Multi-station coordination method for ship segmented manufacturing pipeline

A segmented manufacturing and assembly line technology, applied in ship construction, ship parts, ships, etc., can solve problems such as low efficiency and large cache, and achieve the effect of avoiding delay and solving low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] An embodiment of the present invention provides a multi-station coordination method for a ship segment manufacturing line.

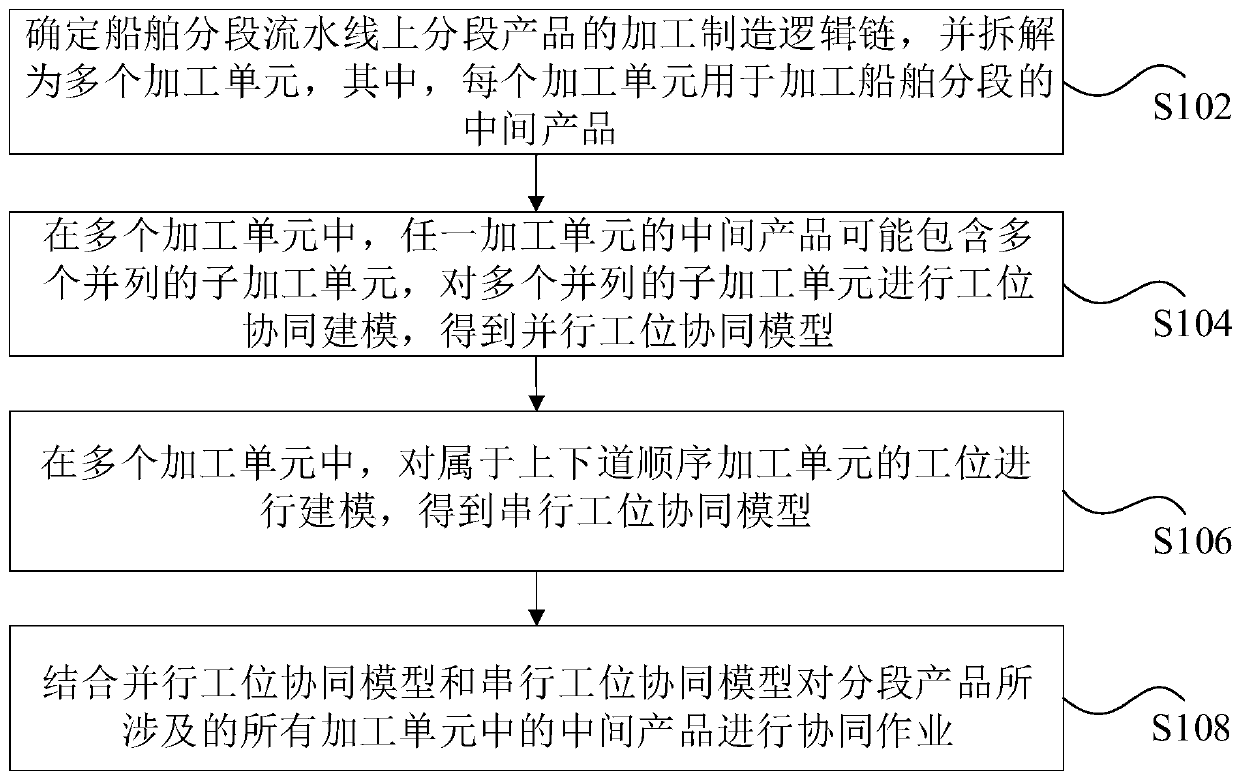

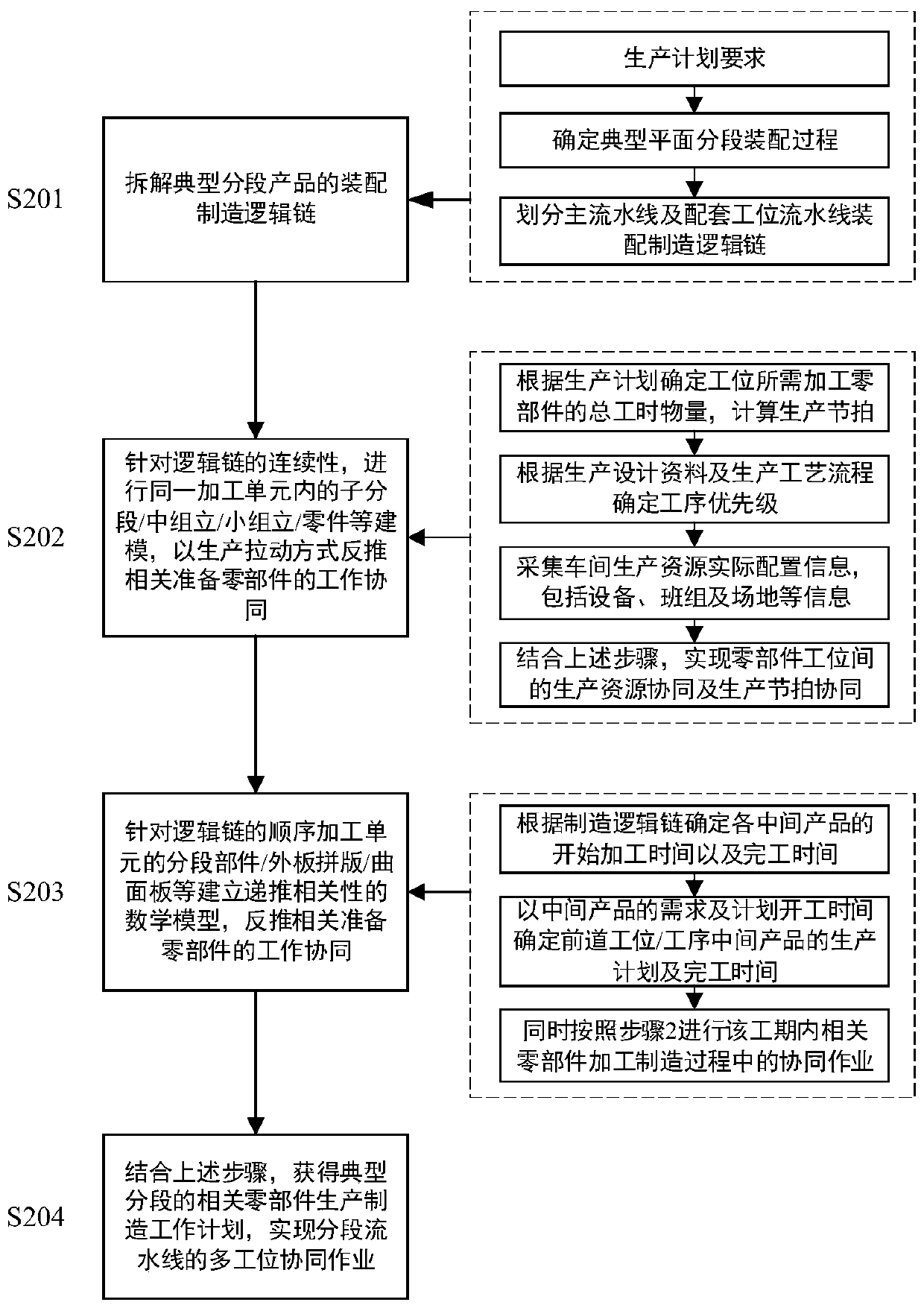

[0034] figure 1 It is a schematic flowchart of a multi-station collaborative method for a ship segment manufacturing line in an embodiment of the present invention. Such as figure 1 As shown, the method includes the following steps:

