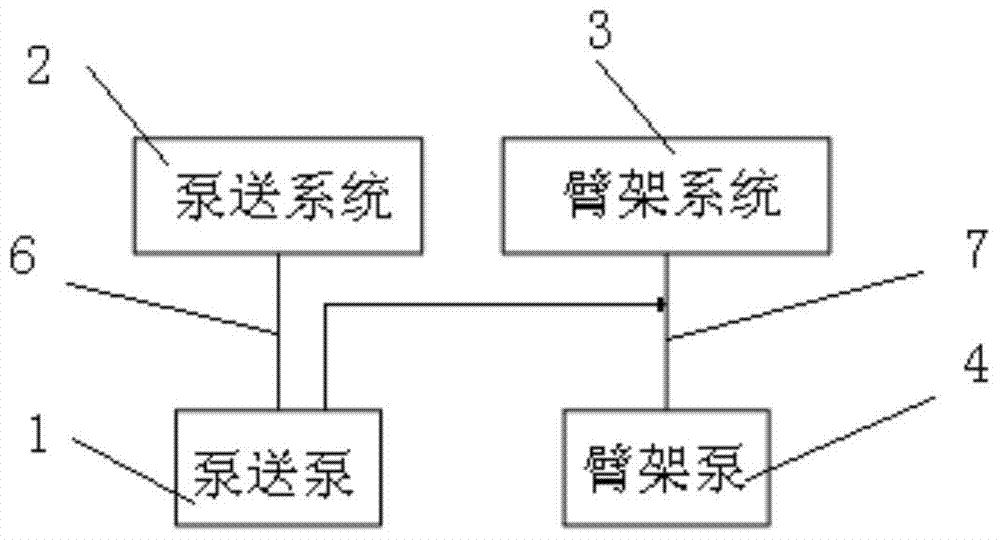

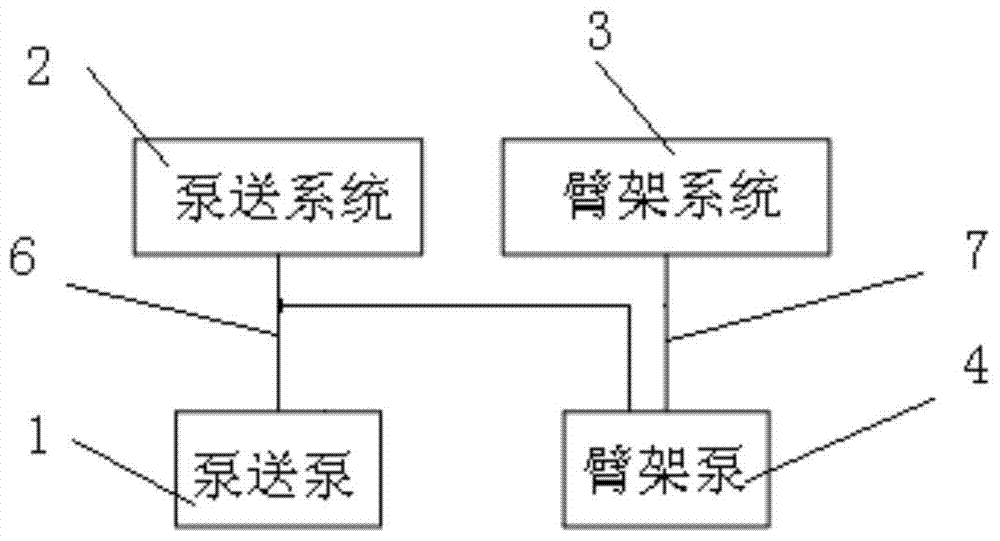

A pump truck hydraulic system and pump truck

ActiveCN104675775BReduce energy consumptionAvoid lost timeServomotor componentsServomotorsControl valvesTruck

The invention discloses a pump truck hydraulic system and a pump truck. The pump truck comprises a pump truck hydraulic system. The pump truck hydraulic system comprises a boom pump, a pumping pump and a control valve group, is communicated with a boom liquid supply pipeline and a pumping liquid supply pipeline and can be switched between the pumping liquid supply state and the boom liquid supply state, wherein the control valve group enables the boom liquid supply pipeline to be communicated with the pumping liquid supply pipeline in one way in the pumping liquid supply state to allow the boom pump to supply hydraulic liquid to the pumping system; in the boom liquid supply state, the control valve group enables the pumping liquid supply pipeline to be communicated with the boom liquid supply pipeline in one way to allow the pumping pump to provide hydraulic liquid for the boom system. The pump truck hydraulic system achieves the following function that two pumps can supply liquid to one system together on the same pump truck and can also conduct liquid supply work independently. Compared with the prior art, the energy consumption can be reduced to the largest extent, and missed working time caused by damage to the single pump is avoided.

