Cable-stayed suspension combined suspending method for cable protection in gallery inspection

A cable protection and hanging technology, which is applied in the field of equipment inspection and maintenance, can solve problems such as high risk factor, delay in construction period, and difficulty in high-altitude operations, so as to achieve high maintenance efficiency, avoid waste, and shorten the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

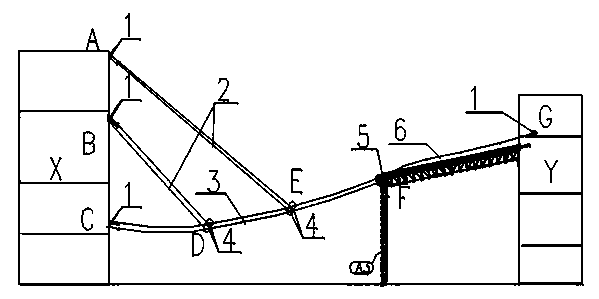

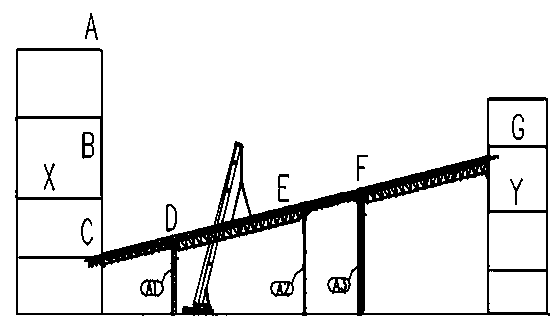

[0029] The specific process of the cable-stayed-cable combined hanging method for protecting cables in corridor inspection and maintenance provided by the present invention is as follows:

[0030] 1. Preparation for hanging:

[0031] 1.1 Lug processing

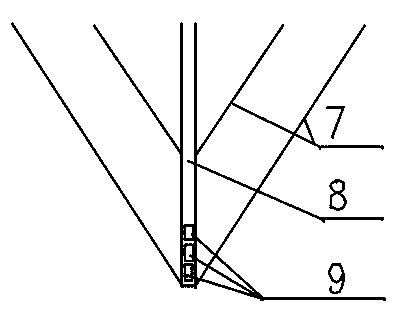

[0032] After calculation, the lifting lug is processed with δ=14~20mm steel plate (such as figure 1 ), the processing quantity is 10 pieces, which are respectively welded on image 3 A, B, C, F, G shown. Among them, F is welded on the top of the tensile support frame (such as figure 2 shown), the rest are used for hanging manual hoists.

[0033] 1.2 Manufacture and installation of tensile support frame

[0034] Analyze and calculate the tensile force after the cable weight is estimated, and make a tensile support frame based on the calculated data (such as figure 2 ), the tensile support frame (5) corresponds to the F of the corridor, using 18#~22# light I-beam as the main support, and 4 channel steels on both sides ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com