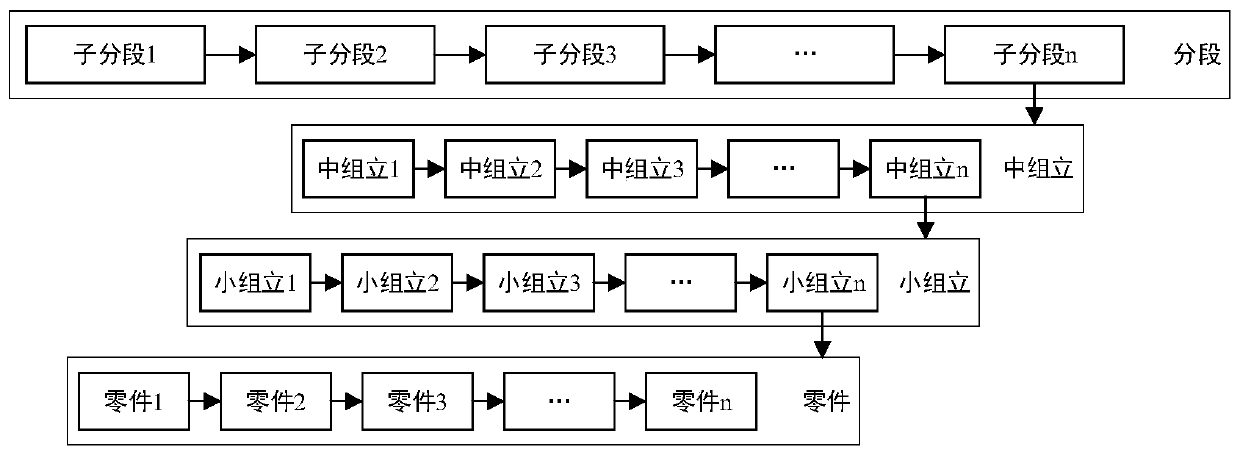

[0035] Step S102, determine the assembly and manufacturing logic chain of the segmented product on the ship segmented assembly line, and disassemble it into multiple processing units (ie, multiple processing procedures), wherein each processing unit is used to process the intermediate product of the ship segment.

[0036] In step S104, among the multiple processing units, the intermediate product of any processing unit may contain multiple parallel sub-processing units, and the station collaborative modeling is performed on the multiple parallel sub-processing units to obtain a parallel station collaborative model....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com