Owner:河北雷萨重型工程机械有限责任公司

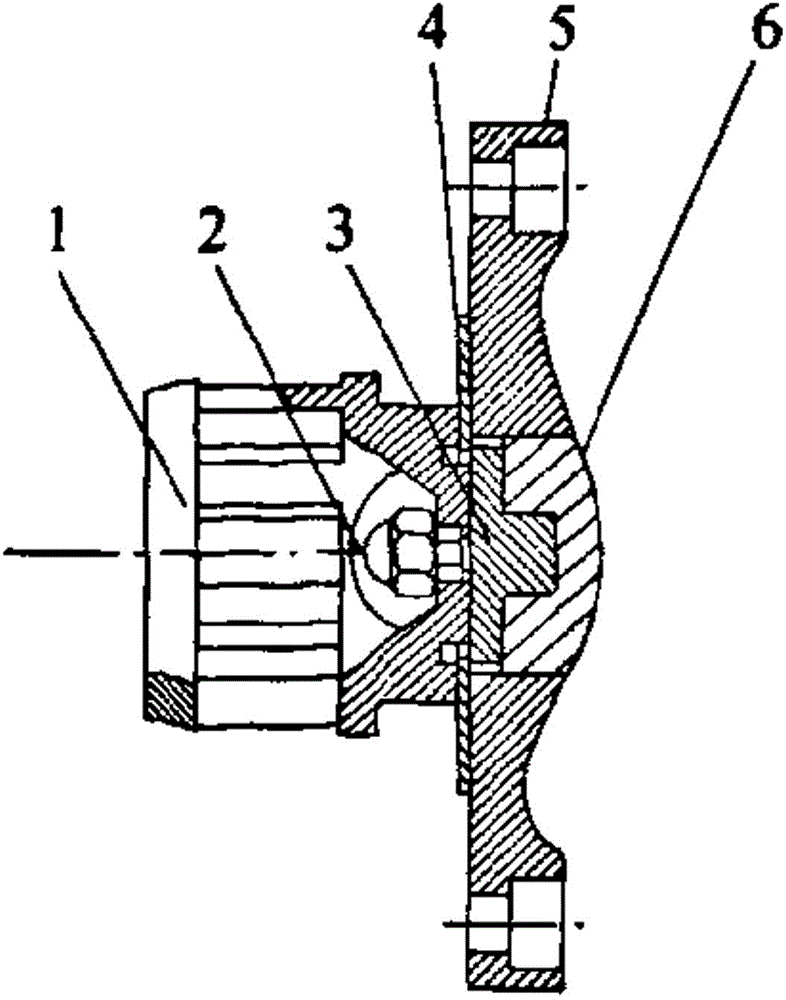

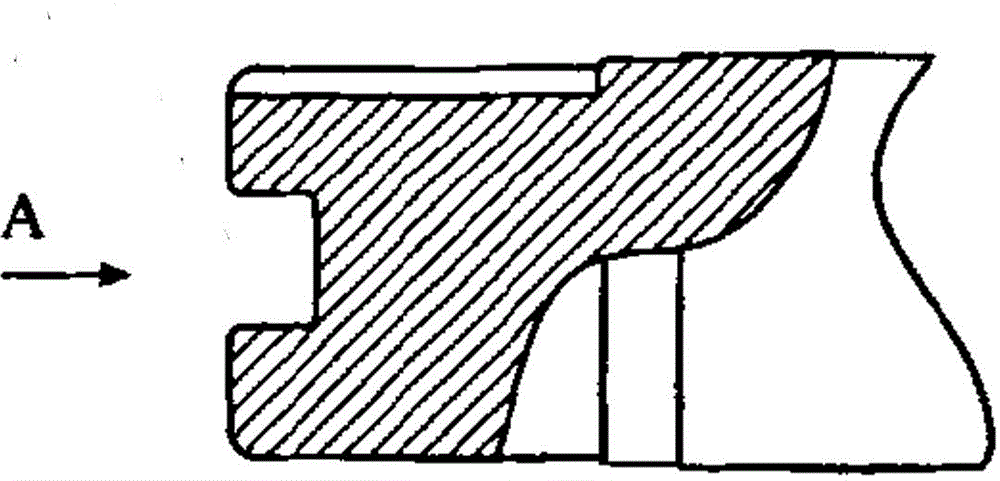

Impeller head transmission device

The invention relates to the field of mechanical equipment, in particular to an impeller head transmission device which comprises an impeller. The impeller is connected to an impeller connection seat in a sleeving mode and fastened to the left end of the impeller connection seat in the axial direction through a cap nut. The impeller connection seat is connected with a transmission shaft, a boss of the impeller connection seat is sleeved with a vane wheel connection disc, and a gasket is arranged between the impeller connection seat and the vane wheel connection disc. After the impeller head works for a long time, the impeller and the impeller connection seat can still be quickly and conveniently replaced, the impeller head transmission shaft does not need to be replaced, manufacturing is convenient, replacing is easy, working time loss is avoided, and production efficiency is improved.

Owner:王海燕

Sealing machine

The invention relates to a box sealing machine. The box sealing machine comprises a machine base, a machine head arranged on the machine base, a cover folding mechanism, an upper machine core and a conveying rail arranged on the machine base, wherein the cover folding mechanism and the upper machine core are arranged on the machine head, and the machine head can move up and down relative to the machine base so as to adjust the distance between the cover folding mechanism and the conveying rail as well as the distance between the upper machine core and the conveying rail. The box sealing machine further comprises a first air cylinder and a cut-off mechanism, wherein the first air cylinder is installed above the machine head, and a piston rod of the first air cylinder is fixedly connected with the machine head; the cut-off mechanism comprises a rotary shaft rotationally arranged on the machine base, a ratchet wheel, a belt wheel, two belts and a pawl, the ratchet wheel and the belt wheel are fixedly installed on the rotary shaft, the two belts are wound on the belt wheel in the opposite directions, the pawl is rotationally arranged on the machine base, a plurality of notches are formed in the edge of the ratchet wheel and arranged in the circumferential direction of the ratchet wheel, one end of a chain is connected with the machine base through a coiled spring, and the other end of the chain is fixedly connected with the machine head. The box sealing machine is low in cost and safe to use.

