Impeller head transmission device

A technology of transmission device and shot blasting device, which is applied in the direction of grinding drive device, grinding/polishing equipment, grinding machine tool parts, etc., can solve the problems of reducing production efficiency, scrapping the transmission shaft, increasing production cost, etc., and achieve improvement Productivity and the effect of avoiding loss of man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

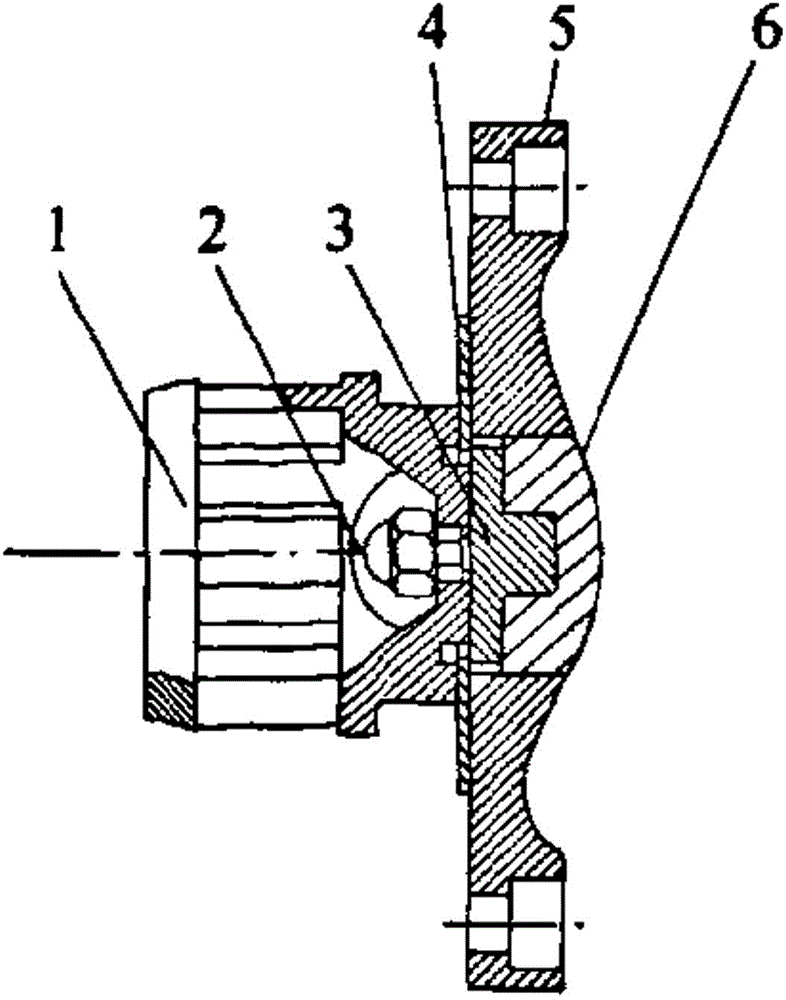

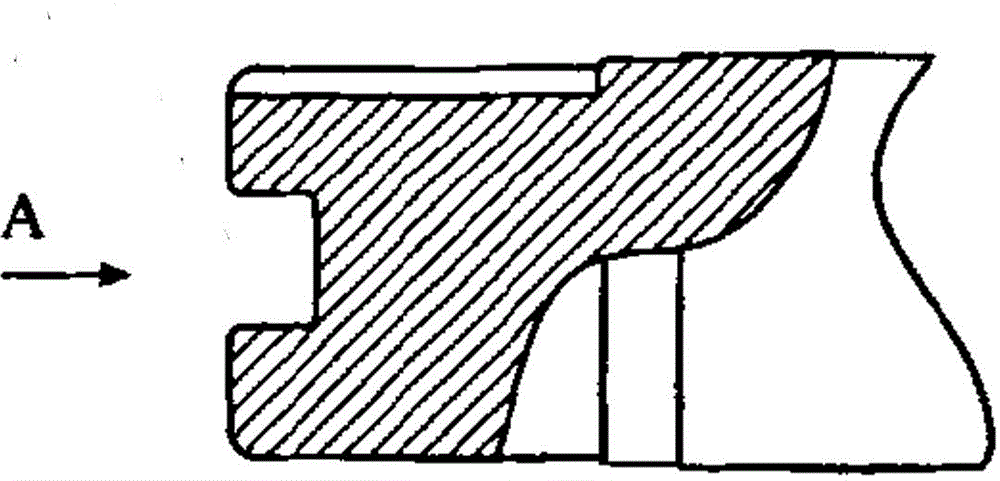

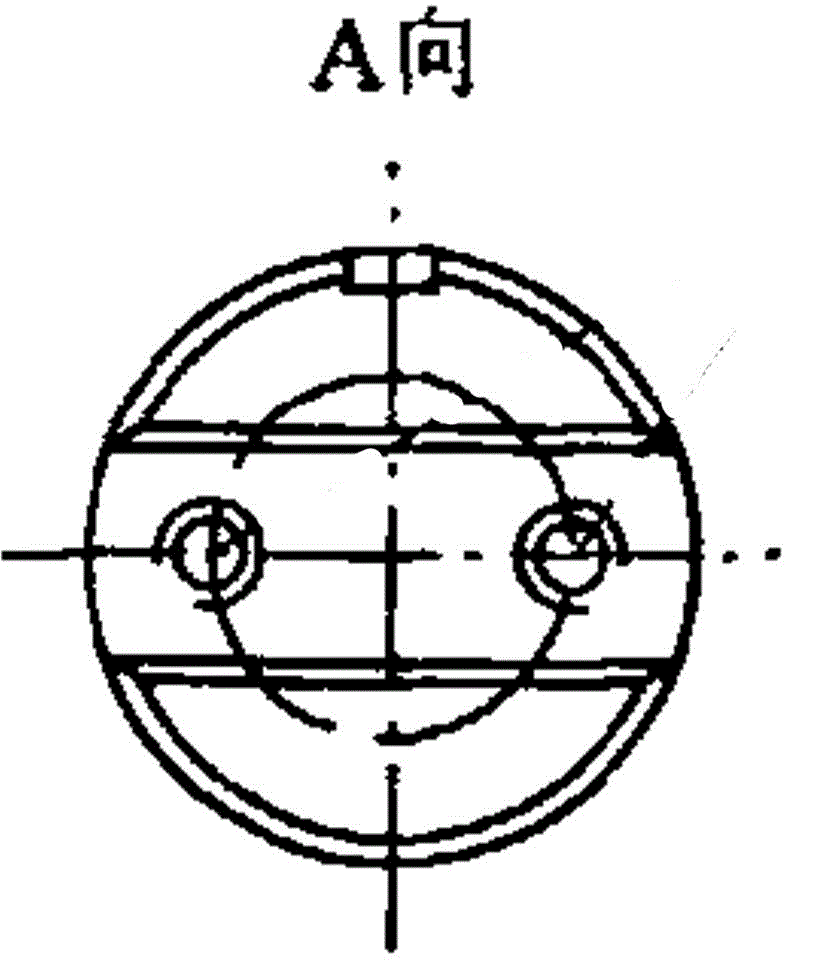

[0013] The transmission device of the shot blasting device of the present invention includes a shot blasting wheel 1, which is sleeved on the shot blasting wheel connecting seat 3, and the shot blasting wheel 1 is fastened on the shot blasting wheel 1 from the axial direction by the cap nut 2 The left end of the wheel connection seat 3, the shot wheel connection seat 3 is connected with the transmission shaft 6, and the radial boss of the shot wheel connection seat 3 is covered with an impeller connection plate 5, the shot wheel connection seat 3 and Gaskets 4 are arranged between the impeller connecting plates 5 . The end that transmission shaft 6 links to each other with the pill-splitting wheel connecting seat 3 is provided with a linear groove, and the pill-splitting wheel connecting seat 3 at this place is provided with an axial boss that cooperates with it. Two threaded holes and counterbores are symmetrically arranged on the shot-splitting wheel connecting seat 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com