Owner:SU ZHOU XUENUO MECHANICAL PROD

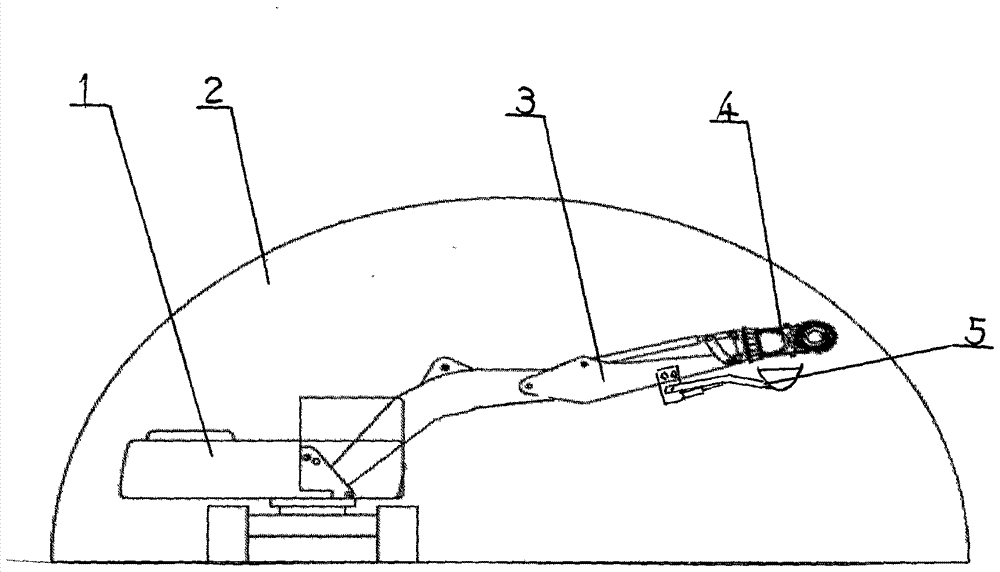

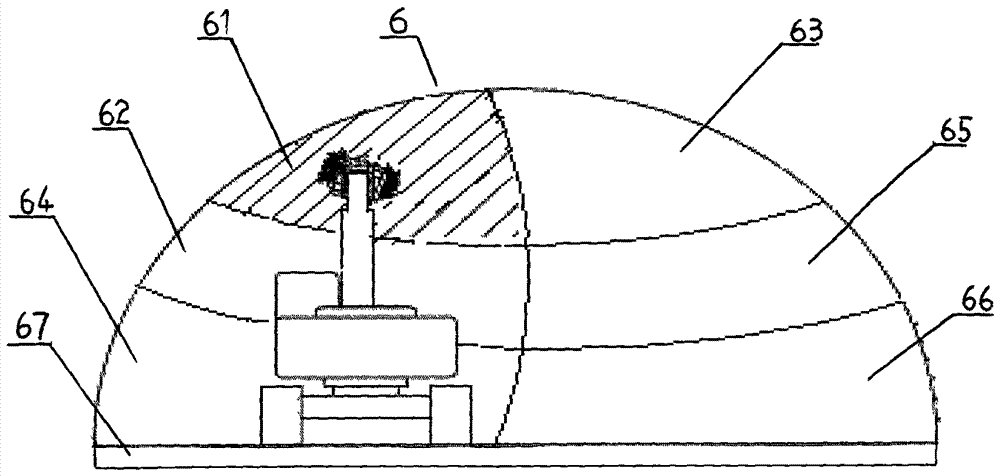

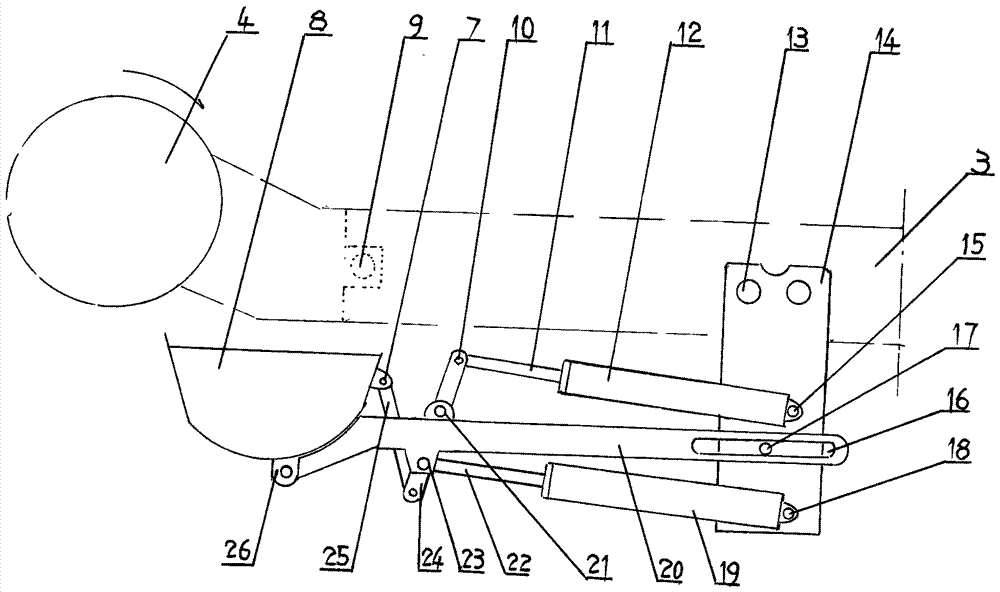

A hydraulic rock-soil milling equipment and method for weak surrounding rock tunnels

ActiveCN104594910BEnsure construction safetyGuaranteed operational safetyUnderground chambersTunnel liningRock tunnelExcavator

The invention belongs to hydraulic rock-soil milling and excavating equipment and a hydraulic rock-soil milling and excavating method for a tunnel in soft and weak surrounding rock. Milling and excavating equipment with a soil moving device is adopted to excavate, and a funnel operating surface is divided into six operation regions which are subjected to operating in sequence through the method. The milling and excavating equipment comprises a hydraulic excavator body, a milling and excavating head and a milling and excavating moveable arm, wherein the soil moving device is arranged on the milling and excavating moveable arm at the rear end of the milling and excavating head; the soil moving device comprises an soil bearing hopper, a load bearing arm, a regulating hydraulic press, a bucket hydraulic press and a connecting base. The hydraulic rock-soil milling and excavating equipment can be used for effectively guaranteeing tunnel construction and operation safety and reducing economic loss caused by geological disasters in construction of the tunnel in soft and weak surrounding rock, and has the advantages of being low in construction resource and cost, easy to construct, high in construction speed, small in safety risk and high in construction quality.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com